IEC 61340-5-1:2016

(Main)Electrostatics - Part 5-1: Protection of electronic devices from electrostatic phenomena - General requirements

Electrostatics - Part 5-1: Protection of electronic devices from electrostatic phenomena - General requirements

IEC 61340-5-1:2016 applies to activities that: manufacture, process, assemble, install, package, label, service, test, inspect, transport or otherwise handle electrical or electronic parts, assemblies and equipment with withstand voltages greater than or equal to 100 V HBM, 200 V CDM and 35 V for isolated conductors. ESDS with lower withstand voltages may require additional control elements or adjusted limits. Processes designed to handle items that have lower ESD withstand voltage(s) can still claim compliance to this standard. This standard provides the requirements for an ESD control program. IEC TR 61340-5-2 [9] provides guidance on the implementation of this standard. This standard does not apply to electrically initiated explosive devices, flammable liquids, gases and powders. The purpose of this standard is to provide the administrative and technical requirements for establishing, implementing and maintaining an ESD control program (hereinafter referred to as the "program"). This edition includes the following significant technical changes with respect to the previous edition:

a) Technical requirements were changed to align IEC 61340-5-1 with other industry ESD standards;

b) Reference documents were updated to reflect newly released IEC standards;

c) A section on product qualification was added;

d) Table 4 was deleted and detailed packaging requirements were deferred to IEC 61340-5-3;

e) Clause A.1 was removed and is now included in IEC 61340-4-6.

The contents of the corrigendum of May 2017 have been included in this copy.

Électrostatique - Partie 5-1: Protection des dispositifs électroniques contre les phénomènes électrostatiques - Exigences générales

L'IEC 61340-5-1:2016 s'applique aux activités concernant: la fabrication, le traitement, l'assemblage, l'installation, l'emballage, l'étiquetage, l'entretien, l'essai, l'examen, le transport ou bien la manipulation des pièces, des ensembles et des équipements électriques ou électroniques présentant des tensions de tenue supérieures ou égales à 100 V sur le modèle du corps humain (HBM), 200 V sur le modèle de dispositif chargé (CDM) et 35 V sur les conducteurs isolés. Des ESDS possédant des tensions de tenue inférieures peuvent nécessiter des éléments de contrôle supplémentaires ou des limites ajustées. Les processus conçus pour manipuler des éléments présentant une ou plusieurs tensions de tenue aux ESD inférieures peuvent toujours déclarer être conformes à la présente norme. La présente norme fournit les exigences nécessaires à un programme de maîtrise des ESD. L'IEC TR 61340-5-2 [9] donne des lignes directrices pour la mise en eouvre de la présente norme. La présente norme ne s'applique pas aux dispositifs explosifs à déclenchement électronique ni aux liquides, gaz et poudres inflammables. L'objectif de la présente norme est de fournir les exigences administratives et techniques pour l'établissement, la mise en oeuvre et la maintenance d'un programme de maîtrise des ESD (ciaprès dénommé "programme"). Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) Des exigences techniques ont été modifiées afin d'aligner l'IEC 61340-5-1 avec les autres normes de l'industrie relatives aux décharges électrostatiques (ESD);

b) Les documents de référence ont été mis à jour afin de refléter les normes IEC récemment publiées;

c) Un paragraphe sur la qualification produit a été ajouté;

d) Le Tableau 4 a été supprimé, et les exigences relatives aux emballages sont désormais décrites dans l'IEC 61340-5-3;

e) L'Article A.1 a été supprimé et figure désormais dans l'IEC 61340-4-6.

Le contenu du corrigendum de mai 2017 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 26-May-2016

- Technical Committee

- TC 101 - Electrostatics

- Drafting Committee

- WG 5 - TC 101/WG 5

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 21-May-2024

- Completion Date

- 31-Mar-2022

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61340-5-1:2016 - “Electrostatics - Part 5-1: Protection of electronic devices from electrostatic phenomena - General requirements” defines the administrative and technical requirements for establishing, implementing and maintaining an ESD control program. The standard applies to activities that manufacture, process, assemble, install, package, label, service, test, inspect, transport or otherwise handle electrical/electronic parts, assemblies and equipment with typical withstand thresholds of ≥ 100 V (HBM), ≥ 200 V (CDM) and ≥ 35 V for isolated conductors. It excludes electrically-initiated explosives and flammable liquids/gases/powders. IEC TR 61340-5-2 gives implementation guidance; Annex A contains normative test methods. This edition incorporates technical alignment with other industry ESD standards, adds product qualification, and defers detailed packaging requirements to IEC 61340-5-3.

Key topics and technical requirements

- ESD control program: required plan documenting scope, responsibilities, tailoring and technical controls. An ESD coordinator role is recommended.

- Administrative elements: ESD control program plan, ongoing training plan, product qualification requirements, and a compliance verification plan (audits and testing).

- Grounding and equipotential bonding: requirements for grounding systems to prevent potential differences between personnel, equipment and conductors.

- Personnel grounding: wrist straps, footwear and other measures to control charge on personnel inside ESD Protected Areas (EPAs).

- ESD Protected Areas (EPA): zoning, material selection and controls to maintain equipotential balance inside work areas.

- Packaging and marking: general packaging/marking requirements are covered; detailed packaging specifications are in IEC 61340-5-3.

- Test methods: Annex A lists test procedures for verifying grounding, wrist straps, footwear and other controls.

- Tailoring and risk: devices with lower ESD withstand voltages may need additional controls or adjusted limits; processes handling such devices can still comply if controls are documented.

Practical applications - who uses it and why

- Target users: electronics manufacturers, PCB assemblers, test labs, packaging/transport teams, service and repair centers, design and quality engineers, and supply chain managers.

- Use cases:

- Establishing company-wide ESD control programs and training curricula.

- Designing EPAs, grounding/equipotential systems and personnel grounding methods.

- Defining product qualification and compliance-verification procedures for HBM/CDM sensitivity.

- Specifying packaging and handling requirements for shipment outside EPAs.

- Integrating ESD controls into quality management and supplier requirements.

Related standards and guidance

- IEC TR 61340-5-2 (implementation guidance)

- IEC 61340-5-3 (detailed packaging requirements)

- Referenced IEC standards and corrigenda (this edition includes the May 2017 corrigendum)

Keywords: IEC 61340-5-1, ESD control, electrostatic discharge, EPA, HBM, CDM, product qualification, grounding, equipotential bonding, personnel grounding, compliance verification.

REDLINE IEC 61340-5-1:2016 - Electrostatics - Part 5-1: Protection of electronic devices from electrostatic phenomena - General requirements Released:5/27/2016 Isbn:9782832234433

IEC 61340-5-1:2016 - Electrostatics - Part 5-1: Protection of electronic devices from electrostatic phenomena - General requirements

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61340-5-1:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrostatics - Part 5-1: Protection of electronic devices from electrostatic phenomena - General requirements". This standard covers: IEC 61340-5-1:2016 applies to activities that: manufacture, process, assemble, install, package, label, service, test, inspect, transport or otherwise handle electrical or electronic parts, assemblies and equipment with withstand voltages greater than or equal to 100 V HBM, 200 V CDM and 35 V for isolated conductors. ESDS with lower withstand voltages may require additional control elements or adjusted limits. Processes designed to handle items that have lower ESD withstand voltage(s) can still claim compliance to this standard. This standard provides the requirements for an ESD control program. IEC TR 61340-5-2 [9] provides guidance on the implementation of this standard. This standard does not apply to electrically initiated explosive devices, flammable liquids, gases and powders. The purpose of this standard is to provide the administrative and technical requirements for establishing, implementing and maintaining an ESD control program (hereinafter referred to as the "program"). This edition includes the following significant technical changes with respect to the previous edition: a) Technical requirements were changed to align IEC 61340-5-1 with other industry ESD standards; b) Reference documents were updated to reflect newly released IEC standards; c) A section on product qualification was added; d) Table 4 was deleted and detailed packaging requirements were deferred to IEC 61340-5-3; e) Clause A.1 was removed and is now included in IEC 61340-4-6. The contents of the corrigendum of May 2017 have been included in this copy.

IEC 61340-5-1:2016 applies to activities that: manufacture, process, assemble, install, package, label, service, test, inspect, transport or otherwise handle electrical or electronic parts, assemblies and equipment with withstand voltages greater than or equal to 100 V HBM, 200 V CDM and 35 V for isolated conductors. ESDS with lower withstand voltages may require additional control elements or adjusted limits. Processes designed to handle items that have lower ESD withstand voltage(s) can still claim compliance to this standard. This standard provides the requirements for an ESD control program. IEC TR 61340-5-2 [9] provides guidance on the implementation of this standard. This standard does not apply to electrically initiated explosive devices, flammable liquids, gases and powders. The purpose of this standard is to provide the administrative and technical requirements for establishing, implementing and maintaining an ESD control program (hereinafter referred to as the "program"). This edition includes the following significant technical changes with respect to the previous edition: a) Technical requirements were changed to align IEC 61340-5-1 with other industry ESD standards; b) Reference documents were updated to reflect newly released IEC standards; c) A section on product qualification was added; d) Table 4 was deleted and detailed packaging requirements were deferred to IEC 61340-5-3; e) Clause A.1 was removed and is now included in IEC 61340-4-6. The contents of the corrigendum of May 2017 have been included in this copy.

IEC 61340-5-1:2016 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 19.040 - Environmental testing; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61340-5-1:2016 has the following relationships with other standards: It is inter standard links to IEC 61340-5-1:2016/COR1:2017, IEC 61340-5-1:2007, IEC 61340-5-1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61340-5-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61340-5-1 ®

Edition 2.0 2016-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrostatics –

Part 5-1: Protection of electronic devices from electrostatic phenomena –

General requirements

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 61340-5-1 ®

Edition 2.0 2016-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrostatics –

Part 5-1: Protection of electronic devices from electrostatic phenomena –

General requirements

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.220.99; 29.020 ISBN 978-2-8322-3443-3

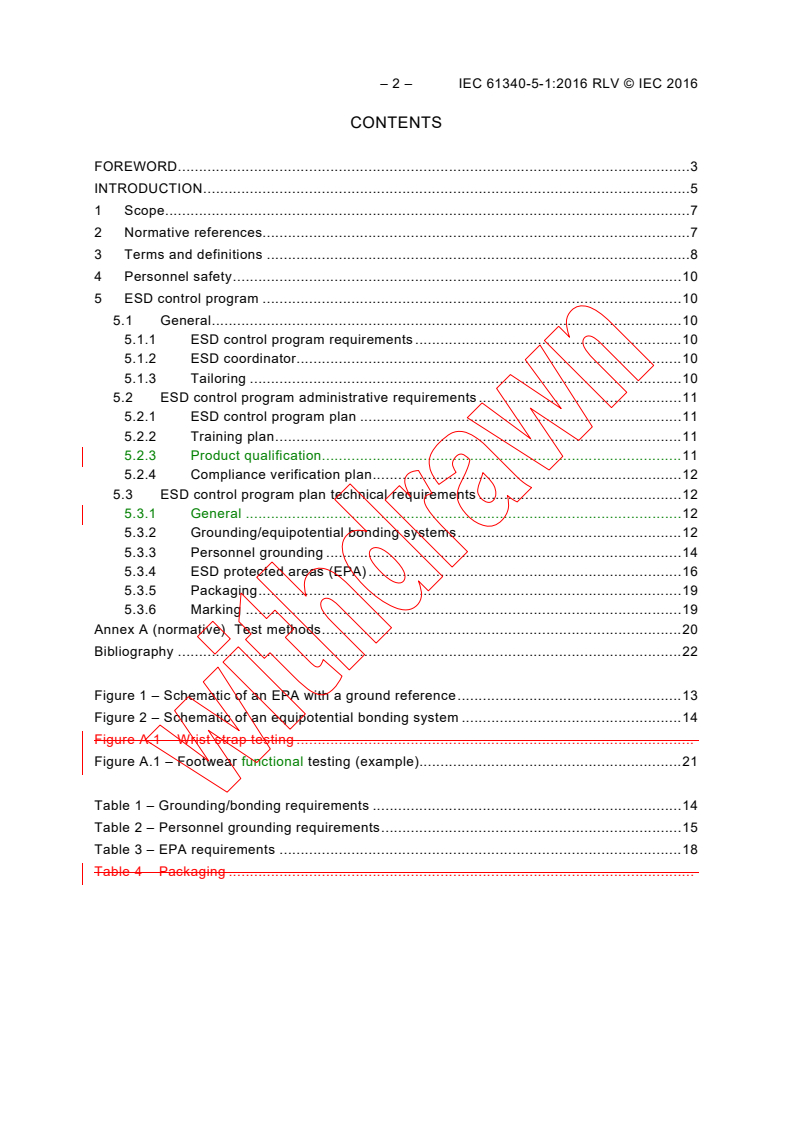

– 2 – IEC 61340-5-1:2016 RLV © IEC 2016

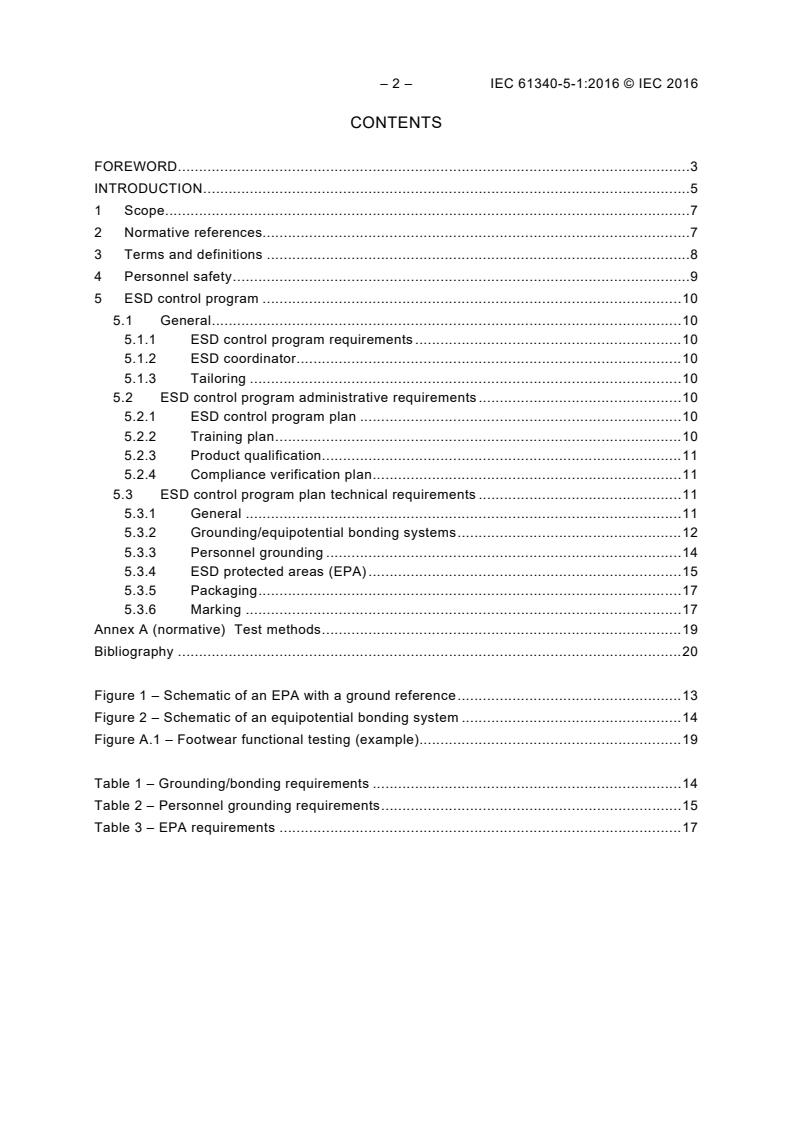

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 8

4 Personnel safety . 10

5 ESD control program . 10

5.1 General . 10

5.1.1 ESD control program requirements . 10

5.1.2 ESD coordinator . 10

5.1.3 Tailoring . 10

5.2 ESD control program administrative requirements . 11

5.2.1 ESD control program plan . 11

5.2.2 Training plan . 11

5.2.3 Product qualification . 11

5.2.4 Compliance verification plan . 12

5.3 ESD control program plan technical requirements . 12

5.3.1 General . 12

5.3.2 Grounding/equipotential bonding systems . 12

5.3.3 Personnel grounding . 14

5.3.4 ESD protected areas (EPA) . 16

5.3.5 Packaging . 19

5.3.6 Marking . 19

Annex A (normative) Test methods . 20

Bibliography . 22

Figure 1 – Schematic of an EPA with a ground reference . 13

Figure 2 – Schematic of an equipotential bonding system . 14

Figure A.1 – Wrist strap testing .

Figure A.1 – Footwear functional testing (example). 21

Table 1 – Grounding/bonding requirements . 14

Table 2 – Personnel grounding requirements . 15

Table 3 – EPA requirements . 18

Table 4 – Packaging .

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 5-1: Protection of electronic devices from

electrostatic phenomena – General requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 4 – IEC 61340-5-1:2016 RLV © IEC 2016

International Standard IEC 61340-5-1 has been prepared by IEC technical committee 101:

Electrostatics.

This second edition cancels and replaces the first edition published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Technical requirements were changed to align IEC 61340-5-1 with other industry ESD

standards;

b) Reference documents were updated to reflect newly released IEC standards;

c) A section on product qualification was added;

d) Table 4 was deleted and detailed packaging requirements were deferred to IEC 6134053;

e) Clause A.1 was removed and is now included in IEC 61340-4-6.

The text of this standard is based on the following documents:

FDIS Report on voting

101/505/FDIS 101/508/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61340 series, published under the general title Electrostatics, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of May 2017 have been included in this copy.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

INTRODUCTION

This part of IEC 61340 covers the requirements necessary to design, establish, implement

and maintain an electrostatic discharge (ESD) control program for activities that: manufacture,

process, assemble, install, package, label, service, test, inspect, transport or otherwise

handle electrical or electronic parts, assemblies and equipment susceptible to damage by

electrostatic discharges greater than or equal to 100 V human body model (HBM), 200 V

charged device model (CDM) and 35 V on isolated conductors. Isolated conductors were

historically represented by machine model (MM). The 35 V limit is related to the level

achievable using ionizers specified in this standard. The MM test is no longer required for

qualification of devices, only the HBM and CDM tests are. The MM test is retained in this

standard for process control of isolated conductors only.

Any contact and physical separation of materials or flow of solids, liquids, or particle-laden

gases can generate electrostatic charges. Common sources of ESD include charged:

personnel, conductors, common polymeric materials, and processing equipment. ESD

damage can occur when:

• a charged person or object comes into contact with an ESD sensitive device (ESDS);

• an ESDS comes into direct contact with a highly conductive surface while exposed to an

electrostatic field;

• a charged ESDS comes into contact with another conductive surface which is at a different

electrical potential. This surface may or may not be grounded.

Examples of ESDS are microcircuits, discrete semiconductors, thick and thin film resistors,

hybrid devices, printed circuit boards and piezoelectric crystals. It is possible to determine

device and item susceptibility by exposing the device to simulated ESD events. The ESD

withstand voltage determined by sensitivity tests using simulated ESD events does not

necessarily represent the ability of the device to withstand ESD from real sources at that

voltage level. However, the levels of sensitivity are used to establish a baseline of

susceptibility data for comparison of devices with equivalent part numbers from different

manufacturers. Three different models have been used for qualification of electronic

components – human body model (HBM), machine model (MM), and charged device model

(CDM). In current practice devices are qualified only using HBM and CDM susceptibility tests.

This standard covers the ESD control program requirements necessary for setting up a

program to handle ESDS, based on the historical experience of both military and commercial

organizations. The fundamental ESD control principles that form the basis of this standard are

as follows.

• Avoid a discharge from any charged, conductive object (personnel and especially

automated handling equipment) into the ESDS. This can be accomplished by bonding or

electrically connecting all conductors in the environment, including personnel, to a known

ground or contrived ground (as on board ship or on aircraft). This attachment creates an

equipotential balance between all conducting objects and personnel. Electrostatic

protection can be maintained at a potential different from a “zero” voltage ground potential

as long as all conductive objects in the system are at the same potential.

• Avoid a discharge from any charged ESD sensitive device. Charging can result from direct

contact and separation or it can be induced by an electric field. Necessary insulators in

the environment cannot lose their electrostatic charge by attachment to ground. Ionization

systems provide neutralization of charges on these necessary insulators (circuit board

materials and some device packages are examples of necessary insulators). Assessment

of The ESD hazard created by electrostatic charges on the necessary insulators in the

work place is required assessed to ensure that appropriate actions are implemented,

according to the risk.

• Once outside of an electrostatic discharge protected area (hereinafter referred to as an

EPA) it is often generally not possible to control the above items, therefore, ESD

protective packaging may be required. ESD protection can be achieved by enclosing ESD

sensitive products in static protective materials, although the type of material depends on

– 6 – IEC 61340-5-1:2016 RLV © IEC 2016

the situation and destination. Inside an EPA, static dissipative materials may provide

adequate protection. Outside an EPA, static discharge shielding materials are

recommended. Whilst all of these materials are not discussed in this standard, it is

important to recognize the differences in their application. For more information see

IEC 61340-5-3.

Each company has different processes, and so will require a different blend of ESD

prevention measures for an optimum ESD control program. It is vital that these Measures are

should be selected, based on technical necessity and carefully documented in an ESD control

program plan, so that all concerned can be sure of the program requirements.

Training is an essential part of an ESD control program in order to ensure that the personnel

involved understand the equipment and procedures they are to use in order to be in

compliance with the ESD control program plan. Training is also essential in raising awareness

and understanding of ESD issues. Without training, personnel are often a major source of

ESD risk. With training, they become an effective first line of defence against ESD damage.

Regular compliance verification checks and tests are essential to ensure that equipment

remains effective and that the ESD control program is correctly implemented in compliance

with the ESD control program plan.

Any contact and physical separation of materials or flow of solids, liquids, or particle-laden

gases can generate electrostatic charges. Common sources of ESD include charged:

personnel, conductors, common polymeric materials, and processing equipment. ESD

damage can occur when:

– a charged person or object comes into contact with an ESDS;

– an ESDS comes into direct contact with a highly conductive surface while exposed to an

electrostatic field;

– a charged ESDS comes into contact with another conductive surface which is at a different

electrical potential. This surface may or may not be grounded.

Examples of ESDS are microcircuits, discrete semiconductors, thick and thin film resistors,

hybrid devices, printed circuit boards and piezoelectric crystals. It is possible to determine

device and item susceptibility by exposing the device to simulated ESD events. The level of

sensitivity, determined by test using simulated ESD events, may not necessarily relate to the

level of sensitivity in a real life situation. However, they are used to establish a baseline of

susceptibility data for comparison of devices with equivalent part numbers from different

manufacturers. Three different models are used for characterization of electronic components

- human body model (HBM), machine model (MM), and charged device model (CDM).

ELECTROSTATICS –

Part 5-1: Protection of electronic devices from

electrostatic phenomena – General requirements

1 Scope

This part of IEC 61340 applies to activities that: manufacture, process, assemble, install,

package, label, service, test, inspect, transport or otherwise handle electrical or electronic

parts, assemblies and equipment susceptible to damage by electrostatic discharges greater

than or equal to 100 V human body model (HBM) with withstand voltages greater than or

equal to 100 V HBM, 200 V CDM and 35 V for isolated conductors. ESDS with lower withstand

voltages may require additional control elements or adjusted limits. Processes designed to

handle items that have lower ESD withstand voltage(s) can still claim compliance to this

standard.

This standard provides the requirements for an ESD control program. The user should refer to

IEC TR 61340-5-2 [9] for provides guidance on the implementation of this standard.

This standard does not apply to electrically initiated explosive devices, flammable liquids,

gases and powders.

The purpose of this standard is to provide the administrative and technical requirements for

establishing, implementing and maintaining an ESD control program (hereinafter referred to

as the “program”).

NOTE Isolated conductors were historically represented by MM.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60364 (all parts), Low-voltage electrical installations

IEC/TS 60479-1, Effects of current on human beings and livestock – Part 1: General aspects

IEC/TS 60479-2, Effects of current on human beings and livestock – Part 2: Special aspects

IEC 60749-26, Semiconductor devices – Mechanical and climatic test methods – Part 26:

Electrostatic discharge (ESD) sensitivity testing – Human body model (HBM)

IEC 61010-1, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

IEC 61140, Protection against electric shock – Common aspects for installation and

equipment

_____________

Numbers in square brackets refer to the bibliography.

– 8 – IEC 61340-5-1:2016 RLV © IEC 2016

IEC 61340-2-3, Electrostatics – Part 2-3: Methods of test for determining the resistance and

resistivity of solid planar materials used to avoid electrostatic charge accumulation

IEC 61340-4-1, Electrostatics – Part 4-1: Standard test methods for specific applications –

Electrical resistance of floor coverings and installed floors

IEC 61340-4-3, Electrostatics – Part 4-3: Standard test methods for specific applications –

Footwear

IEC 61340-4-5, Electrostatics – Part 4-5: Standard test methods for specific applications –

Methods for characterizing the electrostatic protection of footwear and flooring in combination

with a person

IEC 61340-4-6, Electrostatics – Part 4-6: Standard test methods for specific applications –

Wrist straps

IEC 61340-4-7, Electrostatics – Part 4-7: Standard test methods for specific applications –

Ionization

IEC 61340-4-9, Electrostatics – Part 4-9: Standard test methods for specific applications –

Garments

IEC/TR 61340-5-2, Electrostatics – Part 5-2: Protection of electronic devices from

electrostatic phenomena – User guide

IEC 61340-5-3, Electrostatics – Part 5-3: Protection of electronic devices from electrostatic

phenomena – Properties and requirements classification for packaging intended for

electrostatic discharge sensitive devices

ANSI/ESD S1.1, Standard Test Method for the protection of electrostatic charge susceptible

items – Wrist Straps

ANSI/ESD STM2.1, Standard Test Method for the protection of electrostatic discharge

susceptible items – Garments

ANSI/ESD STM3.1, Standard Test Method for the electrostatic discharge susceptible items –

Ionization

ANSI/ESD STM11.31, Standard Test Method for evaluating the performance of electrostatic

discharge shielding materials – Bags

3 Terms and definitions

For the purposes of this document, the following terms and definitions in the future IEC

61340-1-2 as well as the following, apply.

NOTE For the purposes of this document “earth” and “ground” have the same meaning.

3.1

charged device model

CDM

ESD stress model that approximates the discharge event that occurs when a charged

component is quickly discharged to another object at a different electrostatic potential

Note 1 to entry: Charged device model is described in ANSI/ESDA/JEDEC JS-002-2014 [1].

Note 2 to entry: This note only applies to the French language.

3.2

common ground point

grounded device or location where the conductors of two or more ESD control items are

bonded

3.3

common connection point

device or location where the conductors of two or more ESD control items are connected in

order to bring the ESD protective items to the same electrical potential through equipotential

bonding

3.4

equipotential bond

electrical connection of exposed conductive parts (or items used to control ESD) so that they

are at substantially the same voltage under normal and fault conditions

3.5

electrostatic discharge

ESD

rapid transfer of charge between bodies that are at different electrostatic potentials

Note 1 to entry: This note only applies to the French language.

3.6

ESD control items

materials or products designed to prevent the generation of static charge and/or dissipate

static charges that have been generated so as to prevent damage to ESD sensitive devices

3.7

ESD protected area

EPA

area in which an ESDS can be handled with accepted risk of damage as a result of

electrostatic discharge or fields

Note 1 to entry: This note only applies to the French language.

3.8

ESD sensitive device

ESDS

sensitive device, integrated circuit or assembly that may be damaged by electrostatic fields or

electrostatic discharge

3.9

ESD withstand voltage

highest voltage level that does not cause device failure

Note 1 to entry: The device passes all tested lower voltages.

3.10

functional ground

terminal used to connect parts to earth ground for reasons other than safety

3.11

human body model

HBM

ESD stress model that approximates the discharge from the fingertip of a typical human being

onto a pin of a device with another pin grounded

Note 1 to entry: Human body model is described in IEC 60749-26 [2].

– 10 – IEC 61340-5-1:2016 RLV © IEC 2016

Note 2 to entry: This note only applies to the French language.

3.12

machine model

MM

ESD stress model that approximates the discharge to a device pin due to contact of

equipment or tools such as those found in the manufacturing line

Note 1 to entry: Machine model is described in IEC 60749-27 [3].

Note 2 to entry: This note only applies to the French language.

3.13

organization

company, group or body that handles ESDS

3.14

protective earth

terminal used to connect parts to earth for safety reasons

4 Personnel safety

The procedures and equipment described in this standard may expose personnel to

hazardous electrical conditions. Users of this standard are responsible for selecting

equipment that complies with applicable laws, regulatory codes and both external and internal

policy. Users are cautioned that this standard cannot replace or supersede any requirements

for personnel safety.

Electrical hazard reduction practices should shall be exercised and proper grounding

instructions for equipment must shall be followed.

5 ESD control program

5.1 General

5.1.1 ESD control program requirements

An ESD control program, that has been established using the technical limits required by this

standard, will minimize ESD related damage to devices that have an ESD sensitivity greater

than or equal to 100 V HBM as determined through testing using IEC 60749-26. The ESD

control program shall include all the administrative and technical requirements of this

standard. The ESD control program shall document the lowest ESD withstand voltage(s) that

can be handled. The organization shall establish, document, implement, maintain and verify

the compliance of the program in accordance with the requirements of this standard.

5.1.2 ESD coordinator

A person shall be assigned by the organization with the responsibility for implementing the

requirements of this standard including establishing, documenting, maintaining and verifying

the compliance of the program.

5.1.3 Tailoring

This standard, or portions of it, may not apply to all applications. Tailoring is accomplished by

evaluating the applicability of each requirement for the specific application. Upon completion

of the evaluation, requirements may be added, modified or deleted. Tailoring decisions,

including rationale and technical justification, shall be documented.

5.2 ESD control program administrative requirements

5.2.1 ESD control program plan

The organization shall prepare an ESD control program plan that addresses each of the

requirements of the program. Those requirements concern are:

• training,

• product qualification,

• compliance verification,

• grounding/bonding systems,

• personnel grounding,

• EPA requirements,

• packaging systems,

• marking.

The plan is the principal document for implementing and verifying the program. The goal is a

fully implemented and integrated program that conforms to internal quality system

requirements. The plan shall apply to all applicable facets of the organization’s work.

5.2.2 Training plan

The training plan shall define all personnel that are required to have ESD awareness and

prevention training. At a minimum, initial and recurrent ESD awareness and prevention

training shall be provided to all personnel who handle or otherwise come into contact with any

ESDS items. Initial training shall be provided before personnel handle ESD sensitive devices.

The type and frequency of ESD training for personnel shall be defined in the training plan.

The training plan shall include a requirement for maintaining employee training records and

shall document where the records are stored. Training methods and the use of specific

techniques are at the organization’s discretion. The training plan shall include methods used

by the organization to ensure trainee comprehension and training adequacy.

5.2.3 Product qualification

The organization shall qualify all ESD control items that are selected for use as part of the

ESD control program. Tables 2 and 3 list the required product qualification test methods,

associated limits for each ESD control item and other requirements as stated in this standard.

Acceptable evidence of product qualification includes:

a) Product data sheets published by the manufacturer of the ESD control item:

1) The data sheet shall reference the required IEC test method for that item.

2) The data sheet limits shall, at a minimum, comply with the limits for that ESD control

item

b) Test reports from an independent laboratory: the test report shall reference the applicable

IEC test method and the limits shall comply with the limits for that item as specified in this

standard.

c) Test reports generated internally by the organization for its own use: the test report shall

reference the applicable IEC test method and the limits shall comply with the limits for that

item.

d) For ESD control items that were installed by the organization before the adoption of this

standard, on-going compliance verification records can be used as evidence of product

qualification.

For ESD control items that are not listed in Tables 2 and 3, but are considered to be a part of

the ESD control program, the organization using such items shall qualify these products prior

– 12 – IEC 61340-5-1:2016 RLV © IEC 2016

to use. The test method used for product qualification and the user defined acceptance limits

for each item shall be documented in the ESD control program plan.

NOTE IEC TR 61340-5-2 contains guidance for items not listed in Tables 2 and 3 of this document.

5.2.4 Compliance verification plan

A compliance verification plan shall be established to ensure the organization’s fulfilment of

the requirements of the plan. Process monitoring (measurements) shall be conducted in

accordance with a compliance verification plan that identifies the technical requirements to be

verified, the measurement limits and the frequency at which those verifications must shall

occur. The compliance verification plan must shall document the test methods used for

process monitoring and measurements. If the organization uses different test methods that

differ from the standards referenced in to replace those of this standard, the organization

must shall be able to show that the results achieved correlate with the referenced standards.

Where test methods are devised for testing items not covered in this standard, these shall be

adequately documented including corresponding test limits. Compliance verification records

shall be established and maintained to provide evidence of conformity to the technical

requirements.

The test equipment selected shall be capable of making the measurements defined in the

compliance verification plan.

Consideration should be taken regarding the lowest relative humidity levels experienced by

the organization; some of the measurements should be made under these conditions.

5.3 ESD control program plan technical requirements

5.3.1 General

The following subclauses describe the essential technical requirements used in the

development of an ESD control program.

The required limits are based on the test methods or standards listed in Table 1, Table 2 and

Table 3. The compliance verification plan must shall document the methods used to verify the

limits. These procedures may or may not be based on the test methods in each table. Test

methods and corresponding limits used by the organization that differ from the test methods

or references in Tables 1 to 3 shall be documented with a technical justification that supports

their use.

Some of the technical elements listed in Tables 1 to 3 do not have a defined lower resistance

limit. However, a minimum resistance value may be required for safety reasons.

See relevant national requirements and/or IEC 60364[4] series, IEC TS 60479-1[5],

IEC TS 60479-2[6], IEC 61010-1[7] and IEC 61140[8].

5.3.2 Grounding/equipotential bonding systems

In order to eliminate ESD damage, it is necessary to eliminate differences in potential

between ESDS items and other conductors that ESDS might come into contact with such as

personnel, automated handling equipment, fixtures and mobile equipment. All conductive and

dissipative items shall be connected to ground or to each other (equipotential bonding) in

order to eliminate differences in potential. All items that come into contact with ESDS and are

capable of conducting electricity shall be connected to ground or electrically bonded in order

to eliminate differences in potential. This can be achieved in three different ways:

• Grounding using protective earth

The first and preferred ESD ground is protective earth if available. In this case, the ESD

control elements and grounded personnel are connected to protective earth (see

Figure 1).

• Grounding using functional ground

The second acceptable ESD ground is achieved through the use of a functional ground.

This conductor can be a ground rod, stake that is used for grounding the ESD control

items in use at a facility or a separate wiring system that is bonded to the AC ground at

the main service panel (see Figure 1); in order to eliminate differences in potential

between protective earth and the functional ground system, it is highly recommended that

the two systems be electrically bonded together (see Figure 1) the two systems shall be

electrically bonded together where possible.

• Equipotential bonding

In the event that a ground facility is not available, ESD protection can be achieved by

connecting all of the ESD control items together at a common connection point (see

Figure 2). The maximum resistance between any protective item and the common

connection point must shall comply with the limits established for the protective items as

per Tables 2 and 3.

Whichever grounding/bonding system is selected, it shall be referred to as “ground” in the

remainder of this standard.

IEC

Key

1 Wrist strap (band and ground cord)

2 Work surface

3 example of Common ground point

4 ESD Floor mat

5 ESD Floor

6 Protective earth or functional ground (functional ground, if used, should shall be bonded to protective earth)

Figure 1 – Schematic of an EPA with a ground reference

CAUTION: Users are advised to consult local and national electrical codes and regulations

before making any connections to facility electrical wiring systems.

– 14 – IEC 61340-5-1:2016 RLV © IEC 2016

IEC

Key

1 Wrist strap and cord

2 Work surface

3 Common connection point

4 ESD Floor mat

5 ESD Floor

Figure 2 – Schematic of an equipotential bonding system

Table 1 – Grounding/bonding requirements

Technical requirement Grounding method Test method/standard Required limit(s)

Grounding/bonding system Protective earth National electrical system National electrical code

standard limits

Functional ground National electrical system National electrical code

standard limits

If the national electrical

code does not specify a

requirement, then the

resistance between

functional ground and

protective earth shall not

exceed 25 Ω

Equipotential bonding See applicable See limits for each ESD

implementing process from control item from Tables 2

Tables 2 and 3 and 3

5.3.3 Personnel grounding

All personnel shall be grounded or equipotentially bonded according to the requirements

below when handling ESDS. When personnel are seated at ESD protective workstations, they

shall be connected to ground via a wrist strap system.

For standing operations, personnel can be grounded via a wrist strap system or by a

footwear-flooring system. When a footwear-flooring system is used, either of personnel shall

wear ESD footwear on both feet and the two following conditions shall be met:

• the total resistance of the system (from the person, through the footwear and flooring to

equipment ground) shall be less than 3,5 × 10 1,0 × 10 Ω;

• the maximum body voltage generation shall be less than 100 V and the total resistance of

the system shall be less than 1 x10 Ω.

Table 2 – Personnel grounding requirements

Product qualification Compliance verification

Technical ESD control

requirement item b b

Test method Limits Test method Limits

Personnel Wrist straps ANSI/ESD S1.1 See wrist strap system

R < 5 × 10 Ω or

grounding (bands and (5.1) user defined value

ground cords) IEC 61340-4-6

Wrist band ANSI/ESD S1.1

resistance (5.2)

IEC 61340-4-6

– interior Not applicable

≤ 1 × 10 Ω

– exterior > 1 × 10 Ω Not applicable

Wrist strap Not applicable IEC 61340-5-1

R < 3,5 × 10 Ω

a

system Clause A.1

IEC 61340-4-6

Wrist strap

continuity test

c

Footwear IEC 61340-4-3 Conductive: See person/footwear system

<1x10 Ω

Dissipative:

5 8

1x10 ≤R≤1x10 Ω

R ≤ 1 × 10 Ω

See person/footwear system

7 9 d,f

Person/footwe IEC 61340-4-5 IEC 61340-4-5 R < 1,0 × 10 Ω

R <3,5x10 Ω

g

g

ar/flooring

OR

system

R <1,0x10 Ω and

g

body voltage <100

V (average of 5

highest peaks)

R < 1,0 × 10 Ω

g

and absolute value

of body voltage

< 100 V

(average of 5

highest peaks)

Person/footwe Not applicable IEC 61340-5-1 R<3,5x10 Ω

ar system Clause A.2

R < 1,0 × 10 Ω

gp

e

See Annex A

a

For situations where an ESD garment is used as part of the wrist strap grounding path, the total system

resistance including the person, garment and grounding cord should be less than 3,5 × 10 Ω.

b

Symbols used in this table: R refers to resistance to ground, R refers to resistance to groundable point

g gp

c

For the product qualification of footwear, the environmental conditions for testing, using IEC 61340-4-3 should

be (12 ± 3) % RH and 23 °C ± 2 °C.

d

A periodic body voltage generation test should be done to verify the voltage is less than 100 V

e

The resistance limit applies to measuring each foot one by one, not two in parallel.

f 9

The required limit of < 1,0 × 10 Ω is the maximum allowed value. The user should establish an upper limit from

the resistance values that were measured for product qualification for the footwear and the floor to comply with

the < 100 V body voltage generation and use these resistances for compliance verification.

– 16 – IEC 61340-5-1:2016 RLV © IEC 2016

5.3.4 ESD protected areas (EPA)

5.3.4.1 Handling ESDS and access to EPA

Handling of ESDS without ESD protective covering or packaging shall be performed in an

EPA. The boundaries of the EPA shall be clearly identified as EPA boundaries (e.g, caution

signs indicating the existence of the EPA shall can be posted and clearly visible conspicuous

to personnel prior to entry to the EPA.)

NOTE 1 An EPA can, for example, consist of a building, an entire room or a single workstation.

Access to the EPA shall be limited to personnel who have completed appropriate ESD

training. Untrained individuals shall be escorted by trained personnel while in an EPA.

5.3.4.2 Insulators

All non-essential insulators and items (plastics and paper), such as coffee cups, food

wrappers and personal items shall be removed from the workstation or any operation where

unprotected ESDS are handled.

The ESD threat associated with process essential insulators or electrostatic field sources

shall be evaluated to ensure that:

• the electrostatic field at the position where the ESDS are handled shall not exceed

10 000 5 000 V/m;

or

• if the electrostatic potential measured at the surface of the process required insulator

exceeds 2 000 V, the item shall be kept a minimum of 30 cm from the ESDS; and

• if the electrostatic potential measured at the surface of the process required insulator

exceeds 125 V, the item shall be kept a minimum of 2,5 cm from the ESDS.

If the measured electrostatic field or surface potential exceeds the stated limits, ionization or

other charge mitigating techniques shall be used.

Some of the measurements should be taken at the lowest expected relative humidity

experienced by the facility.

NOTE 1 These measurements are made based on the frequency defined in the compliance verification plan.

NOTE 2 An ESD threat is considered a metal to metal contact while the ESDS is in the presence of the field

NOTE 3 The accurate measurement of electrostatic fields requires that the person makin

...

IEC 61340-5-1 ®

Edition 2.0 2016-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrostatics –

Part 5-1: Protection of electronic devices from electrostatic phenomena –

General requirements

Électrostatique –

Partie 5-1: Protection des dispositifs électroniques contre les phénomènes

électrostatiques – Exigences générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61340-5-1 ®

Edition 2.0 2016-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrostatics –

Part 5-1: Protection of electronic devices from electrostatic phenomena –

General requirements

Électrostatique –

Partie 5-1: Protection des dispositifs électroniques contre les phénomènes

électrostatiques – Exigences générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.99; 29.020 ISBN 978-2-8322-3422-8

– 2 – IEC 61340-5-1:2016 © IEC 2016

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 8

4 Personnel safety . 9

5 ESD control program . 10

5.1 General . 10

5.1.1 ESD control program requirements . 10

5.1.2 ESD coordinator . 10

5.1.3 Tailoring . 10

5.2 ESD control program administrative requirements . 10

5.2.1 ESD control program plan . 10

5.2.2 Training plan . 10

5.2.3 Product qualification . 11

5.2.4 Compliance verification plan . 11

5.3 ESD control program plan technical requirements . 11

5.3.1 General . 11

5.3.2 Grounding/equipotential bonding systems . 12

5.3.3 Personnel grounding . 14

5.3.4 ESD protected areas (EPA) . 15

5.3.5 Packaging . 17

5.3.6 Marking . 17

Annex A (normative) Test methods . 19

Bibliography . 20

Figure 1 – Schematic of an EPA with a ground reference . 13

Figure 2 – Schematic of an equipotential bonding system . 14

Figure A.1 – Footwear functional testing (example). 19

Table 1 – Grounding/bonding requirements . 14

Table 2 – Personnel grounding requirements . 15

Table 3 – EPA requirements . 17

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 5-1: Protection of electronic devices from

electrostatic phenomena – General requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61340-5-1 has been prepared by IEC technical committee 101:

Electrostatics.

This second edition cancels and replaces the first edition published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Technical requirements were changed to align IEC 61340-5-1 with other industry ESD

standards;

b) Reference documents were updated to reflect newly released IEC standards;

c) A section on product qualification was added;

d) Table 4 was deleted and detailed packaging requirements were deferred to

IEC 61340-5-3;

– 4 – IEC 61340-5-1:2016 © IEC 2016

e) Clause A.1 was removed and is now included in IEC 61340-4-6.

The text of this standard is based on the following documents:

FDIS Report on voting

101/505/FDIS 101/508/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61340 series, published under the general title Electrostatics, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of May 2017 have been included in this copy.

INTRODUCTION

This part of IEC 61340 covers the requirements necessary to design, establish, implement

and maintain an electrostatic discharge (ESD) control program for activities that: manufacture,

process, assemble, install, package, label, service, test, inspect, transport or otherwise

handle electrical or electronic parts, assemblies and equipment susceptible to damage by

electrostatic discharges greater than or equal to 100 V human body model (HBM), 200 V

charged device model (CDM) and 35 V on isolated conductors. Isolated conductors were

historically represented by machine model (MM). The 35 V limit is related to the level

achievable using ionizers specified in this standard. The MM test is no longer required for

qualification of devices, only the HBM and CDM tests are. The MM test is retained in this

standard for process control of isolated conductors only.

Any contact and physical separation of materials or flow of solids, liquids, or particle-laden

gases can generate electrostatic charges. Common sources of ESD include charged:

personnel, conductors, common polymeric materials, and processing equipment. ESD

damage can occur when:

• a charged person or object comes into contact with an ESD sensitive device (ESDS);

• an ESDS comes into direct contact with a highly conductive surface while exposed to an

electrostatic field;

• a charged ESDS comes into contact with another conductive surface which is at a different

electrical potential. This surface may or may not be grounded.

Examples of ESDS are microcircuits, discrete semiconductors, thick and thin film resistors,

hybrid devices, printed circuit boards and piezoelectric crystals. It is possible to determine

device and item susceptibility by exposing the device to simulated ESD events. The ESD

withstand voltage determined by sensitivity tests using simulated ESD events does not

necessarily represent the ability of the device to withstand ESD from real sources at that

voltage level. However, the levels of sensitivity are used to establish a baseline of

susceptibility data for comparison of devices with equivalent part numbers from different

manufacturers. Three different models have been used for qualification of electronic

components – human body model (HBM), machine model (MM), and charged device model

(CDM). In current practice devices are qualified only using HBM and CDM susceptibility tests.

This standard covers the ESD control program requirements necessary for setting up a

program to handle ESDS, based on the historical experience of both military and commercial

organizations. The fundamental ESD control principles that form the basis of this standard are

as follows.

• Avoid a discharge from any charged, conductive object (personnel and especially

automated handling equipment) into the ESDS. This can be accomplished by bonding or

electrically connecting all conductors in the environment, including personnel, to a known

ground or contrived ground (as on board ship or on aircraft). This attachment creates an

equipotential balance between all conducting objects and personnel. Electrostatic

protection can be maintained at a potential different from a “zero” voltage ground potential

as long as all conductive objects in the system are at the same potential.

• Avoid a discharge from any charged ESD sensitive device. Charging can result from direct

contact and separation or it can be induced by an electric field. Necessary insulators in

the environment cannot lose their electrostatic charge by attachment to ground. Ionization

systems provide neutralization of charges on these necessary insulators (circuit board

materials and some device packages are examples of necessary insulators). The ESD

hazard created by electrostatic charges on the necessary insulators in the work place is

assessed to ensure that appropriate actions are implemented, according to the risk.

• Once outside of an electrostatic discharge protected area (hereinafter referred to as an

EPA) it is generally not possible to control the above items, therefore, ESD protective

packaging may be required. ESD protection can be achieved by enclosing ESD sensitive

products in static protective materials, although the type of material depends on the

situation and destination. Inside an EPA, static dissipative materials may provide

– 6 – IEC 61340-5-1:2016 © IEC 2016

adequate protection. Outside an EPA, static discharge shielding materials are

recommended. Whilst all of these materials are not discussed in this standard, it is

important to recognize the differences in their application. For more information see

IEC 61340-5-3.

Each company has different processes, and so will require a different blend of ESD

prevention measures for an optimum ESD control program. Measures should be selected,

based on technical necessity and carefully documented in an ESD control program plan, so

that all concerned can be sure of the program requirements.

Training is an essential part of an ESD control program in order to ensure that the personnel

involved understand the equipment and procedures they are to use in order to be in

compliance with the ESD control program plan. Training is also essential in raising awareness

and understanding of ESD issues. Without training, personnel are often a major source of

ESD risk. With training, they become an effective first line of defence against ESD damage.

Regular compliance verification checks and tests are essential to ensure that equipment

remains effective and that the ESD control program is correctly implemented in compliance

with the ESD control program plan.

ELECTROSTATICS –

Part 5-1: Protection of electronic devices from

electrostatic phenomena – General requirements

1 Scope

This part of IEC 61340 applies to activities that: manufacture, process, assemble, install,

package, label, service, test, inspect, transport or otherwise handle electrical or electronic

parts, assemblies and equipment with withstand voltages greater than or equal to 100 V HBM,

200 V CDM and 35 V for isolated conductors. ESDS with lower withstand voltages may

require additional control elements or adjusted limits. Processes designed to handle items

that have lower ESD withstand voltage(s) can still claim compliance to this standard.

This standard provides the requirements for an ESD control program. IEC TR 61340-5-2 [9]

provides guidance on the implementation of this standard.

This standard does not apply to electrically initiated explosive devices, flammable liquids,

gases and powders.

The purpose of this standard is to provide the administrative and technical requirements for

establishing, implementing and maintaining an ESD control program (hereinafter referred to

as the “program”).

NOTE Isolated conductors were historically represented by MM.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61340-2-3, Electrostatics – Part 2-3: Methods of test for determining the resistance and

resistivity of solid planar materials used to avoid electrostatic charge accumulation

IEC 61340-4-1, Electrostatics – Part 4-1: Standard test methods for specific applications –

Electrical resistance of floor coverings and installed floors

IEC 61340-4-3, Electrostatics – Part 4-3: Standard test methods for specific applications –

Footwear

IEC 61340-4-5, Electrostatics – Part 4-5: Standard test methods for specific applications –

Methods for characterizing the electrostatic protection of footwear and flooring in combination

with a person

IEC 61340-4-6, Electrostatics – Part 4-6: Standard test methods for specific applications –

Wrist straps

_____________

Numbers in square brackets refer to the bibliography.

– 8 – IEC 61340-5-1:2016 © IEC 2016

IEC 61340-4-7, Electrostatics – Part 4-7: Standard test methods for specific applications –

Ionization

IEC 61340-4-9, Electrostatics – Part 4-9: Standard test methods for specific applications –

Garments

IEC 61340-5-3, Electrostatics – Part 5-3: Protection of electronic devices from electrostatic

phenomena – Properties and requirements classification for packaging intended for

electrostatic discharge sensitive devices

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE For the purposes of this document “earth” and “ground” have the same meaning.

3.1

charged device model

CDM

ESD stress model that approximates the discharge event that occurs when a charged

component is quickly discharged to another object at a different electrostatic potential

Note 1 to entry: Charged device model is described in ANSI/ESDA/JEDEC JS-002-2014 [1].

Note 2 to entry: This note only applies to the French language.

3.2

common ground point

grounded device or location where the conductors of two or more ESD control items are

bonded

3.3

common connection point

device or location where the conductors of two or more ESD control items are connected in

order to bring the ESD protective items to the same electrical potential through equipotential

bonding

3.4

equipotential bond

electrical connection of conductive parts (or items used to control ESD) so that they are at

substantially the same voltage under normal and fault conditions

3.5

electrostatic discharge

ESD

rapid transfer of charge between bodies that are at different electrostatic potentials

Note 1 to entry: This note only applies to the French language.

3.6

ESD control items

materials or products designed to prevent the generation of static charge and/or dissipate