IEC 62576:2018

(Main)Electric double-layer capacitors for use in hybrid electric vehicles - Test methods for electrical characteristics

Electric double-layer capacitors for use in hybrid electric vehicles - Test methods for electrical characteristics

IEC 62576:2018 describes the methods for testing electrical characteristics of electric double-layer capacitor cells (hereinafter referred to as capacitor) to be used for peak power assistance in hybrid electric vehicles. This second edition cancels and replaces the first edition published in 2009. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) information on applicability of this document has been added in Clause 1;

b) the definitions of some terms in Clause 3 have been improved;

c) the description of test procedures in Clause 4 has been clarified;

d) information on endurance cycling test has been added (Annex E).

Condensateurs électriques à double couche pour véhicules électriques hybrides - Méthodes d'essai des caractéristiques électriques

L'IEC 62576:2018 décrit les méthodes d'essai des caractéristiques électriques des cellules de condensateur électrique à double couche (ci-après dénommé "condensateur") utilisées pour l'assistance en puissance de crête dans les véhicules électriques hybrides. Cette deuxième édition annule et remplace la première édition parue en 2009. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) des informations sur le champ d'application du présent document ont été ajoutées dans l'Article 1;

b) les définitions de certains termes de l'Article 3 ont été améliorées;

c) la description des procédures d'essai de l'Article 4 a été clarifiée;

d) des informations sur l'essai cyclique d'endurance ont été ajoutées (Annexe E).

General Information

- Status

- Published

- Publication Date

- 19-Feb-2018

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Feb-2018

- Completion Date

- 02-Mar-2018

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 62576:2018 (Electric double‑layer capacitors for HEVs)

IEC 62576:2018 specifies standardized test methods for electrical characteristics of electric double‑layer capacitor (EDLC) cells intended for peak power assistance in hybrid electric vehicles (HEVs). This is Edition 2.0 (2018), a technical revision of the 2009 edition that clarifies applicability, refines definitions, improves test procedure descriptions, and adds endurance cycling test guidance (Annex E). All tests in the document are defined as type tests for capacitor cells.

Key technical topics and requirements

The standard provides measurement circuits, test procedures and calculation methods for key electrical parameters used in HEV applications:

- Capacitance, internal resistance (ESR) and maximum power density - test circuits, measurement steps and calculation methods.

- Voltage maintenance characteristics - procedures to measure voltage retention under defined load/conditions.

- Energy efficiency (charging/discharging efficiency) - measurement circuits, procedures and calculation of energy efficiency.

- Endurance tests and thermal considerations - informative annexes covering continuous high‑temperature voltage endurance (Annex A), heat equilibrium timing (Annex B), charging/discharging measurement guidance (Annex C), current‑setting procedures (Annex D) and endurance cycling test (Annex E).

- Test equipment and preconditioning - requirements and guidance for reproducible measurements.

- Calculation formulas and criteria for reporting results (e.g., voltage‑time curves, power density calculations) are provided to ensure consistent comparability.

Practical applications

IEC 62576:2018 is designed to support reliable evaluation and specification of EDLC cells used where high‑power bursts and rapid energy recovery are required:

- Validation of EDLC cell performance for peak power assistance during acceleration and regenerative braking in HEVs.

- Type testing by component manufacturers to verify product data (capacitance, ESR, power density, efficiency).

- Supplier‑OEM contractual testing protocols to ensure component suitability for vehicle systems.

- Test laboratories implementing standardized procedures for repeatable, comparable results across products and vendors.

Who should use this standard

- Automotive OEMs and powertrain engineers specifying energy storage components.

- EDLC (supercapacitor) manufacturers and suppliers.

- Independent test and certification laboratories.

- System integrators and researchers developing HEV energy recovery and hybridization strategies.

Related standards

- IEC 62391 series (general EDLC standards) - IEC 62576 complements existing capacitor standards by focusing on HEV‑specific usage patterns and test methods.

Using IEC 62576:2018 helps harmonize EDLC electrical testing for automotive applications, improving comparability, supply‑chain clarity and reliability of high‑power energy storage components in hybrid vehicles.

Buy Documents

IEC 62576:2018 RLV - Electric double-layer capacitors for use in hybrid electric vehicles - Test methods for electrical characteristics Released:2/20/2018 Isbn:9782832254363

IEC 62576:2018 - Electric double-layer capacitors for use in hybrid electric vehicles - Test methods for electrical characteristics Released:2/20/2018 Isbn:9782832253410

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

IEC 62576:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric double-layer capacitors for use in hybrid electric vehicles - Test methods for electrical characteristics". This standard covers: IEC 62576:2018 describes the methods for testing electrical characteristics of electric double-layer capacitor cells (hereinafter referred to as capacitor) to be used for peak power assistance in hybrid electric vehicles. This second edition cancels and replaces the first edition published in 2009. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) information on applicability of this document has been added in Clause 1; b) the definitions of some terms in Clause 3 have been improved; c) the description of test procedures in Clause 4 has been clarified; d) information on endurance cycling test has been added (Annex E).

IEC 62576:2018 describes the methods for testing electrical characteristics of electric double-layer capacitor cells (hereinafter referred to as capacitor) to be used for peak power assistance in hybrid electric vehicles. This second edition cancels and replaces the first edition published in 2009. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) information on applicability of this document has been added in Clause 1; b) the definitions of some terms in Clause 3 have been improved; c) the description of test procedures in Clause 4 has been clarified; d) information on endurance cycling test has been added (Annex E).

IEC 62576:2018 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 31.060.99 - Other capacitors; 33.160.30 - Audio systems; 43.120 - Electric road vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62576:2018 has the following relationships with other standards: It is inter standard links to IEC 62576:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62576:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62576 ®

Edition 2.0 2018-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electric double-layer capacitors for use in hybrid electric vehicles –

Test methods for electrical characteristics

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62576 ®

Edition 2.0 2018-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electric double-layer capacitors for use in hybrid electric vehicles –

Test methods for electrical characteristics

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.060.99; 43.120 ISBN 978-2-8322-5436-3

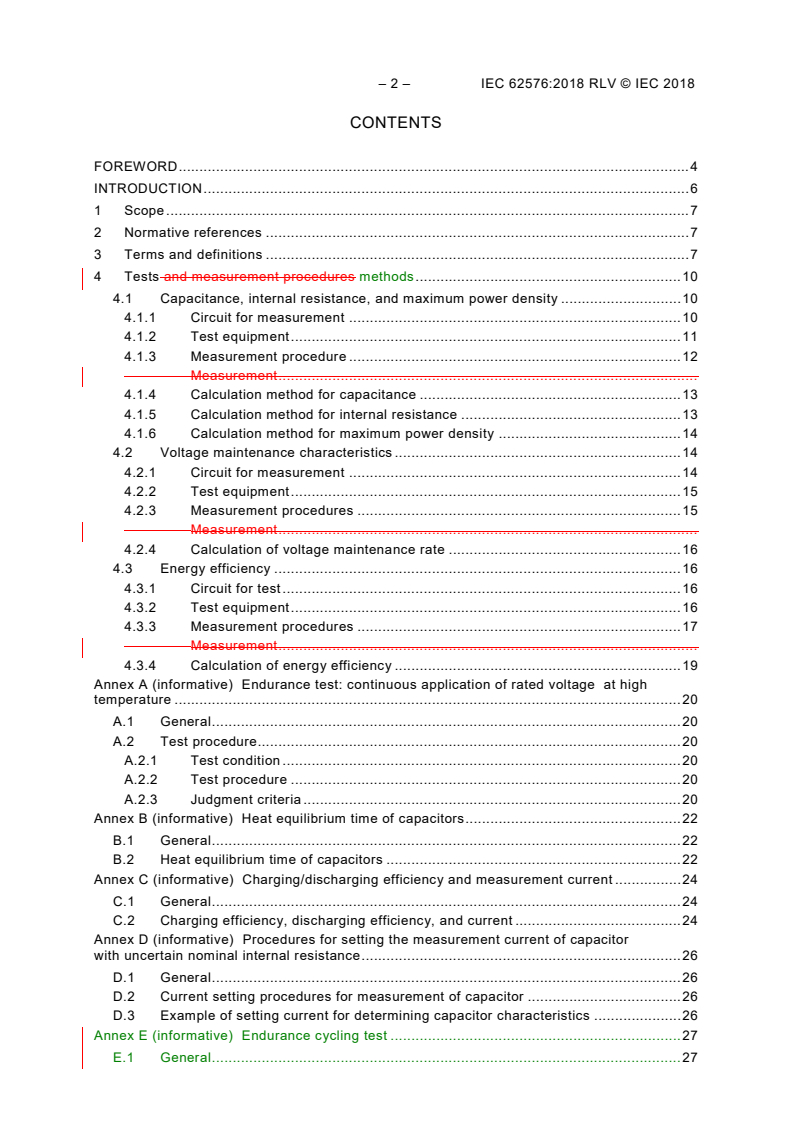

– 2 – IEC 62576:2018 RLV © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Tests and measurement procedures methods . 10

4.1 Capacitance, internal resistance, and maximum power density . 10

4.1.1 Circuit for measurement . 10

4.1.2 Test equipment . 11

4.1.3 Measurement procedure . 12

Measurement .

4.1.4 Calculation method for capacitance . 13

4.1.5 Calculation method for internal resistance . 13

4.1.6 Calculation method for maximum power density . 14

4.2 Voltage maintenance characteristics . 14

4.2.1 Circuit for measurement . 14

4.2.2 Test equipment . 15

4.2.3 Measurement procedures . 15

Measurement .

4.2.4 Calculation of voltage maintenance rate . 16

4.3 Energy efficiency . 16

4.3.1 Circuit for test . 16

4.3.2 Test equipment . 16

4.3.3 Measurement procedures . 17

Measurement .

4.3.4 Calculation of energy efficiency . 19

Annex A (informative) Endurance test: continuous application of rated voltage at high

temperature . 20

A.1 General . 20

A.2 Test procedure . 20

A.2.1 Test condition . 20

A.2.2 Test procedure . 20

A.2.3 Judgment criteria . 20

Annex B (informative) Heat equilibrium time of capacitors . 22

B.1 General . 22

B.2 Heat equilibrium time of capacitors . 22

Annex C (informative) Charging/discharging efficiency and measurement current . 24

C.1 General . 24

C.2 Charging efficiency, discharging efficiency, and current . 24

Annex D (informative) Procedures for setting the measurement current of capacitor

with uncertain nominal internal resistance . 26

D.1 General . 26

D.2 Current setting procedures for measurement of capacitor . 26

D.3 Example of setting current for determining capacitor characteristics . 26

Annex E (informative) Endurance cycling test . 27

E.1 General . 27

E.2 Test method . 27

E.2.1 Test temperature . 27

E.2.2 Test equipment . 27

E.2.3 Preconditioning . 27

E.2.4 Initial measurements . 27

E.2.5 Test steps . 27

E.2.6 Test . 28

E.2.7 End of test criteria . 28

E.2.8 Post-treatment . 29

E.2.9 Final measurement . 29

E.2.10 Acceptance criteria . 29

Bibliography . 30

Figure 1 – Basic circuit for measuring capacitance, internal resistance and maximum

power density . 11

Figure 2 – Voltage–time characteristics between capacitor terminals in capacitance

and internal resistance measurement . 12

Figure 3 – Basic circuit for measuring the voltage maintenance characteristics . 14

Figure 4 – Time characteristics of voltage between capacitor terminals in voltage

maintenance test . 15

Figure 5 – Voltage-time characteristics between capacitor terminals in

charging/discharging efficiency test . 17

Figure B.1 – Heat equilibrium times of capacitors (from 85 °C to 25 °C) . 22

Figure B.2 – Heat equilibrium times of capacitors (from –40 °C to 25 °C) . 23

Figure – Temperature changes of capacitors' central portions (85 °C→25 °C) .

Figure – Temperature changes of capacitors' central portions (–40 °C→25 °C) .

Figure B.3 – Temperature changes of capacitors' central portions . 23

Figure E.1 – Endurance cycling test steps . 28

Table D.1 – Example of setting current for measurement of capacitor . 26

– 4 – IEC 62576:2018 RLV © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC DOUBLE-LAYER CAPACITORS FOR USE IN

HYBRID ELECTRIC VEHICLES – TEST METHODS

FOR ELECTRICAL CHARACTERISTICS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and

non-governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates

closely with the International Organization for Standardization (ISO) in accordance with conditions determined

by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 62576 has been prepared by IEC technical committee 69: Electric

road vehicles and electric industrial trucks.

This second edition cancels and replaces the first edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) information on applicability of this document has been added in Clause 1;

b) the definitions of some terms in Clause 3 have been improved;

c) the description of test procedures in Clause 4 has been clarified;

d) information on endurance cycling test has been added (Annex E).

The text of this International Standard is based on the following documents:

CDV Report on voting

69/486/CDV 69/539/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62576:2018 RLV © IEC 2018

INTRODUCTION

The electric double-layer capacitor (EDLC capacitor) is used as an promising energy storage

system for hybrid electric vehicles (HEVs). EDLC Capacitor-installed HEVs electric vehicles

have begun to be are commercialized with an eye to improving fuel economy by recovering

regenerative energy, and by peak power assistance during acceleration, etc. Although

standards for EDLC capacitors already exists (IEC 62391 series), those for HEVs electric

vehicles involve patterns of use, usage environment, and values of current that are quite

different from those assumed in the existing standards. Standard evaluation and test methods

will be useful for both auto manufacturers and capacitor suppliers to speed up the

development and lower the costs of such EDLCs capacitors. With these points in mind, this

document aims to provide basic and minimum specifications in terms of the methods for

testing electrical characteristics, and to create an environment that supports the expanding

market of HEVs electric vehicles and large capacity EDLCs capacitors. Additional practical

test items to be standardized should be reconsidered after technology and market

stabilization of EDLCs capacitors for HEVs electric vehicles. In terms of Regarding endurance,

which is important in practical use, just a basic concept is set forth in the informative annexes.

ELECTRIC DOUBLE-LAYER CAPACITORS FOR USE IN

HYBRID ELECTRIC VEHICLES – TEST METHODS

FOR ELECTRICAL CHARACTERISTICS

1 Scope

This document describes the methods for testing electrical characteristics of electric

double-layer capacitor cells (hereinafter referred to as "capacitor") used for peak power

assistance in hybrid electric vehicles.

All the tests in this document are type tests.

This document can also be applicable to the capacitor used in idling reduction systems (start

and-stop systems) for the vehicles.

This document can also be applicable to the capacitor modules consisting of more than one

cell.

NOTE Annex E provides information on endurance cycling test.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

Amendment 1(1992)

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

reference temperature

reference temperature (°C) to be used in the test

3.1

ambient temperature

ambient temperature of the air surrounding space in which a the immediate vicinity of a

capacitor is placed

3.2

applied voltage

voltage (V) applied between the terminals of a capacitor

– 8 – IEC 62576:2018 RLV © IEC 2018

3.3

calculation end voltage

voltage (V) at a selected end point for calculating the characteristics including capacitance

under a state of voltage decrease during discharge

3.4

lower category temperature

lowest ambient temperature that a capacitor is designed to operate continuously

3.4

calculation start voltage

voltage (V) at a selected start point for calculating the characteristics including capacitance

under a state of voltage decrease during discharge

3.5

capacitance

ability of a capacitor to store electrical charge (F)

3.6

charge accumulated electrical energy

amount of charged energy (J) accumulated from the beginning to the end of charging

3.7

charge current

I

c

current (A) required to charge a capacitor

3.8

charging efficiency

efficiency under specified charging conditions, and ratio (%) of stored energy to charge

accumulated electrical energy

Note 1 to entry: This value is calculated from the internal resistance of a capacitor.

Note 2 to entry: Refer to Formula C.8.

3.9

constant voltage charging

method of charging a capacitor at specified voltage continuously charging during which the

voltage is maintained at a constant value regardless of charge current or temperature

3.10

discharge accumulated electrical energy

amount of discharged energy (J) accumulated from the beginning to the end of discharging

3.11

discharge current

I

d

current (A) required to discharge a capacitor

3.12

discharging efficiency

efficiency under specified discharging conditions, and ratio (%) of discharge accumulated

electrical energy to stored energy

Note 1 to entry: This value is calculated from the internal resistance of a capacitor.

Note 2 to entry: Refer to Formula C.10.

3.13

electric double-layer capacitor

capacitor

device that stores electrical energy using a double layer in an electrochemical cell, and whose

positive and negative electrodes are of the same material

Note 1 to entry: The electrolytic capacitor is not included in capacitor of this document.

3.14

energy efficiency

E

f

ratio (%) of discharge accumulated electrical energy to charge accumulated electrical energy

under specified charging and discharging conditions

3.15

nominal capacitance

C

N

nominal capacitance value (C ) to be used in design and measurement condition setting (F),

N

generally, at the reference temperature

3.15

internal resistance

combined resistance (Ω) of constituent material specific resistance and inside connection

resistance of a capacitor

3.16

maximum power density

P

dm

maximum power density (W/kg or W/l) that can be recovered from a charged capacitor.

Generally, it is calculated by using the internal resistance and the rated voltage

greatest electrical power output of a capacitor per mass (W/kg) or volume (W/l)

3.17

nominal internal resistance

R

N

nominal value of the internal resistance (R ) to be used in design and measurement condition

N

setting (Ω), generally at the ambient temperature

3.18

post-treatment (recovery)

discharging and storage of a capacitor under specified ambient conditions (temperature,

humidity, and pressure) after tests

Note 1 to entry: Generally, post-treatment implies that a capacitor is discharged and stored until its inner

temperature attains thermal equilibrium with the surrounding temperature before its electrical characteristics are

measured.

3.19

pre-conditioning

charging and discharging and storage of a capacitor under specified ambient conditions

(temperature, humidity, and pressure) before testing.

Note 1 to entry: Generally, pre-conditioning implies that a capacitor is discharged and stored until its inner

temperature attains thermal equilibrium with the surrounding temperature, before its electrical characteristics are

measured.

3.20

voltage treatment

voltage application before measurement of a capacitor’s electrical characteristics

– 10 – IEC 62576:2018 RLV © IEC 2018

NOTE Generally, this treatment is applied to a capacitor that has been stored for a long time or to a capacitor

whose history is not clear.

3.20

rated voltage

U

R

maximum DC voltage (V) that may be applied continuously for a certain time under the upper

category temperature to a capacitor so that a capacitor can exhibit specified demand

characteristics

Note 1 to entry: This voltage is the setting voltage in capacitor design.

Note 2 to entry: The endurance test using the rated voltage is described in Annex A.

3.21

ambient temperature

temperature of air in the vicinity of the device under test, in this document (25 ± 2) °C

3.22

stored energy

energy (J) stored in a capacitor

3.23

upper category temperature

highest ambient temperature that at which a capacitor is designed to operate continuously

3.24

voltage maintenance characteristics

voltage maintenance characteristics of a capacitor when its terminals are open after charging

ability of a capacitor to maintain the voltage, with its terminals open, after a specified time

period subsequent to the charging

3.25

voltage maintenance rate

ratio of voltage maintenance

ratio of the voltage at the open-ended terminals to the charge voltage after a specified time

period subsequent to the charging of a capacitor

3.27

power density

electrical power per unit mass (W/kg) or per unit volume (W/l) that can be recovered from a

charged capacitor

3.28

rated power density

specified maximum power density (W/kg or W/l). Generally, it is calculated by using the

nominal internal resistance and the rated voltage

4 Tests and measurement procedures methods

4.1 Capacitance, internal resistance, and maximum power density

4.1.1 Circuit for measurement

The capacitance and the internal resistance shall be measured by using the constant current

and constant voltage charging and the constant current discharging methods. Figure 1 shows

the basic circuit to be used for the measurement.

Power supply

a)

S

I

CC

Cx

b)

U

CV

IEC

Key

I constant-current

CC

U constant-voltage

CV

A DC ammeter

V DC voltage recorder

S changeover switch

Cx capacitor under test

constant current discharger

a) constant current charging

b) constant voltage charging

Figure 1 – Basic circuit for measuring capacitance, internal resistance

and maximum power density

4.1.2 Test equipment

The test equipment shall be capable of constant current charging, constant voltage charging,

constant current discharging, and continuous measurement of the current and the voltage

between the capacitor terminals in time-series as shown in Figure 2. The test equipment shall

be able to set and measure the current and the voltage with the accuracy equal to ±1 % or less, and

to measure the current and voltage with accuracy equal to ±0,1 %.

The power supply shall provide the constant charge current for the capacitor charge with 95 %

efficiency, set the duration of constant voltage charge, and provide a discharge current

corresponding to the specified discharge efficiency. The DC voltage recorder shall be capable

of conducting measurements and recording with a 5 mV resolution and sampling interval of

100 10 ms or less.

– 12 – IEC 62576:2018 RLV © IEC 2018

Magnified figure

U

R

U

U

Time (s)

T

CV

IEC

Key

U rated voltage (V)

R

U calculation start voltage (V)

U calculation end voltage (V)

∆U voltage drop (V)

T constant voltage charging duration (s)

CV

Figure 2 – Voltage–time characteristics between capacitor terminals

in capacitance and internal resistance measurement

4.1.3 Measurement procedure

Measurements shall be carried out in accordance with the following procedures using the test

equipment specified in 4.1.2.

a) Pre-conditioning

Before measurement, the capacitors shall be fully charged and fully discharged, and then

incubated for 2 h to 6 h under the reference ambient temperature, set at 25 °C ± 2 °C, as

specified in 5.2 in IEC 60068-1, or that specified by the related standards.

NOTE 1 The heat equilibrium time, which provides a reference for the soaking time, is described in Annex B.

NOTE 2 Charging and discharging can be repeated if necessary until the capacity and internal resistance are

stabilized.

EXAMPLE

Charge and discharge the sample using the current specified by the manufacturer in the following order:

1) fully discharge;

2) charge up to U ;

R

3) discharge down to 0,5 U ;

R

4) repeat 2) and 3) ten times.

b) Sample setting

Fit the sample capacitors with the test equipment.

c) Test equipment setup

Unless otherwise specified by related standards, the test equipment shall be set up in the

following manner.

1) Set the constant current I for charging. At this current, the capacitors shall be able to

c

charge with 95 % charging efficiency based on their nominal internal resistance R .

N

The current value is calculated by I = U /38R . The constant current value or the

c R N

charging efficiency may be changed according to the agreement between the customer

and the supplier.

Voltage (V)

∆U

∆U

NOTE The general concept for 95 % charging or discharging efficiency is described in Annex C. When the

rated value of internal resistance of a capacitor is uncertain, the current for the measurement can be set

according to the advisable procedures described in Annex D.

2) Set the maximum voltage for constant current charging as the rated voltage U .

R

3) Set the duration of constant voltage charging T to 300 s.

cv

4) Set the constant current discharge value. This value shall allow for a 95 % discharging

efficiency based on the capacitor’s nominal internal resistance R , and is calculated by

N

I = U /40R .

d R N

The constant current value or the discharging efficiency may be changed according to

the agreement between the customer and the supplier.

5) Set the sampling interval to 100 10 ms or less, and set the test-equipment so as to

measure the voltage drop characteristics up to 0,5 U .

R

d) Test

According to the set-up in 4.1.3 c), charge and discharge the sample in the following order,

and measure the voltage between the capacitor terminals as shown in Figure 2:

– constant current charging up to U ;

R

– constant voltage charging at U for 300 s;

R

– constant current discharging down to 0,4 U .

R

4.1.4 Measurement

After the setting as specified above, the voltage-time characteristics between capacitor

terminals as shown in Figure 2 shall be measured.

4.1.4 Calculation method for capacitance

The capacitance C shall be calculated using Formula (1) based on the voltage-time

characteristics between capacitor terminals obtained in 4.1.4.

NOTE This calculation method is called "energy conversion capacitance method".

2W

C = (1)

2 2

(0,9U ) − (0,7U )

R R

where

C is the capacitance (F) of capacitor;

W is the measured discharged energy (J) from calculation start voltage (0,9 U ) to

R

calculation end voltage (0,7 U );

R

U is the rated voltage (V).

R

4.1.5 Calculation method for internal resistance

The internal resistance R shall be calculated using Formula (2) based on the voltage-time

characteristics between capacitor terminals obtained in 4.1.4.

∆U

(2)

R =

I

d

where

R is the internal resistance (Ω) of capacitor;

I is the discharge current (A);

d

ΔU is the voltage drop (V).

– 14 – IEC 62576:2018 RLV © IEC 2018

To obtain ΔU , apply the straight-line approximation to the voltage drop characteristics from

the calculation start voltage (0,9 U ) to the calculation end voltage (0,7 U ) by using the least

R R

squares method. Obtain the intercept (voltage value) of the straight line at the discharge start

time. ΔU is the difference of voltages (V) between the intercept voltage value and the set

value of constant voltage charging.

NOTE This calculation method is called "least squares internal resistance method".

4.1.6 Calculation method for maximum power density

The maximum power density P is calculated by using the internal resistance value

dm

calculated in 4.1.5 and Formula (3).

NOTE This calculation method is called "matched impedance power density method".

0,25U

R

P =

(3)

dm

RM

where

P is the maximum power density of capacitor (W/kg or W/l);

dm

U is the rated voltage (V);

R

R is the calculated internal resistance (Ω);

M is the mass or volume of capacitor (kg or l).

4.2 Voltage maintenance characteristics

4.2.1 Circuit for measurement

Figure 3 shows the basic circuit for measuring the voltage maintenance characteristics.

Power supply

a)

I

CC

S

Cx

b)

U

CV

IEC

Key

I constant-current

CC

U constant-voltage

CV

V V DC voltmeter

1 2

S changeover switch

Cx capacitor under test

a) constant current charging

b) constant voltage charging

Figure 3 – Basic circuit for measuring the voltage maintenance characteristics

4.2.2 Test equipment

The test equipment shall be capable of constant current charging, constant voltage charging,

and continuous measurement of the voltage between the capacitor terminals in time-series as

shown in Figure 4. The power supply shall provide the constant charge current for the

capacitor charge with 95 % efficiency and set the duration of constant voltage charging. The

test equipment shall be able to set and measure the current and the voltage by the accuracy

equal to ±1 % or less.

The DC voltage recorders V1 and V2 shall have a resolution of 5 mV or less for voltage

measurement. The input impedance of the recorder shall be sufficiently high so that

measurement errors are negligible.

U

R

U

end

Time

T T T

cc1 cv1 oc1

IEC

Key

U rated voltage (V)

R

T charging duration with 95 % efficiency (s)

cc1

T duration of constant voltage charging (s)

cv1

T duration of measurement soaking time (h)

oc1

U voltage when T is 72 h (V)

end OC1

Figure 4 – Time characteristics of voltage between capacitor terminals

in voltage maintenance test

4.2.3 Measurement procedures

The measurements shall be carried out in accordance with the following procedures using the

test equipment specified in 4.2.2.

a) Pre-conditioning

Before measurement, the capacitors shall be fully charged and fully discharged, and then

incubated for 2 h to 6 h under the reference ambient temperature, set at 25 °C ± 2 °C, as

specified in 5.2 in IEC 60068-1, or that specified by the related standards.

NOTE 1 The heat equilibrium time, which provides a reference for the soaking time, is described in Annex B.

NOTE 2 Charging and discharging can be repeated if necessary until the capacity and internal resistance are

stabilized.

EXAMPLE

Charge and discharge the sample using the current specified by the manufacturer in the following order:

1) fully discharge;

2) charge up to U ;

R

3) discharge down to 0,5 U ;

R

4) repeat 2) and 3) ten times.

Voltage (V)

– 16 – IEC 62576:2018 RLV © IEC 2018

b) Sample setting

Fit the sample capacitors with the test equipment.

c) Test equipment setup

Unless otherwise specified by related standards, the test equipment shall be set up in the

following manner.

1) Set the constant current value for charging. At this current, the capacitors shall be able

to charge with 95 % charging efficiency based on their nominal internal resistance. The

current value is calculated by I = U /38R .

c R N

The constant current value or the charging efficiency may be changed according to the

agreement between the customer and the supplier.

NOTE The general concept for 95 % charging or discharging efficiency is described in Annex C. When

the rated value of internal resistance of a capacitor is uncertain, the current for the measurement can be

set according to the advisable procedures described in Annex D.

2) Set the maximum voltage for constant current charging to the rated voltage U .

R

3) Set the duration of constant voltage charging T to 300 s.

cv1

4) After specified charging duration, set the capacitor terminals open.

c) Test

1) According to the setup in 4.2.3 c), charge the sample in the following order:

– constant current charging up to U ;

R

– constant voltage charging at U for 300 s.

R

2) Open the capacitor terminals, and after 72 h, measure the voltage between the

capacitor terminals.

4.2.4 Measurement

After the setting as specified above, measure the voltage between capacitor terminals when

T in Figure 4 is 72 h.

OC1

4.2.4 Calculation of voltage maintenance rate

The voltage maintenance rate A is calculated by Formula (4).

U

end

(4)

Α = ×100

U

R

where

A is the voltage maintenance rate (%);

U is the voltage between open capacitor terminals after 72 h (T ) has elapsed;

end OC1

U is the rated voltage (V).

R

4.3 Energy efficiency

4.3.1 Circuit for test

The energy efficiency test shall be conducted by the constant current charging and

discharging. Figure 1 shows the basic circuit required for this test.

4.3.2 Test equipment

The test equipment shall be as specified in 4.1.2.

The test equipment shall be capable of constant current charging, constant voltage charging,

constant current discharging, and continuous measurement of the current and the voltage

between the capacitor terminals in time-series as shown in Figure 5. The test equipment shall

be able to set and measure the current and the voltage by the with an accuracy equal to ±1 %

or less.

The power supply shall provide the constant charge current for the capacitor charge with 95 %

efficiency, set the duration of constant voltage charge, and provide a discharge current

corresponding to the specified discharge efficiency. The DC voltage recorder shall be capable

of conducting measurements and recording with a 5 mV resolution and sampling interval of

100 ms or less.

U

R

Constant current

discharge

0,5U

R

t t t

0 UR 0,5UR

T T T T T

cc11 cv11 cc12 cv12 cc13

Time (s)

IEC

Key

U rated voltage (V)

R

T constant current charging duration (s) up to 0,5U

CC11 R

T constant voltage charging duration (s) up to at 0,5U

CV11 R

T constant current charging duration (s) up to U

CC12 R

T constant voltage charging duration (s) at U

CV12 R

T constant current discharging duration (s) from U to 0,5 U

CC13 R R

Figure 5 – Voltage-time characteristics between capacitor terminals

in charging/discharging efficiency test

4.3.3 Measurement procedures

The measurements shall be carried out in accordance with the following procedures by using

the test equipment specified in 4.3.2.

a) Pre-conditioning

Before measurement, the capacitor shall be fully charged and fully discharged, and then

incubated for 2 h to 6 h under the reference ambient temperature, set at 25 °C ± 2 °C, as

specified in 5.2 in IEC 60068-1, or that specified by the related standards.

NOTE 1 The heat equilibrium time which provides a reference for the soaking time is in Annex B.

NOTE 2 Charging and discharging can be repeated if necessary until the capacity and internal resistance are

stabilized.

Voltage (V)

Current (A)

– 18 – IEC 62576:2018 RLV © IEC 2018

EXAMPLE

Charge and discharge the sample using the current specified by the manufacturer in the following order:

1) fully discharge;

2) charge up to U ;

R

3) discharge down to 0,5 U ;

R

4) repeat 2) and 3) ten times.

b) Sample setting

Fit the sample capacitors with the test equipment.

c) Test equipment setup

Unless otherwise specified by related standards, the test equipment shall be set up as

follows.

and from 0,5 U to U . At this

1) Set the constant current for charging from 0 V to 0,5 U

R R R

current, the capacitors shall be able to charge with 95 % charging efficiency based on

their nominal internal resistance R . The current value is calculated by I =U /38R .

N c R N

The constant current value or the charging efficiency may be changed according to the

agreement between the customer and the supplier.

NOTE The general concept for 95 % charging or discharging efficiency is described in Annex C. When

the rated value of internal resistance of a capacitor is uncertain, the current for the measurement can be

set according to the advisable procedures described in Annex D.

2) Set the duration of constant voltage charging T at 0,5 U to 300 s, and T at U

CV11 R cv12 R

to 10 s.

3) Set the constant current discharge value. This value shall allow for a 95 % discharging

efficiency based on the capacitor’s nominal internal resistance R and is calculated by

N

I = U /40R .

d R N

The constant current value or the discharging efficiency may be changed according to

the agreement between the customer and the supplier.

NOTE The general concept for 95 % charging or discharging efficiency is described in Annex C. When

the rated value of internal resistance of a capacitor is uncertain, the current for the measurement can be

set according to the advisable procedures described in Annex D.

4) Discharging can be deemed complete when the voltage between the capacitor

terminals reaches 0,5 U .

R

d) Test

1) According to the set-up in 4.3.3 c), charge and discharge the sample in the following

order:

– constant current charging up to 0,5 U ;

R

– constant voltage charging at 0,5 U for 300 s;

R

– constant current charging from 0,5 U up to U ;

R R

– constant voltage charging at U for 10 s;

R

– constant current discharging down to 0,4 U .

R

2) Obtain the charge accumulated electrical energy during T and T and the

CC12 CV12

discharge accumulated electrical energy during T .

CC13

4.3.4 Measurement

After setting up the test equipment as mentioned above, test the following: constant current

charging up to 0,5 U , constant voltage charging at 0,5 U , constant current charging up to

R R

U , constant voltage charging at U , and constant current discharging down to 0,5 U in that

R R R

order. Obtain the charge accumulated electrical energy from 0,5 U (during T and T )

R CC12 CV12

and the discharge accumulated electrical energy during discharging T .

CC13

4.3.4 Calculation of energy efficiency

The energy efficiency E can be obtained by Formula (5) based on the voltage-time and

f

current-time characteristics between 0,5 U to U .

R R

W

d

E = ×100 (5)

f

W

c

where

E is the energy efficiency (%);

f

W is the discharged electrical energy (J) during T period;

d CC13

W is the charged electrical energy (J) during T plus T period.

c cc12 cv12

W can be obtained by Formula (6).

d

t

0,5

U

R

W = I U(t)dt (6)

d d

∫

t

W can be obtained by Formula (7).

c

t

U

R

W = I U(t)dt (7)

c c

∫

t

– 20 – IEC 62576:2018 RLV © IEC 2018

Annex A

(informative)

Endurance test: continuous application of rated voltage

at high temperature

A.1 General

Annex A describes the endurance test for continuous application of rated voltage at high

temperature that is a factor to define

...

IEC 62576 ®

Edition 2.0 2018-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric double-layer capacitors for use in hybrid electric vehicles –

Test methods for electrical characteristics

Condensateurs électriques à double couche pour véhicules électriques hybrides –

Méthodes d'essai des caractéristiques électriques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 62576 ®

Edition 2.0 2018-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric double-layer capacitors for use in hybrid electric vehicles –

Test methods for electrical characteristics

Condensateurs électriques à double couche pour véhicules électriques hybrides –

Méthodes d'essai des caractéristiques électriques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.060.99; 43.120 ISBN 978-2-8322-5341-0

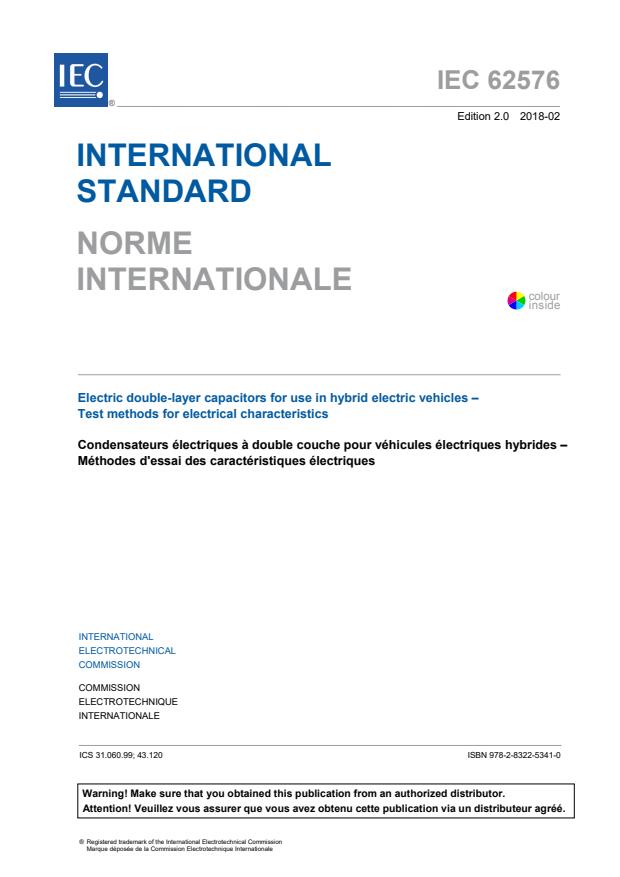

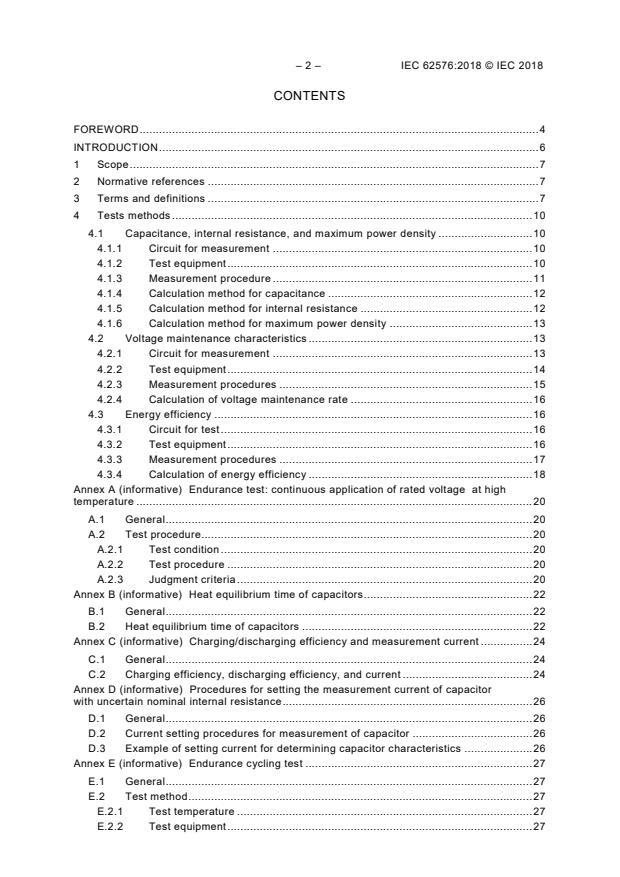

– 2 – IEC 62576:2018 © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Tests methods . 10

4.1 Capacitance, internal resistance, and maximum power density . 10

4.1.1 Circuit for measurement . 10

4.1.2 Test equipment . 10

4.1.3 Measurement procedure . 11

4.1.4 Calculation method for capacitance . 12

4.1.5 Calculation method for internal resistance . 12

4.1.6 Calculation method for maximum power density . 13

4.2 Voltage maintenance characteristics . 13

4.2.1 Circuit for measurement . 13

4.2.2 Test equipment . 14

4.2.3 Measurement procedures . 15

4.2.4 Calculation of voltage maintenance rate . 16

4.3 Energy efficiency . 16

4.3.1 Circuit for test . 16

4.3.2 Test equipment . 16

4.3.3 Measurement procedures . 17

4.3.4 Calculation of energy efficiency . 18

Annex A (informative) Endurance test: continuous application of rated voltage at high

temperature . 20

A.1 General . 20

A.2 Test procedure . 20

A.2.1 Test condition . 20

A.2.2 Test procedure . 20

A.2.3 Judgment criteria . 20

Annex B (informative) Heat equilibrium time of capacitors . 22

B.1 General . 22

B.2 Heat equilibrium time of capacitors . 22

Annex C (informative) Charging/discharging efficiency and measurement current . 24

C.1 General . 24

C.2 Charging efficiency, discharging efficiency, and current . 24

Annex D (informative) Procedures for setting the measurement current of capacitor

with uncertain nominal internal resistance . 26

D.1 General . 26

D.2 Current setting procedures for measurement of capacitor . 26

D.3 Example of setting current for determining capacitor characteristics . 26

Annex E (informative) Endurance cycling test . 27

E.1 General . 27

E.2 Test method . 27

E.2.1 Test temperature . 27

E.2.2 Test equipment . 27

E.2.3 Preconditioning . 27

E.2.4 Initial measurements . 27

E.2.5 Test steps . 27

E.2.6 Test . 28

E.2.7 End of test criteria . 28

E.2.8 Post treatment . 29

E.2.9 Final measurement . 29

E.2.10 Acceptance criteria . 29

Bibliography . 30

Figure 1 – Basic circuit for measuring capacitance, internal resistance and maximum

power density . 10

Figure 2 – Voltage–time characteristics between capacitor terminals in capacitance

and internal resistance measurement . 11

Figure 3 – Basic circuit for measuring the voltage maintenance characteristics . 14

Figure 4 – Time characteristics of voltage between capacitor terminals in voltage

maintenance test . 15

Figure 5 – Voltage-time characteristics between capacitor terminals in

charging/discharging efficiency test . 17

Figure B.1 – Heat equilibrium times of capacitors (from 85 °C to 25 °C) . 22

Figure B.2 – Heat equilibrium times of capacitors (from –40 °C to 25 °C) . 23

Figure B.3 – Temperature changes of capacitors' central portions . 23

Figure E.1 – Endurance cycling test steps . 28

Table D.1 – Example of setting current for measurement of capacitor . 26

– 4 – IEC 62576:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC DOUBLE-LAYER CAPACITORS FOR USE IN

HYBRID ELECTRIC VEHICLES – TEST METHODS

FOR ELECTRICAL CHARACTERISTICS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and

non-governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates

closely with the International Organization for Standardization (ISO) in accordance with conditions determined

by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62576 has been prepared by IEC technical committee 69: Electric

road vehicles and electric industrial trucks.

This second edition cancels and replaces the first edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) information on applicability of this document has been added in Clause 1;

b) the definitions of some terms in Clause 3 have been improved;

c) the description of test procedures in Clause 4 has been clarified;

d) information on endurance cycling test has been added (Annex E).

The text of this International Standard is based on the following documents:

CDV Report on voting

69/486/CDV 69/539/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62576:2018 © IEC 2018

INTRODUCTION

The electric double-layer capacitor (capacitor) is used as an energy storage system for

vehicles. Capacitor-installed electric vehicles are commercialized with an eye to improving

fuel economy by recovering regenerative energy, and by peak power assistance during

acceleration, etc. Although standards for capacitors already exists (IEC 62391 series), those

for electric vehicles involve patterns of use, usage environment, and values of current that are

quite different from those assumed in the existing standards. Standard evaluation and test

methods will be useful for both auto manufacturers and capacitor suppliers to speed up the

development and lower the costs of such capacitors. With these points in mind, this document

aims to provide basic and minimum specifications in terms of the methods for testing

electrical characteristics, and to create an environment that supports the expanding market of

electric vehicles and large capacity capacitors. Additional practical test items to be

standardized should be reconsidered after technology and market stabilization of capacitors

for electric vehicles. Regarding endurance, which is important in practical use, just a basic

concept is set forth in the informative annexes.

ELECTRIC DOUBLE-LAYER CAPACITORS FOR USE IN

HYBRID ELECTRIC VEHICLES – TEST METHODS

FOR ELECTRICAL CHARACTERISTICS

1 Scope

This document describes the methods for testing electrical characteristics of electric

double-layer capacitor cells (hereinafter referred to as "capacitor") used for peak power

assistance in hybrid electric vehicles.

All the tests in this document are type tests.

This document can also be applicable to the capacitor used in idling reduction systems (start

and-stop systems) for the vehicles.

This document can also be applicable to the capacitor modules consisting of more than one

cell.

NOTE Annex E provides information on endurance cycling test.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

ambient temperature

temperature of the air, in the immediate vicinity of a capacitor

3.2

applied voltage

voltage (V) applied between the terminals of a capacitor

3.3

calculation end voltage

voltage (V) at a selected end point for calculating the characteristics including capacitance

under a state of voltage decrease during discharge

3.4

calculation start voltage

voltage (V) at a selected start point for calculating the characteristics including capacitance

under a state of voltage decrease during discharge

– 8 – IEC 62576:2018 © IEC 2018

3.5

capacitance

ability of a capacitor to store electrical charge (F)

3.6

charge accumulated electrical energy

amount of charged energy (J) accumulated from the beginning to the end of charging

3.7

charge current

I

c

current (A) required to charge a capacitor

3.8

charging efficiency

efficiency under specified charging conditions, and ratio (%) of stored energy to charge

accumulated electrical energy

Note 1 to entry: This value is calculated from the internal resistance of a capacitor.

Note 2 to entry: Refer to Formula C.8.

3.9

constant voltage charging

charging during which the voltage is maintained at a constant value regardless of charge

current or temperature

3.10

discharge accumulated electrical energy

amount of discharged energy (J) accumulated from the beginning to the end of discharging

3.11

discharge current

I

d

current (A) required to discharge a capacitor

3.12

discharging efficiency

efficiency under specified discharging conditions, and ratio (%) of discharge accumulated

electrical energy to stored energy

Note 1 to entry: This value is calculated from the internal resistance of a capacitor.

Note 2 to entry: Refer to Formula C.10.

3.13

electric double-layer capacitor

capacitor

device that stores electrical energy using a double layer in an electrochemical cell, and whose

positive and negative electrodes are of the same material

Note 1 to entry: The electrolytic capacitor is not included in capacitor of this document.

3.14

energy efficiency

E

f

ratio (%) of discharge accumulated electrical energy to charge accumulated electrical energy

under specified charging and discharging conditions

3.15

internal resistance

combined resistance (Ω) of constituent material specific resistance and inside connection

resistance of a capacitor

3.16

maximum power density

P

dm

greatest electrical power output of a capacitor per mass (W/kg) or volume (W/l)

3.17

nominal internal resistance

R

N

nominal value of the internal resistance (R ) to be used in design and measurement condition

N

setting (Ω), generally at the ambient temperature

3.18

post-treatment

discharging and storage of a capacitor under specified ambient conditions (temperature,

humidity, and pressure) after tests

Note 1 to entry: Generally, post-treatment implies that a capacitor is discharged and stored until its inner

temperature attains thermal equilibrium with the surrounding temperature before its electrical characteristics are

measured.

3.19

pre-conditioning

charging and discharging and storage of a capacitor under specified ambient conditions

(temperature, humidity, and pressure) before testing.

Note 1 to entry: Generally, pre-conditioning implies that a capacitor is discharged and stored until its inner

temperature attains thermal equilibrium with the surrounding temperature, before its electrical characteristics are

measured.

3.20

rated voltage

U

R

maximum DC voltage (V) that may be applied continuously for a certain time under the upper

category temperature to a capacitor so that a capacitor can exhibit specified demand

characteristics

Note 1 to entry: This voltage is the setting voltage in capacitor design.

Note 2 to entry: The endurance test using the rated voltage is described in Annex A.

3.21

ambient temperature

temperature of air in the vicinity of the device under test, in this document (25 ± 2) °C

3.22

stored energy

energy (J) stored in a capacitor

3.23

upper category temperature

highest ambient temperature at which a capacitor is designed to operate continuously

3.24

voltage maintenance characteristics

ability of a capacitor to maintain the voltage, with its terminals open, after a specified time

period subsequent to the charging

– 10 – IEC 62576:2018 © IEC 2018

3.25

voltage maintenance rate

ratio of voltage maintenance

ratio of the voltage at the open-ended terminals to the charge voltage after a specified time

period subsequent to the charging of a capacitor

4 Tests methods

4.1 Capacitance, internal resistance, and maximum power density

4.1.1 Circuit for measurement

The capacitance and the internal resistance shall be measured by using the constant current

and constant voltage charging and the constant current discharging. Figure 1 shows the basic

circuit to be used for the measurement.

Power supply

a)

S

I

CC

Cx

b)

U

CV

IEC

Key

I constant-current

CC

U constant-voltage

CV

A DC ammeter

V DC voltage recorder

S changeover switch

Cx capacitor under test

constant current discharger

a) constant current charging

b) constant voltage charging

Figure 1 – Basic circuit for measuring capacitance, internal resistance

and maximum power density

4.1.2 Test equipment

The test equipment shall be capable of constant current charging, constant voltage charging,

constant current discharging, and continuous measurement of the current and the voltage

between the capacitor terminals in time-series as shown in Figure 2. The test equipment shall

be able to set the current and the voltage with the accuracy equal to ±1 % or less, and to measure

the current and voltage with accuracy equal to ±0,1 %.

The power supply shall provide the constant charge current for the capacitor charge with 95 %

efficiency, set the duration of constant voltage charge, and provide a discharge current

corresponding to the specified discharge efficiency. The DC voltage recorder shall be capable

of conducting measurements and recording with a sampling interval of 10 ms or less.

Magnified figure

U

R

U

U

Time (s)

T

CV

IEC

Key

U rated voltage (V)

R

U calculation start voltage (V)

U calculation end voltage (V)

∆U voltage drop (V)

T constant voltage charging duration (s)

CV

Figure 2 – Voltage–time characteristics between capacitor terminals

in capacitance and internal resistance measurement

4.1.3 Measurement procedure

Measurements shall be carried out in accordance with the following procedures using the test

equipment specified in 4.1.2.

a) Pre-conditioning

Before measurement, the capacitors shall be fully charged and fully discharged, and then

incubated for 2 h to 6 h under the ambient temperature or that specified by the related

standards.

NOTE 1 The heat equilibrium time, which provides a reference for the soaking time, is described in Annex B.

NOTE 2 Charging and discharging can be repeated if necessary until the capacity and internal resistance are

stabilized.

EXAMPLE

Charge and discharge the sample using the current specified by the manufacturer in the following order:

1) fully discharge;

2) charge up to U ;

R

3) discharge down to 0,5 U ;

R

4) repeat 2) and 3) ten times.

b) Sample setting

Fit the sample capacitors with the test equipment.

c) Test equipment setup

Unless otherwise specified by related standards, the test equipment shall be set up in the

following manner.

1) Set the constant current I for charging. At this current, the capacitors shall be able to

c

charge with 95 % charging efficiency based on their nominal internal resistance R .

N

The current value is calculated by I = U /38R . The constant current value or the

c R N

Voltage (V)

∆U

∆U

– 12 – IEC 62576:2018 © IEC 2018

charging efficiency may be changed according to the agreement between the customer

and the supplier.

NOTE The general concept for 95 % charging or discharging efficiency is described in Annex C. When the

rated value of internal resistance of a capacitor is uncertain, the current for the measurement can be set

according to the advisable procedures described in Annex D.

2) Set the maximum voltage for constant current charging as the rated voltage U .

R

3) Set the duration of constant voltage charging T to 300 s.

cv

4) Set the constant current discharge value. This value shall allow for a 95 % discharging

efficiency based on the capacitor’s nominal internal resistance R , and is calculated by

N

I = U /40R .

d R N

The constant current value or the discharging efficiency may be changed according to

the agreement between the customer and the supplier.

5) Set the sampling interval to 10 ms or less, and set the test-equipment so as to

measure the voltage drop characteristics up to 0,5 U .

R

d) Test

According to the set-up in 4.1.3 c), charge and discharge the sample in the following order,

and measure the voltage between the capacitor terminals as shown in Figure 2:

– constant current charging up to U ;

R

– constant voltage charging at U for 300 s;

R

– constant current discharging down to 0,4 U .

R

4.1.4 Calculation method for capacitance

The capacitance C shall be calculated using Formula (1) based on the voltage-time

characteristics between capacitor terminals obtained in 4.1.4.

NOTE This calculation method is called "energy conversion capacitance method".

2W

(1)

C=

2 2

(0,9U ) − (0,7U )

R R

where

C is the capacitance (F) of capacitor;

W is the measured discharged energy (J) from calculation start voltage (0,9 U ) to

R

calculation end voltage (0,7 U );

R

U is the rated voltage (V).

R

4.1.5 Calculation method for internal resistance