IEC TR 62602:2009

(Main)Conductors of insulated cables - Data for AWG and KCMIL sizes

Conductors of insulated cables - Data for AWG and KCMIL sizes

IEC/TR 62602:2009, which is a technical report, specifies the nominal cross-sectional areas, in the range 20 AWG to 2 000 kcmil (0,52 mm2 to 1 010 mm2), for conductors in electric power cables and cords for a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid and stranded copper, aluminium and aluminium alloy conductors in cables for fixedinstallations and flexible copper conductors. This technical report is not intended to apply to conductors designed for use in cables intended for telecommunication or data transmission, winding wires or similar products. Unless indicated to the contrary in a particular clause, this technical report relates to conductors in finished cables and not to conductors made or supplied for inclusion into a cable. The annexes give supplementary information covering measurement of resistance (Annex A), temperature correction factors for resistance measurement (Annex B) and dimensional limits of circular conductors (Annex C).

Âmes des câbles isolés - Informations relatives aux sections exprimées en AWG et KCMIL

La CEI/TR 62602:2009, qui est un rapport technique, spécifie les sections nominales, dans la plage de 20 AWG à 2 000 kcmil (0,52 mm2 à 1 010 mm2) des âmes des conducteurs et des câbles électriques de puissance, dans une large gamme de spécifications. Des exigences sur le nombre et le diamètre des brins et les valeurs de résistance sont également incluses. Les âmes concernées sont les âmes massives et câblées, en cuivre, en aluminium et en alliage d'aluminium, destinées aux câbles pour installations fixes et les âmes en cuivre pour conducteurs souples. Le présent rapport technique n'a pas vocation à s'appliquer aux âmes destinées aux câbles de télécommunication ou de transmission de données, aux fils de bobinage ou à des produits similaires. Sauf indication contraire dans un article particulier, ce rapport technique porte sur les âmes des câbles terminés, et non sur les âmes seules ou fournies pour la fabrication d'un câble. Des annexes donnent des informations complémentaires sur la mesure de la résistance (Annexe A), les facteurs de correction de température à utiliser dans les mesures de résistance (Annexe B) et les limites dimensionnelles des âmes circulaires (Annexe C).

General Information

- Status

- Published

- Publication Date

- 28-Sep-2009

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 19 - TC 20/WG 19

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Sep-2009

- Completion Date

- 15-Jan-2010

Overview

IEC TR 62602:2009 is a technical report published by the International Electrotechnical Commission (IEC) that provides detailed data on conductors of insulated cables sized according to the American Wire Gauge (AWG) and kcmil systems. Covering nominal cross-sectional areas ranging from 20 AWG to 2000 kcmil (approximately 0.52 mm² to 1010 mm²), this report specifies conductor dimensions, resistance values, and construction requirements for solid and stranded conductors made from copper, aluminium, and aluminium alloys. It focuses on power cables and cords used predominantly in fixed installations and flexible cable applications.

This report complements IEC 60228, which uses metric sizing, by addressing the specific needs of regions where AWG and kcmil sizing are standard, such as North America. It aims to support harmonization toward a unified international conductor sizing system.

Key Topics

Conductor Size Range and Classification

The report covers conductor sizes from 20 AWG to 2000 kcmil and classifies conductors into four classes based on construction and flexibility:- Class 1: Solid conductors for fixed installations

- Class 2: Stranded conductors for fixed installations

- Class 5: Flexible copper conductors

- Class 6: Highly flexible copper conductors

Materials and Mechanical Properties

Conductors include plain or metal-coated annealed copper and aluminium or aluminium alloy, with specified tensile strength ranges for solid and stranded aluminium conductors, ensuring mechanical reliability in different applications.Electrical Resistance and Measurement

The technical report provides maximum resistance values for conductors, emphasizing the resistance of single-core cables while offering correction factors for multi-core configurations. Annexes detail precise resistance measurement methods and temperature correction formulas to ensure accurate assessments under varying conditions.Dimensional Specifications

Dimensional limits and tolerances for circular conductors-both solid and stranded-are specified, allowing manufacturers and users to maintain consistency and compatibility in cable production and application.Exclusions and Scope Limitations

The standard does not apply to conductors intended for telecommunications, data transmission cables, winding wires, or other specialized wire products. It also primarily addresses conductors as finished within cables rather than as standalone components for cable assembly.

Applications

IEC TR 62602:2009 is essential for stakeholders involved in:

Power Cable Manufacturing

Guiding manufacturers on conductor dimensions and resistance to meet regional sizing standards (AWG/kcmil), enabling consistent electrical and mechanical performance in power distribution and industrial cables.Cable Design and Engineering

Providing electrical engineers and designers with reliable reference data for conductor resistance values and cross-sectional properties, essential for calculating current carrying capacity, voltage drop, and thermal performance.Quality Assurance and Testing

Supplying test methods and temperature correction factors for measuring conductor resistance, supporting accurate quality control and compliance verification across different conductor types and sizes.International Harmonization Efforts

Serving as a foundational document in the IEC TC 20 committee’s three-stage plan to harmonize conductor sizes globally, ultimately aiming for a combined standard to facilitate international trade and equipment interoperability.

Related Standards

IEC 60228: Conductors of Insulated Cables

The principal IEC standard that defines conductor cross-sectional areas and performance requirements using metric-based sizes. IEC TR 62602 complements this by integrating AWG and kcmil data to bridge regional differences.National Electrical Codes and Regulations

Many countries, especially in North America, mandate the use of AWG/kcmil conductor sizes in electrical installation codes, making IEC TR 62602 a vital reference in aligning international standards with these legal frameworks.ISO/IEC Directives, Part 2

The document adheres to international procedures for drafting standards and reports, ensuring alignment with globally recognized standardization processes.

By adhering to IEC TR 62602:2009, manufacturers, engineers, and regulators can ensure consistent conductor sizing, reliable electrical performance, and smooth transition toward globally harmonized cable standards. This technical report fills a vital role in international standardization of power cable conductors sized by AWG and kcmil systems.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 62602:2009 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Conductors of insulated cables - Data for AWG and KCMIL sizes". This standard covers: IEC/TR 62602:2009, which is a technical report, specifies the nominal cross-sectional areas, in the range 20 AWG to 2 000 kcmil (0,52 mm2 to 1 010 mm2), for conductors in electric power cables and cords for a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid and stranded copper, aluminium and aluminium alloy conductors in cables for fixedinstallations and flexible copper conductors. This technical report is not intended to apply to conductors designed for use in cables intended for telecommunication or data transmission, winding wires or similar products. Unless indicated to the contrary in a particular clause, this technical report relates to conductors in finished cables and not to conductors made or supplied for inclusion into a cable. The annexes give supplementary information covering measurement of resistance (Annex A), temperature correction factors for resistance measurement (Annex B) and dimensional limits of circular conductors (Annex C).

IEC/TR 62602:2009, which is a technical report, specifies the nominal cross-sectional areas, in the range 20 AWG to 2 000 kcmil (0,52 mm2 to 1 010 mm2), for conductors in electric power cables and cords for a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid and stranded copper, aluminium and aluminium alloy conductors in cables for fixedinstallations and flexible copper conductors. This technical report is not intended to apply to conductors designed for use in cables intended for telecommunication or data transmission, winding wires or similar products. Unless indicated to the contrary in a particular clause, this technical report relates to conductors in finished cables and not to conductors made or supplied for inclusion into a cable. The annexes give supplementary information covering measurement of resistance (Annex A), temperature correction factors for resistance measurement (Annex B) and dimensional limits of circular conductors (Annex C).

IEC TR 62602:2009 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables; 31.200 - Integrated circuits. Microelectronics. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62602:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TR 62602 ®

Edition 1.0 2009-09

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Conductors of insulated cables – Data for AWG and KCMIL sizes

Âmes des câbles isolés – Informations relatives aux sections exprimées en AWG

et KCMIL

IEC/TR 62602:2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TR 62602 ®

Edition 1.0 2009-09

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Conductors of insulated cables – Data for AWG and KCMIL sizes

Âmes des câbles isolés – Informations relatives aux sections exprimées en

AWG et KCMIL

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

R

CODE PRIX

ICS 29.060.20 ISBN 978-2-88910-771-1

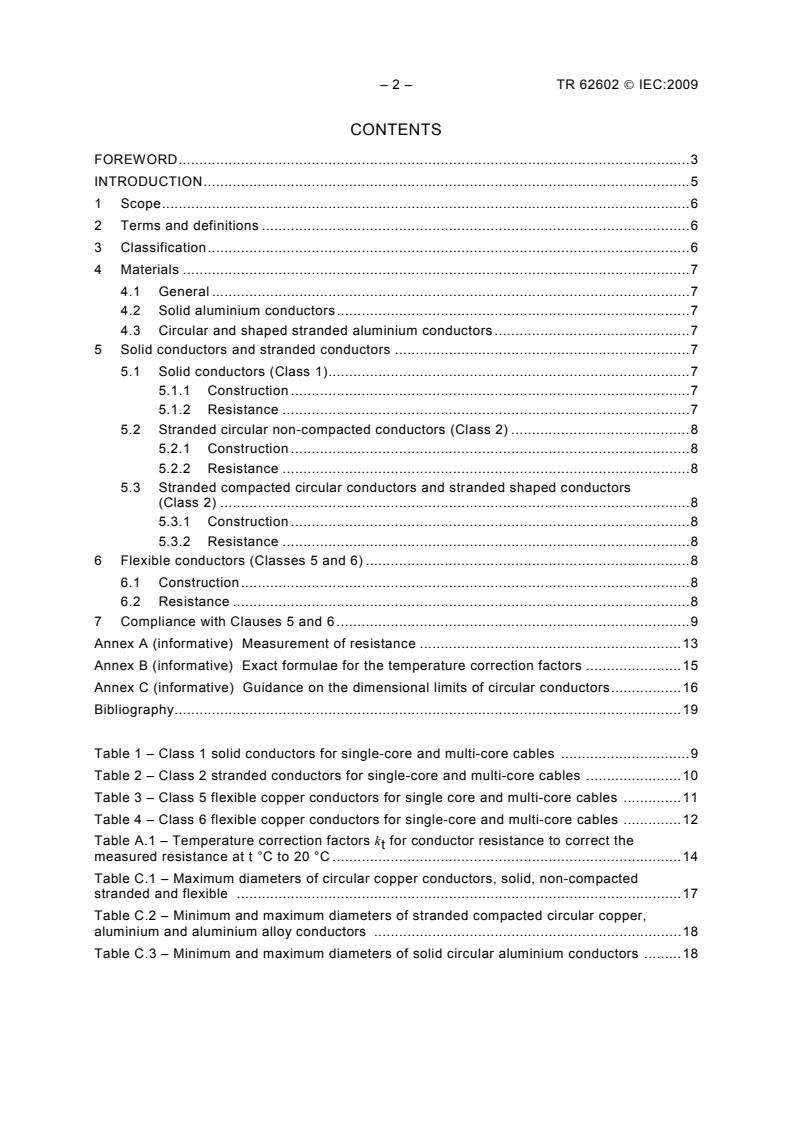

– 2 – TR 62602 © IEC:2009

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Terms and definitions .6

3 Classification.6

4 Materials .7

4.1 General .7

4.2 Solid aluminium conductors.7

4.3 Circular and shaped stranded aluminium conductors .7

5 Solid conductors and stranded conductors .7

5.1 Solid conductors (Class 1).7

5.1.1 Construction .7

5.1.2 Resistance .7

5.2 Stranded circular non-compacted conductors (Class 2) .8

5.2.1 Construction .8

5.2.2 Resistance .8

5.3 Stranded compacted circular conductors and stranded shaped conductors

(Class 2) .8

5.3.1 Construction .8

5.3.2 Resistance .8

6 Flexible conductors (Classes 5 and 6) .8

6.1 Construction.8

6.2 Resistance .8

7 Compliance with Clauses 5 and 6 .9

Annex A (informative) Measurement of resistance .13

Annex B (informative) Exact formulae for the temperature correction factors .15

Annex C (informative) Guidance on the dimensional limits of circular conductors.16

Bibliography.19

Table 1 – Class 1 solid conductors for single-core and multi-core cables .9

Table 2 – Class 2 stranded conductors for single-core and multi-core cables .10

Table 3 – Class 5 flexible copper conductors for single core and multi-core cables .11

Table 4 – Class 6 flexible copper conductors for single-core and multi-core cables .12

Table A.1 – Temperature correction factors k for conductor resistance to correct the

t

measured resistance at t °C to 20 °C .14

Table C.1 – Maximum diameters of circular copper conductors, solid, non-compacted

stranded and flexible .17

Table C.2 – Minimum and maximum diameters of stranded compacted circular copper,

aluminium and aluminium alloy conductors .18

Table C.3 – Minimum and maximum diameters of solid circular aluminium conductors .18

TR 62602 © IEC:2009 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONDUCTORS OF INSULATED CABLES –

DATA FOR AWG AND KCMIL SIZES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC/TR 62602, which is a technical report, has been prepared by IEC technical committee 20:

Electric cables.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

20/1048/DTR 20/1061/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – TR 62602 © IEC:2009

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

TR 62602 © IEC:2009 – 5 –

INTRODUCTION

Conductors described in IEC 60228 [1] are specified in metric sizes. North America and

certain other regions at present use conductor sizes and characteristics according to the

American Wire Gauge (AWG) system, and kcmil for larger sizes. The use of these sizes is

currently prescribed across North America and elsewhere for installations by sub-national

regulations. IEC TC 20 cable product standards do not prescribe cables with AWG/kcmil

conductors.

IEC TC 20 recognizes the need to produce a single, harmonized standard for conductors that

is truly international. Harmonization, in this respect, is understood as the merging of AWG-

based and metric-based sizes to produce one rationalized range of conductor sizes for power

cables. TC 20 also recognizes that the development of such a harmonized standard is a long-

term project.

A three-stage approach, which will culminate in a single International Standard for

conductors, has been agreed.

Stage one of the approach is to produce a technical report that defines the range of

AWG/kcmil sizes that are to be considered in the harmonization process.

Stage two of the process is to develop this technical report by starting the rationalization

process. The test methods and requirements in this technical report are to be aligned with

those in IEC 60228.

The third and final stage will be to produce a harmonized standard, based on IEC 60228 and

the work of the first two stages, with a single, rationalized range of conductor sizes. The

present expectation is that the third stage will not be achieved before 2020.

This technical report provides resistance and dimensional details for AWG and kcmil sizes as

well as giving approximate equivalent metric nominal cross-sectional areas.

The tabulated values of resistance given in this technical report are for single-core cables.

Factors are given to determine the maximum resistance for multi-core cables. The alignment

of single-core and multi-core cable conductor resistance is to be considered in stage two.

—————————

Figures in square brackets refer to the bibliography.

– 6 – TR 62602 © IEC:2009

CONDUCTORS OF INSULATED CABLES –

DATA FOR AWG AND KCMIL SIZES

1 Scope

IEC/TR 62602, which is a technical report, specifies the nominal cross-sectional areas, in the

2 2

range 20 AWG to 2 000 kcmil (0,52 mm to 1 010 mm ), for conductors in electric power

cables and cords for a wide range of types. Requirements for numbers and sizes of wires and

resistance values are also included. These conductors include solid and stranded copper,

aluminium and aluminium alloy conductors in cables for fixed installations and flexible copper

conductors.

This technical report is not intended to apply to conductors designed for use in cables

intended for telecommunication or data transmission, winding wires or similar products.

Unless indicated to the contrary in a particular clause, this technical report relates to

conductors in finished cables and not to conductors made or supplied for inclusion into a

cable.

The annexes give supplementary information covering measurement of resistance (Annex A),

temperature correction factors for resistance measurement (Annex B) and dimensional limits

of circular conductors (Annex C).

2 Terms and definitions

For the purposes of this document, the following definitions apply.

2.1

metal-coated

coated with a thin layer of suitable metal, such as tin or tin alloy

2.2

nominal cross-sectional area

value that identifies a particular size of conductor but is not subject to direct measurement

NOTE Each particular size of conductor in this technical report is required to meet a maximum resistance value.

3 Classification

The conductors have been divided into four classes, 1, 2, 5 and 6. Those in Classes 1 and 2

are intended for use in cables for fixed installations. Classes 5 and 6 are intended for use in

flexible cables and cords but may also be used for fixed installations:

– Class 1: solid conductors;

– Class 2: stranded conductors;

– Class 5: flexible conductors;

– Class 6: flexible conductors which are more flexible than Class 5.

TR 62602 © IEC:2009 – 7 –

4 Materials

4.1 General

The conductors consist of one of the following:

• plain or metal-coated annealed copper;

• aluminium or aluminium alloy.

4.2 Solid aluminium conductors

Circular and shaped solid aluminium conductors are made from aluminium such that the

tensile strength of the completed conductor is within the following limits:

Nominal cross-sectional area Tensile strength

2 2

mm N/mm

≤13 110 to 165

21 and 34 60 to 130

42 60 to 110

54 and above 60 to 90

NOTE The values given above are not applicable to aluminium alloy conductors.

4.3 Circular and shaped stranded aluminium conductors

Stranded aluminium conductors are made from aluminium such that the tensile strength of the

individual wires is within the following limits:

Nominal cross-sectional area Tensile strength

2 2

mm N/mm

Up to 200

≤13

21 and above 125 to 205

NOTE 1 The values given above are not applicable to aluminium alloy conductors.

NOTE 2 This data can only be checked on wires taken before stranding and not on wires taken from a stranded

conductor.

5 Solid conductors and stranded conductors

5.1 Solid conductors (Class 1)

5.1.1 Construction

a) Solid conductors (Class 1) consist of one of the materials specified in Clause 4.

b) Solid copper conductors are of circular cross-section.

NOTE Solid copper conductors having nominal cross-sectional areas of 21 mm and above are for particular

types of cable, e.g. mineral insulated, and not for general purposes.

2 2

c) Solid aluminium and solid aluminium alloy conductors of sizes 3,3 mm to 34 mm are of

circular cross-section. Larger sizes are of circular cross-section for single-core cables and

may be of either circular or shaped cross-section for multi-core cables.

5.1.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 7,

does not exceed the appropriate maximum value given in Table 1.

– 8 – TR 62602 © IEC:2009

NOTE For solid aluminium alloy conductors, having the same nominal cross-sectional area as an aluminium

conductor, the resistance value given in Table 1 should be multiplied by a factor of 1,162, unless otherwise agreed

between the manufacturer and the purchaser.

5.2 Stranded circular non-compacted conductors (Class 2)

5.2.1 Construction

a) Stranded circular non-compacted conductors (Class 2) consist of one of the materials

specified in Clause 4.

b) The wires in each conductor all have the same nominal diameter.

c) The number of wires in each conductor is not less than the appropriate minimum number

given in Table 2.

5.2.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 7,

does not exceed the appropriate maximum value given in Table 2.

5.3 Stranded compacted circular conductors and stranded shaped conductors

(Class 2)

5.3.1 Construction

a) Stranded compacted circular conductors and stranded shaped conductors (Class 2)

consist of one of the materials specified in Clause 4. Stranded shaped copper, aluminium

or aluminium alloy conductors have a nominal cross-sectional area of not less than

67 mm .

b) The ratio of the diameters of two different wires in the same conductor does not exceed 2.

c) The number of wires in each conductor is not less than the appropriate minimum number

given in Table 2.

NOTE This requirement applies to conductors made with wires of circular cross-section before compaction and

not to conductors made with pre-shaped wires.

5.3.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 7,

does not exceed the appropriate value given in Table 2.

6 Flexible conductors (Classes 5 and 6)

6.1 Construction

a) Flexible conductors (Classes 5 and 6) consist of plain or metal-coated annealed copper.

b) The wires in each conductor have the same nominal diameter.

c) The diameter of the wires in each conductor does not exceed the appropriate maximum

value given in Tables 3 or 4.

6.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 7,

does not exceed the appropriate maximum value given in Tables 3 or 4.

TR 62602 © IEC:2009 – 9 –

7 Compliance with Clauses 5 and 6

Compliance with the requirements of 5.1.1, 5.2.1, 5.3.1 and 6.1 is checked on the completed

cable by inspection and measurement, where practicable.

Compliance with the requirements for resistance given in 5.1.2, 5.2.2, 5.3.2 and 6.2 is

checked by measurement in accordance with Annex A and corrected for temperature by the

factors in Table A.1.

Table 1 – Class 1 solid conductors for single-core and multi-core cables

1 2 3 4 5

a

Maximum resistance of single-core conductors at 20 °C

Circular, annealed copper conductors Aluminium and

Nominal cross-

Size

aluminium alloy

sectional area

Plain Metal-coated

conductors, circular

d

or shaped

mm AWG Ω/km Ω/km Ω/km

0,52 20 33,9 35,2 -

0,82 18 21,4 22,2 -

1,3 16 13,5 14,0 -

2,1 14 8,45 8,78 -

b

3,3 12 5,31 5,53 8,71

b

5,3 10 3,34 3,48 5,48

b

8,4 8 2,10 2,16 3,45

b

13 6 1,32 1,36 2,17

c c b

21 4 0,832 0,856 1,36

c c b

34 2 0,523 0,538 0,857

c c

42 1 0,415 0,427 0,680

c c

54 1/0 0,329 0,337 0,539

c c

67 2/0 0,261 0,267 0,428

c c

85 3/0 0,207 0,212 0,339

c c

107 4/0 0,164 0,168 0,269

a

Resistance factors for multi-core cables:

– Insulated conductors cabled in one layer Table 1 values × 1,02;

– Insulated conductors cabled in more than one layer Table 1 values × 1,03; or

– Insulated conductors cabled as an assembly of other pre-cabled units Table 1 values × 1,04.

b 2

Aluminium conductors to 34 mm circular only . See 5.1.1.c)

c

See note to 5.1.1.b)

d

See note to 5.1.2

—————————

[2] UL 1581 May 6, 2003 – Table 30.1 & 30.2

– 10 – TR 62602 © IEC:2009

Table 2 – Class 2 stranded conductors for single-core and multi-core cables

1 2 3 4 5 6 7 8 9 10 11 12

Minimum number of wires in the Maximum resistance of single-core

a

conductor conductors at 20 °C

Nominal Aluminium or

cross Size/cross- Circular Annealed copper aluminium

Circular Shaped

sectional sectional area compacted conductor alloy

area conductor

Metal-

Plain

Cu Al Cu Al Cu Al coated

wires

wires

mm AWG kcmil

Ω/km Ω/km Ω/km

0,52 20 7 - - - - - 34,6 36,7 -

0,82 18 7 - - - - - 21,8 23,2 -

1,3 16 7 - - - - - 13,7 14,6 -

2,1 14 7 - - - - - 8,62 8,96 -

3,3 12 7 7 - - - - 5,43 5,64 8,88

5,3 10 7 7 - - - - 3,41 3,55 5,59

8,4 8 7 7 7 7 - - 2,14 2,23 3,52

13 6 7 7 7 7 - - 1,35 1,40 2,21

21 4 7 7 7 7 - - 0,848 0,882 1,39

34 2 7 7 7 7 - - 0,534 0,555 0,875

42 1 19 19 18 18 - - 0,423 0,440 0,693

54 1/0 19 19 18 18 - - 0,335 0,349 0,550

67 2/0 19 19 18 18 15 15 0,266 0,276 0,436

85 3/0 19 19 18 18 15 15 0,211 0,219 0,346

107 4/0 19 19 18 18 15 15 0,167 0,172 0,274

127 250 37 37 35 35 28 28 0,142 0,147 0,232

177 350 37 37 35 35 28 28 0,101 0,105 0,166

253 500 37 37 35 35 28 28 0,070 8 0,072 9 0,116

380 750 61 61 58 58 47 47 0,047 2 0,048 6 0,077 4

507 1 000 61 61 58 58 47 47 0,035 4 0,036 4 0,058 0

633 1 250 91 91 91 - - - 0,028 3 0,029 2 0,046 4

760 1 500 91 91 91 - - - 0,023 6 0,024 3 0,038 7

887 1 750 91 91 91 - - - 0,020 2 0,020 8 0,033 2

1 014 2 000 127 127 127 - - - 0,017 7 0,018 2 0,029 0

a

Resistance factors for multi-core cables:

– Insulated conductors cabled in one layer Table 2 values × 1,02;

– Insulated conductors cabled in more than one layer Table 2 values × 1,03; or

– Insulated conductors cabled as an assembly of other pre-cabled units Table 2 values × 1,04

—————————

[2] Resistance UL 1581 May 6, 2003 – Table 30.3 and 30.4 Class B

Strand – Circular ASTM B8 (Cu) B231 (Al) B801 (ACM Al), Combination Unilay ASTM B787 (Cu)

B786 (Al), Compact ASTM B496 (Cu) B400 (Al)

TR 62602 © IEC:2009 – 11 –

Table 3 – Class 5 flexible copper conductors for single core and multi-core cables

1 2 3 4 5 6

Nominal Maximum diameter Maximum resistance of single-core

a

cross- Size/cross- of wires in conductors at 20 °C

sectional sectional area conductor

Plain wires Metal-coated wires

area

mm AWG kcmil mm

Ω/km Ω/km

2,1 14 0,24 8,70 9,24

3,3 12 0,30 5,48 5,81

5,3 10 0,38 3,45 3,66

8,4 8 0,29 2,18 2,33

13 6 0,37 1,38 1,46

21 4 0,46 0,865 0,918

27 3 0,52 0,686 0,728

34 2 0,42 0,547 0,580

42 1 0,47 0,434 0,460

54 1/0 0,52 0,344 0,357

67 2/0 0,59 0,272 0,284

85 3/0 0,66 0,216 0,224

107 4/0 0,74 0,172 0,180

127 250 0,62 0,146 0,152

177 350 0,74 0,104 0,108

253 500 0,88 0,072 9 0,075 8

380 750 0,84 0,049 1 0,051 0

507 1 000 0,97 0,036 8 0,038 2

633 1 250 1,08 0,029 5 0,030 6

a

Resistance factors for multi-core cables:

– insulated conductors cabled in one layer Table 3 values × 1,02;

– insulated conductors cabled in more than one layer Table 3 values × 1,03; or

– insulated conductors cabled as an assembly of other pre-cabled units Table 3 values × 1,04

—————————

[2] Resistance UL 1581 May 6, 2003 – Table 30.7 ASTM Class G (14 AWG-10 AWG)

Resistance UL 1581 May 6, 2003 – Table 30.8 ASTM Class H (8 AWG-1250 kcmil)

Max Wire Diameter ASTM B 173 (Nom + 0,01 mm)

– 12 – TR 62602 © IEC:2009

Table 4 – Class 6 flexible copper conductors for single-core and multi-core cables

1 2 3 4 5 6

Nominal Maximum diameter Maximum resistance of single-core

a

cross- Size/cross- of conductors at 20 °C

sectional sectional area wires in

Plain wires Metal-coated wires

area conductor

mm AWG kcmil mm

Ω/km Ω/km

2,1 14 0,17 8,61 9,25

3,3 12 0,17 5,53 5,94

5,3 10 0,17 3,48 3,73

8,4 8 0,17 2,18 2,35

13 6 0,17 1,39 1,49

21 4 0,17 0,873 0,937

34 2 0,17 0,554 0,595

42 1 0,17 0,440 0,472

54 1/0 0,17 0,349 0,374

67 2/0 0,17 0,276 0,300

85 3/0 0,17 0,221 0,238

107 4/0 0,17 0,175 0,189

127 250 0,17 0,149 0,159

177 350 0,17 0,106 0,114

253 500 0,17 0,074 3 0,079 8

380 750 0,17 0,049 5 0,053 1

507 1 000 0,17 0,037 1 0,039 9

a

Resistance factors for multi-core cables:

– Insulated conductors cabled in one layer Table 4 values × 1,02;

– Insulated conductors cabled in more than one layer Table 4 values × 1,03; or

– Insulated conductors cabled as an assembly of other pre-cabled units Table 4 values × 1,04

—————————

[2] Resistance UL 1581 May 6, 2003 – Table 30.11 ASTM Class M

Max Wire Diameter ASTM B 172 Class M (Nom + 0,01 mm)

TR 62602 © IEC:2009 – 13 –

Annex A

(informative)

Measurement of resistance

The cable is kept in the test area for sufficient time to ensure that the conductor temperature

has reached a level which permits an accurate determination of resistance, using the

correction factors provided.

Measure the d.c. resistance of the conductor(s), either on a complete length of cable or

flexible cord or on a sample of cable or flexible cord of at least 1 m in length, at room

temperature and record the temperature at which the measurement is made. Adjust the

measured resistance by means of the correction factors given in Table A.1.

Calculate the resistance per kilometre length of cable from the length of the complete cable

and not from the length of the individual core or wires.

If necessary, correction to 20 °C and 1 km length is made by applying the following formula:

1 000

R = R ⋅k ⋅

20 t t

L

where

k is the temperature correction factor from Table A.1;

t

R is the conductor resistance at 20 °C, Ω/km;

R is the measured conductor resistance, Ω;

t

L is the length of the cable, m

– 14 – TR 62602 © IEC:2009

Table A.1 – Temperature correction factors k for conductor resistance to correct

t

the measured resistance at t °C to 20 °C

1 2 1 2

Temperature of conductor Correction factor, Temperature of conductor Correction factor,

at time of measurement k , at time of measurement k ,

t t

all conductors all conductors

t °C t °C

0 1,087 21 0,996

1 1,082 22 0,992

2 1,078 23 0,988

3 1,073 24 0,984

4 1,068 25 0,980

5 1,064 26 0,977

6 1,059 27 0,973

7 1,055 28 0,969

8 1,050 29 0,965

9 1,046 30 0,962

10 1,042 31 0,958

11 1,037 32 0,954

12 1,033 33 0,951

13 1,029 34 0,947

14 1,025 35 0,943

15 1,020 36 0,940

16 1,016 37 0,936

17 1,012 38 0,933

18 1,008 39 0,929

19 1,004 40 0,926

20 1,000

NOTE The values of correction factors k are based on a resistance-temperature coefficient of 0,004 per K at

t

20 °C.

The values of temperature correction factors specified in Column 2 are approximate but give practical values well

within the accuracy that can normally be achieved in the measurements of conductor temperature and length of

cables or flexible cords.

For more accurate values for the temperature correction factors for copper and aluminium, reference should be

made to Annex B. However, these should not be treated as a requirement for testing in compliance with this

technical report in the assessment of resistances.

TR 62602 © IEC:2009 – 15 –

Annex B

(informative)

Exact formulae for the temperature correction factors

B.1 Annealed copper conductors: plain or metal coated

254,5 1

K = = B.1)

t,Cu

234,5 +t 1 + 0,00393()t − 20

B.2 Aluminium conductors

248 1

K = = (B.2)

t,Al

228 +t 1+ 0,00403()t − 20

NOTE For aluminium alloys, reference should be made to the manufacturer.

In the above cases, t refers to the temperature of the conductor at the time of measurement in

degrees Celsius.

– 16 – TR 62602 © IEC:2009

Annex C

(informative)

Guidance on the dimensional limits of circular conductors

C.1 Object

This annex is intended as a guide to manufacturers of cables and cable connectors to assist

in ensuring that the conductors and connectors are dimensionally compatible. It gives

guidance on dimensional limits for the following types of conductor included in this technical

report:

a) circular solid conductors, (Class 1) of copper, aluminium and aluminium alloy;

b) circular and compacted circular stranded conductors, (Class 2), of copper, aluminium and

aluminium alloy.

c) flexible conductors, (Classes 5 and 6), of copper.

C.2 Dimensional limits for circular copper conductors

The diameters of circular copper conductors should not exceed the values given in Table C.1.

If minimum diameters for Class 1 circular copper conductors are needed, reference can be

made to the minimum diameters for solid circular aluminium or aluminium alloy conductors

indicated in Table C.3.

C.3 Dimensional limits for stranded compacted circular copper, aluminium

and aluminium alloy conductors

The diameters of stranded compacted circular copper, aluminium and aluminium alloy

conductors should not exceed the maximum values and should be not less than the minimum

values given in Table C.2.

In the exceptional case of uncompacted circular stranded aluminium or aluminium alloy

conductors, the maximum diameters should not exceed the corresponding values for copper

conductors given in Table C.1.

C.4 Dimensional limits for circular solid aluminium conductors

The diameters of circular solid aluminium and aluminium alloy conductors should not exceed

the maximum values and should be not less than the minimum values given in Table C.3.

TR 62602 © IEC:2009 – 17 –

Table C.1 – Maximum diameters of circular copper conductors, solid,

non-compacted stranded and flexible

1 2 3 4 5 6 7

Nominal Size/cross- Conductors in cables for fixed Flexible

a

Conductor

cross-sectional sectional area installations conductors

area in

area

AWG kcmil Solid Stranded

circular mils

mm (Class 5 and 6)

(Class 1) (Class 2)

mm

mm mm

2,1 14 4 110 1,64 1,86 2,13

3,3 12 6 530 2,07 2,35 2,67

5,3 10 10 380 2,61 2,97 3,36

8,4 8 16 510 3,30 3,73 4,28

13 6 26 240 4,16 4,72 5,39

21 4 41 740 5,24 5,94 6,82

34 2 66 360 6,61 7,49 8,59

42 1 83 690 7,42 8,51 9,70

54 1/0 105 600 8,33 9,55 10,9

67 2/0 133 100 9,36 10,7 12,2

85 3/0 167 800 10,5 12,1 13,8

107 4/0 211 600 11,8 13,5 15,4

127 250 250 000 - 14,8 16,8

177 350 350 000 - 17,5 19,8

253 500 500 000 - 20,9 23,7

380 750 750 000 - 25,6 29,4

507 1 000 1 000 000 - 29,6 33,9

633 1 250 1 250 000 - 33,1 37,9

760 1 500 1 500 000 - 36,2 -

887 1 750 1 750 000 - 39,1 -

1 014 2 000 2 000 000 - 41,9 -

a

The values given for flexible conductors are intended to allow for both Class 5 and Class 6 conductors.

—————————

[2] UL 1581 May 6, 2003 – Table 20.1 Solid

UL 1581 May 6, 2003 – Table 20.4 ASTM Class B

ASTM B173-01a Class G (14 AWG-10 AWG) (nom. inches * 1,01 *25,4)

ASTM B173-01a Class H (8 AWG-1250 kcmil) (nom. inches * 1,01 *25,4)

– 18 – TR 62602 © IEC:2009

Table C.2 – Minimum and maximum diameters of stranded compacted circular copper,

aluminium and aluminium alloy conductors

1 2 3 4 5 6

Nominal Size/cross- Conductor Stranded compacted circular conductors

cross-sectional sectional area (Class 2)

area in

area circular mils

2 AWG kcmil Minimum diameter Maximum diameter

mm

mm mm

8,4 8 16 510 3,23 3,43

13 6 26 240 4,22 4,34

21 4 41 740 5,31 5,46

34 2 66 360 6,68 6,88

42 1 83 690 7,44 7,67

54 1/0 105 600 8,36 8,61

67 2/0 133 100 9,35 9,65

85 3/0 167 800 10,5 10,8

107 4/0 211 600 11,8 12,2

127 250 250 000 13,0 13,3

177 350 350 000 15,3 15,8

253 500 500 000 18,3 18,9

380 750 750 000 22,6 23,3

507 1000 1 000 000 26,4 27,2

Table C.3 – Minimum and maximum diameters of solid circular aluminium conductors

1 2 3 4

Nominal Solid conductors (Class 1)

cross-sectional Size

Minimum Maximum

area

mm AWG mm mm

5,3 10 2,54 2,61

8,4 8 3,20 3,30

13 6 4,03 4,16

21 4 5,09 5,24

34 2 6,41 6,61

42 1 7,20 7,42

54 1/0 8,09 8,33

67 2/0 9,08 9,36

85 3/0 10,2 10,5

107 4/0 11.5 11,8

—————————

[2] UL 1581 May 6, 2003 – Table 20.2 Round Compact-Stranded Conductors.

[2] UL 1581 May 6, 2003 – Table 20.1 Solid Conductor Dimensions

TR 62602 © IEC:2009 – 19 –

Bibliography

[1] IEC 60228, Conductors of insulated cables

[2] UL 1581 May 6, 2003, Electrical Wire, Cables, and Flexible Cords

___________

– 20 – TR 62602 © CEI:2009

SOMMAIRE

AVANT-PROPOS.22

INTRODUCTION.24

1 Domaine d’application .25

2 Termes et définitions .25

3 Classification.25

4 Matériaux .26

4.1 Rémarques préliminaires.26

4.2 Âmes massives en aluminium.26

4.3 Âmes câblées circulaires et sectorales en aluminium .26

5 Âmes massives et câblées .26

5.1 Âmes massives (Classe 1) .26

5.1.1 Construction .26

5.1.2 Résistance .26

5.2 Âmes câblées de section circulaire, non rétreintes (Classe 2) .27

5.2.1 Construction .27

5.2.2 Résistance .27

5.3 Âmes câblées rétreintes de section circulaire et âmes sectorales câblées

(Classe 2) .27

5.3.1 Construction .27

5.3.2 Résistance .27

6 Âmes souples (Classes 5 et 6) .27

6.1 Construction.27

6.2 Résistance .27

7 Contrôle de la conformité aux Articles 5 et 6.28

Annexe A (informative) Mesure de la résistance .32

Annexe B (informative) Formules exactes pour les facteurs de correction de

température .34

Annexe C (informative) Indications pour les limites dimensionnelles des âmes

circulaires .35

Bibliographie.38

Tableau 1 – Âmes massives de Classe 1 pour câbles monoconducteurs et

multiconducteurs .

Tableau 2 – Âmes câblées de Classe 2 pour câbles monoconducteurs et

multiconducteurs .29

Tableau 3 – Âmes souples de Classe 5 pour câbles monoconducteurs et

multiconducteurs .30

Tableau 4 – Âmes souples de Classe 6 pour câbles monoconducteurs et

multiconducteurs.

Tableau A.1 – Facteurs de correction de température k , pour ramener à 20 °C la

t

résistance mesurée à t °C.33

Tableau C.1 – Diamètres maximaux des âmes circulaires en cuivre, massives, câblées

non rétreintes et souples .36

Tableau C.2 – Diamètres minimaux et maximaux des âmes câblées rétreintes

circulaires en cuivre, en aluminium et alliage d’aluminium .37

TR 62602 © CEI:2009 – 21 –

Tableau C.3 – Diamètres minimaux et maximaux des âmes circulaires massives en

aluminium .37

– 22 – TR 62602 © CEI:2009

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

ÂMES DES CÂBLES ISOLÉS –

INFORMATIONS RELATIVES AUX SECTIONS

EXPRIMÉES EN AWG ET KCMIL

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'en

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...