IEC 60086-1:2000

(Main)Primary batteries - Part 1: General

Primary batteries - Part 1: General

Standardizes primary batteries with respect to their electrochemical system, dimensions, nomenclature, terminal configurations, markings, test methods, typical performance safety and environmental aspects.

General Information

- Status

- Published

- Publication Date

- 21-Nov-2000

- Technical Committee

- TC 35 - Primary cells and batteries

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 08-Dec-2006

- Completion Date

- 26-Oct-2025

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60086-1:2000 - Primary batteries – Part 1: General is the foundational IEC standard that establishes common terminology, basic requirements and test methods for primary (non-rechargeable) cells and batteries. It standardizes electrochemical systems, nomenclature, terminal configurations, markings, dimensions (cross-referenced to IEC 60086‑2/‑3), test methods and guidance on performance, safety and environmental aspects. This part forms the basis for other parts of the IEC 60086 series and is intended to ensure interchangeability and reliable performance of consumer primary batteries.

Key topics and technical requirements

- Scope and definitions: Clear terminology (e.g., primary cell, open-circuit voltage (OCV), on-load voltage, service output, minimum average duration (MAD), leakage).

- Design and dimensions: General design principles and references to physical dimensions in IEC 60086‑2 and IEC 60086‑3; terminal configuration and materials requirements to ensure reliable electrical contact.

- Performance and testing:

- Service output and discharge testing procedures, including application tests and service output tests.

- Methods for OCV and on-load measurements and definitions of end‑point voltage.

- Specification and calculation methods for minimum average duration (MAD) (see Annex D).

- Test conditions and sampling procedures (pre-discharge conditioning, storage effects, load resistance, timing and measuring equipment).

- Quality assurance and sampling: Sampling plans and product quality indices referenced to standards such as IEC 60410 and ISO sampling guidance.

- Marking, packaging and handling: Marking requirements and code of practice for packaging, shipment, storage, use and disposal (Annex B).

- Annexes: Normative and informative annexes covering designation/nomenclature (A), packaging/shipping (B), equipment design (C), MAD calculation (D), guidelines for standardization (E), preferred dimensions (F), standard discharge voltage method (G) and preparation of standard methods of measuring performance (H).

Applications and users

IEC 60086-1 is used by:

- Battery manufacturers - to design, mark and test primary batteries for interoperability and regulatory compliance.

- Device designers and OEMs - to select standard battery types and ensure form, fit and function in consumer products.

- Test laboratories and quality teams - to perform discharge, OCV and MAD testing and sampling.

- Regulators, importers and retailers - to verify labeling, packaging and storage practices.

- Environmental & safety professionals - to follow packaging/ disposal guidance and to refer to safety parts IEC 60086‑4 and IEC 60086‑5.

Related standards

- IEC 60086 series (Parts 2, 3, 4, 5)

- Normative refs cited: IEC 60410, IEC 61429, ISO 3951 and ISO/IEC Directives.

Keywords: IEC 60086-1, primary batteries standard, nomenclature, battery dimensions, discharge testing, MAD, OCV, battery packaging, battery terminals, sampling, service output.

Frequently Asked Questions

IEC 60086-1:2000 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Primary batteries - Part 1: General". This standard covers: Standardizes primary batteries with respect to their electrochemical system, dimensions, nomenclature, terminal configurations, markings, test methods, typical performance safety and environmental aspects.

Standardizes primary batteries with respect to their electrochemical system, dimensions, nomenclature, terminal configurations, markings, test methods, typical performance safety and environmental aspects.

IEC 60086-1:2000 is classified under the following ICS (International Classification for Standards) categories: 29.220.10 - Primary cells and batteries; 31.100 - Electronic tubes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60086-1:2000 has the following relationships with other standards: It is inter standard links to IEC 60086-1:2006, IEC 60086-1:1996/AMD1:1998, IEC 60086-1:1996/AMD2:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60086-1:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60086-1

Ninth edition

2000-11

Primary batteries –

Part 1:

General

Piles électriques –

Partie 1:

Généralités

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

60086-1

Ninth edition

2000-11

Primary batteries –

Part 1:

General

Piles électriques –

Partie 1:

Généralités

IEC 2000 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

X

International Electrotechnical Commission

For price, see current catalogue

– 2 – 60086-1 © IEC:2000(E)

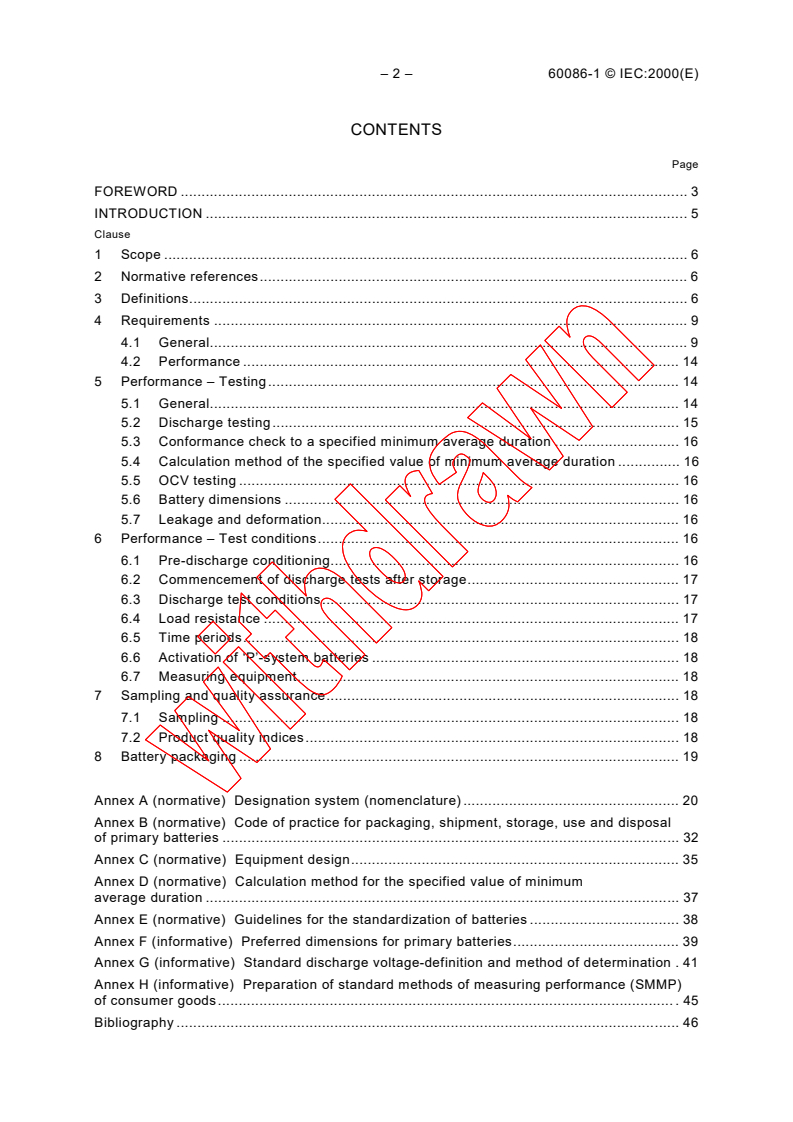

CONTENTS

Page

FOREWORD . 3

INTRODUCTION .5

Clause

1 Scope . 6

2 Normative references. 6

3 Definitions. 6

4 Requirements . 9

4.1 General. 9

4.2 Performance . 14

5 Performance – Testing. 14

5.1 General. 14

5.2 Discharge testing. 15

5.3 Conformance check to a specified minimum average duration . 16

5.4 Calculation method of the specified value of minimum average duration . 16

5.5 OCV testing . 16

5.6 Battery dimensions . 16

5.7 Leakage and deformation. 16

6 Performance – Test conditions. 16

6.1 Pre-discharge conditioning. 16

6.2 Commencement of discharge tests after storage. 17

6.3 Discharge test conditions. 17

6.4 Load resistance . 17

6.5 Time periods. 18

6.6 Activation of ‘P’-system batteries . 18

6.7 Measuring equipment. 18

7 Sampling and quality assurance. 18

7.1 Sampling . 18

7.2 Product quality indices. 18

8 Battery packaging . 19

Annex A (normative) Designation system (nomenclature) . 20

Annex B (normative) Code of practice for packaging, shipment, storage, use and disposal

of primary batteries . 32

Annex C (normative) Equipment design. 35

Annex D (normative) Calculation method for the specified value of minimum

average duration . 37

Annex E (normative) Guidelines for the standardization of batteries . 38

Annex F (informative) Preferred dimensions for primary batteries. 39

Annex G (informative) Standard discharge voltage-definition and method of determination . 41

Annex H (informative) Preparation of standard methods of measuring performance (SMMP)

of consumer goods.45

Bibliography . 46

60086-1 © IEC:2000(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

–––––––––––

PRIMARY BATTERIES –

Part 1: General

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60086-1 has been prepared by IEC technical committee 35:

Primary cells and batteries.

This ninth edition cancels and replaces the eighth edition and its amendments 1 and 2,

published in 1996, and constitutes a technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

35/1131/FDIS 35/1141/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B, C, D and E form an integral part of this standard.

Annex F, G and H are for information only.

– 4 – 60086-1 © IEC:2000(E)

The committee has decided that the contents of this publication will remain unchanged until

2001. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

IEC 60086 consists of the following parts, under the general title: Primary batteries:

– Part 1: General

1)

– Part 2: Physical and electrical specifications

– Part 3: Watch batteries

– Part 4: Safety of lithium batteries

1)

– Part 5: Safety of batteries with aqueous electrolyte

A bilingual version of this standard may be issued at a later date.

___________

1)

To be published.

60086-1 © IEC:2000(E) – 5 –

INTRODUCTION

The technical content of this part of IEC 60086 provides fundamental requirements and

information on primary cells and batteries. In this sense, part 1 is the main component of

IEC 60086 and forms the basis for the subsequent parts. For example, this part includes

elementary information on definitions, nomenclature, dimensions and marking. While specific

requirements are included, the content of this part tends to explain methodology (how) and

justification (why).

The objective of IEC 60086-1 is to benefit primary battery users, device designers and battery

manufacturers by ensuring that batteries from different manufacturers are interchangeable

according to a standard form, fit and function. Furthermore, to ensure compliance with the

above, this part specifies standard test methods for testing primary cells and batteries.

Over the years, this part has been changed to improve its content and remains under

continual scrutiny to ensure that the publication is kept up to date with the advances in both

battery and battery-powered device technologies. This current revision is the result of a

reformatting initiative, as well as some content changes, aimed at making it more user-

friendly, less ambiguous, and on a cross-reference basis, fully harmonized with other parts of

IEC 60086 (such as IEC 60086-2 and IEC 60086-3).

NOTE Safety information has been removed from IEC 60086-1 and is now available in IEC 60086-4 and

IEC 60086-5.

– 6 – 60086-1 © IEC:2000(E)

PRIMARY BATTERIES –

Part 1: General

1 Scope

The purpose of this part of IEC 60086 is to standardize primary batteries with respect to their

electrochemical system, dimensions, nomenclature, terminal configurations, markings, test

methods, typical performance, safety and environmental aspects.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60086. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this part of IEC 60086 are encouraged to investigate the possibility of

applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

2)

IEC 60086-2, Primary batteries – Part 2: Physical and electrical specifications

IEC 60086-3:1995, Primary batteries – Part 3: Watch batteries

IEC 60086-4:2000, Primary batteries – Part 4: Safety of lithium batteries

2)

IEC 60086-5, Primary batteries – Part 5: Safety of batteries with aqueous electrolyte

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

IEC 61429:1995, Marking of secondary cells and batteries with the international recycling

symbol ISO 7000-1135

ISO 3951:1989, Sampling procedures and charts for inspection by variables for percent non-

conforming

ISO/IEC Directives – Part 2: 1992

3 Definitions

For the purpose of this part of IEC 60086, the following definitions apply.

3.1

application test

test which simulates the actual use of a battery in a specific application, for example "portable

lighting", "tape recorder" or "transistor radio" test

___________

2)

To be published.

60086-1 © IEC:2000(E) – 7 –

3.2

discharge (of a primary battery)

operation during which a battery delivers current to an external circuit

3.3

dry (primary) battery

primary battery in which the liquid electrolyte is immobilized

3.4

effective internal resistance – DC method

resistance of any electrical component determined by calculating the ratio between the

voltage drop ΔU across this component and the range of current Δi passing through this

component and causing the voltage drop R = ΔU / Δi

NOTE As an analogy, the internal d.c. resistance R of any electrochemical cell is defined by the the following

i

relation:

Δ

U (V)

R (Ω) = (1)

i

Δi (A)

The internal d.c. resistance is illustrated by the schematic voltage transient as given below:

U

U (i )

1 1

ΔU

Ω

Δ

U

ΔU(t) U = ƒ(i , t)

2 2

Δ

U'

Ω

U (i )

2 2

Δt Δt'

t

t t t

1 2 3

IEC 2178/2000

Figure 1 – Schematic voltage transient

As can be seen from this diagram, the voltage drop ΔU of the two components differs in

nature, as shown in the following relation:

ΔU = ΔU + ΔU (t)(2)

Ω

The first component ΔU for (t = t ) is independent of time, and results from the increase in

Ω 1

current Δi according to the relation:

ΔU = Δi × R (3)

Ω Ω

In this relation, R is a pure ohmic resistance. The second component ΔU (t) is time

Ω

dependent and is of electrochemical origin.

3.5

end-point voltage

specified closed circuit voltage at which a service output test is terminated

3.6

leakage

unplanned escape of electrolyte, gas or other material from a battery

– 8 – 60086-1 © IEC:2000(E)

3.7

minimum average duration (MAD)

minimum average time on discharge which is met by a set of batteries

NOTE The discharge test is carried out according to the specified methods or standards and designed to show

conformity with the standard applicable to the battery types.

3.8

nominal voltage of a primary battery

suitable approximate value of voltage used to identify the voltage of a primary battery

3.9

on-load voltage

closed circuit voltage (CCV)

voltage across the terminals of a battery when it is on discharge

3.10

open-circuit voltage (OCV)

off-load voltage

voltage across the terminals of a battery when no external current is flowing

3.11

primary battery

one or more primary cells, including case, terminals and marking

3.12

primary cell

source of electrical energy obtained by the direct conversion of chemical energy not designed

to be charged by any other electrical source

3.13

service output (of a primary battery)

service life, or capacity, or energy output of a battery under specified conditions of discharge

3.14

service output test

test designed to measure the service output of a battery

NOTE A service output test may be prescribed, for example, when:

a) an application test is too complex to replicate;

b) the duration of an application test would make it impractical for routine testing purposes.

3.15

storage life

duration, under specified conditions, at the end of which a battery retains its ability to perform

a specified service output

3.16

terminals (of a primary battery)

conductive parts provided for the connection of a battery to external conductors

60086-1 © IEC:2000(E) – 9 –

4 Requirements

4.1 General

4.1.1 Design

Primary batteries are sold mainly in consumer markets. In recent years, they have become

more sophisticated in both chemistry and construction, for example both capacity and rate

capability have increased to meet the growing demands from new, battery-powered

equipment technology.

When designing primary batteries, the aforementioned considerations shall be taken into

account. Specifically, their dimensional conformity and stability, their physical and electrical

performance and their safe operation under normal use and foreseeable misuse conditions

shall be assured.

4.1.2 Battery dimensions

The dimensions for individual types of batteries are given in IEC 60086-2 and IEC 60086-3.

4.1.3 Terminals

Terminals shall be in accordance with clause 7 of IEC 60086-2.

Their physical shape shall be designed in such a way that they ensure that the batteries make

and maintain good electrical contact at all times.

They shall be made of materials that provide adequate electrical conductivity and corrosion

protection.

4.1.3.1 Contact pressure resistance

When mentioned in the battery specification tables or the individual specification sheets in

IEC 60086-2, the following applies:

– a force of 10 N applied through a steel ball of 1 mm diameter at the centre of each contact

area for a period of 10 s shall not cause any apparent deformation which might prevent

satisfactory operation of the battery.

NOTE See also IEC 60086-3 for exceptions.

4.1.3.2 Cap and base

This type of terminal is used for batteries which have their dimensions specified according to

figures 1, 2, 3 or 4 of IEC 60086-2, and which have the cylindrical side of the battery insulated

from the terminals.

4.1.3.3 Cap and case

This type of terminal is used for batteries which have their dimensions specified according

figures 2, 3 or 4 of IEC 60086-2, but in which the cylindrical side of the battery forms part of

the positive terminal.

4.1.3.4 Screw terminals

This contact consists of a threaded rod in combination with either a metal or insulated metal

nut.

– 10 – 60086-1 © IEC:2000(E)

4.1.3.5 Flat contacts

These are essentially flat metal surfaces adapted to make electrical contact by suitable

contact mechanisms bearing against them.

4.1.3.6 Flat or spiral springs

These contacts comprise flat metal strips or spirally wound wire which are in a form that

provides pressure contact.

4.1.3.7 Plug-in sockets

These are made up of a suitable assembly of metal contacts, mounted in an insulated housing

or holding device and adapted to receive corresponding pins of a mating plug.

4.1.3.8 Snap-fasteners

These contacts are composed of a combination comprising a stud (non-resilient) for the

positive terminal and a socket (resilient) for the negative terminal.

They shall be of suitable metal so as to provide efficient electrical connection when joined to

the corresponding parts of an external circuit.

4.1.3.8.1 Spacing of contacts

The spacing between the stud and socket is given in the following table, and applies from

centre to centre. The stud always forms the positive connection and the socket the negative

connection on the battery.

Table 1 – Spacing of contacts

Nominal voltage Standard Miniature

Vmm mm

9 35 ± 0,4 12,7 ± 0,25

4.1.3.8.2 Non-resilient snap-fastener connectors (studs)

Dimensions are given in millimetres.

All dimensions not specified are free. The shape of the stud shall be chosen so that the

dimensions specified are conformed to.

a

r

d

c

r

b

IEC 2179/2000

Figure 2 – Standard stud

60086-1 © IEC:2000(E) – 11 –

a

r

d

c

r

b

IEC 2180/2000

Figure 3 – Miniature stud

Table 2 – Snap-fastener connectors

Standard Miniature

mm mm

a 7,16 ± 0,05 5,72 ± 0,05

b

0,07

+

5,38 ± 0,05

6,65

0,05

−

c 3,20 ± 0,1 3,00 ± 0,1

d 2,67 ± 0,05 2,54 ± 0,05

r

+0,05 +0,1

0,61 0,9

−0,08 −0,3

r

+0,3 +0,2

0,4 0,3

0 0

4.1.3.8.3 Resilient snap-fastener connectors (sockets)

Dimensions and requirements:

The dimensions of the resilient (socket) parts of snap-fastener connectors are not specified as

such. The properties shall be such that:

a) the resiliency ensures that the standardized studs can be properly mated;

b) good electrical contact is maintained.

4.1.3.9 Wire

Wire leads shall be single- or multi-strand flexible insulated tinned copper. The insulation may

be cotton braid or suitable plastic. The positive terminal wire covering shall be red and the

negative black.

4.1.3.10 Spring clips

Spring clips are generally used on batteries not readily available to the consumer, when the

corresponding parts of the external circuit are not precisely known. They shall be of spring

brass or of other material having similar properties.

– 12 – 60086-1 © IEC:2000(E)

4.1.4 Classification (electrochemical system)

Primary batteries are classified according to their electrochemical system.

Each system, with the exception of the zinc-ammonium chloride, zinc chloride-manganese

dioxide system, has been allocated a letter denoting the particular system.

The electrochemical systems that have been standardized up to now are given in table 3.

Table 3 – Standardized electrochemical systems

Nominal Maximum

Negative voltage open circuit

Letter Electrolyte Positive electrode

voltage

electrode

V V

– Zinc Ammonium chloride, Manganese dioxide 1,5 1,725

Zinc chloride

A Zinc Ammonium chloride, Oxygen 1,4 1,55

Zinc chloride

B Lithium Organic electrolyte Carbon monofluoride 3 3,7

C Lithium Organic electrolyte Manganese dioxide 3 3,7

E Lithium Non-aqueous inorganic Thionyl chloride (SOCl)3,6 3,9

F Lithium Organic electrolyte Iron disulfide (FeS ) 1,5 1,83

G Lithium Organic electrolyte Copper (II) oxide (CuO) 1,5 2,3

L Zinc Alkali metal hydroxide Manganese dioxide 1,5 1,65

P Zinc Alkali metal hydroxide Oxygen 1,4 1,68

S Zinc Alkali metal hydroxide Silver oxide (Ag O) 1,55 1,63

NOTE 1 The value of the nominal voltage is not verifiable, therefore it is only given as a reference.

NOTE 2 The maximum open-circuit voltage is measured as defined in 5.4 and 6.7.1.

NOTE 3 When referring to an electrochemical system, common protocol is to list negative electrode first,

followed by positive electrode, i.e. lithium-iron disulfide.

4.1.5 Designation

The designation of primary batteries is based on their physical parameters, their

electrochemical system as well as modifiers, if needed.

A comprehensive explanation of the designation system (nomenclature) can be found in

annex A.

4.1.6 Marking

4.1.6.1 General

With the exception of batteries designated as small, each battery shall be marked with the

following information:

a) designation;

b) year and month or week of manufacture, which may be in code, or the expiration of a

guarantee period, in clear;

c) polarity of terminals (when applicable);

d) nominal voltage;

e) name or trade mark of the manufacturer or supplier.

60086-1 © IEC:2000(E) – 13 –

4.1.6.2 Small batteries

a) When this subclause is invoked in IEC 60086-2, 4.1.6.1a) and 4.1.6.1c) shall be marked

on the battery. Subclauses 4.1.6.1b), 4.1.6.1d) and 4.1.6.1e) may be given on the

immediate package instead of on the battery.

b) For P-system batteries, 4.1.6.1a) may be on the battery, the sealing tab or the package,

4.1.6.1c) may be marked on the sealing tab of the battery and/or on the battery.

Subclauses 4.1.6.1b), 4.1.6.1d) and 4.1.6.1e) may be given on the immediate package

instead of on the battery.

c) Caution for ingestion of small batteries shall be taken. Refer to IEC 60086-4 and

IEC 60086-5 for details.

4.1.6.3 Marking of batteries regarding method of disposal

Marking of batteries with respect to the method of disposal shall be in accordance with local

legal requirements. Where required, refer to IEC 61429.

4.1.7 Interchangeability: battery voltage

Primary batteries as presently standardized in IEC 60086 can be categorized by their

3)

standard discharge voltage U . For a new battery system, its interchangeability by voltage is

s

assessed for compliance with the following formula:

n × (U – 15 %) ≤ m × U ≤ n × (U + 15 %)

r s r

where

n is the number of cells connected in series, based on reference voltage U ;

r

m is the number of cells connected in series, based on standard discharge voltage U .

s

Currently, two voltage ranges that conform to the above formula have been identified. They

are identified by reference voltage U , which is the midpoint of the relevant voltage range.

r

Voltage range 1, U = 1,4 (V): Batteries having a standard discharge voltage m × U equal to

r s

or within the range of n × 1,19 (V) to n × 1,61 (V).

Voltage range 2, U = 3,2 (V): Batteries having a standard discharge voltage m × U equal to

s

r

or within the range of n × 2,72 (V) to n × 3,68 (V).

The term standard discharge voltage and related quantities, as well as the methods of their

determination, are given in annex G.

NOTE For single-cell batteries and for multi-cell batteries assembled with cells of the same voltage range, m and

n will be identical; m and n will be different for multi-cell batteries if assembled with cells from a different voltage

range than those of an already standardized battery.

Voltage range 1 encompasses all presently standardized batteries with a nominal voltage of

about 1,5 (V), i.e. "no-letter" system, systems A, F, G, L, P and S.

Voltage range 2 encompasses all presently standardized batteries with a nominal voltage of

about 3 (V), i.e. systems B, C and E.

___________

3)

The standard discharge voltage U was introduced to comply with the principle of experimental verifiability.

s

Neither the nominal voltage nor the maximum off-load voltage complies with this requirement.

– 14 – 60086-1 © IEC:2000(E)

Because batteries from voltage range 1 and voltage range 2 show significantly different

discharge voltages, they shall be designed to be physically non-interchangeable. Before

standardizing a new electrochemical system, its standard discharge voltage shall be

determined in accordance with the procedure given in annex G to resolve its inter-

changeability by voltage.

WARNING

Failure to comply with this requirement can present safety hazards to the user, such as fire,

explosion, leakage and/or device damage.

This requirement is necessary for safety and operational reasons.

4.2 Performance

4.2.1 Discharge performance

Discharge performance of primary batteries is specified in IEC 60086-2 and IEC 60086-3.

4.2.2 Dimensional stability

The dimensions of batteries shall conform with the relevant specified dimensions as given in

IEC 60086-2 and IEC 60086-3 at all times during testing under the standard conditions given

in this specification.

NOTE 1 An increase in battery height of 0,25 mm can occur with button cells of the B, C, G, L and P systems, if

discharged below end-point voltage.

NOTE 2 For certain button cells (coin cells) of the C and B systems, a decrease in battery height may occur as

discharge continues.

4.2.3 Leakage

When batteries are stored and discharged under the standard conditions given in this

specification, no leakage shall occur.

4.2.4 Open-circuit voltage limits

The maximum open-circuit voltage of batteries shall not exceed the values given in 4.1.4.

4.2.5 Service output

Discharge durations, initial and delayed, of batteries shall meet the requirements given in

IEC 60086-2 and IEC 60086-3.

4.2.6 Safety

When designing primary batteries, safety under conditions of intended use and foreseeable

misuse as prescribed in IEC 60086-4 and IEC 60086-5 shall be considered.

5 Performance – Testing

5.1 General

For the preparation of standard methods of measuring performance (SMMP) of consumer

goods, refer to annex H.

60086-1 © IEC:2000(E) – 15 –

5.2 Discharge testing

The discharge tests in this standard fall into two categories:

– application tests;

– service output tests.

In both categories of tests, discharge loads are specified in accordance with 6.4.

The methods of determining the load and test conditions are as follows:

5.2.1 Application tests

a) The equivalent resistance is calculated from the average current and average operating

voltage of the equipment under load.

b) The functional end-point voltage and the equivalent resistance value are obtained from the

data on all the equipment measured.

c) The median class defines the resistance value and the end-point voltage to be used for

the discharge test.

d) If the data are concentrated in two or more widely separated groups, more than one test

may be required.

e) In selecting the daily discharge period, the total weekly usage of the equipment is

considered.

The daily period then becomes the nearest preferred value (see 6.5) to one-seventh of the

total weekly usage.

NOTE 1 Some fixed resistance tests have been chosen to permit simplicity of design and ensure reliability of the

test equipment, despite the fact that, in specific instances, constant current or constant wattage tests may be a

better representation of the application.

In the future, alternative load conditions may become unavoidable. It is also inevitable that the

load characteristics of a particular category of equipment will change with time in a

developing technology.

The precise determination of the functional end-point voltage of the equipment is not always

possible. The discharge conditions are at best a compromise selected to represent a category

of equipment which may have widely divergent characteristics.

Nevertheless, in spite of these limitations, the derived application test is the best approach

known for the estimation of battery capability for a particular category of equipment.

NOTE 2 In order to minimize the proliferation of application tests, the tests specified should be those accounting

for 80 % of the market by battery size.

5.2.2 Service output tests

For service output tests the value of the load resistor should be selected such that the service

output approximates 30 days.

When full capacity is not realized within the required time scale, the service output may be

extended to the shortest suitable duration thereafter by selecting a discharge load of higher

ohmic value, as defined in 6.4.

– 16 – 60086-1 © IEC:2000(E)

5.3 Conformance check to a specified minimum average duration

In order to check the conformance of a battery, any of the application tests or service output

tests specified in IEC 60086-2 and IEC 60086-3 may be chosen.

The test shall be carried out as follows:

a) Test nine batteries.

b) Calculate the average without the exclusion of any result.

c) If this average is equal to or greater than the specified figure and no more than one

battery has a service output of less than 80 % of the specified figure, the batteries are

considered to conform to service output.

d) If this average is less than 80 % of the specified figure and/or more than one battery has a

service output of less than 80 % of the specified figure, repeat the test on another sample

of nine batteries and calculate the average as previously.

e) If the average of this second test is equal to or greater than the specified figure and no

more than one battery has a service output of less than 80 % of the specified figure, the

batteries are considered to conform to service output.

f) If the average of the second test is less than the specified figure and/or more than one

battery has a service output of less than 80 % of the specified figure, the batteries are

considered not to conform and no further testing is permitted.

NOTE Discharge performance of primary batteries is specified in IEC 60086-2.

5.4 Calculation method of the specified value of minimum average duration

This method is described in annex D.

5.5 OCV testing

Open-circuit voltage shall be measured with the voltage measuring equipment specified in 6.7.1.

5.6 Battery dimensions

Dimensions shall be measured with the measuring equipment specified in 6.7.2.

5.7 Leakage and deformation

After the service output has been determined under the specified environmental conditions,

the discharge shall be continued in the same way until the closed circuit voltage drops for the

first time below 40 % of the nominal voltage of the battery. The requirements of 4.1.3, 4.2.2

and 4.2.3 shall be met.

NOTE For watch batteries, the visual examination for leakage shall be carried out in accordance with clause 9 of

IEC 60086-3.

6 Performance – Test conditions

6.1 Pre-discharge conditioning

Storage before discharge testing and the actual discharge test is carried out under well

defined conditions. Unless otherwise specified, the conditions given in table 4 shall apply.

Discharge conditions shown are further referred to as standard conditions.

60086-1 © IEC:2000(E) – 17 –

Table 4 – Conditions for storage before and during discharge testing

Storage Relative Discharge Relative

Type of test Duration

conditions humidity conditions humidity

°C % °C %

60 days maximum after

a

Initial discharge test 20 ± 2 60 ± 15 20 ± 2 60 ± 15

date of manufacture

a

Delayed discharge test 20 ± 2 60 ± 15 12 months 20 ± 2 60 ± 15

Delayed discharge test

c

45 ± 2 50 ± 15 13 weeks 20 ± 2 60 ± 15

b

(high temperature)

a

During short periods only, the storage temperature may deviate from these limits without exceeding 20 °C ± 5 °C.

b

This test is carried out when a storage test at high temperature is required. Performance requirements are the

subject of agreement between the manufacturer and customer.

c

Batteries to be stored unpacked.

6.2 Commencement of discharge tests after storage

The period between the completion of storage and the start of a delayed discharge test shall

not exceed 14 days.

During this period the batteries shall be kept at 20 °C ± 2 °C and 60 % ± 15 % RH.

At least one day in these conditions shall be allowed for normalization before starting a

discharge test after storage at high temperature.

6.3 Discharge test conditions

In order to test a battery it shall be discharged as specified in IEC 60086-2 until the voltage

on load drops for the first time below the specified end-point. The service output may be

expressed as a duration, in ampere-hours or in watt-hours.

When IEC 60086-2 specifies service outputs for more than one discharge test, batteries shall

meet all of these requirements in order to comply with this specification.

6.4 Load resistance

The value of the resistive load (which includes all parts of the external circuit) shall be as

specified in the relevant specification sheet and shall be accurate to ±0,5 %.

When formulating new tests, the resistive load, expressed in ohms, shall, whenever possible,

be as follows:

1,00 1,10 1,20 1,30 1,50 1,60 1,80 2,00

2,20 2,40 2,70 3,00 3,30 3,60 3,90 4,30

4,70 5,10 5,60 6,20 6,80 7,50 8,20 9,10

together with their decimal multiples or sub-multiples.

– 18 – 60086-1 © IEC:2000(E)

6.5 Time periods

The periods on-discharge and off-discharge shall be as specified in IEC 60086-2.

When formulating new tests, whenever possible one of the following daily periods should be

adopted:

1 min 5 min 10 min 30 min

1 h 2 h 4 h 24 h (continuous)

Other cases are specified in IEC 60086-2, if necessary.

6.6 Activation of ‘P’-system batteries

A period of at least 10 min shall elapse between activation and the commencement of

electrical measurement.

6.7 Measuring equipment

6.7.1 Voltage measurement

The accuracy of the measuring equipment shall be ≤0,25 % and the precision shall be ≤50 %

of the value of the last significant digit. The internal resistance of the measuring instrument

shall be ≥1 MΩ.

6.7.2 Mechanical measurement

The accuracy of the measuring equipment shall be ≤0,025 % and the precision shall be ≤50 %

of the value of the last significant digit.

7 Sampling and quality assurance

The use of sampling plans or product quality indices may be agreed between manufacturer

and purchaser.

Where no agreement is specified the options in 7.1 and/or 7.2 are recommended.

7.1 Sampling

7.1.1 Testing by attributes

When testing by attributes is required, the sampling plan chosen shall be in accordance with

the specifications of IEC 60410. The individual parameters to be tested and the acceptable

quality level (AQL) values shall be defined (a minimum of three batteries of the same type

shall be tested).

7.1.2 Testing by variables

When testing by variables is required, the sampling plan chosen shall be in accordance with

ISO 3951. The individual parameters to be tested, the sample size and the acceptable quality

level (AQL) shall be defined.

7.2 Product quality indices

Consideration may be given to utilizing one of the indices below as a means for assessing

and ensuring product quality.

60086-1 © IEC:2000(E) – 19 –

7.2.1 Capability index (Cp)

Cp is an index that represents the capability of a process. It explains how much of the

tolerance range could be used up by the within sample process variation, σ′, and is defined as

Cp = (USL-LSL)/Process Width where Process Width is expressed as 6 R / d . If the ratio is

≥1 and centered, the process is capable of making parts to specification. However, at Cp = 1,

automatically 2 700 parts per million are outside of specifications.

NOTE USL = upper specification limit; LSL = lower specification limit.

7.2.2 Capability index (Cpk)

Cpk is another process capability index that tells whether the process is capable of meeting

tolerances and whether the process is centered around the target value.

Like Cp, it is assumed the samples come from a stable process and variation is random

variation, measured as within sample variation, R / d , from the control chart, where σ′ = R / d .

2 2

Cpk is the minimum of:

USL − X X − LSL

or

3 σ′ 3 σ′

7.2.3 Performance index (Pp)

Pp is a process performance index that explains how much of the tolerance range is used up

by the total variation in the system. It is a measure of how the system is actually performing

because all sources of variation are included in σ´ . This σ´ is calculated by taking all the

Τ Τ

observations as one large sample. Pp is defined as (USL – LSL)/6σ´ .

Τ

7.2.4 Performance index (Ppk)

Ppk is another process performance index that is a measure of actual process performance

as Pp above, but like Cpk it also tells how well the process is centred.

Ppk is the minimum of:

USL − X X − LSL

or

3 σ′ 3 σ′

T T

where σ´ includes all sources of variation in the system.

Τ

8 Battery packaging

A code of practice for battery packaging, shipment, storage, use and disposal can be found in

annex B.

– 20 – 60086-1 © IEC:2000(E)

Annex A

(normative)

Designation system (nomenclature)

The battery designation system (nomenclature) defines as unambiguously as possible the

physical dimensions, shape, electrochemical system, nominal voltage and, where necessary,

the type of terminals, rate capability and special characteristics.

This annex is divided into two clauses.

A.1 defines the designation system (nomenclature) in use up to October 1990.

A.2 defines the designation system (nomenclature) in use since October 1990 to accommodate

present and future needs.

A.1 Designation system in use up to October 1990

This clause applies to all batteries which have been standardized up to October 1990 and will

remain valid for those batteries after that date.

A.1.1 Cells

A cell is designated by a capital letter followed by a number. The letters R, F and S define

round, flat (layer built) and square cells, respectively. The letter, together with the following

4)

number , is defined by a set of nominal dimensions.

Where a single-cell battery is specified, the maximum dimensions of the battery instead of the

nominal dimensions of the cell are given in tables A.1, A.2 and A.3. Note that these tables do

not include electrochemistries, except for the no letter system, or other modifiers. These other

parts of the designation system (nomenclature) follow in A.1.2, A.1.3 and A.1.4. These tables

only provide core physical designations for single cells or single batteries.

___________

4)

At the time this system was applied, numbers were allocated sequentially. Omissions in the sequence arise

because of deletions or by the different approach to numbering used even before the sequential system.

60086-1 © IEC:2000(E) – 21 –

1)

Table A.1 – Physical designation and dimensions of round cells and batteries

Nominal cell dimensions Maximum battery dimensions

mm mm

Physical designation

Diameter Height Diameter Height

R06 10 22 – –

R03 – – 10,5 44,5

R01 – – 12,0 14,7

R0 11 19 – –

R1 – – 12,0 30,2

R3 13,5 25 – –

R4 13,5 38 – –

R6 – – 14,5 50,5

R9 – – 16,0 6,2

R10 – – 21,8

37,3

R12 – – 21,5 60,0

R14 – – 26,2 50,0

R15 24 70 – –

R17 25,5 17 – –

R18 25,5 83 – –

R19 32 17 – –

R20 – – 34,2 61,5

R22 32 75 – –

R25 32 91 – –

R26 32 105 – –

R27 32 150 – –

R40 – – 67,0 172,0

R41 – – 7,9 3,6

R42 – – 11,6 3,6

R43 – – 11,6

4,2

R44 – – 11,6 5,4

R45 9,5 3,6 – –

R48 – – 7,9 5,4

R50 – – 16,4 16,8

R51 16,5 50,0 – –

R52 – – 16,4 11,4

R53 – – 23,2 6,1

R54 – – 11,6 3,05

R55 – – 11,6 2,1

R56 – – 11,6 2,6

R57 – – 9,5 2,7

R58 – – 7,9 2,1

R59 – – 7,9 2,6

R60 – – 6,8 2,15

R61 7,8 39

– –

R62 – – 5,8 1,65

R63 – – 5,8 2,15

R64 – – 5,8 2,70

R65 – – 6,8 1,65

R66 – – 6,8 2,60

R67 – – 7,9 1,65

R68 – – 9,5 1,65

R69 – – 9,5 2,10

R70 – – 5,8 3,6

1)

The complete dimensions of batteries are given in IEC 60086-2 and IEC 60086-3.

-----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...