IEC 60086-4:2000

(Main)Primary batteries - Part 4: Safety of lithium batteries

Primary batteries - Part 4: Safety of lithium batteries

Specifies tests and requirements for primary lithium batteries to ensure their safe operation under intended use or reasonably foreseeable misuse.

General Information

- Status

- Published

- Publication Date

- 09-Mar-2000

- Technical Committee

- TC 35 - Primary cells and batteries

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 10-Sep-2007

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60086-4:2000 - "Primary batteries - Part 4: Safety of lithium batteries" is the International Electrotechnical Commission standard that specifies safety requirements and test provisions for primary lithium batteries. Its purpose is to ensure safe operation under both intended use and reasonably foreseeable misuse. The standard covers consumer and industrial primary lithium cells and batteries in common shapes (cylindrical, button/coin, prismatic) and addresses hazards unique to lithium systems (flammable materials, internal pressure, overheating).

Key Topics

- Scope and definitions: Clarifies terminology for primary cells, consumer vs industrial batteries, high‑power vs low‑power batteries, venting, leakage, explosion and distortion thresholds (definitions used to assess risk).

- Design requirements: Emphasizes prevention of abnormal temperature rise, current‑limiting construction, and means to relieve excessive internal pressure (venting) as essential design concepts for safe lithium batteries.

- Quality plan and sampling: Manufacturers must implement a documented quality plan and sample production lots according to established quality control procedures.

- Testing and requirements: The standard prescribes tests for both intended use and reasonably foreseeable misuse (sampling, test sequence and test procedures) to verify safe behavior under normal and abusive conditions.

- Information for safety and instructions: Mandates safety information for designers and end users covering charge protection, parallel connections, handling, packaging, transportation, display, storage and disposal.

- Marking and documentation: Requirements for safety notices, labeling and user instructions so hazardous conditions are communicated effectively.

Applications

Who uses IEC 60086-4:

- Battery manufacturers - to design and verify safe primary lithium batteries, implement quality plans, and demonstrate conformance to international safety expectations.

- Product designers and OEMs - to specify battery safety features (charge protection, parallel connection guidance) when integrating lithium primary batteries into devices (cameras, portable electronics, sensors).

- Test laboratories and compliance engineers - to develop test programs addressing intended use and reasonably foreseeable misuse scenarios.

- Transport, packaging and retail - to follow guidance on packaging, storage, display and disposal to minimize risk during distribution and sale.

- Regulators and safety assessors - to reference internationally‑accepted safety criteria when evaluating battery‑related hazards.

Related Standards

- IEC 60086-1 (Primary batteries - Part 1: General) - normative reference for terminology and general battery requirements.

- IEC 60050, IEC 60027, IEC 60417, IEC 60617 - referenced for vocabulary, symbols and graphical markings.

Keywords: IEC 60086-4, lithium batteries safety, primary lithium batteries, safety tests, battery design, venting, quality plan, reasonably foreseeable misuse.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60086-4:2000 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Primary batteries - Part 4: Safety of lithium batteries". This standard covers: Specifies tests and requirements for primary lithium batteries to ensure their safe operation under intended use or reasonably foreseeable misuse.

Specifies tests and requirements for primary lithium batteries to ensure their safe operation under intended use or reasonably foreseeable misuse.

IEC 60086-4:2000 is classified under the following ICS (International Classification for Standards) categories: 29.220.10 - Primary cells and batteries; 31.100 - Electronic tubes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60086-4:2000 has the following relationships with other standards: It is inter standard links to IEC 60086-4:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60086-4:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60086-4

Second edition

2000-03

Primary batteries –

Part 4:

Safety of lithium batteries

Piles électriques –

Partie 4:

Sécurité des piles au lithium

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is to be found at the following IEC sources:

• IEC web site*

•

Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL IEC

STANDARD

60086-4

Second edition

2000-03

Primary batteries –

Part 4:

Safety of lithium batteries

Piles électriques –

Partie 4:

Sécurité des piles au lithium

IEC 2000 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

V

International Electrotechnical Commission

For price, see current catalogue

– 2 – 60086-4 © IEC:2000(E)

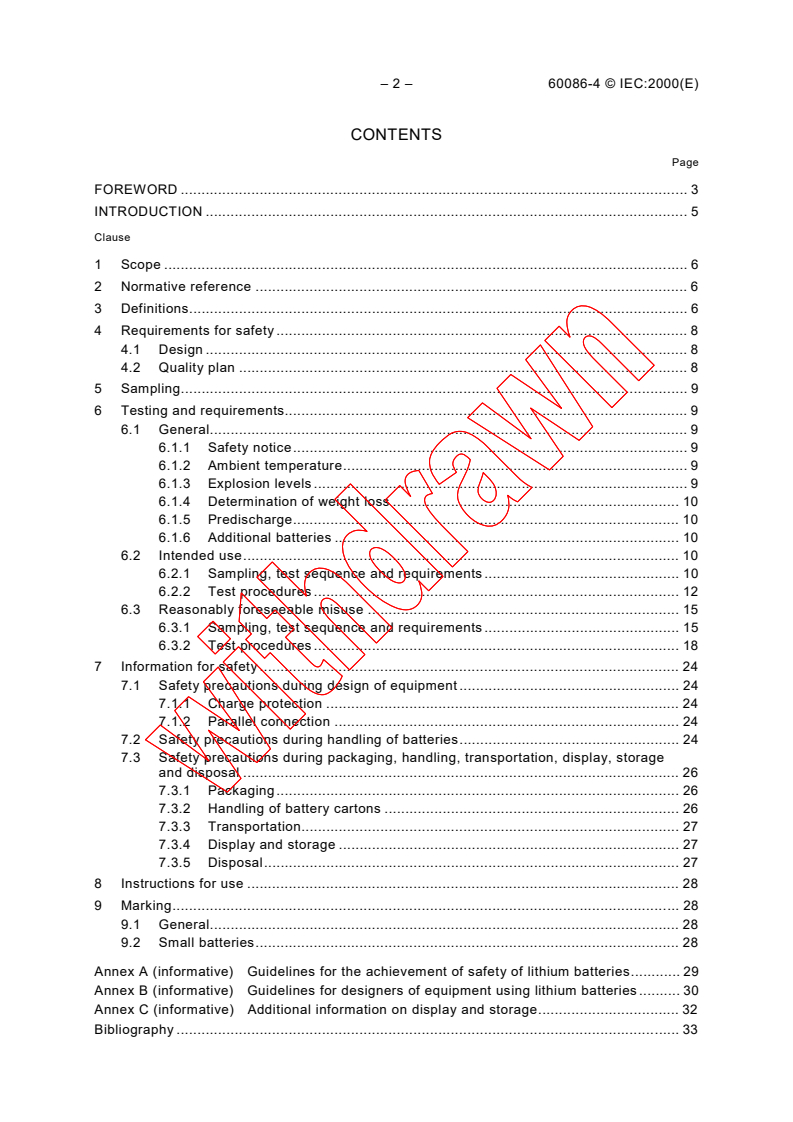

CONTENTS

Page

FOREWORD . 3

INTRODUCTION .5

Clause

1 Scope . 6

2 Normative reference . 6

3 Definitions. 6

4 Requirements for safety . 8

4.1 Design . 8

4.2 Quality plan . 8

5 Sampling. 9

6 Testing and requirements. 9

6.1 General. 9

6.1.1 Safety notice. 9

6.1.2 Ambient temperature. 9

6.1.3 Explosion levels . 9

6.1.4 Determination of weight loss . 10

6.1.5 Predischarge. 10

6.1.6 Additional batteries . 10

6.2 Intended use. 10

6.2.1 Sampling, test sequence and requirements . 10

6.2.2 Test procedures . 12

6.3 Reasonably foreseeable misuse . 15

6.3.1 Sampling, test sequence and requirements . 15

6.3.2 Test procedures . 18

7 Information for safety . 24

7.1 Safety precautions during design of equipment . 24

7.1.1 Charge protection . 24

7.1.2 Parallel connection . 24

7.2 Safety precautions during handling of batteries. 24

7.3 Safety precautions during packaging, handling, transportation, display, storage

and disposal . 26

7.3.1 Packaging. 26

7.3.2 Handling of battery cartons . 26

7.3.3 Transportation. 27

7.3.4 Display and storage . 27

7.3.5 Disposal. 27

8 Instructions for use . 28

9 Marking. 28

9.1 General. 28

9.2 Small batteries. 28

Annex A (informative) Guidelines for the achievement of safety of lithium batteries. 29

Annex B (informative) Guidelines for designers of equipment using lithium batteries . 30

Annex C (informative) Additional information on display and storage. 32

Bibliography . 33

60086-4 © IEC:2000(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRIMARY BATTERIES –

Part 4: Safety of lithium batteries

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60086-4 has been prepared by IEC technical committee 35:

Primary cells and batteries.

This second edition cancels and replaces the first edition, published in 1996, and constitutes

a technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

35/1114/FDIS 35/1125/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B and C are for information only.

– 4 – 60086-4 © IEC:2000(E)

IEC 60086 consists of the following parts, under the general title Primary batteries:

– Part 1: General

– Part 2: Specification sheets

– Part 3: Watch batteries

– Part 4: Safety of lithium batteries

– Part 5: Safety of batteries with aqueous electrolyte

The committee has decided that the contents of this publication will remain unchanged

until 2002.

At this date the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

60086-4 © IEC:2000(E) – 5 –

INTRODUCTION

The concept of safety is closely related to safeguarding the integrity of people and property.

This standard specifies requirements and tests for lithium batteries and has been prepared in

accordance with ISO/IEC guidelines, taking into account all relevant national and international

standards which apply.

Lithium batteries are different from conventional primary batteries using aqueous electrolyte

in that they contain flammable materials.

Consequently, it is important to take safety precautions very carefully during design,

production, distribution, use, and disposal of lithium batteries. Based on such special

characteristics, lithium batteries for consumer applications were initially small in size and had

low power output. There were also lithium batteries with high power output which were used

for special industrial applications and were characterized as being “technician replaceable”.

The first edition of IEC 60086-4 (1996) was drafted to accommodate the above situation.

However, from around the end of the 1980s, lithium batteries with high power output have

started to be widely used in the consumer replacement market, mainly as a power source in

camera applications.

Since the demand for such lithium batteries with high power output has significantly increased

in recent years, various manufacturers have started to produce these types of lithium

batteries. As a consequence of this situation, the safety aspects for lithium batteries with high

power output have been included in this second edition of IEC 60086-4.

Safety is a balance between freedom from hazard and other requirements to be met by the

product. There can be no absolute safety. Even at the highest level of safety, the product can

only be relatively safe. In this respect, decision-making is based on risk evaluation and safety

judgement.

As safety will pose different problems, it is impossible to provide a set of precise provisions

and recommendations that will apply in every case. However, this standard, when followed on

a judicious “use when applicable” basis, will provide reasonably consistent standards for

safety.

– 6 – 60086-4 © IEC:2000(E)

PRIMARY BATTERIES –

Part 4: Safety of lithium batteries

1 Scope

This International Standard specifies tests and requirements for primary lithium batteries to

ensure their safe operation under intended use and reasonably foreseeable misuse.

2 Normative reference

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this International Standard. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent edition of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60086-1:1996, Primary batteries – Part 1: General

3 Definitions

For the purpose of this part of IEC 60086, the definitions given in IEC 60086-1 (some of which

are repeated below for convenience) and the following definitions apply.

3.1

battery (primary)

one or more primary cells, including case, terminals and marking

3.2

button battery

small round battery, where the overall height is less than the diameter; batteries complying

with IEC 60086-1, figures 2, 3 and 4

3.3

cell (primary)

a source of electrical energy obtained by the direct conversion of chemical energy, that is not

designed to be charged by any other electrical source

3.4

consumer batteries

batteries readily available in the commercial retail market and that are considered user

replaceable, i.e. replaceable without the need of special tools

3.5

cylindrical battery

primary battery with cylindrical geometry where the overall height is equal to or greater than

the diameter; batteries complying with IEC 60086-1, figures 1A and 1B

3.6

depth of discharge (DOD)

percentage of rated capacity discharged from a battery

60086-4 © IEC:2000(E) – 7 –

3.7

distortion

any change in physical dimensions exceeding 10 %

3.8

explosion, battery (battery explosion)

an instantaneous release wherein solid matter from any part of the battery is propelled to a

distance greater than 25 cm away from the battery

3.9

fire

combustion of cell/battery components with emission of flame

3.10

harm

physical injury and/or damage to health or property

3.11

hazard

a potential source of harm

3.12

high power battery

a battery that can deliver most of its energy within a short time at ambient temperature

3.13

industrial batteries

batteries not normally available to the consumer. Such batteries are often referred to as

“technician replaceable” because of the skill required for their handling and installation

3.14

intended use

the use of a product, process or service under conditions or for purposes in accordance with speci-

fications and instructions provided by the supplier, including information for publicity purposes

3.15

leakage

unplanned escape of electrolyte, gas or other material from a battery

3.16

low power battery

a battery that cannot deliver most of its energy within a short time at ambient temperature

3.17

nominal voltage

a suitable approximate value of voltage used to identify the voltage of a primary battery

3.18

open circuit voltage (OCV)

voltage across the terminals of a battery when no external current is flowing

3.19

overheating

a condition when battery temperature rises above the temperature range specified by the

manufacturer

– 8 – 60086-4 © IEC:2000(E)

3.20

prismatic battery

primary battery with non-round geometry; batteries not complying with 4.3 of IEC 60086-1

3.21

rated capacity

capacity of a battery determined under conditions specified in the relevant standard (if

applicable) and declared by the manufacturer or supplier. Also sometimes referred to as

nominal capacity

3.22

reasonably foreseeable misuse

the use of a product, process or service under conditions or for purposes not intended by the

supplier, but which may happen, as a result of common human behaviour

3.23

risk

the probable rate of occurrence of a hazard causing harm and the degree of severity of

the harm

3.24

safety

freedom from unacceptable risk of harm

3.25

venting

the release of excessive internal pressure from a battery in a manner intended by design to

preclude explosion

4 Requirements for safety

4.1 Design

Lithium batteries are categorized by their chemical composition (anode, cathode, electrolyte),

internal construction (bobbin, spiral) and are available in cylindrical, button/coin, and

prismatic configuration. It is necessary to consider all relevant safety aspects at the battery

design stage, recognizing the fact that they may differ considerably, depending on the specific

lithium system, power output and battery configuration.

The following design concepts for safety are common to all lithium batteries.

a) Abnormal temperature rise above the critical value defined by the manufacturer shall be

prevented by design.

b) Temperature increases in the battery shall be controlled by a design which limits current

flow.

c) Batteries shall be designed to relieve excessive internal pressure (not applicable to low

power industrial batteries).

See annex A for guidelines for the achievement of safety of lithium batteries.

4.2 Quality plan

The manufacturer shall prepare a quality plan defining the procedures for the inspection of

materials, components, cells and batteries during the course of manufacture, to be applied to

the total process of producing a specific type of battery.

60086-4 © IEC:2000(E) – 9 –

5 Sampling

Samples shall be taken randomly from production lots in accordance with accepted quality

control procedures.

NOTE 1 Many tests in this standard require preliminary conditioning of the samples such as preliminary discharge

or storage at elevated temperature.

NOTE 2 Details of sample size for type approval and conditioning are found in clause 6.

6 Testing and requirements

6.1 General

6.1.1 Safety notice

WARNING:

These tests call for the use of procedures which may result in injury if adequate

precautions are not taken.

It has been assumed in the drafting of these tests that their execution is undertaken

by appropriately qualified and experienced technicians using adequate protection.

6.1.2 Ambient temperature

Unless otherwise specified, the tests shall be carried out at (20 ± 5) °C.

6.1.3 Explosion levels

In order to quantify the explosion as defined in 3.8, the following procedure is provided. The

test battery is placed on the steel plate shown in figure 1. The mesh chamber is centred over

the test battery. The test battery is then subjected to the relevant test procedure. The result

shall be determined using the following two levels.

NE: battery does not explode.

NE2: battery explodes but ejected solid material does not pass through the mesh chamber

specified in figure 1.

CAUTION

Avoid short-circuiting. For protection, the mesh chamber shall be in a place that is separated

from the observer.

0,6 m

0,6 m

0,3 m

1 2

IEC 109/2000

NOTE The figure shows an aluminium wire mesh chamber (2) of octagonal shape resting on a steel plate (1). The

aluminium wire has a diameter of 0,25 mm. The mesh has 16 to 18 wires per 25,4 mm.

Figure 1 – Mesh chamber

– 10 – 60086-4 © IEC:2000(E)

6.1.4 Determination of weight loss

In order to quantify the weight loss referred to in table 2, the following procedure is provided.

W − W

1 2

ΔW = × 100 %

W

where

W is the weight before the test;

W is the weight after the test;

ΔW is the weight loss.

When weight loss does not exceed the values in table 1, it shall be considered as “no weight

loss”.

Table 1 – Weight loss limits

Weight W of battery Weight loss limit

W 0,5 %

≤ 1 g

0,2 %

1 g < W ≤ 5 g

W

> 5 g 0,1 %

6.1.5 Predischarge

Where a test requires predischarge (25 %, 50 %, 75 % or 100 %), the test batteries shall be

discharged to the respective depth of discharge with a resistive load with which the rated

capacity is obtained or with a current specified by the manufacturer.

6.1.6 Additional batteries

Where additional batteries are required to perform a test, they shall be of the same type as

the test battery.

Where additional batteries are required to perform a test, the total number n of batteries in

i

series, including the test battery, shall be determined by calculating:

n = 12 V/U

n

and determining n by rounding up n to the nearest decimal integer while n ≥ n = i

i i min

where

U is the nominal voltage of one battery;

n

n is the total number of batteries;

i

n is the minimum number (2 or 3) of batteries given in the respective test description.

min

EXAMPLE 1 Let the minimum number of batteries be given as n = 2 and let the test battery have a nominal

min

U n

voltage = 3,6 V. Calculate = 3D and determine n = 4.

n

EXAMPLE 2 Let the minimum number of batteries be given as n = 3 and let the test battery have a nominal

min

voltage U = 10 V. Calculate n = 1,2 and determine n = 3.

n 3

6.2 Intended use

6.2.1 Sampling, test sequence and requirements

Figure 2 gives an overview of the test sequence and samples to be taken for intended use

tests while table 2 contains the requirements.

60086-4 © IEC:2000(E) – 11 –

Test batteries

Consumer

Low power High power

a b

Single Multi

40 60 60

6.2.2.3

Vibration

10 ±0,8 mm,

6.2.1

10 Hz to 55 Hz

Inspection

per table 2

6.2.1

Inspection

per table 2

6.2.2.1

Discharge 1

specified rate, 20 °C

6.2.2.4

__________ Shock

60 °C 3 ms avg. 75 g

n

Undischarged batteries

6.2.1

to 6.3.2.1 External short circuit

Inspection

per table 2

6.2.2.2

Discharge 2

high rate, 20 °C 10

__________ End of test

60 °C

6.2.2.7

6.2.2.6

Altitude

High temperature

10 10 max. 11,6 kPa, 6 h

5 h, 100 °C 10

_______________

6.2.1

30 d, 60 °C 10

Inspection

per table 2

6.2.2.5

Thermal shock

6.2.1

48 h, 75 °C; 60 h, –20 °C

Final inspection

per table 2

6.2.1

to 6.3.2.1 External short circuit

Inspection

per table 2

IEC 110/2000

NOTE The line type indicates the battery class.

a, b

cell batteries.

Figure 2 – Sampling and sequence of intended use tests

Industrial

– 12 – 60086-4 © IEC:2000(E)

Table 2 – Intended use tests and requirements

Requirements

Consumer batteries

Test Intended use

Industrial

High power batteries

simulation

batteries

Low power

Single cell Multicell

batteries

batteries batteries

Electrical tests A-1 Discharge 1 NL, NV, NE, * * NL, NV, NE,

NF NF

A-2 Discharge 2 * NL, NV, NE, NL, NV, NE, *

NF NF

Mechanical tests B-1 Vibration NW, ND, NL, NW, ND, NL, NW, ND, NL, NW, ND, NL,

NV, NE, NF NV, NE, NF NV, NE, NF NV, NE, NF

B-2 Shock NW, ND, NL, NW, ND, NL, NW, ND, NL, NW, ND, NL,

NV, NE, NF NV, NE, NF NV, NE, NF NV, NE, NF

Environmental tests C-1 Thermal shock NL, NV, NE, NL, NV, NE, NL, NV, NE, NL, NV, NE,

NF NF NF NF

C-2 High * NV, NE, NF NV, NE, NF *

temperature

C-3 Altitude NW, ND, NL, NW, ND, NL, NW, ND, NL, NW, ND, NL,

simulation NV, NE, NF NV, NE, NF NV, NE, NF NV, NE, NF

Additional requirements:

Distortion: Distortion shall be reported with the cause.

Venting: If electrolyte leaks from the vent area without vent operation, it shall be considered as leakage.

*: Not applicable.

NW: No weight loss (see 6.1.4).

ND: No distortion.

NL: No leakage.

NV: No venting.

NE: No explosion.

NE2: See 6.1.3.

NF: No fire.

6.2.2 Test procedures

6.2.2.1 Electrical test A-1 – Discharge 1

a) Purpose

This test simulates the actual use of batteries. The limiting resistance value shall be

specified for each battery type.

b) Test procedure

The undischarged battery is discharged, under limiting resistor R for a test duration t :

1 d

t = C × R /U

d n 1 n

where

t is the test duration;

d

C is the nominal capacity;

n

U is the nominal voltage;

n

R is a resistive load selected such that the average current draw is the same as the

maximum discharge current specified by the manufacturer.

60086-4 © IEC:2000(E) – 13 –

The maximum discharge current specified by the manufacturer shall be such that any

protective device used in the battery will not activate during the course of the test.

The test shall be carried out at (20 ± 2) °C until the battery is fully discharged and, in a

separate test, at (60 ± 2) °C until the battery is fully discharged.

c) Requirements

See table 2.

6.2.2.2 Electrical test A-2 – Discharge 2

a) Purpose

This test simulates the use of batteries in cameras and similar applications. In general, a

pulse discharge test of approximately 1 A is specified as the test for camera applications.

However, when the film drive motor is stalled, there is a continuous current flow.

b) Test procedure

An undischarged test battery shall be continuously discharged with a resistive load R

taken from table 3.

Table 3 – Resistive load R

Battery type Resistive load R

Ω

CR17345 2,00

CR-P2 3,90

2CR5 3,90

NOTE Table to be modified or expanded

when additional batteries are standardized.

The test shall be carried out at (20 ± 2) °C for 24 h and, separately, at (60 ± 2) °C for 24 h.

c) Requirements

See table 2.

6.2.2.3 Mechanical test B-1 – Vibration

a) Purpose

This test simulates vibration during transportation. The test condition is generally specified

*

in UN (1995) [14] and others.

b) Test procedure

The test batteries shall be subjected to simple harmonic motion with an amplitude of

0,8 mm (1,6 mm total maximum excursion). The frequency shall be varied at a rate

of 1 Hz/min between 10 Hz and 55 Hz, and return in no less than 90 min and no more

than 100 min. The test battery shall be tested in three mutually perpendicular directions.

If a test battery has only two axes of symmetry, it shall be tested in two directions

perpendicular to each axis.

The test shall be conducted with undischarged batteries and with fully discharged

batteries.

c) Requirements

See table 2.

———————

*

Figures in square brackets refer to the bibliography.

– 14 – 60086-4 © IEC:2000(E)

6.2.2.4 Mechanical test B-2 – Shock

a) Purpose

This test simulates crash conditions or rough handling during transportation. The test

condition is generally specified in UN (1995) [14] and others.

b) Test procedure

The test batteries shall be secured to the testing machine by means of a rigid mount which

will support all mounting surfaces of each test battery. Each test battery shall be subjected

to a total of three shocks of equal magnitude. The shocks shall be applied in each of

three mutually perpendicular axes. Each shock shall be applied in a direction normal to a

face of the test battery. For each shock, the test battery shall be accelerated in such

a manner that during the first three milliseconds the minimum average acceleration

is 75 g . The peak acceleration shall be between 125 g and 175 g .

n n n

The test shall be conducted with undischarged batteries and with fully discharged batteries.

The test shall be conducted using the batteries previously subjected to the vibration test.

c) Requirements

See table 2.

6.2.2.5 Environmental test C-1 – Thermal shock

a) Purpose

This test assesses battery seal integrity under conditions of rapid temperature changes.

b) Test procedure

Test batteries shall be stored for 48 h at a temperature of (75 ± 2) °C, followed by storage

for 6 h at a temperature of (–20 ± 2) °C, followed by storage for at least 24 h at ambient

temperature. The maximum time for transfer to each temperature shall be 5 min.

The test shall be conducted using the batteries previously subjected to the altitude

simulation test.

c) Requirements

See table 2.

6.2.2.6 Environmental test C-2 – High temperature

a) Purpose

This test simulates:

1) the condition wherein the overtemperature protection device does not operate properly

and;

2) exposure of a battery to high temperature for a long period.

b) Test procedure

Test batteries shall be stored for 5 h at a temperature of (100 ± 2) °C, followed by storage

for 8 h at (20 ± 2) °C. In a separate test, test batteries shall be stored for 30 days at a

temperature of (60 ± 2) °C, followed by storage for 8 h at (20 ± 2) °C.

c) Requirements

See table 2.

60086-4 © IEC:2000(E) – 15 –

6.2.2.7 Environmental test C-3 – Altitude

a) Purpose

This test simulates air transportation under low pressure conditions. The test condition is

generally specified in UN (1995) [14] and others.

b) Test procedure

Test batteries shall be stored at a pressure of 11,6 kPa or less for at least 6 h and at a

temperature of (20 ± 2) °C.

c) Requirements

See table 2.

6.3 Reasonably foreseeable misuse

6.3.1 Sampling, test sequence and requirements

Figure 3 gives an overview of the test sequence and samples to be taken for the tests

simulating reasonably foreseeable misuse while table 4 contains the requirements.

– 16 – 60086-4 © IEC:2000(E)

from 6.2.2.5 Thermal shock

Test batteries Additional batteries

Consumer Consumer

Low power High power Low power High power

from 6.2.2.4 Shock

a b a b

Single Multi Single Multi

40 60 55 5×(n -1) + 15 + 30×(n -1)

3 2

10×(n -1) 30×(n -1)

2 2

6.1.5 6.1.5

Predischarge Predischarge

discharge to the respective DOD discharge to the respective DOD

0 % 25 % 50 % 75 % 100 % 0 % 25 % 50 % 75 %

6.3.2.1

Short circuit

0,1 Ω; 55 °C

6.3.2.2 n = 3

min

5×(1+n -1)

Charge 1

Conditioning Storage

with resistor R 10 days; 60 °C 10 days; 20 °C

6.3.2.3

Charge 2

5×(1+3)

without resistor

6.3.2.4

Charge 3

with power supply 5

6.3.2.8

5 6.3.2.7 n = 2

min

Free fall

Overdischarge 3

6 × from 1 m

internal resistance

6.3.2.6 n = 2

min

6.3.2.9 5×(1+n -1)

Overdischarge 2

5×(1+n -1)

Crush

with resistor R

5×(1+n -1) 5

17 MPa 5

5×(1+n -1)

5×(1+n -1)

6.3.2.10

5 5×(1+n -1)

Thermal abuse

ramp to 130 °C 5 6.3.2.5 n = 2

min

5×(1+n2-1)

Overdischarge 1

5×(1+n -1)

with resistor R

6.3.1

All test batteries 60

Final inspection

75 per table 4

IEC 111/2000

NOTE 1 The line type indicates the battery class.

NOTE 2 n ≥ n = i is the total number of batteries, see 6.1.6.

i min

a, b

cell batteries.

Figure 3 – Sampling and sequence of tests simulating reasonably foreseeable misuse

Industrial

5×(1+n -1)

5×(1+n -1)

5×(1+n -1)

5×(1+ -1)

n

5×(1+n -1)

5×(1+n -1)

Industrial

60086-4 © IEC:2000(E) – 17 –

Table 4 – Reasonably foreseeable misuse tests and requirements

Requirements

Consumer batteries

Misuse

Test

simulation

Low power High power batteries

Industrial

batteries

batteries

Single cell Multicell

batteries batteries

Electrical tests D-1 External short NE, NF NE, NF NE, NF NE2, NF

circuit

D-2 Charge 1 NE, NF * * NE2, NF

D-3 Charge 2 * NE, NF * *

D-4 Charge 3 NE, NF NE, NF NE, NF NE2, NF

D-5 Overdischarge 1 NE, NF * * NE2, NF

D-6 Overdischarge 2 * NE, NF NE, NF *

D-7 Overdischarge 3 * NE, NF NE, NF *

Mechanical tests E-1 Free fall NV, NE, NF NV, NE, NF NV, NE, NF NE, NF

E-2 Crush NE, NF NE, NF NE, NF NE, NF

Environmental tests F-1 Climatic- NE2, NF NE2, NF NE2, NF NF

Thermal abuse

Additional requirements:

Distortion: Distortion shall be reported with the cause.

Venting: If electrolyte leaks from the vent area without vent operation, it shall be considered as leakage.

*: Not applicable.

NW: No weight loss (see 6.1.4).

ND: No distortion.

NL: No leakage.

NV: No venting.

NE: No explosion.

NE2: See 6.1.3.

NF: No fire.

– 18 – 60086-4 © IEC:2000(E)

6.3.2 Test procedures

6.3.2.1 Electrical test D-1 – External short circuit

a) Purpose

This misuse may occur during handling of batteries. Resistance value and temperature are

the same as those specified in UN (1995) [14] and others.

b) Test procedure

The test batteries shall be stabilized at (55 ± 2) °C and then subjected to a short-circuit

condition with a total external resistance of less than 0,1 Ω at (55 ± 2) °C. This short-

circuit condition is continued for at least 1 h after the battery case temperature has

returned to (55 ± 2) °C.

The test shall be conducted using the batteries previously subjected to the vibration test

and shock test, and, separately, using the batteries previously subjected to the altitude

simulation test and the thermal shock test (see figure 3).

c) Requirements

See table 4.

6.3.2.2 Electrical test D-2 – Charge 1

a) Purpose

This test simulates the condition when one battery in a set is reversed. It is based on UN

(1995) [14].

b) Test procedure

A test battery is connected in series with (n – 1) undischarged additional batteries of the

same type in such a way that the terminals of the test battery are connected in reverse.

The total number n of batteries shall be determined using the method given in 6.1.6

with n = 3.

min

A resistive load R is connected in series to the above assembly of batteries where R is

3 3

selected such that the average current draw is the same as the maximum discharge

current specified by the manufacturer.

The circuit shall be closed, charging the test battery. The test shall be continued until

the total voltage reaches 10 % of the original open circuit voltage or for 24 h, whichever

is longer.

The test shall be carried out at (20 ± 2) °C.

+ – – + – + – +

B B .B

Key

1 2 n

B Test battery

B . B Additional batteries

2 n

R

R Resistive load 3 IEC 112/2000

Figure 4 – Charge 1

c) Requirements

See table 4.

60086-4 © IEC:2000(E) – 19 –

6.3.2.3 Electrical test D-3 – Charge 2

a) Purpose

This test simulates the condition when one battery in a set is reversed.

b) Test procedure

A test battery is connected in series with three additional undischarged batteries of the

same type in such a way that the terminals of the test battery are connected in reverse.

The resistance of the interconnecting circuit shall be less than or equal to 0,1 Ω.

The test shall be carried out at (20 ± 2) °C for 24 h.

+ – – + – + – +

B B .B

1 2 4

IEC 113/2000

Key

B Test battery

B . B Additional batteries, undischarged

2 4

Figure 5 – Charge 2

c) Requirements

See table 4.

6.3.2.4 Electrical test D-4 – Charge 3

a) Purpose

This test simulates the condition when a battery is fitted within a device and is exposed to

a reverse voltage from an external power supply, for example memory backup equipment

with a defective diode (see 7.1.1). The test condition is based upon UL 1642 [13].

b) Test procedure

Each test battery shall be subjected to a charging current of three times the current I

c

specified by the battery manufacturer by connecting it in opposition to a d.c. power supply.

Unless the power supply allows for setting the current, the specified charging current

shall be obtained by connecting a resistor of the appropriate size and rating in series with

the battery.

The test duration shall be calculated using the formula:

t = 2,5 × C /(3 × I )

d n c

where

t is the test duration;

d

C is the nominal capacity;

n

I is the charging current specified by the manufacturer.

c

The test shall be carried out at (20 ± 2) °C.

c) Requirements

See table 4.

– 20 – 60086-4 © IEC:2000(E)

6.3.2.5 Electrical test D-5 – Overdischarge 1

a) Purpose

This test simulates the condition when one discharged battery is connected in series with

other undischarged batteries. The test condition is based upon UN (1995) [14].

b) Test procedure

Each test battery shall be predischarged to 50 % depth of discharge. It shall then be

connected in series with (n – 1) undischarged additional batteries of the same type.

The total number n of batteries shall be determined using the method given in 6.1.6

with n = 2.

min

A resistive load R is connected in series to the above assembly of batteries where R is

4 4

selected such that the average current draw is the same as the maximum discharge

current specified by the manufacturer.

The test shall be carried out until the total voltage reaches 10 % of the original open

circuit voltage or for 24 h, whichever is longer.

The test shall be carried out at (20 ± 2) °C.

The test shall be repeated with fully predischarged test batteries.

– + – + – +

B B .B

1 2 n

R

4 IEC 114/2000

Key

B Test battery, 50 % predischarged and, in a separate test, 100 % predischarged

B . B Additional batteries, undischarged

2 n

R Resistive load

Figure 6 – Overdischarge 1

c) Requirements

See table 4.

60086-4 © IEC:2000(E) – 21 –

6.3.2.6 Electrical test D-6 – Overdischarge 2

a) Purpose

This test simulates the condition when one discharged battery is connected in series with

other undischarged batteries. The test further simulates the use of batteries in motor

powered appliances where, in general, currents over 1 A are required.

b) Test procedure

The test battery shall be predischarged to 25 % depth of discharge. It shall then be

connected in series with (n – 1) undischarged additional batteries of the same type and a

resistive load R where n and R are taken from table 5.

5 2 5

Table 5 – Total number of batteries and resistive load R

n

2 5

Battery type Total number of batteries n Resistive load R

2 5

Ω

CR17345 4 8,20

CR-P2 2 8,20

2CR5 2 8,20

NOTE Table to be modified or expanded when additional batteries are

standardized.

The test shall be carried out at (20 ± 2) °C for 24 h.

The test shall be repeated twice, namely with test batteries predischarged to 50 % and

75 % depth of discharge.

– + – + – +

B B .B

1 2 n

R IEC 115/2000

Key

B Test battery, 25 % predischarged and, in separate tests, 50 % and 75 % predischarged.

B . B Additional batteries, undischarged

2 n

R Resistive load

Figure 7 – Overdischarge 2

c) Requirements

See table 4.

– 22 – 60086-4 © IEC:2000(E)

6.3.2.7 Electrical test D-7 – Overdischarge 3

a) Purpose

This test simulates the condition when a battery with abnormally high internal resistance is

connected in series with normal batteries.

b) Test procedure

The test battery shall be predischarged to 25 % depth of discharge. It shall then be stored

at (60 ± 2) °C for 10 days to increase the internal resistance. Additional batteries shall be

predischarged to the same depth of discharge. They shall be stored at ambient

temperature for 10 days. The preconditioned test battery shall be connected in series

with (n – 1) preconditioned additional batteries and a resistive load R where n and R

2 5 2 5

are taken from table 5.

The test shall be carried out at (20 ± 2) °C for 24 h.

The test shall be repeated twice, namely with test and additional batteries predischarged

to 50 % and 75 % depth of discharge.

– + – + – +

B B .B

1 2 n

R IEC 116/2000

Key

B Test battery, 25 % predischarged and preconditioned at (60 ± 2) °C for 10 days and, in separate

tests, 50 % and 75 % predischarged

B . B Additional batteries, 25 % predischarged and stored at (20 ± 2) °C for 10 days and, in separate

2 n

tests, 50 % and 75 % predischarged

R Resistive load

Figure 8 – Overdischarge 3

c) Requirements

See table 4.

6.3.2.8 Mechanical test E-1 – Free fall

a) Purpose

This test simulates the situation when a battery is accidentally dropped. The test condition

is based upon IEC 60068-2-32 [6].

b) Test procedure

Undischarged test batteries shall be dropped from a height of 1 m onto a concrete surface.

Each test battery shall be dropped six times, a prismatic battery once on each of its

six faces, a round battery twice in each of the three axes shown in figure 9. The test

batteries shall be stored for 1 h afterwards.

60086-4 © IEC:2000(E) – 23 –

The test shall be repeated with test batteries predischarged to 25 % depth of discharge.

z

x

y

IEC 117/2000

Figure 9 – Axes for free fall

c) Requirements

See table 4.

6.3.2.9 Mechanical test E-2 – Crush

a) Purpose

This test simulates the condition when a battery is exposed to forces encountered during

household waste disposal, e.g. trash compaction. The test conditions are the same as

those specified in UL 1642 [13].

b) Test procedure

A test battery shall be crushed between two flat surfaces. The force shall be applied by a

vice or by a hydraulic ram with a 32 mm diameter piston. The crushing shall be continued

until a pressure reading of 17 MPa is reached on the hydraulic ram, applied force

approximately 13 kN. Once the maximum pressure has been obtained the pressure shall

be released.

A cylindrical battery shall be crushed with its longitudinal axis parallel to the flat surfaces

of the crushing apparatus. A prismatic battery shall be crushed by applying the force in the

direction of one of the two axes perpendicular to its longitudinal axis, and, separately, by

applying the force in the direction of the other one of these two axes. A button/coin battery

shall be crushed by applying the force on its flat surfaces.

Each test battery shall only be crushed once.

c) Requirements

See table 4.

6.3.2.10 Environmental test F-1 – Thermal abuse

a) Purpose

This test simulates the condition when a battery is exposed to an extremely high

temperature.

b) Test procedure

A test battery shall be placed in an oven and the temperature raised at a rate of 5 °C/min

to a temperature of (130 ± 2) °C at which the battery shall remain for 10 min.

c) Requirements

See table 4.

– 24 – 60086-4 © IEC:2000(E)

7 Information for safety

7.1 Safety precautions during design of equipment

See also annex B for guidelines for designers of equipment using lithium batteries.

7.1.1 Charge protection

When incorporating a primary lithium battery into a memory back-up circuit, a blocking diode

and current limiting resistor or other protective devices shall be used to prevent the main

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...