IEC 62550:2017

(Main)Spare parts provisioning

Spare parts provisioning

IEC 62550:2017 describes requirements for spare parts provisioning as a part of supportability activities that affect dependability performance so that continuity of operation of products, equipment and systems for their intended application can be sustained. This document is intended for use by a wide range of suppliers, maintenance support organizations and users and can be applied to all items.

Approvisionnement en pièces de rechange

IEC 62550:2017 spécifie les exigences relatives à l’approvisionnement en pièces de rechange relevant des activités de supportabilité ayant une incidence sur les caractéristiques de sûreté de fonctionnement et permettant ainsi d’assurer la continuité du fonctionnement des produits, des matériels et des systèmes pour leur application prévue. Le présent document est destiné à être utilisé par un large éventail de fournisseurs, d’organisations de support logistique à la maintenance et d’utilisateurs et peut être appliqué à toutes les entités.

Mots clés : pièces de rechange nécessaires

General Information

- Status

- Published

- Publication Date

- 19-Jan-2017

- Technical Committee

- TC 56 - Dependability

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Jan-2017

- Completion Date

- 04-Feb-2017

Overview

IEC 62550:2017 is an international standard published by the International Electrotechnical Commission (IEC) addressing spare parts provisioning within supportability activities. The standard outlines requirements to ensure the continuity of operation for products, equipment, and systems by managing spare parts effectively. It focuses on sustaining dependability performance across various industries and applications.

This standard is designed for a broad audience including suppliers, maintenance support organizations, and users. Its principles and methods are applicable to all types of items requiring spare parts, making it a valuable resource for optimizing maintenance strategies and inventory management worldwide.

Key Topics

IEC 62550:2017 covers the entire spare parts provisioning lifecycle, emphasizing practical processes and decision-making tools to enhance operational readiness. Major areas include:

Spare Parts Identification and Classification

Describes types of spare parts and their roles within the system, integrating spare parts identification with the level of repair analysis (LORA).Demand Forecasting

Provides methods to predict spare parts requirements using consumption data, failure rates, and statistical techniques such as moving averages, exponential smoothing, and regression analysis.Quantification and Inventory Optimization

Details quantification procedures for both repairable and non-repairable items, including probabilistic models and ABC (Pareto) analysis to prioritize parts based on criticality and usage.Documentation

Highlights the importance of comprehensive spare parts documentation, including illustrated parts catalogues (IPC) and parts catalogues to facilitate effective identification and ordering.Supply Management

Covers supply chain considerations such as sourcing policies (insourcing, outsourcing, single sourcing, global sourcing), obsolescence management, and flow control of repairable spare parts to ensure availability.Measures of Effectiveness

Introduces performance metrics like fill rate, risk of shortage, expected backorders, mean waiting time, and system availability to evaluate spare parts provisioning effectiveness.

Applications

IEC 62550 provides practical guidance for organizations aiming to improve:

Maintenance Support Operations: Enables better planning and management of spare parts inventories ensuring timely repairs and minimal downtime.

Reliability and Availability Enhancement: Supports strategies that sustain operational readiness and reduce system unavailability due to spare parts shortages.

Inventory Cost Control: Helps balance cost and availability through optimized stocks and informed procurement strategies, reducing overstock while avoiding critical failures.

Supply Chain Management: Assists in selecting appropriate sourcing strategies worldwide and managing obsolescence risks effectively.

This standard is essential for industries with complex electrotechnical systems including manufacturing, energy, telecommunications, transportation, and other sectors where system dependability is critical.

Related Standards

While IEC 62550 focuses on spare parts provisioning, it aligns with other IEC and international standards involved in maintenance, reliability, and logistics, such as:

- IEC 60300 series – Dependability management and availability goals

- ISO 55000 series – Asset management standards covering lifecycle and supportability

- IEC 61508 – Functional safety standards in electrotechnical systems

- IEC 61092 – Electrical equipment for ships, for specific spare parts considerations

- ISO 9001 – Quality management systems applicable to supplier and maintenance practices

Adhering to IEC 62550 alongside these complementary standards enhances comprehensive maintenance planning and supports international best practices in spare parts and asset management.

Keywords: IEC 62550, spare parts provisioning, spare parts management, inventory optimization, demand forecasting, maintenance support, supply chain management, system availability, reliability engineering, IEC standards.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC 62550:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Spare parts provisioning". This standard covers: IEC 62550:2017 describes requirements for spare parts provisioning as a part of supportability activities that affect dependability performance so that continuity of operation of products, equipment and systems for their intended application can be sustained. This document is intended for use by a wide range of suppliers, maintenance support organizations and users and can be applied to all items.

IEC 62550:2017 describes requirements for spare parts provisioning as a part of supportability activities that affect dependability performance so that continuity of operation of products, equipment and systems for their intended application can be sustained. This document is intended for use by a wide range of suppliers, maintenance support organizations and users and can be applied to all items.

IEC 62550:2017 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 03.120.01 - Quality in general; 21.020 - Characteristics and design of machines, apparatus, equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62550:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62550 ®

Edition 1.0 2017-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Spare parts provisioning

Approvisionnement en pièces de rechange

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62550 ®

Edition 1.0 2017-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Spare parts provisioning

Approvisionnement en pièces de rechange

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 03.120.01; 21.020 ISBN 978-2-8322-3834-9

– 2 – IEC 62550:2017 © IEC 2017

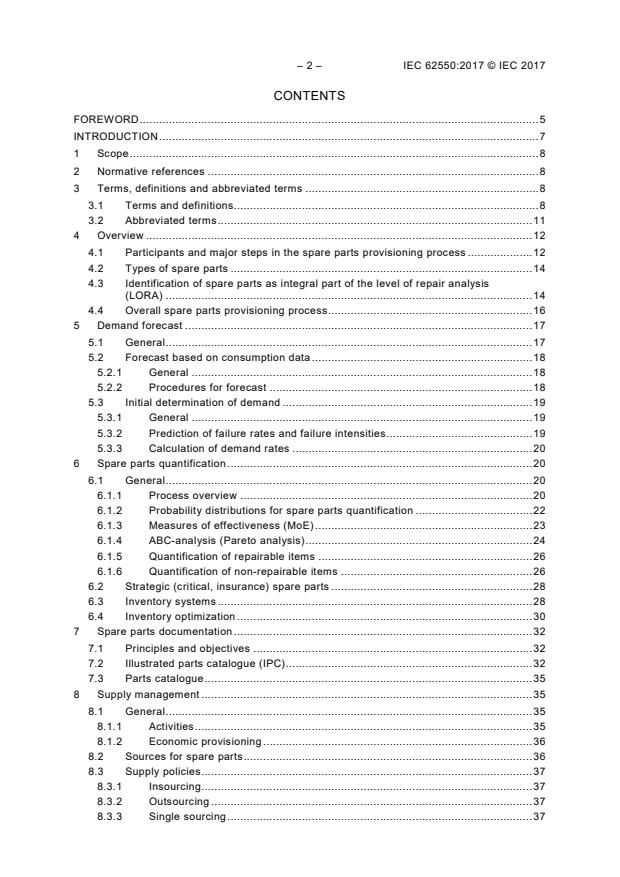

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviated terms . 8

3.1 Terms and definitions . 8

3.2 Abbreviated terms . 11

4 Overview . 12

4.1 Participants and major steps in the spare parts provisioning process . 12

4.2 Types of spare parts . 14

4.3 Identification of spare parts as integral part of the level of repair analysis

(LORA) . 14

4.4 Overall spare parts provisioning process . 16

5 Demand forecast . 17

5.1 General . 17

5.2 Forecast based on consumption data . 18

5.2.1 General . 18

5.2.2 Procedures for forecast . 18

5.3 Initial determination of demand . 19

5.3.1 General . 19

5.3.2 Prediction of failure rates and failure intensities . 19

5.3.3 Calculation of demand rates . 20

6 Spare parts quantification . 20

6.1 General . 20

6.1.1 Process overview . 20

6.1.2 Probability distributions for spare parts quantification . 22

6.1.3 Measures of effectiveness (MoE) . 23

6.1.4 ABC-analysis (Pareto analysis) . 24

6.1.5 Quantification of repairable items . 26

6.1.6 Quantification of non-repairable items . 26

6.2 Strategic (critical, insurance) spare parts . 28

6.3 Inventory systems . 28

6.4 Inventory optimization . 30

7 Spare parts documentation . 32

7.1 Principles and objectives . 32

7.2 Illustrated parts catalogue (IPC) . 32

7.3 Parts catalogue . 35

8 Supply management . 35

8.1 General . 35

8.1.1 Activities . 35

8.1.2 Economic provisioning . 36

8.2 Sources for spare parts . 36

8.3 Supply policies . 37

8.3.1 Insourcing . 37

8.3.2 Outsourcing . 37

8.3.3 Single sourcing . 37

8.3.4 Global sourcing . 38

8.3.5 Concurrent sourcing . 38

8.3.6 Obsolescence management . 39

8.4 Planning and control of the flow of repairable spare parts . 39

Annex A (informative) Prognosis of demand . 40

A.1 General . 40

A.2 Synthetic determining of demand . 40

A.3 Prognosis based on consumption data . 41

A.3.1 Overview . 41

A.3.2 Forecast on the basis of the moving average . 41

A.3.3 Forecast on the basis of the weighted moving average . 42

A.3.4 Forecast on the basis of exponential smoothing . 42

A.3.5 Forecast on the basis of regression analysis . 43

Annex B (informative) Measures of effectiveness . 44

B.1 General . 44

B.2 Stock-related measures of effectiveness . 44

B.2.1 Fill rate (FR) and risk of shortage (ROS) . 44

B.2.2 Expected backorders (EBO). 46

B.2.3 Mean waiting time (MWT) . 47

B.3 System-related measures of effectiveness . 48

B.3.1 Operational system availability (A ) . 48

op

B.3.2 Number of systems not operationally ready (NOR). 49

Annex C (informative) Example: Quantification of spare parts and optimization of

inventory stocks . 50

C.1 General . 50

C.2 Product breakdown structure . 50

C.3 Calculation of spare parts quantities and costs . 52

Bibliography . 54

Figure 1 – Participants and major steps in the spare parts provisioning process . 13

Figure 2 – Identification of spare parts . 16

Figure 3 – Spare parts provisioning process during design and development . 17

Figure 4 – Spare parts provisioning process during utilization . 21

Figure 5 – Principle of an ABC-analysis . 25

Figure 6 – Inventory control policies . 27

Figure 7 – Hierarchically structured inventory system . 28

Figure 8 – Single-product-single-inventory models . 30

Figure 9 – Idealized inventory model for non-repairable items . 31

Figure 10 – Supply management activities . 36

Figure A.1 – Procedures of demand forecast . 40

Figure B.1 – Diagram for the determination of the fill rate (FR) with a Poisson demand . 45

Figure B.2 – Diagram for the determination of the factor K for the required fill rate . 46

Figure B.3 – Inventory system with a backorder case . 46

Figure B.4 – Diagram for the determination of the mean waiting time (MWT) with a

Poisson demand . 48

Figure C.1 – Structure of the DCN . 50

– 4 – IEC 62550:2017 © IEC 2017

Figure C.2 – Inventory system for the DCN . 53

Table 1 – Responsibilities, targets, and measurements for suppliers, maintainers,

operator and users . 13

Table C.1 – First indenture level – Data communication network . 51

Table C.2 – Second indenture level – Communication system . 51

Table C.3 – Third indenture level – Power supply system . 51

Table C.4 – Third indenture level – Main processor . 51

Table C.5 – Third indenture level – Fan system . 52

Table C.6 – Investments in spare repairable items . 52

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SPARE PARTS PROVISIONING

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62550 has been prepared by IEC technical committee 56:

Dependability.

The text of this standard is based on the following documents:

FDIS Report on voting

56/1711/FDIS 56/1719/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – IEC 62550:2017 © IEC 2017

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

Spare parts provisioning is the process for planning necessary spare parts under

consideration of a customer's needs and requirements.

Proper planning and control of spare parts is a critical component of effective supportability. If

the right parts are not available when needed for routine maintenance or repairs, downtime is

prolonged. If too many spare parts are available, the enterprise absorbs excessive costs and

the overhead of carrying inventory.

Spare part planning and supply to achieve business objectives are based on four goals:

• the right spare part;

• in the right quantity;

• at the right time;

• at the right place.

Spare parts provisioning is a prerequisite for all types of maintenance tasks, such as

replacements and repairs. Spare parts for corrective maintenance tasks should be supplied at

random intervals for steady state availability. It may take three to four repairs before steady

state availability is reached. In this period repairs may be clustered, and the need can vary

significantly over time. For preventive and on-condition maintenance, fixed intervals or

approximately fixed intervals for replacement items may occur. Coordination of demand for

spare parts with supply of spare parts at the required time is an important factor. Unavailable

materials are one of the most cited reasons for delays in the completion of maintenance

tasks.

The availability of spare parts is one of the factors that impacts system downtime.

Methodologies such as integrated logistic support (ILS) and its subsidiary logistic support

analysis (LSA) provide necessary information for spare parts provisioning. This information

includes system breakdown, maintenance concept, and supply concept. Spare part

optimization will cover issues typically giving answers to questions such as:

• which spare parts should be stored within the maintenance organization or by a supplier?

• how many spare parts of each type should be stocked?

Spare part optimization is based on operations research methods and selected reliability

methods and may be analytical or use Monte Carlo simulations. The optimization process

aims at balancing the cost of holding spare parts against the probability and cost of spare part

shortage.

Before spare parts can be ordered, procedures for procurement, administration and storage of

required material should be specified. Additionally, a general supply concept should be

compiled and specified.

Correct material supply procedures will guarantee that spare parts are ordered in time and

delivered when requested. The procedures also include control of the repair of replacement

parts as well as the monitoring of repair turn-around times. All organizations involved, from

production to purchasing and storage, via maintenance, should have complete transparency

about material availability and possible completion of the task. The planned material costs in

the task should be compared with its consumption. These are then documented and form the

basis of usage-controlled materials planning. With this process, inventory of spare parts can

be optimized to meet availability requirements with minimum inventory levels.

This document is applicable to all industries where supportability has a major impact on the

dependability of the item through its life cycle.

– 8 – IEC 62550:2017 © IEC 2017

SPARE PARTS PROVISIONING

1 Scope

This document describes requirements for spare parts provisioning as a part of supportability

activities that affect dependability performance so that continuity of operation of products,

equipment and systems for their intended application can be sustained.

This document is intended for use by a wide range of suppliers, maintenance support

organizations and users and can be applied to all items.

2 Normative references

There are no normative references in this document.

3 Terms, definitions and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

NOTE Some terms listed in IEC 60050-192 are also included here for the convenience of the reader.

3.1 Terms and definitions

3.1.1

consumables

any item which is expendable, may be regularly replaced and generally is not product specific

EXAMPLE Oil, grease, nuts, bolts and screws, gaskets, etc.

Note 1 to entry: Generally consumable items are relatively low cost.

3.1.2

corrective maintenance

maintenance carried out after fault detection to effect restoration

Note 1 to entry: Corrective maintenance of software invariably involves some modification.

[SOURCE: IEC 60050-192:2015, 192-06-06]

3.1.3

failure

loss of ability to perform as required

Note 1 to entry: A failure of an item is an event that results in a fault state of that item: see fault

[IEC 60050-192:2015, 192-04-01].

Note 2 to entry: Qualifiers, such as catastrophic, critical, major, minor, marginal and insignificant, may be used to

categorize failures according to the severity of consequences, the choice and definitions of severity criteria

depending upon the field of application.

Note 3 to entry: Qualifiers, such as misuse, mishandling and weakness, may be used to categorize failures

according to the cause of failure.

[SOURCE: IEC 60050-192:2015, 192-03-01]

3.1.4

indenture level

level of sub-division within a system hierarchy

EXAMPLE System, subsystem, assembly, and component.

Note 1 to entry: From the maintenance perspective, the indenture level depends upon various factors, including

the complexity of the item's construction, the accessibility of sub items, skill level of maintenance personnel, test

equipment facilities, and safety considerations.

[SOURCE: IEC 60050-192:2015, 192-01-05]

3.1.5

integrated logistic support

ILS

management process to determine and co-ordinate the provision of all materials

and resources required to meet the needs for operation and maintenance

[SOURCE: IEC 60050-192:2015, 192-01-30]

3.1.6

item

subject being considered

Note 1 to entry: The item may be an individual part, component, device, functional unit, equipment, subsystem, or

system.

Note 2 to entry: The item may consist of hardware, software, people or any combination thereof.

[SOURCE: IEC 60050-192:2015, 192-01-01, modified — omission of internal references and

Notes 3, 4 and 5]

3.1.7

level of maintenance

maintenance level

set of maintenance actions to be carried out at a specified indenture level

[SOURCE: IEC 60050-192:2015, 192-06-04]

3.1.8

line replaceable item

LRI

replaceable hardware or software unit which can be replaced directly on the equipment by the

user or by a maintenance support facility

Note 1 to entry: In some projects instead of LRI the term line replaceable unit (LRU) is applied.

3.1.9

maintenance

combination of all technical and management actions intended to retain an item in, or restore

it to, a state in which it can perform as required

Note 1 to entry: Management is assumed to include supervision activities.

[SOURCE: IEC 60050-192:2015, 192-06-01]

– 10 – IEC 62550:2017 © IEC 2017

3.1.10

maintenance policy

maintenance concept

definition of the maintenance objectives, line of maintenance, indenture levels, maintenance

levels, maintenance support, and their interrelationships

Note 1 to entry: The maintenance policy provides the basis for maintenance planning, determining supportability

requirements, and developing logistic support.

[SOURCE: IEC 60050-192:2015, 192-06-02]

3.1.11

line of maintenance

maintenance echelon

position in an organization where specified levels of maintenance are to be carried out

EXAMPLE 1st line – field; 2nd line – repair shop; and 3rd line – manufacturer's facility.

Note 1 to entry: The line of maintenance is characterized by the level of skill of the personnel, the facilities

available, the location, etc.

[SOURCE: IEC 60050-192:2015, 192-06-03]

3.1.12

maintenance support

provision of resources to maintain an item

Note 1 to entry: Resources include human resources, support equipment, materials and spare parts, maintenance

facilities, documentation and information, and maintenance information systems.

[SOURCE: IEC 60050-192:2015, 192-01-28]

3.1.13

maintenance action

maintenance task

sequence of elementary maintenance activities

EXAMPLE Fault localization, fault diagnosis, repair and function checkout.

[SOURCE: IEC 60050-192:2015, 192-06-11]

3.1.14

non-repairable item

item that cannot, under given conditions, after a failure, be returned to a state in which it can

perform as required

Note 1 to entry: The “given conditions” may include technical, economic and other considerations.

Note 2 to entry: An item that is non-repairable under some conditions may be repairable under other conditions.

[SOURCE: IEC 60050-192:2015, 192-01-12]

3.1.15

obsolescence

transition from availability from the original manufacturer to unavailability or a permanent

transition from operability to non-functionality due to external reasons

3.1.16

preventive maintenance

preventative maintenance

maintenance carried out to mitigate degradation and reduce the probability of failure

[SOURCE: IEC 60050-192:2015, 192-06-05, modified — deletion of Note1 to entry]

3.1.17

repairable item

item that can, under given conditions, after a failure, be returned to a state in which it can

perform as required

Note 1 to entry: The “given conditions” may include technical, economic and other considerations.

Note 2 to entry: An item that is repairable under some conditions may be non-repairable under other conditions.

[SOURCE: IEC 60050-192:2015, 192-01-11]

3.1.18

spare part

component or part, either non-repairable or repairable, from the associated bill of material

used to maintain or repair machinery or equipment

3.1.19

stock position

any location where a spare part is foreseen to be inventoried

Note 1 to entry: The terms stock and inventory are generally interchangeable.

3.1.20

supportability

ability to be supported to sustain the required availability with a defined

operational profile and given logistic and maintenance resources

Note 1 to entry: Supportability of an item results from the inherent maintainability, combined with factors external

to the item that affect the relative ease of providing the required maintenance and logistic support.

[SOURCE: IEC 60050-192:2015, 192-01-31, modified — omission of internal reference]

3.1.21

system

set of interrelated items that collectively fulfil a requirement

Note 1 to entry: A system is considered to have a defined real or abstract boundary.

Note 2 to entry: External resources (from outside the system boundary) may be required for the system to

operate.

Note 3 to entry: A system structure may be hierarchical, e.g. system, subsystem, component, etc.

Note 4 to entry: Conditions of use and maintenance should be expressed or implied within the requirement.

[SOURCE: IEC 60050-192:2015, 192-01-03]

3.2 Abbreviated terms

BOM Bill of material

CS Communication system

DCN Data communication network

DTN Data transport network

EBO Expected backorders

FR Fill rate

ILS Integrated logistic support

IP Initial provisioning

– 12 – IEC 62550:2017 © IEC 2017

IPC Illustrated parts catalogue

IPD Initial provisioning data

LORA Level of repair analysis

LRI/LRU Line replaceable item/Line replaceable unit

MAD Mean administrative delay

MoE Measures of effectiveness

MDT Mean down time

MLD Mean logistic delay

MRT Mean repair time

MTBF Mean operating time between failures

MTBR Mean time between replacements

MTD Mean technical delay

MTTF Mean time to failure

MTTR Mean time to restoration

MWT Mean waiting time

NFF No fault found

NI Not illustrated

NOR Not operationally ready

OEM Original equipment manufacturer

QPNHA Quantity per next higher assembly

ROS Risk of shortage

TAT Turn-around time

TT Transportation time

4 Overview

4.1 Participants and major steps in the spare parts provisioning process

Items, which are foreseen to be replaced during maintenance actions are defined as spare

parts. The storage of spare parts is part of a comprehensive material provisioning process

which ensures that the required spare parts for maintenance are provided in the necessary

quantity, at the appropriate point in time and in the right place.

This document is applicable to items, which include all types of products, equipment and

systems (hardware and associated software). Most of these require a certain level of

maintenance to ensure that their required functionality, dependability, capability, and

economic, safety and regulatory requirements are achieved.

The availability of a supported system is influenced by the overall effectiveness of

maintenance. Thus, the availability of a system can be regarded as the general objective for

spare parts provisioning. The potential impact of obsolescence should also be considered as

an influencing factor (see IEC 62402).

The operator of an item has to offer a high level of service and performance. The

maintenance organization is responsible for the effectiveness, elapsed time, and cost of the

maintenance activities. An overview of specific responsibilities and targets as well as the

major steps in the spare parts provisioning process are shown in Figure 1.

Supplier (contractor) Maintenance organization

Spare parts

Customer Operator

provisioning

Main tasks and objectives

of spare parts provisioning

Demand forecast Quantification and Spare parts Supply management

optimization documentation

Responsibilities

and targets

IEC

Figure 1 – Participants and major steps in the spare parts provisioning process

For satisfying the demand of spare parts, the following considerations have to be made:

• which spare parts are required;

• how many spare parts should be stocked;

• where should the spare parts be stored;

• when should the spare parts be ordered or reordered;

• what is the most economical solution for all participants.

In Table 1, responsibilities, targets and measurements for the different participants are shown

as an example.

Table 1 – Responsibilities, targets, and measurements

for suppliers, maintainers, operator and users

Supplier of spare parts Maintenance organization Operator/user

Responsibility appropriate spare parts

high availability of maintained high operational availability

availability items

quality of delivered items high maintenance service

quality of supply service

Target profit with supply of spare ensure that the system is operator: operational profit and

parts successfully restored availability

certification of items (if profit of the maintenance user: high service performance

required) organization

Measurements service level system down times system availability

lead time maintenance cost quality of service

repair quality

– 14 – IEC 62550:2017 © IEC 2017

4.2 Types of spare parts

For most maintenance tasks, materials and spare parts are required. When a component fails,

it is replaced by a new or repaired component. The time of the replacement depends on the

maintenance concept. If the failed item is repairable, it can be repaired off-line or in situ. The

repair-by-replacement policy requires that new or ready-for-use spare parts are quickly

available at the moment that failures occur.

During maintenance, some materials, referred to as consumables, are consumed or replaced

and are not able to be re-used. Other items are called spare parts and are distinguished as

• repairable items, or

• non-repairable items.

Ideally, repairable items can be repaired in each case. In some instances, such as when the

repair is not economic or not technically possible, or where the reliability of the item has been

degraded by the number of repair actions undertaken, they are condemned and replaced by a

new item.

In many projects, especially for large systems, repairable items can represent a significant

proportion of the initial investment in spare parts. With regard to products such as household

equipment, entertainment equipment or even cars, repairable items represent a smaller

portion.

Non-repairable items are ones that are not able to be repaired due to technical factors or are

not worthwhile to be repaired due to economical reasons. They are then condemned and

replaced by a new item. The quantity of non-repairable items is determined similarly to the

repairable items by the demand rate and the time until a new part is made available. This time

comprises the procurement lead time, administrative delay times, and transport times.

Non-repairable items are consumed during maintenance. The initial investment in those items

compared to repairable items is small, but the yearly cost for replenishment may be

considerable.

In addition to repairable and non-repairable items, consumables have to be provided, such as

nuts, bolts, washers, lubricants. When applicable, consumables are mentioned, but it is not

the intention of this document to address consumables in detail.

4.3 Identification of spare parts as integral part of the level of repair analysis (LORA)

LORA is a specific trade-off study that is used to identify the optimum maintenance level or

location for a repair to be undertaken. LORA will also identify the lowest repairable item such

as a bearing or motor, or a complete motor generator, which relates to the combination of

spares cost plus labour cost times task frequency versus opportunity costs that provides the

best return on investment for the organization. It may be used for design optimization or as

part of a support system assessment.

During the design stages, LORA addresses a number of scenarios, which may include the

following:

a) The maintenance methodology, such as to:

– replace and dispose;

– repair in situ;

– replace and repair externally.

b) The indenture level for removal such as to:

– remove the item as part of a sub-assembly, and replace and repair at the current

maintenance echelon level;

– remove the item as part of a sub-assembly, and replace and repair at a higher

maintenance echelon level;

– remove and replace the item with repair at the current echelon level;

– remove and replace the item with repair at a higher echelon level.

c) The echelon, such as:

– during operational use;

– in the field with the system non-operational;

– at a repair shop (may be multi-echelon);

– at the manufacturer’s site.

LORA also has to operate within a number of constraints such as:

• the maintenance concept which may pre-determine the maintenance echelons and their

capability of repair;

• criticality of the items;

• user policy and constraints;

• safety criteria;

• proprietary aspects;

• customer requirements;

• economic aspects.

The types of spare parts that are needed are defined during the development of the

maintenance concept and it is part of the LORA process and/or the establishment of the

required supportability.

The principles of spare parts identification are illustrated in Figure 2.

– 16 – IEC 62550:2017 © IEC 2017

Failure causes Removability Accessibility Fault localisation

such as: • welded • easy • possible

• loss • glued • more difficult • partly possible

• deflection

• riveted • difficult • not possible

• leakage

• screwed

• torsion

• pressed

• compression

• wear and tear

• vibration

• temperature

• corrosion

• mishandling

Spare part

selection

No

Next higher

Spare part?

assembly

Yes

Economics Maintainability Maintenance concept

• repair cost versus • repairable • concept exists

acquisition cost • non-repairable • not yet determined

Repairable

spare part type?

No

Yes

Repairable Non-repairable

IEC

Figure 2 – Identification of spare parts

All spare parts, consumable items, special supplies and related inventories needed to support

corrective and preventive maintenance tasks are elements of supportability. The quantity of

spare parts to be supplied and stocked should be determined for each maintenance echelon

(see Clause 6).

The vast majority of spare part (and consumable) quantities for scheduled preventive tasks

may be derived deterministically as the requirements for each task are known in advance.

However, some tasks, which include a condition monitoring element will require parts to

replace items identified as failed or failing. Such parts may be required as part of the task

which identified the need or later as part of a scheduled corrective task. In either case, the

quantification of spare parts required can be performed in the same manner as that for any

corrective task.

4.4 Overall spare parts provisioning process

The overall spare parts provisioning process can start when the maintenance concept has

been elaborated as described in the previous subclause and when a supply concept is

available. Both the maintenance and supply concept may be adjusted during the spare parts

provisioning process.

In Figure 3, the major steps in the spare parts provisioning process are shown.

Supply concept

Maintenance concept

Start

Yes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...