IEC 62321-2:2013

(Main)Determination of certain substances in electrotechnical products - Part 2: Disassembly, disjointment and mechanical sample preparation

Determination of certain substances in electrotechnical products - Part 2: Disassembly, disjointment and mechanical sample preparation

IEC 62321-2:2013 provides strategies of sampling along with the mechanical preparation of samples from electrotechnical products, electronic assemblies and electronic components. These samples can be used for analytical testing to determine the levels of certain substances as described in the test methods in other parts of IEC 62321. Restrictions for substances will vary between geographic regions and from time to time. This Standard describes a generic process for obtaining and preparing samples prior to the determination of any substance which are under concern.

IEC 62321-2:2013 has the status of a horizontal standard in accordance with IEC Guide 108.

Détermination de certaines substances dans les produits électrotechniques - Partie 2: Démontage, désassemblage et préparation mécanique de l'échantillon

L'IEC 62321-2:2013 fournit des stratégies d'échantillonnage ainsi que la préparation mécanique d'échantillons de produits électrotechniques, ensembles électroniques et composants électroniques. Ces échantillons peuvent être utilisés pour un essai analytique visant à déterminer les niveaux de certaines substances, comme décrit dans les méthodes d'essai des autres parties de l'IEC 62321. Les restrictions concernant les substances varient selon les régions géographiques et de temps à autres. La présente norme décrit un processus général permettant d'obtenir et de préparer des échantillons avant de déterminer toute substance posant problème.

L'IEC 62321-2:2013 a le statut de norme horizontale conformément au Guide IEC 108.

General Information

- Status

- Published

- Publication Date

- 24-Jun-2013

- Technical Committee

- TC 111 - Environmental standardization for electrical and electronic products and systems

- Drafting Committee

- WG 3 - TC 111/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 30-Aug-2021

- Completion Date

- 30-Aug-2019

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62321-2:2013, titled Determination of certain substances in electrotechnical products - Part 2: Disassembly, disjointment and mechanical sample preparation, is an international standard published by the International Electrotechnical Commission (IEC). This standard provides comprehensive guidelines and strategies for the sampling and mechanical preparation of electrotechnical products, electronic assemblies, and components prior to analytical testing for restricted substances.

As a horizontal standard aligned with IEC Guide 108, IEC 62321-2:2013 lays out a generic, methodical process to ensure representative sampling from complex electronic products. This preparation is crucial for accurate determination of regulated hazardous substances as per other parts of the IEC 62321 series.

Key Topics

Sampling Strategies: The standard covers various approaches to sampling, including complete product sampling, partial and complete disassembly, and partial and complete disjointment of components. It addresses challenges related to the complexity and heterogeneity of electrotechnical products.

Mechanical Sample Preparation: Detailed methods are provided for manual cutting, coarse and fine grinding or milling, homogenizing, and very fine grinding of polymers and organic materials. These procedures ensure sample uniformity and representativeness for subsequent chemical analysis.

Considerations for Sampling: IEC 62321-2 emphasizes factors such as sample size relative to detection limits, composite testing of disjointable samples, and managing non-uniform "homogeneous materials." It also discusses how to determine sampling positions within materials for the best accuracy.

Quality Assurance and Equipment: The standard outlines necessary apparatus, equipment, and materials to uphold quality and reproducibility in sample preparation.

Examples and Tool Guidance: Informative annexes include disassembly and sampling procedures for common devices like mobile phones, specialized tools used in sampling, and probabilistic assessments regarding the presence of certain substances.

Applications

IEC 62321-2:2013 is indispensable for stakeholders involved in environmental compliance, product safety, and materials testing within the electrotechnical industry. Key applications include:

Regulatory Compliance Testing: Assisting manufacturers, test laboratories, and regulatory bodies in preparing samples that accurately reflect the presence of restricted substances such as lead, mercury, cadmium, hexavalent chromium, and certain brominated flame retardants.

Environmental Risk Management: Supporting efforts to minimize hazardous substances in electrical and electronic equipment by enabling reliable analytical testing.

Product Development and Quality Control: Providing clear guidance on sample handling and preparation to monitor compliance throughout product lifecycle stages.

Global Market Access: Helping businesses meet ever-evolving substance restrictions across geographic regions by facilitating consistent and replicable testing methods.

Related Standards

IEC 62321-2:2013 forms part of the broader IEC 62321 series, which addresses the Determination of certain substances in electrotechnical products. Related parts include:

IEC 62321-1: Overview and general requirements for chemical analysis.

IEC 62321-3-x: Specific test methods such as for lead, mercury, cadmium, and hexavalent chromium determination.

IEC 62321-4 to IEC 62321-7: Additional analytical techniques for brominated flame retardants, phthalates, and other substances.

This cohesive standardization framework ensures harmonized approaches in sample preparation, testing, and reporting of restricted substances in electrical and electronic products.

By following IEC 62321-2:2013, organizations can achieve reliable, representative sampling and sample preparation to support accurate and consistent testing for substances of concern in compliance with international environmental standards.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

Sponsored listings

Frequently Asked Questions

IEC 62321-2:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Determination of certain substances in electrotechnical products - Part 2: Disassembly, disjointment and mechanical sample preparation". This standard covers: IEC 62321-2:2013 provides strategies of sampling along with the mechanical preparation of samples from electrotechnical products, electronic assemblies and electronic components. These samples can be used for analytical testing to determine the levels of certain substances as described in the test methods in other parts of IEC 62321. Restrictions for substances will vary between geographic regions and from time to time. This Standard describes a generic process for obtaining and preparing samples prior to the determination of any substance which are under concern. IEC 62321-2:2013 has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-2:2013 provides strategies of sampling along with the mechanical preparation of samples from electrotechnical products, electronic assemblies and electronic components. These samples can be used for analytical testing to determine the levels of certain substances as described in the test methods in other parts of IEC 62321. Restrictions for substances will vary between geographic regions and from time to time. This Standard describes a generic process for obtaining and preparing samples prior to the determination of any substance which are under concern. IEC 62321-2:2013 has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-2:2013 is classified under the following ICS (International Classification for Standards) categories: 13.020.01 - Environment and environmental protection in general; 43.040.10 - Electrical and electronic equipment; 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62321-2:2013 has the following relationships with other standards: It is inter standard links to IEC PAS 62596:2009, IEC 62321-2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62321-2:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62321-2 ®

Edition 1.0 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 2: Disassembly, disjointment and mechanical sample preparation

Détermination de certaines substances dans les produits électrotechniques –

Partie 2: Démontage, désassemblage et préparation mécanique de l'échantillon

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62321-2 ®

Edition 1.0 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 2: Disassembly, disjointment and mechanical sample preparation

Détermination de certaines substances dans les produits électrotechniques –

Partie 2: Démontage, désassemblage et préparation mécanique de l'échantillon

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.020; 43.040.10 ISBN 978-2-83220-837-3

– 2 – 62321-2 © IEC:2013

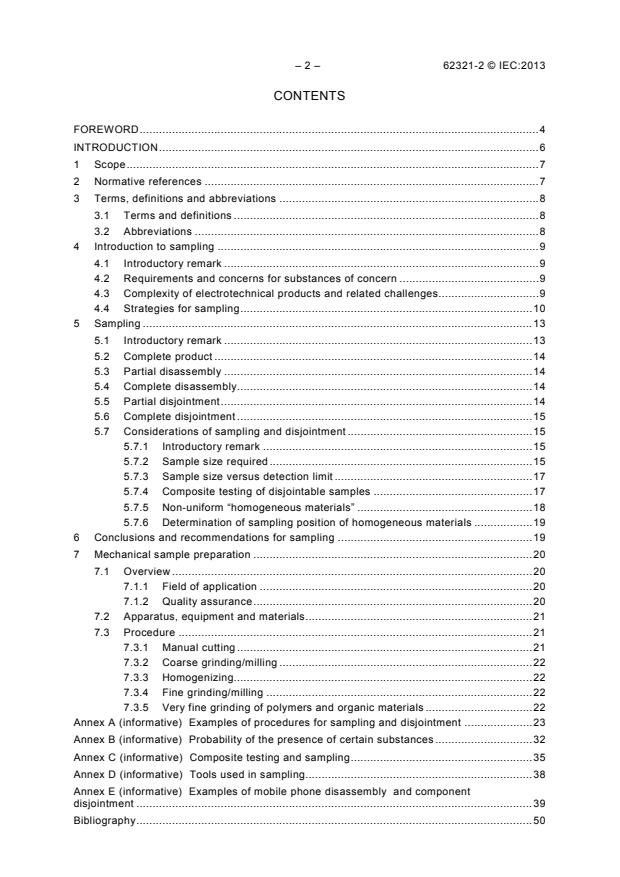

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviations . 8

3.1 Terms and definitions . 8

3.2 Abbreviations . 8

4 Introduction to sampling . 9

4.1 Introductory remark . 9

4.2 Requirements and concerns for substances of concern . 9

4.3 Complexity of electrotechnical products and related challenges. 9

4.4 Strategies for sampling . 10

5 Sampling . 13

5.1 Introductory remark . 13

5.2 Complete product . 14

5.3 Partial disassembly . 14

5.4 Complete disassembly . 14

5.5 Partial disjointment . 14

5.6 Complete disjointment . 15

5.7 Considerations of sampling and disjointment . 15

5.7.1 Introductory remark . 15

5.7.2 Sample size required . 15

5.7.3 Sample size versus detection limit . 17

5.7.4 Composite testing of disjointable samples . 17

5.7.5 Non-uniform “homogeneous materials” . 18

5.7.6 Determination of sampling position of homogeneous materials . 19

6 Conclusions and recommendations for sampling . 19

7 Mechanical sample preparation . 20

7.1 Overview . 20

7.1.1 Field of application . 20

7.1.2 Quality assurance . 20

7.2 Apparatus, equipment and materials. 21

7.3 Procedure . 21

7.3.1 Manual cutting . 21

7.3.2 Coarse grinding/milling . 22

7.3.3 Homogenizing. 22

7.3.4 Fine grinding/milling . 22

7.3.5 Very fine grinding of polymers and organic materials . 22

Annex A (informative) Examples of procedures for sampling and disjointment . 23

Annex B (informative) Probability of the presence of certain substances . 32

Annex C (informative) Composite testing and sampling . 35

Annex D (informative) Tools used in sampling. 38

Annex E (informative) Examples of mobile phone disassembly and component

disjointment . 39

Bibliography . 50

62321-2 © IEC:2013 – 3 –

Figure 1 – Generic iterative procedure for sampling . 11

Figure 2 – Cross-section of a 900 µm wide lead oxide-based resistor (SMD) . 19

Figure A.1 – Methodology for sampling and disjointment . 24

Figure A.2 – Sampling of DVD player . 25

Figure A.3 – Sampling of CRT . 26

Figure A.4 – Sampling of LCD TV . 27

Figure A.5 – Sampling of PDA/phone . 28

Figure A.6 – Sampling of desk fan . 29

Figure A.7 – Sampling of components – Thick film resistor . 30

Figure A.8 – Sampling of components – SMD potentiometer . 31

Figure D.1 – Hot gas gun for removing the electronic components . 38

Figure D.2 – Vacuum pin to remove the target electronic devices . 38

Figure E.1 – Mobile phone type A with battery charger and camera lens cap . 39

Figure E.2 – Mobile phone type A with battery and back cover removed . 40

Figure E.3 – Partial disassembly of a mobile phone (type B) into its major components . 41

Figure E.4 – Complete disassembly of the key pad . 42

Figure E.5 – Complete disassembly of the bottom housing . 42

Figure E.6 – Complete disassembly of the other housing/frame . 43

Figure E.7 – Components of the TFT display of the mobile phoneafter partial

disjointment . 43

Figure E.8 – Components of the main PWB of the mobile phone after partial

disjointment . 44

Figure E.9 – Disjointment of lead frame component . 46

Figure E.10 – BGA package prior to disjointment . 47

Figure E.11 – BGA package disjointed by the hand removal procedure . 47

Figure E.12 – Solder ball material collected from BGA using a hand removal procedure . 48

Figure E.13 – BGA solder ball removal using the ball shear procedure . 48

Table 1 – Minimum number of lead frame samples required for analytical testing . 16

Table 2 – Levels of a certain substance in a composite sample . 18

Table B.1 – Probability of the presence of certain substances in materials and

components used in electrotechnical products (1 of 3) . 32

Table C.1 – Calculated maximum concentration for a composite sample based on

detection limit . 36

Table C.2 – Required detection limit for a composite sample based on the maximum

allowable concentration . 37

Table E.1 – Possible certain substances or screening substances from a mobile phone . 40

Table E.2 – Possible certain substances in major components of the mobile phone . 41

Table E.3 – Examples of disjointment for typical small electronic components . 45

– 4 – 62321-2 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 2: Disassembly, disjointment and mechanical sample preparation

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62321-2 has been prepared by IEC technical committee 111:

Environmental standardization for electrical and electronic products and systems.

It has the status of a horizontal standard in accordance with IEC Guide 108.

The first edition of IEC 62321:2008 was a 'stand-alone' standard that included an introduction,

an overview of test methods, a mechanical sample preparation as well as various test method

clauses.

This first edition of IEC 62321-2 is a partial replacement of IEC 62321:2008, forming a

structural revision and generally replacing Clause 5 and incorporating IEC/PAS 62596:2009

[1] which will be withdrawn upon publication of IEC 62321-2.

___________

Numbers in square brackets refer to the Bibliography.

62321-2 © IEC:2013 – 5 –

Future parts in the IEC 62321 series will gradually replace the corresponding clauses in

IEC 62321:2008. Until such time as all parts are published, however, IEC 62321:2008 remains

valid for those clauses not yet re-published as a separate part.

The text of this standard is based on the following documents:

FDIS Report on voting

111/301/FDIS 111/311/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62321 series can be found on the IEC website under the general

title: Determination of certain substances in electrotechnical products

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62321-2 © IEC:2013

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries this has resulted in the adaptation of regulations

affecting wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd) and polybrominated diphenyl

ethers (PBDEs)) in electrotechnical products, is a source of concern in current and proposed

regional legislation.

The purpose of the IEC 62321 series is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

WARNING – Persons using this International Standard should be familiar with normal

laboratory practice. This standard does not purport to address all of the safety

problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national

regulatory conditions.

62321-2 © IEC:2013 – 7 –

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 2: Disassembly, disjointment and mechanical sample preparation

1 Scope

This part of IEC 62321 provides strategies of sampling along with the mechanical preparation

of samples from electrotechnical products, electronic assemblies and electronic components.

These samples can be used for analytical testing to determine the levels of certain

substances as described in the test methods in other parts of IEC 62321. Restrictions for

substances will vary between geographic regions and from time to time. This Standard

describes a generic process for obtaining and preparing samples prior to the determination of

any substance which are under concern.

This standard does not provide:

– full guidance on each and every product that could be classified as electrotechnical

equipment. Since there is a huge variety of electrotechnical components, with various

structures and processes, along with the continuous innovations in the industry, it is

unrealistic to attempt to provide procedures for the disjointment of every type of

component;

– guidance regarding other routes to gather additional information on certain substances in

a product, although the information collected has relevance to the sampling strategies in

this standard;

– safe disassembly and mechanical disjointment instructions related to electrotechnical

products (e.g. mercury-containing switches) and the recycling industry (e.g. how to handle

CRTs or the safe removal of batteries). See IEC 62554 [2] for the disjointment and

mechanial sample preparation of mercury-containing fluorescent lamps;

– the definition of a “unit” as the sample;

– sampling procedures for packaging and packaging materials;

– analytical procedures to measure the levels of certain substances. This is covered by

other standards (for example other parts of IEC 62321), which are referred to as the "test

standard" in this standard;

– guidelines for assessment of compliance.

NOTE Further guidance on assessment procedures is provided by IEC/TR 62476 [3].

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1, Determination of certain substances in electrotechnical products – Part 1

Introduction and overview

IEC 62321-3-1, Determination of certain substances in electrotechnical products – Part 3-1:

Screening – Lead, mercury, cadmium, total chromium and total bromine using X-ray

fluorescence spectrometry

– 8 – 62321-2 © IEC:2013

IEC 62321-3-2, Determination of certain substances in electrotechnical products – Part 3-2:

Screening – Total bromine in polymers and electronics by combustion – Ion chromatography

(C-IC)

IEC 62321-4, Determination of certain substances in electrotechnical products – Part 4:

Determination of mercury in polymers, metals and electronics by CV-AAS, CV-AFS, ICP-OES

and ICP-MS

IEC 62321-5, Determination of certain substances in electrotechnical products – Part 5:

Determination of cadmium, lead and chromium in polymers and electronics and cadmium and

lead in metals by AAS, AFS, ICP-OES, ICP-AES and ICP-MS

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the definitions given in IEC 62321-1, as well as the

following, apply.

3.1.1

composite testing

testing two or more materials as a single sample that could be mechanically disjointed if

necessary

3.1.2

certain substance

cadmium, lead, mercury, hexavalent chromium, polybrominated biphenyl, polybrominated

diphenyl ether

NOTE IEC 62321-1 includes test methods for the evaluation of each of the substances identified in the definition

above.

3.2 Abbreviations

AC Alternating current

BGA Ball grid array (electronic component)

CRT Cathode ray tube (television)

DVD Digital versatile disc

IC Integrated circuit

JEDEC Joint Electronic Devices Engineering Council

LCD Liquid crystal display

MDL Method detection limit

OEM Original equipment manufacturer

PAS Publicly Available Specification

PCB Printed circuit board

PDA Personal digital assistant

PWB Printed wiring board

SIM Subscriber identity module

SMD Surface mounted device

TFT Thin film transistor

TV Television

___________

62321-2 © IEC:2013 – 9 –

USB Universal serial bus

4 Introduction to sampling

4.1 Introductory remark

Obtaining a sample (i.e. sampling) is the first step in analysing electrotechnical products for

the presence of certain substances. The strategy and process of sampling are often as

important as the analytical measurement itself. Hence an effective sampling strategy requires

a clear understanding of the electrotechnical product, reasons for the analysis and the

requirements that are to be met.

Sampling and testing for certain substances are performed for many reasons including:

– business-to-business for commercial release (e.g. contractual agreement between the

OEM and component manufacturer);

– compliance with regulatory limits;

– forensic/impact assessment (why the product does not satisfy contractual or legal

requirements, when did this happen, and how many products are affected?)

4.2 Requirements and concerns for substances of concern

While many governments, industry partners and other stakeholders have their own

requirements, it is not the intention of this standard to discuss fully all of these differences.

However, awareness of different limits for certain substances is an important step in preparing

the sampling strategy. Subclause 4.2 highlights the main areas of concern regarding the

requirements for certain substances.

– Certain substances: not all geographic regions or industrial partners restrict the same

substances. For example, some regions have chosen to restrict the use of only a few

specific PBDE compounds, while others have a broader restriction regarding this class of

flame-retardants. When sampling a product, component etc. it is critical to keep in mind

what are the applicable legal requirements.

– Allowable limits for certain substances: generally speaking, the allowable levels of most

certain substances are below 1 000 mg/kg. Some geographic regions and industrial

partners have limits below 1 000 mg/kg. For some product types, limits for certain

substances are above 1 000 mg/kg, e.g. lead in copper and aluminum alloys.

– Application of the allowable level: the manner in which the allowable level of a certain

substance is applied to an electrotechnical product determines the sampling strategy and

how the test results are interpreted. Many geographic regions apply their allowable limits

to "homogeneous materials". In this standard, an “homogeneous material” is as defined in

IEC 62542 [4]. However, the interpretation of "homogeneous material" is not consistent

across the different regions.

– Applicable exemptions: some types of electrotechnical products are exempt from certain

substances requirements. These exemptions may be based on different rationales

including the scope of the restrictions (e.g. for military purposes), the application of the

material (e.g. high melting temperature solder), size of the sample, or the electrical

properties of the product.

4.3 Complexity of electrotechnical products and related challenges

The complex characteristics of electrotechnical products are another important consideration

when preparing a sampling strategy. These characteristics have a bearing on the practical

execution of sampling and analysis. The following elements are identified as relevant to

analysis and sampling:

a) Miniaturization: Miniaturization is one of the key trends in the electrotechnical industry.

This implies that more functionality is provided within a smaller volume. More and more

of printed wiring board (PWB) every year.

components and materials are used per cm

– 10 – 62321-2 © IEC:2013

Taking samples for measurement from these small amounts of material is difficult. For

example, the size of surface mounted devices (SMDs) is too small for regular tools to

further disjoint or separate and the quantity of the remaining sample is often too small

after disjointment to satisfy the requirements of adequate analysis.

b) Number of homogeneous materials: many components have complex structures and are

constructed of multiple layers of different materials. In a typical case, one single

component has more than 10 to 20 material layers, whereas many electrotechnical

products or assemblies contain hundreds or thousands of components. This means one

electrotechnical product can have more than 1 000 to more than 10 000 homogeneous

materials. Often, homogeneous materials adhere too tightly together for a clean

separation in a practical manner (see Figure 2). Experience has shown that the

composition often changes due to molecular diffusion between materials (e.g. the

composition of a plating is affected by a base material containing lead). Similarly, present-

day electrotechnical products are made of many components and parts. A typical TV or

laptop computer, for example, contains thousands of parts/components. Hence the design

database for an OEM may include several tens of thousands of components. In Annex E

this point is further illustrated in the disassembly of a mobile phone.

c) "Invisible" substances: another complicating factor in sampling and analysis is that

generally certain substances are not visible. A component containing a certain substance

may look and perform in an identical manner to one that does not. The presence or

absence of certain substances can vary from lot to lot in the manufacturing process

without any readily observable clues. While there are some visible indications (e.g. a

yellow coating on steel products suggests the presence of hexavalent chromium) as to the

presence of certain substances, visual detection is not practical.

d) Batch-to-batch variations: most product assembly manufacturers use commodity

components from several suppliers simultaneously, e.g. cables, resistors and capacitors.

Commodity components are mixed during production, because technically they are fully

interchangeable as long as they fit the umbrella specification. However, in most cases

they are not chemically identical. Furthermore, experience has shown that base materials

can be changed by commodity manufacturers (e.g. in times of shortage) which leads to a

change in the chemical composition as well. Notification of these changes does not always

occur if the component still meets its technical specification.

e) Depth of the supply chain: producing electronic components/parts involves a complex

supply chain. Relatively simple products, such as an external cable, can utilize supply

chains at least seven tiers deep. The supply chain for a more complex component such as

an LCD screen or IC, is considerably deeper.

These characteristics of the electrotechnical industry show that the management of certain

substances, along with sampling and analysis, is not straightforward. The size and number of

components, and complexity of the supply chain make it challenging to fully grasp the

locations of certain substances in an electrotechnical product. The prospect of implementing

homogeneous material level sampling and testing at the upper regions of the supply chain

(towards finished products) is not practical for complex products.

NOTE Oxidation states of certain substances may not be stable over time. For example, the concentration of

hexavalent chromium in corrosion protection layers can change significantly with time and storage conditions.

4.4 Strategies for sampling

While different sampling approaches may be utilized as appropriate for the broad range of

electrotechnical products, it is possible to describe a generic procedure that will be applicable

in the majority of cases. This is illustrated by the iterative loops of sampling, disassembly and

disjointment shown in Figure 1.

62321-2 © IEC:2013 – 11 –

IEC 1253/13

Figure 1 – Generic iterative procedure for sampling

The process depicted in Figure 1 can have several iterative loops including:

st

• 1 iteration: partial disassembly (see 5.3);

nd

• 2 iteration: complete disassembly (see 5.4);

rd

• 3 iteration: partial disjointment (see 5.5);

th

• 4 – nth iteration: complete disjointment (see 5.6).

These iterative steps are described further in Clause 5.

Development of the sampling strategy for a particular electrotechnical product/part/ assembly

begins with an information gathering stage. Some basic questions to be considered include:

– What is the complexity of the product/part/assembly and is it practical to consider

sampling and testing at the homogeneous material level?

– Which substances are restricted?

– What are the allowable limits for these certain substances?

– Are there appropriate exemptions for the certain substance?

– Is a bill of materials available for the components/assemblies/materials in the product?

– Are specifications/drawings of the components available?

– What is the depth of the supply chain for the components and materials in this product?

– Are material declarations for this product available?

– Is there any previous experience evaluating this product or similar products that could be

helpful?

– 12 – 62321-2 © IEC:2013

– Is there any published probability of the presence matrices for the materials or parts used

in this product?

– Was any screening (e.g. X-ray fluorescence) previously performed on this product or

similar products that could be helpful?

– Is there any information regarding the manufacturing process of materials/components

(metal making or IC production) used in this product or similar products that could be

helpful?

– Are there any perceived process controls present at the component or material suppliers

(e.g. level of trust in the manufacturer)?

– Is there any history of concern with the component or material supplier?

The answers to these questions and other characteristics will influence the sampling strategy.

The organization’s position in the supply chain will determine what extent of sampling is

appropriate. Release for production of products/components etc. requires a more in-depth

sampling strategy than an occasional verification check on specifications. In order to optimize

costs and efficiency, the desired outcome of the testing needs to be understood. As

previously stated, it is often impractical to sample and test all components/materials. An

organization is left to determine the optimum balance of effort/costs against effectiveness of

the sampling strategy. Some considerations to minimize sampling/testing efforts and costs are

listed below:

– homogeneous materials with a low probability of containing certain substances (less likely

to contain restricted substances hence pose a lower risk of non-confomity if not tested,

see Annex B);

– applicable exemptions for certain substances (the presence of certain substances would

not affect conformity);

– material declarations;

– historical test data (evidence for the probability of containing certain substances);

– composite sampling and testing (covers several materials in a single test, but other factors

shall be considered, see 5.7.3 and Annex C);

– minimum sample size necessary to run analytical tests and the number of samples

necessary to determine whether or not it’s practical to test.

The sampling strategy will depend very much on the ultimate objective of analysis. One

strategy (perhaps used by enforcement authorities) is an analysis to verify if the product

contains at least one certain substance exceeding the allowable limit. This approach involves

gradual, selective sampling, targeting deliberately those parts of the product that are either

known, or are likely to contain certain substances. Each sampling phase could be followed by

analysis. If the results show no certain substances above the allowable limit, a further stage

of sampling and analysis could be performed. Once the test results exceed the allowable limit

for at least one certain substance in any part, the product as a whole is deemed non-

compliant and no further sampling and analysis are necessary. Annex B provides a list of

components which currently have a probability of the presence of one or more of substances

of concern.

Another strategy is to prove total compliance of the product, as far as possible down to the

homogeneous material level. This approach would be typical for the product or component

manufacturer. Samples would be prepared from each individual material or component. As the

objective is to cover all components and materials in a product/assembly, other routes may be

used to gather information on a product level. In the downstream supply chain process

documentation and/or analysis reports may exist that would reduce the effort required in

sampling and analysis.

Once the objective of the analysis has been defined, feasibility of the testing is performed

(e.g. is the sample mass/size/volume sufficient?). Further sampling and disjointment may be

necessary, where a choice can be made to either completely disjoint or only select materials

62321-2 © IEC:2013 – 13 –

with a high probability of containing certain substances. Table B.1 is used to assist in the

identification of these components and materials.

If testing is appropriate, the relevant testing procedure shall be followed. Where certain

substances are present in the product/part there may be an applicable exemption (some

examples are given in Table B.1).

Following the flowchart in Figure 1 is an iterative process, retrieving samples at an ever

deeper level. How far this process is pursued will depend on the objective of the sampling

strategy. After the screening steps, further analytical testing is undertaken as necessary.

5 Sampling

5.1 Introductory remark

This standard only provides general sampling guidelines, which are intended to form the basis

of the sampling strategy appropriate to the electrotechnical product.

Before sampling, the following questions need to be addressed:

a) Based on available knowledge of the product, can any sections/parts be identified that are

likely to contain certain substances (see Annex B)?

b) Is it practical to analyse any of these sections/parts without disassembly?

c) Can the section/part selected be regarded as homogeneous material for the purpose of

the analysis?

d) Is the section/part selected for analysis representative?

e) Does the sample selected fulfil the criteria of minimum mass, area, thickness or volume

required by the chosen analytical methods?

The answers to these questions will determine the sampling strategy and the extent of

disassembly and disjointment, if any, required to provide representative samples that are

homogeneous and of sufficient quantity to permit a valid analysis.

Whenever possible, sampling shall be performed by stages of minimal disassembly and

disjointment. Each stage is followed by an assessment of its effectiveness (see the flowchart

in Figure 1), typically by screening analysis (see IEC 62321-3-1 and IEC 62321-3-2).

Depending on the results of the assessment and objectives of the analysis, further

disassembly, disjointment and sampling shall be performed, as required, especially for

verification analysis of the product’s components and materials. This approach offers the least

expensive, fastest and the most efficient means of analysis, especially when undertaken on

the finished product.

The numerous types and diversity of electrotechnical products make it impractical to provide

detailed sampling strategies for each one. Instead, procedures covering five increasingly

destructive levels of sampling are described.

Annex A provides generic sampling flowcharts based on Figure 1 for certain characteristic

electrotechnical products: DVD player, CRT tube, LCD TV set, PDA/phone and a desk fan,

along with two components, a thick film resistor and SMD potentiometer.

Annex D lists some commonly used disassembly and disjointment tools.

When determining certain substances it is strongly recommended to ensure that the tools

used are free from the substances of interest to avoid possible contamination.

– 14 – 62321-2 © IEC:2013

Annex E gives examples of the disassembly and disjointment, covering for two types of

mobile phone, along with the disjointment of various small electronic components, in

particular integrated circuit lead frame and ball grid array (BGA) packages.

5.2 Complete product

Sampling of the complete product is the first, non-destructive step in the iterative sampling

strategy where representative parts of the product can be analysed in their present form

without disassembly or disjointment.

However, "complete product" is a relative term. For example, an AC power cord is a complete

product for its manufacturer, but it may be just a component in a TV set. Complete products

may be evaluated without disassembly if they have a very simple construction, or if the

locations of expected certain substances are known and it is possible to test for them without

disassembly. Examples of such products are power cords, printer or other peripheral cables,

equipment housings, etc.

NOTE Even a seemingly simple product such as a power cord may be composed of perhaps 10 to 20 different

homogeneous materials.

5.3 Partial disassembly

The product is disassembled down to its major components and subassemblies and tested

non-destructively, where possible. See Annex E.

5.4 Complete disassembly

Complete disassemby separates all components as far as possible, while still permitting

reassembly to give an operational product. See Annex E.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...