IEC 60505:2011

(Main)Evaluation and qualification of electrical insulation systems

Evaluation and qualification of electrical insulation systems

IEC 60505:2011 establishes the basis for estimating the ageing of electrical insulation systems (EIS) under conditions of either electrical, thermal, mechanical, environmental stresses or combinations of these (multifactor stresses). It specifies the principles and procedures that shall be followed, during the development of EIS functional test and evaluation procedures, to establish the estimated service life for a specific EIS. This standard should be used by all IEC technical committees responsible for equipment having an EIS. The contents of the corrigendum of March 2017 have been included in this copy.

Evaluation et qualification des systèmes d'isolation électrique

La CEI 60505:2011 établit les bases de l'estimation du vieillissement des systèmes d'isolation électrique (SIE) dans des conditions de contraintes électriques, thermiques, mécaniques, environnementales ou de combinaisons de ces contraintes (contraintes multifactorielles). Elle spécifie les principes et les procédures qui doivent être suivis, au cours du développement d'essais fonctionnels ou de procédures d'évaluation des SIE, pour établir la durée de vie estimée d'un SIE spécifique. Il convient que tous les comités d'études de la CEI responsables de matériels ayant un SIE utilisent la présente norme. Le contenu du corrigendum de mars 2017 a été pris en considération dans cet exemplaire.

Loading guide for dry-type power transformers

General Information

- Status

- Published

- Publication Date

- 10-Jul-2011

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 6 - TC 112/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-Jul-2011

- Completion Date

- 15-Jul-2011

Relations

- Corrected By

IEC 60505:2011/COR1:2017 - Corrigendum 1 - Evaluation and qualification of electrical insulation systems - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60505:2011 - Evaluation and qualification of electrical insulation systems - defines a harmonized framework for estimating the ageing and establishing the service life of electrical insulation systems (EIS). The standard addresses ageing caused by electrical, thermal, mechanical and environmental stresses, including multifactor (combined) stresses, and specifies the principles and procedures to be followed when developing EIS functional tests and evaluation methods. This edition incorporates the corrigendum of March 2017.

Key topics

- Ageing mechanisms and stress categories - guidance on evaluating how electrical, thermal, mechanical and environmental stresses (alone or combined) affect insulation performance over time.

- Principles for test development - procedural requirements for designing functional and accelerated ageing tests that produce data suitable for lifetime estimation.

- Service life estimation - methods and procedural steps to translate test results into an estimated service life for a specific EIS (qualitative and quantitative reporting expectations).

- Qualification and pass/fail criteria - how to define acceptance limits, failure modes to monitor, and documentation needed to support qualification decisions.

- Multifactor stress assessment - emphasis on combined-stress test sequences and interaction effects when single-stress tests are insufficient.

- Traceability and reporting - requirements for test records, sample selection, environmental control and statistical interpretation to support reproducible qualification outcomes.

Applications

IEC 60505:2011 provides practical value across the insulation lifecycle:

- Manufacturers of motors, transformers, generators, cables and other electrical equipment use it to design and qualify insulation systems and to define accelerated ageing tests.

- Test laboratories adopt its principles to develop reproducible functional test programs and to report credible service-life estimates.

- Certification bodies and compliance teams use it to assess insulation qualification evidence submitted for product approvals.

- R&D and materials engineers rely on the standard when comparing insulation materials, validating new formulations, or investigating failure root causes.

- Asset owners and maintenance planners use service-life estimates to inform replacement schedules and reliability planning.

Who should use this standard

- IEC technical committees responsible for equipment that contains EIS

- Insulation system designers and material suppliers

- Accredited test laboratories and certification bodies

- Electrical equipment manufacturers and reliability engineers

Related standards

For a complete qualification program, IEC 60505 is typically used alongside other insulation and ageing references such as IEC 60216 (thermal endurance of insulating materials) and IEC 60085 (thermal classification of insulating materials), and the specific product standards relevant to the equipment under test. Consult the applicable IEC technical committee for normative references.

Keywords: IEC 60505:2011, electrical insulation systems, insulation ageing, service life estimation, multifactor stresses, insulation qualification, functional test development.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60505:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Evaluation and qualification of electrical insulation systems". This standard covers: IEC 60505:2011 establishes the basis for estimating the ageing of electrical insulation systems (EIS) under conditions of either electrical, thermal, mechanical, environmental stresses or combinations of these (multifactor stresses). It specifies the principles and procedures that shall be followed, during the development of EIS functional test and evaluation procedures, to establish the estimated service life for a specific EIS. This standard should be used by all IEC technical committees responsible for equipment having an EIS. The contents of the corrigendum of March 2017 have been included in this copy.

IEC 60505:2011 establishes the basis for estimating the ageing of electrical insulation systems (EIS) under conditions of either electrical, thermal, mechanical, environmental stresses or combinations of these (multifactor stresses). It specifies the principles and procedures that shall be followed, during the development of EIS functional test and evaluation procedures, to establish the estimated service life for a specific EIS. This standard should be used by all IEC technical committees responsible for equipment having an EIS. The contents of the corrigendum of March 2017 have been included in this copy.

IEC 60505:2011 is classified under the following ICS (International Classification for Standards) categories: 29.080.30 - Insulation systems; 29.180 - Transformers. Reactors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60505:2011 has the following relationships with other standards: It is inter standard links to IEC 60505:2011/COR1:2017, IEC 60505:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60505:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-1997

Loading guide for dry-type power transformers

Loading guide for dry-type power transformers

Guide de charge pour transformateurs de puissance du type sec

Ta slovenski standard je istoveten z: IEC 60505 Ed. 4.0

ICS:

29.180 Transformatorji. Dušilke Transformers. Reactors

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

NORME

CEI

INTERNATIONALE IEC

INTERNATIONAL

Première

édition

STANDARD

First edition

Le contenu du corrigendum d'avril 1991 a

été incorporé dans cette réimpression

The contents of the corrigendum of April 1991 has been included in this reprint

Guide de charge pour transformateurs

de puissance du type sec

Loading guide for dry-type power transformers

© CEI 1995 Droits de reproduction réservés — Copyright — all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée sous quelque forme que ce soit et par aucun pro- any form or by any means, electronic or mechanical,

cédé, électronique ou mécanique, y compris la photocopie et including photocopying and microfilm, without permission

les microfilms, sans l'accord écrit de l'éditeur. in writing from the publisher.

Bureau Central de la Commission Electrotechnique Internationale 3, rue de Varembé

Genève, Suisse

Commission Electrotechnique Internationale CODE PRIX

International Electrotechnical Commission PRICE CODE

S

IEC Mer+tgyuapoaHaa 3nelsrporexHH4ecnaa

HoMUCCUR

• Pour prix, voir

• catalogue en vigueur

For price, see current catalogue

— 3

905 © I E C 1987

CONTENTS

Page

FOREWORD 5

PREFACE 5

Clause

1. Scope 7

2. Object 7

3. Symbols 9

PART 1

4. Basis of guide

5. Algorithm for basic `use of life' calculations

6. Limitations 29

PART 2

7. Basis of establishing load curves

8. Selection of appropriate load curve with examples

905 ©IEC 1987 — 5 —

INTERNATIONAL ELECTROTECHNICAL COMMISSION

LOADING GUIDE

FOR DRY-TYPE POWER TRANSFORMERS

FOREWORD

1) The formal decisions or agreements of the I EC on technical matters, prepared by Technical Committees on which all the

National Committees having a special interest therein are represented, express, as nearly as possible, an international

consensus of opinion on the subjects dealt with.

2) They have the form of recommendations for international use and they are accepted by the National Committees in that

sense.

3) In order to promote international unification, the I E C expresses the wish that all National Committees should adopt the

text of the I E C recommendation for their national rules in so far as national conditions will permit. Any divergence

between the I E C recommendations and the corresponding national rules should, as far as possible, be clearly indicated in

the latter.

PREFACE

This guide has been prepared by IEC Technical Committee No. 14: Power transformers.

The text of this guide is based on the following documents:

Six Months' Rule Report on Voting

14(CO)60 14(CO)63

Full information on the voting for the approval of this guide can be found in the Voting Report

indicated in the above table.

The following 1 EC Publications are quoted in this guide:

Publications Nos. 76-1 (1976): Power transformers, Part 1: General.

726 (1982): Dry-type power transformers.

905 © I E C 1987 7

LOADING GUIDE

FOR DRY-TYPE POWER TRANSFORMERS

1. Scope

This guide is applicable to naturally cooled dry-type power transformers complying with

IEC Publication 726 and operated within the limitations referred to in Clause 6. Six different

insulation systems are taken into account, identified by their system temperatures.

Because there are numerous combinations of different insulation systems and constructions

it is possible to make loading recommendations only of a general nature. For this reason the

guide is in two parts:

— the first part makes no loading recommendations, but gives the method of calculating

loading conditions when the variable parameters are known as the result of prototype

testing of a particular construction and/or insulation system. The calculations are given in

the form of an algorithm from which computer programs can be written;

— the second part assumes constant values for the variable parameters, with the exception of

the insulation temperature limits (Table I) and the temperature of external cooling air,

irrespective of insulation system or construction, thereby enabling load curves to be

produced.

The guide indicates how dry-type transformers may be operated without exceeding the

acceptable limit of deterioration of insulation through thermal effects. The acceptable limit of

deterioration of insulation is defined as that which occurs when the dry-type transformer is

operating under rated conditions at the basic temperature of the external cooling air.

2. Object

The object of this guide is to permit the calculation of, and to indicate the permissible loading

under certain defined conditions in terms of rated current, for the guidance of users and to help

planners to choose the rated power of transformers required for new installations.

The basic temperature of the external cooling air is assumed to be 20 °C. Guidance is given

for this temperature, and also for external cooling air temperatures of 10 °C and 30 °C.

Deviations from these temperatures are provided for in such a way that the increased use of life

when operated with a higher external cooling air temperature is balanced by a reduced use of

life with a lower external cooling air temperature.

In practice, uninterrupted continuous operation at full rated current is unusual, and this

guide gives recommendations for cyclic daily loads, taking into account seasonal variations of

ambient temperature. The daily use of life due to thermal effects is compared with normal daily

use of life which results when the dry-type transformer is operating at rated voltage and

current, with an external cooling air temperature of 20 °C.

905 ©I E C 1987 — 9 —

Load curves, Figures 5 (1) to 5 (12) on pages 32 to 43, show the permissible load current

which will result in a normal daily use of life for winding insulation systems having insulation

system temperatures of 105, 120, 130, 155, 180 and 220 °C in the following two sets of

conditions:

a)

continuous duty with different temperatures of external cooling air,

b)

cyclic duty with different temperatures of external cooling air.

Note. —

It is assumed that the transformer is adequately ventilated and the increased losses resulting from an

overload do not significantly change the temperature of the cooling air.

3.

Symbols

The following symbols are used in this guide:

a = subscript representing "ambient" (external cooling air)

c =

subscript representing the "hot spot of the winding" at rated current and basic

temperature of external cooling air

cc =

subscript representing the highest permissible "hot spot of the winding" according to

this guide

d =

subscript representing the doubling of the rate of using life

e =

subscript representing the final "average of winding" for any value of load current

= subscript representing the initial "average of winding" for any value of load current

= integer variable representing the number of the day in the year (1^j-.365)

K1, K2i . K, . K

N = load currents as fractions of rated currents

m = subscript representing maximum "average of winding". (Thus for continuous rated

current,

A0c/Z, and for a short time in excess of rated current, D°

m = 08cc/

AOmr =

Z,

resulting in a greater than normal rate of using life during this period)

n

= subscript representing any one period during the daily load cycle

q = exponent of K

by which the average temperature rise varies with load current

r =

subscript representing rated value

t = time

tb =

duration, in hours, at any load current K 1 (tb , 24 — tp)

tp =

maximum permissible duration, in hours, at any load current

K2

t1 , t2, . tn

, . tN = duration of each load condition period

w =

subscript representing the winding

wh

subscript representing the "hot spot of winding"

A

= amplitude of annual variations in the daily average ambient temperature (sinusoidal

variation is assumed)

B =

amplitude of daily variations in the ambient temperature (sinusoidal variation is

assumed)

I =

load current in amperes (any value); I r = rated current

k

=

subscript representing any individual load period prior to the start of the load period

to for which the calculation is being made

905 © I E C 1987 – 11 –

L = life consumption in hours

calculated annual use of life

Lan

LR = relative rate of using life

N = number of different load periods for a day

T = sum of the individual load periods tk prior to the start of the load period t„ for which

the calculation is being made

Z = ratio between hot spot and average winding temperature rises (see also explanations

to subscript m)

«

arbitrary variable used in determining the relative rate of using life

=

AO =

temperature rise in kelvins

accuracy factor for estimation of the hot-spot temperature at the beginning of the 24 h

E =

period

8 = temperature in degrees Celsius

Dad = daily average ambient temperature

0a,, = annual average ambient temperature

r = thermal time constant of windings at rated current, in hours

PART 1

4. Basis of guide

4.1.

Introduction

The life of a dry-type transformer is related to the deterioration of its insulation through

thermal ageing. Experience indicates that the normal life of a transformer is some tens of years.

It cannot be stated more precisely, because it may vary even between identical units, owing in

particular to operating factors which may differ from one transformer to another.

In practice, uninterrupted continuous operation at full load current is unusual and so account

should be taken of the various operating conditions and the subsequent fluctuation of the rate

of thermal deterioration of the transformer insulation.

It is necessary therefore:

a) To define "normal" expectation of life as a function of the rated load current and the rated

hot spot temperature of the winding insulation.

b) To relate the increase in hot spot winding temperature to the increase in the rate of

insulation deterioration.

c) To devise a method of calculating the net effect of variation in the winding hot spot

temperature due to changes in load period, load current and ambient temperature, on the

thermal ageing of the insulation.

d) To then compare the net "use of life" due to the sum of the different factors in the load

cycle, with the definition of "normal use of life". Hence, any of the parameters in the load

cycle can be adjusted to give a normal expectation of transformer life.

905 © I E C 1987 – 13 –

4.2 Parameters used in the calculations

4.2.1

Temperature limits

TABLE I

Temperature limits

Hot spot winding Average winding

Insulation

temperature temperature-rise

system

temperature (°C) limits at rated current

(K)

(IEC Publi-

rated highest

(I EC Publication 726)

cation 726)

permissible

(40,r)

(°C) (Bcc)

(Bc)

105 (A) 95 140 60

120 (E) 110 155

120 165 80

130 (B)

145 190 100

155 (F)

220 125

180 (H) 175

210 250 150

220(C)

is used to calculate normal life consumption. Under certain operating

4.2.2 The parameter 0,

conditions in which it is permissible to exceed this normal consumption level, high overloads

may be applied, resulting in a hot spot temperature considerably higher than O. Thus a

parameter 0 cn representing the absolute limit of the hot spot temperature has been introduced.

This temperature is that beyond which the rate of deterioration of the insulation becomes

and 8cc.)

inadmissible. (See Table I for values of 0,

4.2.3 The value of parameter 0d is taken as the increase in hot spot temperature which doubles the

rate of using life.

4.2.4 The basic value required for calculating the life consumption level is the temperature at the

hottest spot. For this purpose, it is necessary to know the temperature rise at this position for

each load condition and the ambient temperature. There are at least two methods of obtaining

the hot spot temperature rise:

Kn;

a) can be determined by performing temperature-rise tests with various loads

AOWhn

b) by using the formula:

= Z OBwr Knq (1)

OBwhn

In this case, it is necessary to know the values of Z, AO, and q.

It is preferable to use, whenever possible, the results of tests giving thus removing any

AOWhn,

uncertainty regarding the validity of the factor Z and the value of q. Experience shows that q

and Z assume different values depending on the type of transformer and the level of the load

current at which it operates.

wh„ may be possible only on prototype

Note. — With some types of winding construction determination of AB

transformers.

AOWh = f (K), which can be used to

On the basis of the test results, a curve can be plotted of

for each K n necessary for the calculation.

determine the corresponding

AOwhn

905©IEC1987 — 15 —

4.2.5 Values obtained during temperature-rise tests carried out on a prototype under different load

conditions:

z = thermal time constant in hours;

Note. — The winding to be taken into consideration is that with the shortest time constant.

40wr

= average winding temperature rise at the assigned rating;

4B =

f (K): temperature rise at the hottest spot, under the established conditions, as a

wh

function of the load.

4.2.6 Values obtained by means of ageing tests carried out on models of insulating systems:

Bc =

...

IEC 60505 ®

Edition 4.0 2011-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Evaluation and qualification of electrical insulation systems

Évaluation et qualification des systèmes d'isolation électrique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60505 ®

Edition 4.0 2011-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Evaluation and qualification of electrical insulation systems

Évaluation et qualification des systèmes d'isolation électrique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XC

ICS 29.080.30 ISBN 978-2-88912-539-5

– 2 – 60505 © IEC:2011

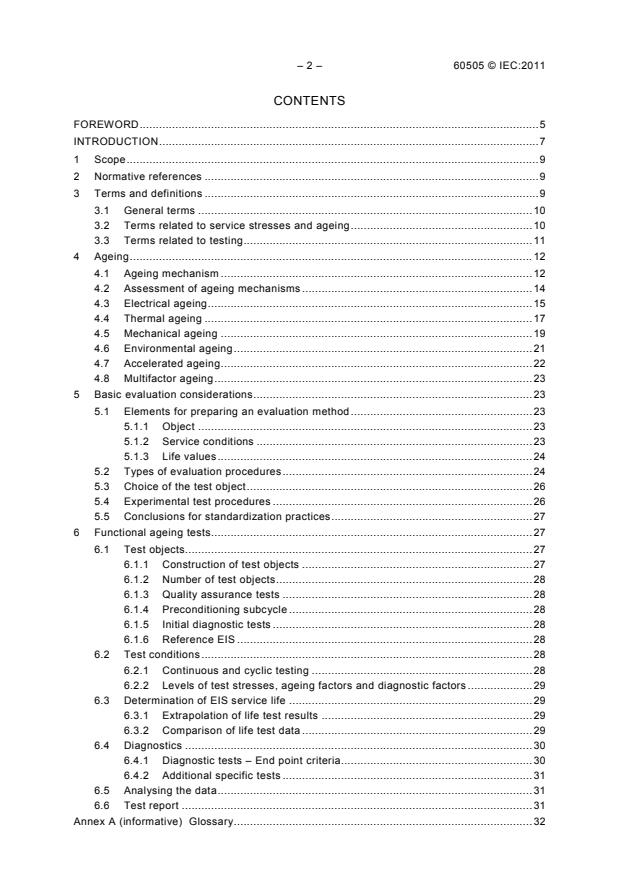

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 9

3.1 General terms . 10

3.2 Terms related to service stresses and ageing . 10

3.3 Terms related to testing . 11

4 Ageing . 12

4.1 Ageing mechanism . 12

4.2 Assessment of ageing mechanisms . 14

4.3 Electrical ageing . 15

4.4 Thermal ageing . 17

4.5 Mechanical ageing . 19

4.6 Environmental ageing . 21

4.7 Accelerated ageing . 22

4.8 Multifactor ageing . 23

5 Basic evaluation considerations . 23

5.1 Elements for preparing an evaluation method . 23

5.1.1 Object . 23

5.1.2 Service conditions . 23

5.1.3 Life values . 24

5.2 Types of evaluation procedures . 24

5.3 Choice of the test object . 26

5.4 Experimental test procedures . 26

5.5 Conclusions for standardization practices . 27

6 Functional ageing tests. 27

6.1 Test objects. 27

6.1.1 Construction of test objects . 27

6.1.2 Number of test objects . 28

6.1.3 Quality assurance tests . 28

6.1.4 Preconditioning subcycle . 28

6.1.5 Initial diagnostic tests . 28

6.1.6 Reference EIS . 28

6.2 Test conditions . 28

6.2.1 Continuous and cyclic testing . 28

6.2.2 Levels of test stresses, ageing factors and diagnostic factors . 29

6.3 Determination of EIS service life . 29

6.3.1 Extrapolation of life test results . 29

6.3.2 Comparison of life test data . 29

6.4 Diagnostics . 30

6.4.1 Diagnostic tests – End point criteria. 30

6.4.2 Additional specific tests . 31

6.5 Analysing the data . 31

6.6 Test report . 31

Annex A (informative) Glossary . 32

60505 © IEC:2011 – 3 –

Bibliography . 71

Figure 1 – Ageing of an EIS . 13

Figure 2 – Intrinsic/extrinsic electrical ageing of practical EIS . 15

Figure 3 – Intrinsic/extrinsic thermal ageing of practical EIS . 17

Figure 4 – Intrinsic/extrinsic mechanical ageing of practical EIS . 20

Figure 5 – Intrinsic/extrinsic environmental ageing of practical EIS . 22

Figure 6 – Elements of evaluation methods . 23

Figure 7 – Type of evaluation procedure . 25

Figure 8 – Selection of test object . 26

Figure 9 – Establishing the test method . 27

Figure A.1 – Surface abrasion damage . 32

Figure A.2 – Surface enamel peeling like string . 32

Figure A.3 – Scheme of the measurement set-up for the charging/discharging current . 33

Figure A.4 – Example of sample preparation . 33

Figure A.5 – Charging/discharging current on HDPE film . 34

Figure A.6 – Property versus time behaviour, detection of threshold (end point, p )

L

and maintenance time . 35

Figure A.7 – Correspondence between the ageing plots of the property p (in red),

obtained at different stress levels, and the resulting life line . 35

Figure A.8 – Example of charge injection of positive carriers (holes) from the anode

and of negative charge carriers (electrons) from the cathode in a PE flat specimen,

detected by space charge measurement performed by PEA method . 36

Figure A.9 – Stress-strain curve for a typical material . 37

Figure A.10 – Scheme of measurement set- up for charging/discharging current . 38

Figure A.11 – Example of sample preparation . 38

Figure A.12 – Charging/discharging current on HDPE film . 38

Figure A.13 – Charging current at 135 °C and different values of DC electrical field . 39

Figure A.14 – Charging current at 120 °C and different values of DC electrical field . 39

Figure A.15 – Corona at post insulator head . 40

Figure A.16 – Corona on top and arcing to ground . 40

Figure A.17 – Stages of mechanical ductile fracture (cracking) (Source unknown) . 41

Figure A.18 – Photo showing orderings in epoxy structure and void . 42

Figure A.19 – Discharge between conductors through air. 44

Figure A.20 – Paper insulation degraded by electrical surface discharges . 44

Figure A.21 – Example of electric strength test on XLPE sample 0,2 mm thick . 45

Figure A.22 – Two parameters Weibull plot electric strength results performed on

seven XLPE specimens, 0,2 mm thick . 45

Figure A.23 – Loss angle of a dielectric . 47

Figure A.24 – Loss factor for pre-treated and thermally aged (at 110 °C and 130 °C)

XLPE cables measured at 90 °C plotted vs. frequency . 47

Figure A.25 – Field lines from a positive charge above a plane conductor . 48

Figure A.26 – Electrical tree. 49

Figure A.27 – EPDM ashing and erosion on fitting . 50

Figure A.28 – Failing external insulation . 51

– 4 – 60505 © IEC:2011

Figure A.29 – Failing external insulation . 51

Figure A.30 – Critical failure of solid cable insulation (XLPE) by electrical breakdown . 52

Figure A.31 – Example flashover . 53

Figure A.32 – Substation – Outdoor installation . 54

Figure A.34 – Internal interfaces in epoxy structure and void . 56

Figure A.35 – Example of craze and crack development in an inter-lamellar space

under mechanical tension T . 57

Figure A.36 – Water treeing . 58

Figure A.37 – After 11 years in service UV and moisture impact . 59

Figure A.38 – Random (amorphous) structure of a molecular chain . 59

Figure A.39 – Oriented structure (semi-crystalline) of a molecular chain . 59

Figure A.40 – Typical morphology of melt-grown polyethylene spherulites . 60

Figure A.41 – Areas in which PD generally occur . 61

Figure A.42 – Classes of defect – Internal, surface and corona PD . 61

Figure A.43 – Basic PD measurement circuit . 62

Figure A.44 – Examples of PD patterns relevant to internal, surface and corona PD . 62

Figure A.45 – GIS research – Metal conductor protrusion . 63

Figure A.46 – Internally strained epoxy – Frozen in strains in epoxy resin due to

thermal stress, measured by TMA curves . 64

Figure A.47 – Externally strained parts in an on-load tap changer (OLTC) . 64

Figure A.48 – A material being loaded in a) compression, b) tension, c) shear . 65

Figure A.49 – Effect of thermal-mechanical stresses leading to interfacial electrical

tracking . 66

Figure A.50 – Stress-strain curve for a typical material . 66

Figure A.51 – Over crimped rod; breaks during tensile test . 67

Figure A.52 – Typical installation fault . 68

Figure A.53 – Surface tracking on sheds and fitting end . 68

Figure A.54 – Vented trees – Initiate at interface . 69

Figure A.55 – Tape wrinkling . 70

Table 1 – Ageing temperatures . 19

Table 2 – Cyclical and continuous procedures . 30

60505 © IEC:2011 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

EVALUATION AND QUALIFICATION

OF ELECTRICAL INSULATION SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60505 has been prepared by IEC technical committee 112:

Evaluation and qualification of electrical insulating materials and systems.

This fourth edition cancels and replaces the third edition, published in 2004, and constitutes a

technical revision.

The main change with respect to the previous edition is the addition of a Glossary in the form

of Annex A to this standard.

The text of this standard is based on the following documents:

FDIS Report on voting

112/174/FDIS 112/184/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – 60505 © IEC:2011

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of March 2017 have been included in this copy.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

60505 © IEC:2011 – 7 –

INTRODUCTION

The life of an electrical insulation system (EIS) or systems frequently determines the life of

electrical equipment which can be affected by electrical, thermal, mechanical or

environmental stresses acting either individually or in combination.

Intended, estimated or proven service life times are essential parameters for describing the

life of electrical insulation systems. In the early days of electrotechnical engineering, life

figures were rather vague. The limitation of the life of the insulation under thermal stress was

one of the first indicators of the effect of ageing in some equipment in service. As experience

in using EIS increased, it was appreciated that there was a need to select specific materials

having satisfactory life time at a given temperature, to enable the required service life to be

achieved and to allow for the calculation of the thermal capability of equipment.

The user of this standard may evaluate existing test methods and provide correlation with his

equipment. Therefore, the user of this standard is responsible for demonstrating the validity of

the existing test method in accordance with the principles of this standard.

The determination of the prospective life is a fundamental task when developing and

designing an EIS. Estimated service life of an EIS needs to be established for several

reasons:

– for type testing when introducing a new EIS into production;

– for quality assurance of production;

– for estimating the life expectancy of new equipment;

– for estimating the remaining life for maintenance purposes.

“Ageing” focuses on the mechanisms affecting the EIS performance. “Evaluation” links these

potential mechanisms by “Analysis” and “Diagnostics” to the design of a specific kind of

evaluation test procedure.

The keyword structure below meets such requirements and allows an easier choice of the

parts of interest.

– 8 – 60505 © IEC:2011

60505 © IEC:2011 – 9 –

EVALUATION AND QUALIFICATION

OF ELECTRICAL INSULATION SYSTEMS

1 Scope

This International Standard establishes the basis for estimating the ageing of electrical

insulation systems (EIS) under conditions of either electrical, thermal, mechanical,

environmental stresses or combinations of these (multifactor stresses).

It specifies the principles and procedures that shall be followed, during the development of

EIS functional test and evaluation procedures, to establish the estimated service life for a

specific EIS.

This standard should be used by all IEC technical committees responsible for equipment

having an EIS.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60216-2, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of

test criteria

IEC 60216-3, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

IEC 60216-5, Electrical insulating materials – Thermal endurance properties – Part 5:

Determination of relative thermal endurance index (RTE) of an insulating material

IEC 60493-1, Guide for the statistical analysis of ageing test data – Part 1: Methods based on

mean values of normally distributed test results

IEC 60544-1, Electrical insulating materials – Determination of the effects of ionizing radiation

– Part 1: Radiation interaction and dosimetry

IEC/TS 61251, Electrical insulating materials – AC voltage endurance evaluation –

Introduction

IEC 62539, Guide for the statistical analysis of electrical insulation breakdown data

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

– 10 – 60505 © IEC:2011

3.1 General terms

3.1.1

electrical insulation system

EIS

insulating structure containing one or more electrical insulating materials (EIM) together with

associated conducting parts employed in an electrotechnical device

3.1.2

electrical insulating material

EIM

material with negligibly low electric conductivity, used to separate conducting parts at different

electrical potentials

[IEC 60050-212:2010, 212-11-01, modified]

3.1.3

reference EIS

established EIS evaluated on the basis of either a known service experience record or a

known comparative functional evaluation

3.1.4

candidate EIS

EIS under evaluation to determine its service capability (with regard to electrical, thermal,

mechanical, environmental or multifactor stresses)

3.1.5

intended life

design life of an EIS under service conditions

3.1.6

estimated life

expected service life derived from either service experience or the results of tests performed

in accordance with appropriate evaluation procedures, or both, as established by the

responsible organization or technical committee

3.1.7

evaluation

establishment of relationships between service requirements and life data obtained from

service experience analysis or from the results of functional tests

3.2 Terms related to service stresses and ageing

3.2.1

ageing stress

electrical, thermal, mechanical or environmental stress whose action on an EIS causes

irreversible property changes

3.2.2

potentially destructive stress

stress in service which can cause the failure of the aged EIS, alone or in combination with

other stresses

3.2.3

service conditions

combination of stresses and duty that are to be expected in a specific application of an

electrical device

60505 © IEC:2011 – 11 –

3.2.4

reference operating conditions

service conditions of the equipment to which the test conditions of the functional test

procedure are related

3.2.5

service requirements

specified stresses, intended performance and duty of an electrical device

3.2.6

service experience

the quantitative and/or qualitative record during service, with or without failure of an EIS

3.2.7

ageing

irreversible changes of the properties of an EIS due to action by one or more stresses

NOTE 1 Some changes (e.g. hydrolytic changes) can be partly reversible if the ambient conditions change.

NOTE 2 Ageing leads to degradation of the EIS.

3.2.8

intrinsic ageing

irreversible changes of fundamental properties of an EIS caused by the action of ageing

factors on the EIS

3.2.9

extrinsic ageing

irreversible changes of properties of an EIS caused by action of ageing factors on

unintentionally introduced imperfections in the EIS

3.2.10

interaction

modifications of the type or degree of ageing produced by the combination of two or more

stresses relative to their ageing effect if acting individually on separate objects

3.2.11

direct interaction

interaction between simultaneously applied stresses that differs from that occurring with

sequentially applied stresses

3.2.12

indirect interaction

interaction which occurs between simultaneously applied stresses, which remains unchanged

when the factors are applied sequentially

3.3 Terms related to testing

3.3.1

functional test

procedure to obtain information about the suitability of an EIS under specified conditions

3.3.2

test object

sample of original equipment or part thereof, or model representing the equipment completely

or partially, including the EIS, to be used in a functional test

– 12 – 60505 © IEC:2011

3.3.3

accelerated ageing

ageing resulting of an increase in the level and/or frequency of application of the stress

beyond normal service conditions

3.3.4

accelerated test

functional test applying accelerated ageing to shorten testing time

3.3.5

conditioning

subjecting a specimen to an atmosphere of a specified relative humidity or complete

immersion in water or other liquid, at a specified temperature for a specified period of time

3.3.6

prediagnostic conditioning

variable or fixed stresses, which can be applied continuously or periodically to an EIS to

enhance the ability of a functional test to detect the degree of ageing

NOTE Prediagnostic conditioning may cause additional ageing.

3.3.7

diagnostic factor

variable or fixed stress which is applied to an EIS to establish the degree of ageing

3.3.8

diagnostic test

periodic or continuous application of a specified level of a diagnostic factor to a test object to

determine whether or when the end-point criterion has been reached

3.3.9

end-point criterion

moment when a system is no longer able to fulfil its service purposes

3.3.10

life

time for a property to reach the end-point criterion for objects in functional tests

3.3.11

test cycle

in a test, repetitive period of application of one or more stresses, either sequentially or

simultaneously, and of diagnostic factors

3.3.12

subcycle

defined period within test cycle

NOTE The subcycle may be, for instance, a period of application of high temperature and humidity for influencing

the system properties, or application of high voltage for diagnostic purposes

4 Ageing

4.1 Ageing mechanism

Ageing is defined as the irreversible changes of the properties of an EIS due to action by one

or more stresses. Ageing stresses may cause either intrinsic or extrinsic ageing. A schematic

representation of the basic process is shown in Figure 1.

60505 © IEC:2011 – 13 –

Ageing stresses

Electrical Thermal Mechanical Environmental

EIS

Ageing mechanisms

Intrinsic/extrinsic

Electrical Thermal Mechanical Environmental

Direct/indirect interactions

Failure

IEC 1231/11

Figure 1 – Ageing of an EIS

The type and level of contamination and/or the extent of imperfections in an EIS will, in many

types of electrical apparatus, significantly affect the service performance. In general, the

fewer and less severe the contaminant and/or defects in the EIS, the better is its

performance. To avoid obtaining misleading results from functional tests, a candidate EIS

should contain, as far as practicable, the full range of contaminants and/or defects expected

when the actual system is used in service.

The ageing stresses produce electrical, thermal, mechanical or environmental ageing

mechanisms that eventually lead to failure. During ageing, applied stresses, which initially do

not affect the EIS, can cause additional ageing and, as a result, modify the rate of

degradation.

When ageing is dominated by one ageing factor, this is referred to as single-factor ageing.

Multifactor ageing occurs when more than one ageing factor substantially affects the ageing

of the EIS. Ageing factors can act synergistically, i.e. there can be direct interactions between

the stresses. Interactions may be either positive or negative.

The ageing of a practical EIS may be complex and failure is usually caused by a combination

of ageing mechanisms, even if there is only one dominant ageing factor as, for example, in

single-factor ageing.

Where experience or existing knowledge of how a specific EIS will perform in service is

limited, the user of this standard shall decide whether single or multifactor test procedures are

appropriate for his specific equipment or apparatus.

NOTE The classification of the operational environments of electrical equipment is dealt with in IEC publications

prepared by IEC technical committee 75, and methods for environmental endurance testing of electrical equipment

are described in IEC publications prepared by IEC technical committee 50 (notably IEC sub-committee 50B), see

bibliography.

When speaking of environmental effects, this is understood to comprise environments other

than the normal standard laboratory atmospheres specified in IEC 60212.

A number of other standards that provide methods of exposure or characterization of

insulation are listed in the bibliography.

– 14 – 60505 © IEC:2011

4.2 Assessment of ageing mechanisms

Figures 2, 3, 4 and 5, present four flow charts which describe respectively in some detail

intrinsic and extrinsic electrical, thermal, mechanical and environmental ageing of an EIS.

Each chart is based on the service experience of different types of EIS and shows possible

mechanisms of deterioration and failure that can occur for the different types of ageing and

the interactions between ageing factors. Although several failure mechanisms are shown, the

charts are not intended to be exhaustive of mechanisms that might be found in actual service

conditions of all equipment. It is important to note that ageing that leads to possible failure is

usually caused by more than one mechanism.

These charts should be used as follows:

a) as a checklist to determine the ageing mechanisms of equipment and apparatus. The

mechanisms can occur sequentially or simultaneously;

b) to develop functional and accelerated ageing tests or test cycles. The magnitudes and

types of applied stresses and their duration will depend upon how they affect the ageing

mechanisms;

c) to develop suitable diagnostic tests or test cycles to assess the condition of the EIS.

Based on knowledge of service experience, operating conditions and the properties of the

components of the EIS under consideration, the user of this standard should select one or

more charts that show the main ageing factor or factors. The various ageing mechanisms that

lead to failure should be carefully examined, taking into account the levels of contaminants

and defects in the EIS. A revised chart, which only includes the relevant ageing mechanisms,

should then be produced as an aid in the development of the functional ageing and diagnostic

test cycles.

If there is insufficient information available concerning service experience and/or the possible

ageing mechanism, then the ageing conditions should be based upon the most severe levels

of stresses expected in service for which the EIS has been designed.

60505 © IEC:2011 – 15 –

4.3 Electrical ageing

CONTAMINANTS PRODUCED BY: DEFECTS

• Impurities • Processing • Cavities

• Particles • Manufacture • Protrusions

• By-products • Transport • Interfaces, cracks

• Moisture • Installation • Missing components

• Material • Thermal, mechanical • Wrinkles

incompatibilities and environmental

• Processing errors

etc. stress

• Discontinuities

• Abuse, accident

etc.

• Mis-application

etc.

ELECTRICAL STRESS (a.c., d.c., f, transients)

ELECTRICAL INSULATION SYSTEM

Intrinsic Surface, partial Absorption, Charge Water Cavity formation

breakdown discharge, corona conduction injection treeing and expansion, or

current mechanical rupture

Chemical changes Cavity

Breakdown

formation

Corrosive

Tracking Erosion Temperature

Partial

by-products

rise

discharges

Flashover

Loss of Thermal

Electrical Partial

conductor ageing

treeing discharge

Electrical continuity

treeing

FAILURE

(Different mechanisms of failure occur)

IEC 1232/11

NOTE Other stresses may contribute to failure.

Figure 2 – Intrinsic/extrinsic electrical ageing of practical EIS

Electric ageing (either a.c., d.c. or impulse) involves:

a) the effects of partial discharges when the local field strength exceeds the breakdown

strength in the liquid or gaseous dielectric adjacent to, or included in, the EIS;

b) the effects of tracking;

c) the effects of treeing;

d) the effects of electrolysis;

– 16 – 60505 © IEC:2011

e) the effects, related to those above, on adjacent surfaces of two insulating materials where

tangential fields of relatively high value can occur;

f) the effects of increased temperatures produced by high dielectric losses;

g) the effect of space charges.

Figure 2 shows intrinsic/extrinsic electrical ageing where electrical stresses are considered to

be the main ageing factor. Consider the example of a simple EIS consisting of two parallel

plane conductors embedded in an insulating material. Protrusions are known to occur on the

surfaces of conductors, and impurities (e.g., dust particles, etc.) can be included within the

insulation. The accelerated ageing should, therefore, be carried out by using ageing factors

that increase charge injection, for example by high voltage, and the diagnostic tests should be

designed to enable measurement of the effect of the injected charge and/or the partial

discharge characteristics.

In many practical EIS, the electrical ageing process that leads to failure is complex. No rigid

mathematical models have yet been developed which predict fully how the ageing factors

affect the life of an EIS. However, one empirical relationship, the inverse power model, is

often used to relate a.c. and d.c. electrical stress with life. This states that:

−n

L ∝ V

where

L is the life (time to failure or time to end-point);

V is the voltage;

n is the voltage life exponent.

The inverse power law model predicts a linear relationship between life and voltage when

plotted on log-log graph paper. Other models may be used.

Electrical ageing may also be accelerated by testing at a higher frequency than that

experienced in normal service. The frequency increase shall have been shown to provide no

change of the ageing mechanism, in the stress range, for either the candidate or the

reference system.

In special cases it may be possible to perform electrical endurance tests with stepwise

increasing stress for each test object. It is also necessary to specify a definite mathematical

relationship between stress level and time to failure, as well as a method for reducing test

results to a common time or a common stress level value. Either fixed or increasing stress

levels may be used in cyclic tests.

For data processing and life line presentations, refer to IEC/TS 61251 and IEC 62539.

60505 © IEC:2011 – 17 –

4.4 Thermal ageing

CONTAMINANTS DEFECTS

PRODUCED BY:

• Impurities • Cavities

• Processing

• Particles • Protrusions

• Manufacture

• By-products • Interfaces, cracks

• Transport, storage

• Wrinkles

• Moisture

• Installation

• Material

• Missing components

• Electrical, mechanical

incompatibilities

• Processing errors

and environmental

etc.

• Discontinuities

stresses

etc.

• Abuse, accident

• Misapplication

etc.

TEMPERATURE – high, low, cyclic, gradient

ELECTRICAL INSULATION SYSTEM

Change in state Chemical reactions Modify electric

Thermomechanical

of material stress

• Localized or bulk

• Various rates

Localized at defect or

contaminants or bulk, dependant

e.g.: on defects, Cracks,

contaminants

• Melting

delaminations

• Vaporization

• Crystallisation

• Re-crystallization

• Glass transition

Increase in temperature

• Morphological

changes

etc.

Material modifications Corrosive

by-products

Cracks,

Localized or bulk, e.g.:

delaminations

• Polymerization

Penetration of

• Depolymerization

external

• Reduced mechanical

properties

contaminants

Penetration of

• Formation of hydrophilic Loss, migration

Loss of external

compounds of insulants

mechanical

contaminants

• Formation of conducting

strength

Loss,

compounds

migration of

• Water absorption,

Loss of

insulants

adsorption

mechanical

etc.

strength

Electrical Electrical ageing

(partial discharge,

ageing

Loss of conductor

electrical treeing,

(partial discharge,

continuity

etc.)

electrical treeing,

etc.)

FAILURE

(Different mechanisms of failure occur)

IEC 1233/11

NOTE Other stresses may contribute to failure.

Figure 3 – Intrinsic/extrinsic thermal ageing of practical EIS

– 18 – 60505 © IEC:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...