IEC TS 63102:2021

(Main)Grid code compliance assessment methods for grid connection of wind and PV power plants

Grid code compliance assessment methods for grid connection of wind and PV power plants

IEC TS 63102:2021(E) highlights recommended technical methods of grid code compliance assessment for grid connection of wind and PV power plants as the basic components of grid connection evaluation. The electrical behaviour of wind and PV power plants in this technical specification includes frequency and voltage range, reactive power capability, control performance including active power based control and reactive power based control, fault ride through capability and power quality. Compliance assessment is the process of determining whether the electrical behaviour of wind and PV power plants meets specific technical requirements in grid codes or technical regulations. The assessment methods include compliance testing, compliance simulation and compliance monitoring. The input for compliance assessment includes relevant supporting documents, testing results and validated simulation models, and continuous monitoring data. The scope of this technical specification only covers assessment methods from a technical aspect; processes related to certification are not included. This technical specification is applicable to wind and PV power plants connected to the electrical power grid.

General Information

- Status

- Published

- Publication Date

- 02-Sep-2021

- Technical Committee

- SC 8A - Grid Integration of Renewable Energy Generation

- Drafting Committee

- JWG 4 - TC 8/SC 8A/JWG 4

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-Sep-2021

- Completion Date

- 07-Oct-2021

Overview

IEC TS 63102:2021 provides recommended technical methods for grid code compliance assessment of wind and photovoltaic (PV) power plants. It defines how to determine whether the electrical behaviour of wind and PV plants meets grid code or regulatory requirements for connection to the electrical power grid. The technical specification covers assessment approaches - testing, simulation, and monitoring - and the required inputs such as supporting documentation, test results, validated simulation models and continuous monitoring data. Note: the document addresses technical assessment methods only; certification processes are not included.

Key Topics

- Electrical behaviour covered

- Frequency and voltage range

- Reactive power capability

- Control performance (active-power-based and reactive-power-based control)

- Fault ride through capability

- Power quality (harmonics, flicker)

- Assessment methods

- Compliance testing (plant field testing)

- Compliance simulation (including harmonic and fault simulations)

- Compliance monitoring (continuous performance monitoring)

- CHIL (Controller Hardware-in-the-Loop) testing setups and guidance

- Inputs for assessment

- Relevant supporting documents and design data

- Type-test and plant testing results

- Validated simulation models

- Continuous monitoring data and signal lists

- Supplementary guidance

- Annexes on monitoring implementation, CHIL setups, harmonic simulation and performance indices

Practical Applications

IEC TS 63102 is intended to guide technical evaluation of grid-connected wind and PV power plants during:

- Grid-connection studies and compliance verification

- Commissioning and plant acceptance testing

- Ongoing performance monitoring and compliance reporting

- Pre-fault and fault-condition simulation and validation

Primary use cases include verifying reactive power capability, validating fault ride through behaviour, checking active/reactive control performance, and assessing power quality impacts (harmonics and flicker).

Who Should Use This Standard

- Grid operators and transmission/distribution system owners responsible for connection compliance

- Renewable plant engineers and designers preparing documentation, models and test plans

- Test laboratories and commissioning teams executing compliance tests

- System modelers and simulation engineers validating dynamic performance

- Consultants and regulators developing or enforcing grid codes

Related Standards

IEC TS 63102 complements other IEC and regional grid-integration and power-quality standards that address detailed testing procedures, equipment type-testing and regulatory requirements. Users should consult applicable national/regional grid codes alongside this Technical Specification when performing compliance assessments.

Keywords: IEC TS 63102, grid code compliance, wind power plants, PV power plants, compliance assessment methods, fault ride through, reactive power capability, CHIL, power quality, monitoring, simulation, testing.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 63102:2021 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Grid code compliance assessment methods for grid connection of wind and PV power plants". This standard covers: IEC TS 63102:2021(E) highlights recommended technical methods of grid code compliance assessment for grid connection of wind and PV power plants as the basic components of grid connection evaluation. The electrical behaviour of wind and PV power plants in this technical specification includes frequency and voltage range, reactive power capability, control performance including active power based control and reactive power based control, fault ride through capability and power quality. Compliance assessment is the process of determining whether the electrical behaviour of wind and PV power plants meets specific technical requirements in grid codes or technical regulations. The assessment methods include compliance testing, compliance simulation and compliance monitoring. The input for compliance assessment includes relevant supporting documents, testing results and validated simulation models, and continuous monitoring data. The scope of this technical specification only covers assessment methods from a technical aspect; processes related to certification are not included. This technical specification is applicable to wind and PV power plants connected to the electrical power grid.

IEC TS 63102:2021(E) highlights recommended technical methods of grid code compliance assessment for grid connection of wind and PV power plants as the basic components of grid connection evaluation. The electrical behaviour of wind and PV power plants in this technical specification includes frequency and voltage range, reactive power capability, control performance including active power based control and reactive power based control, fault ride through capability and power quality. Compliance assessment is the process of determining whether the electrical behaviour of wind and PV power plants meets specific technical requirements in grid codes or technical regulations. The assessment methods include compliance testing, compliance simulation and compliance monitoring. The input for compliance assessment includes relevant supporting documents, testing results and validated simulation models, and continuous monitoring data. The scope of this technical specification only covers assessment methods from a technical aspect; processes related to certification are not included. This technical specification is applicable to wind and PV power plants connected to the electrical power grid.

IEC TS 63102:2021 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering; 27.180 - Wind turbine energy systems; 33.160.30 - Audio systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 63102:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 63102 ®

Edition 1.0 2021-09

TECHNICAL

SPECIFICATION

colour

inside

Grid code compliance assessment methods for grid connection of wind and PV

power plants

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 63102 ®

Edition 1.0 2021-09

TECHNICAL

SPECIFICATION

colour

inside

Grid code compliance assessment methods for grid connection of wind and PV

power plants

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160; 27.180 ISBN 978-2-8322-1022-1

– 2 – IEC TS 63102:2021 IEC 2021

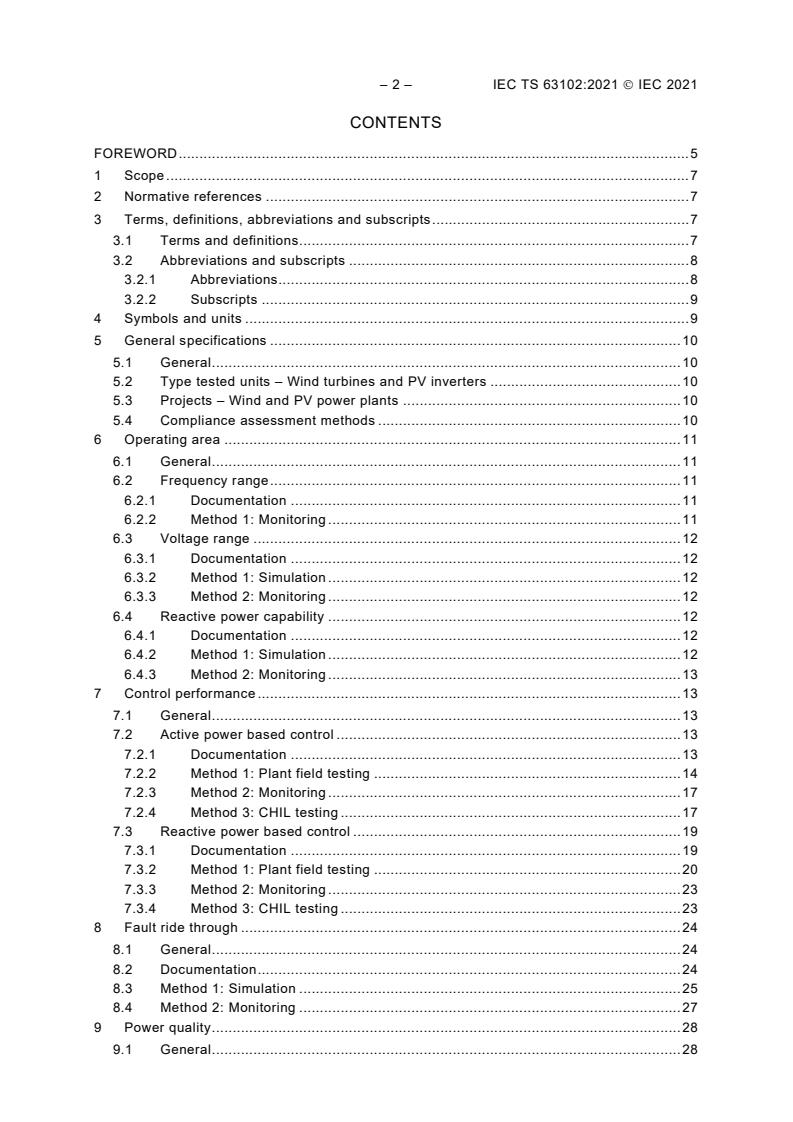

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, abbreviations and subscripts . 7

3.1 Terms and definitions . 7

3.2 Abbreviations and subscripts . 8

3.2.1 Abbreviations . 8

3.2.2 Subscripts . 9

4 Symbols and units . 9

5 General specifications . 10

5.1 General . 10

5.2 Type tested units – Wind turbines and PV inverters . 10

5.3 Projects – Wind and PV power plants . 10

5.4 Compliance assessment methods . 10

6 Operating area . 11

6.1 General . 11

6.2 Frequency range . 11

6.2.1 Documentation . 11

6.2.2 Method 1: Monitoring . 11

6.3 Voltage range . 12

6.3.1 Documentation . 12

6.3.2 Method 1: Simulation . 12

6.3.3 Method 2: Monitoring . 12

6.4 Reactive power capability . 12

6.4.1 Documentation . 12

6.4.2 Method 1: Simulation . 12

6.4.3 Method 2: Monitoring . 13

7 Control performance . 13

7.1 General . 13

7.2 Active power based control . 13

7.2.1 Documentation . 13

7.2.2 Method 1: Plant field testing . 14

7.2.3 Method 2: Monitoring . 17

7.2.4 Method 3: CHIL testing . 17

7.3 Reactive power based control . 19

7.3.1 Documentation . 19

7.3.2 Method 1: Plant field testing . 20

7.3.3 Method 2: Monitoring . 23

7.3.4 Method 3: CHIL testing . 23

8 Fault ride through . 24

8.1 General . 24

8.2 Documentation . 24

8.3 Method 1: Simulation . 25

8.4 Method 2: Monitoring . 27

9 Power quality . 28

9.1 General . 28

9.2 Current harmonics and inter-harmonics . 28

9.2.1 Documentation . 28

9.2.2 Method 1: Plant Field testing . 28

9.3 Flicker . 29

9.3.1 Documentation . 29

9.3.2 Method 1: Plant field testing . 29

Annex A (informative) Monitoring of electrical performance of wind and PV power

plants. 30

A.1 Overview. 30

A.2 Responsibilities . 30

A.3 Basic principles . 30

A.4 Monitoring signals . 30

A.5 Monitoring hardware . 31

Annex B (informative) Controller hardware in the loop (CHIL) testing setup . 32

B.1 General . 32

B.2 Power plant modelling . 32

B.3 Set-up . 32

Annex C (informative) Harmonic simulation for wind and PV power plants . 34

C.1 General . 34

C.2 General simulation methods . 35

Annex D (informative) Control performance index . 37

Bibliography . 38

Figure 1 – An example of PQ diagram . 13

Figure 2 – Example of figure for active power ramp rate test . 15

Figure 3 – Example of figure for set point test of active power . 15

Figure 4 – Example of figure for frequency control test . 16

Figure 5 – Example of figure for frequency control test with simulated frequency

variation . 18

Figure 6 – Example figure for set point control of reactive power as control reference

(reactive power control mode) . 21

Figure 7 – Example of figure for set point control of voltage as control reference

(voltage control mode) . 22

Figure 8 – Example of figure for voltage control test . 23

Figure 9 – Layout of grid with symmetrical fault . 25

Figure 10 – Layout of grid with unsymmetrical fault . 25

Figure 11 – Example of active power recovery . 27

Figure 12 – Equivalent circuit of the grid and the power plant . 29

Figure B.1 – Test bench diagram . 33

Figure C.1 – Ideal harmonic current source illustration for harmonic distortion

calculation . 34

Figure C.2 – Converter harmonic model as a Norton/Thevenin equivalent circuit . 35

Figure C.3 – Norton equivalent harmonic current source illustration for network

harmonic distortion calculation . 35

Figure C.4 – Power electronics average model Norton equivalent circuit representation . 36

Figure D.1 – Performance index of active and reactive power based control . 37

– 4 – IEC TS 63102:2021 IEC 2021

Table 1 – Overview of assessment methods . 11

Table 2 – Example table for maximum variation value of active power . 16

Table 3 – Example of table for performance index of set point test. 17

Table 4 – Example of table for performance index of frequency control response . 17

Table 5 – Example of table for functionality test of frequency control . 19

Table 6 – Example of table for coordination functionality of active power set point and

frequency control . 19

Table 7 – Example of table for reactive power control testing . 22

Table 8 – Example of table for voltage control testing . 23

Table 9 – Example of table for voltage control test . 24

Table 10 – Recommended scenario of pre-fault operation modes . 26

Table 11 – Recommended scenario of grid fault types and under/over voltage levels . 26

Table 12 – Example table for fault ride through simulation results . 27

Table A.1 – Monitoring signals . 31

Table B.1 – CHIL system boundaries . 33

Table B.2 – Signal list . 33

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

GRID CODE COMPLIANCE ASSESSMENT METHODS FOR GRID

CONNECTION OF WIND AND PV POWER PLANTS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TS 63102 has been prepared by subcommittee SC 8A: Grid integration of renewable

energy generation, of IEC technical committee TC 8: System aspects of electrical energy

supply. It is a Technical Specification.

The text of this Technical Specification is based on the following documents:

Draft Report on voting

8A/80/DTS 8A/86/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

– 6 – IEC TS 63102:2021 IEC 2021

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement,

available at www.iec.ch/members_experts/refdocs. The main document types developed by

IEC are described in greater detail at www.iec.ch/standardsdev/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

GRID CODE COMPLIANCE ASSESSMENT METHODS FOR GRID

CONNECTION OF WIND AND PV POWER PLANTS

1 Scope

This technical specification highlights recommended technical methods of grid code

compliance assessment for grid connection of wind and PV power plants as the basic

components of grid connection evaluation. The electrical behaviour of wind and PV power

plants in this technical specification includes frequency and voltage range, reactive power

capability, control performance including active power based control and reactive power

based control, fault ride through capability and power quality.

Compliance assessment is the process of determining whether the electrical behaviour of

wind and PV power plants meets specific technical requirements in grid codes or technical

regulations. The assessment methods include compliance testing, compliance simulation and

compliance monitoring. The input for compliance assessment includes relevant supporting

documents, testing results and validated simulation models, and continuous monitoring data.

The scope of this technical specification only covers assessment methods from a technical

aspect; processes related to certification are not included.

This technical specification is applicable to wind and PV power plants connected to the

electrical power grid.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-415:1999, International Electrotechnical Vocabulary – Part 415: Wind turbine

generator systems

IEC 61400-21-1, Wind energy generation systems – Part 21-1: Measurement and assessment

of electrical characteristics – Wind turbines

IEC 62934, Grid integration of renewable energy generation – Terms and definitions

3 Terms, definitions, abbreviations and subscripts

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61400-21-1,

IEC 60050-415, IEC 62934 and the following apply.

ISO and IEC also maintain terminological database for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC TS 63102:2021 IEC 2021

3.1.1

compliance monitoring

monitoring activity with the purpose of demonstrating the continuous compliance with the

required specifications throughout the lifetime of the power plant

3.1.2

compliance simulation

simulation activity with the purpose of demonstrating the compliance with the required

specifications, especially where testing is not applicable or risk of damaging the facility exists

3.1.3

controller hardware in the loop testing

CHIL testing

testing method for the subject controller based on physical and digital real-time simulation

Note 1 to entry: A simulation model is used to build the external real-time testing environment. Then a closed loop

test system is composed of the simulation model and embedded physical controller under test.

3.1.4

grid code

document that recommends practices or procedures for the activities of connection,

management, planning, development and maintenance of the electrical transmission and

distribution grid, as well as dispatching and metering, etc.

3.1.5

grid code compliance

demonstration that the electrical behaviours of power plants satisfy specific technical

requirements in grid codes or technical regulations

3.2 Abbreviations and subscripts

3.2.1 Abbreviations

The following abbreviations are used in this document:

CHIL controller hardware in the loop

CIGRE International Council on Large Electric Systems

CT Current Transformer

DB Dead Band

FACTS Flexible Alternating Current Transmission Systems

HVDC High Voltage Direct Current

OF Over Frequency

OVRT over-voltage ride-through

PCS power conditioning system

PV photovoltaic

POC point of connection

PQ active power and reactive power

SCR short circuit ratio

STATCOM static synchronous compensator

TS technical specification

UF Under Frequency

UVRT under-voltage ride-through

VT Voltage Transformer

3.2.2 Subscripts

F fault

meas measured value

max maximum

min minimum

n nominal

Omax maximum value of over voltage fault

poc-s produced by the grid

poc-c produced by the power plant

ref reference value

s variable of grid

sa phase A of grid

sb phase B of grid

sc phase C of grid

Umin minimum value of under voltage fault

4 Symbols and units

In this document, the following symbols and units are used.

I tested results of the current at POC (A)

poc

I harmonic currents produced by the grid (A)

poc-s

I harmonic currents produced by the power plant (A)

poc-c

I equivalent current of the grid

s

I equivalent current of the plant

c

P active power of the power plant (W)

P active power rated value (W)

n

P active power measured value (pu)

meas

P maximum long-term flicker

lt

P maximum background long-term flicker

lt0

P maximum long-term flicker caused by power plant

ltRE

Q reactive power of the power plant (Var)

Q reactive power reference value (pu)

ref

Q reactive power measured value (pu)

meas

Q maximum reactive power at POC (Var)

max

Q minimum reactive power at POC (Var)

min

S short circuit power (VA)

k

U rated value of voltage at POC (V)

n

U voltage of the grid (V)

s

U phase A voltage of the grid (V)

sa

U phase B voltage of the grid (V)

sb

U phase C voltage of the grid (V)

sc

U maximum voltage under normal operation at POC (V)

max

U minimum voltage under normal operation at POC (V)

min

– 10 – IEC TS 63102:2021 IEC 2021

U minimum value under voltage according to gird codes (V)

Umin

U maximum value over voltage according to gird codes (V)

Omax

U tested results of the voltage at POC (V)

poc

Z equivalent impedance of the power plant (Ω)

c

Z equivalent fault impedance (Ω)

F

Z equivalent impedance of the grid (Ω)

s

Z phase A equivalent impedance of the grid (Ω)

sa

Z phase B equivalent impedance of the grid (Ω)

sb

Z phase C equivalent impedance of the grid (Ω)

sc

5 General specifications

5.1 General

Technical requirements of wind and PV power plants for connecting to the grid were given in

the grid codes, such as operating area, active power control, reactive power control, fault ride

through, etc. Some existing IEC standards like IEC 61400-21 (all parts) and IEC 61400-27 (all

parts) specify the measurement procedures, modelling and validation methods of electrical

characteristics for wind turbines and wind power plants. This technical specification will

specify the compliance assessment methods of the electrical behaviours stipulated in the grid

codes.

5.2 Type tested units – Wind turbines and PV inverters

Type tested units are a series of wind turbines or PV inverters that have a common design,

materials and major components, subject to a common manufacturing process and uniquely

described by specific values or ranges of values of machine parameters and design

conditions. The definition of a type tested unit is dependent on the characteristics being

assessed and should be agreed by all stakeholders. Type testing is usually performed only

once per type in order to prove the general capability for all units of this type.

5.3 Projects – Wind and PV power plants

Wind or PV power plants are usually built clustering many units and jointly connecting them to

the grid. For these, a project based assessment needs to be performed. This means using

results from the type tested assessment, but taking the site-specific parameters into account.

5.4 Compliance assessment methods

In general, methods of project based compliance assessment can be classified into three

general categories:

• testing, including field testing and controller hardware in the loop (CHIL) testing;

• simulation;

• monitoring.

NOTE Annex A includes detailed information and recommendations for monitoring.

Normally for each electrical behaviour there is more than one compliance assessment method.

The selection of assessment methods should be carried out by system operators taking into

consideration the following factors:

• the technology of the project, including whether the performance is likely to drift or

degrade over a particular time-frame;

• experience with the particular generation technology, including manufacturer's advice;

• the connection point arrangement;

• an assessment of the risks and costs of different testing methods, including consideration

of the relative size of the plant;

• the availability and location of testing equipment, monitoring/metering equipment and

other necessary facilities.

Table 1 gives an overview of recommended assessment methods for different electrical

behaviors.

Table 1 – Overview of assessment methods

Field testing CHIL Simulation Monitoring

Frequency

x

range

Operating area Voltage range x x

Reactive power

x x

capability

Control performance x x x

Fault ride through x x

Power quality x

x: recommended assessment methods.

6 Operating area

6.1 General

As the frequency and voltage of the power system are not constant, the wind and PV power

plants need to be capable of being operated continuously or for certain durations within

specified frequency and voltage ranges required by the grid codes. Reactive power capability

is also required to help maintain the system voltage and fulfil reactive power demand of the

grid. The operating area is generally focused on steady state conditions. For compliance

assessment of transient behaviour during grid faults, see Clause 8.

Assessment of the operating area is the assessment of appropriate equipment rating. This

rating assessment for power plants should be based on the units and the additional

equipment installed in the plant. This assessment can be undertaken in the planning phase

based on related documentation and load flow simulations. The continuous compliance should

be monitored as well. Field testing at the wind or PV power plant level is not recommended for

confirmation of the entire frequency and voltage area since this testing can endanger both

grid and plant safety. However, field testing could be conducted to confirm reactive power

capability and a limited range within the frequency or voltage area.

6.2 Frequency range

6.2.1 Documentation

Related documentation should be provided in the planning phase declaring the frequency

range of units and additional equipment installed in the power plant. For the units and

additional equipment, specification or manufacturer declarations should be submitted.

6.2.2 Method 1: Monitoring

The POC of the power plant and main equipment within the plant should be monitored and

assessed continuously. For the evaluation of power plant operability with decreased or

increased grid frequency, the protection settings at POC should be documented.

– 12 – IEC TS 63102:2021 IEC 2021

6.3 Voltage range

6.3.1 Documentation

Corresponding documentation should be provided in order to prove the voltage operational

range of units and additional equipment are installed in the power plant. For each component

under assessment, specification or manufacturer declarations should be submitted.

For additional equipment installed in the power plant, documentation of those components

should be provided. Documentation may include, but should not be limited to rating plate data,

environmental assumptions and corresponding calculations.

6.3.2 Method 1: Simulation

The voltage range of power plants is referred to the POC. All terminals of the units and main

equipment within the plant should be assessed (e.g. transformers, reactive power

compensation devices). This can be achieved by load flow simulation, during which

corresponding assumptions should be made for the worst realistic cases at all terminals.

Dynamic simulation (with base frequency domain 50 Hz/60 Hz RMS simulation) can help

confirm the withstand time of wind and PV power plants capability to voltages in the voltage

area. Modelling and model validation procedure can refer to IEC 61400-27-1 and

IEC 61400-27-2.

6.3.3 Method 2: Monitoring

The POC of the power plant and main equipment within the plant should be monitored and

assessed continuously. For the evaluation of power plant operability with decreased or

increased grid voltage, the protection settings at POC should be documented.

6.4 Reactive power capability

6.4.1 Documentation

For wind power plants, tests for reactive power capability should be performed for each type

of wind turbine according to IEC 61400-21-1. When each PCS device is individually equipped

with a voltage detection device and reactive power control function, it is sufficient to perform a

verification test for that function at the manufacturer's factory or testing laboratory, making

field testing optional. Alternatively, corresponding type test reports can be assessed if they

have been performed in the past. The scope of required testing depends on grid codes. If no

type tests exist, corresponding tests should be performed instead.

If the plant contains reactive power compensation devices, corresponding documentation

should be provided declaring their reactive power capability. For STATCOM, the available

operation modes should be listed and clarified in detail. Corresponding type test reports,

specification or manufacturer declarations should be submitted.

6.4.2 Method 1: Simulation

Before simulation, the reactive power capability of unit models should be configured according

to IEC 61400-27-1 based on type testing results. The maximum and minimum reactive power

capability of the power plant should be verified with load flow calculations, which are

determined by the capability of the units and other components like cables, transformers and

compensation devices.

Simulation procedure of maximum reactive power capability:

• Set all units to the appropriate control mode with the reference value equal to the

maximum operation voltage, or set all units to reactive power control mode with the

reference values equal to the maximum reactive power.

• Execute a sequence of load flow simulations with varying active power levels.

Simulation procedure of minimum reactive power capability:

• Set all units to the appropriate control mode with the reference value equal to the

minimum operation voltage, or set all units to reactive power control mode with the

reference values equal to the minimum reactive power.

• Execute a sequence of load flow simulations with varying active power levels.

The maximum and minimum operation voltage is based on the voltage range of continuous

operation in 6.3. For low active power level (e.g. P < 10 %P ), if reactive power capability

n

were not required in grid codes, then relevant simulation scenarios are not mandatory. The

simulation results can be summarized as a PQ-diagram including both the grid code

requirements and the plant capability (see Figure 1 as an example).

Figure 1 – An example of PQ diagram

6.4.3 Method 2: Monitoring

The reactive power at the plant POC should be monitored and assessed continuously.

7 Control performance

7.1 General

Grid codes require power plants to be properly controlled keeping power systems in balance

and stable condition. Depending on grid codes, the active power outputs of power plants

could be controlled by either active power or grid frequency variation settings. This kind of

control performance is named active power based control. Meanwhile the control reference of

reactive power could be selected from either reactive power, grid voltage or power factor

settings, and the related control performance is named reactive power based control.

Control performance assessment intends to assess the functionality and controllability of

plants in both normal and dynamic operation states. The electrical behaviour can be directly

tested in pre-commercial operation phase if permitted by system operators. Some special test

cases should be performed by CHIL, due to the unchangeable grid frequency and safe range

of voltage. The control performance of power plants can also be assessed and monitored

during commercial operation.

7.2 Active power based control

7.2.1 Documentation

Specification or manufacturer declarations of plant controllers should be submitted.

– 14 – IEC TS 63102:2021 IEC 2021

7.2.2 Method 1: Plant field testing

The active power at POC can be measured with variant control references such as set point

and ramp rate. In order to assess frequency control performance, variant frequency signals

can be injected into the plant controller to simulate a grid frequency incident. During plant

field testing the injected system frequency should be manipulated within certain frequency

operation range according to grid codes, normally including Under-Frequency (UF) range,

Dead-Band (DB) range, and Over-Frequency (OF) range. The testing procedure should refer

to IEC 61400-21-2 .

Plant field testing should meet the following conditions:

• The available active power output of power plant should be at least 50 % of rated power.

• The plant active power production at POC and control reference signal should be

monitored and documented continuously at the same time.

• The plant active power production, grid frequency at POC and control reference signal

should be monitored and documented at the same time, when the frequency control is

performed.

• If a grid meter is used for the measurement, the sampling frequency of grid meter output

should be at least 10 Hz.

• If no grid meter is used, the measurements should be obtained by CT/VT sensors, and the

sampling frequency of measurements should be at least 1 kHz.

• During a field test, all measurements signals should be time stamped, in order to assess

the plant control timing related performance, for instance, rise time.

• The testing results should be reported as 0,1 s average data.

The contents of plant field testing include:

• active power ramp rate test;

• active power set point test;

• frequency control test (variant frequency signals injected into the plant controller to

simulate a grid frequency incident).

Results of plant field testing should be presented in the following form:

• Figure: time series of active power set point value and measured active power output in

the ramp rate test, see Figure 2.

• Figure: time series of control reference and measured active power output in the set point

test, see Figure 3.

• Figure: time series of adjustment response of injected frequency test, see Figure 4.

____________

Under preparation. Stage at the time of publication: IEC/CCDV 61400-21-2:2021.

Figure 2 – Example of figure for active power ramp rate test

Figure 3 – Example of figure for set point test of active power

– 16 – IEC TS 63102:2021 IEC 2021

Figure 4 – Example of figure for frequency control test

• Table: Maximum variation value in 10 min and 1 min of active power in the ramp rate test,

see Table 2. It can be calculated by using sliding window in the test data.

• Table: Control settling time, overshoot as percentage of reference and static error for each

control reference in the set point test, see Table 3. The calculation method of performance

index described in Annex D.

• Table: Control response time, control settling time, active power before and after the

injected frequency disturbance and static error in the frequency control test, see Table 4.

Performance indexes are described in Annex D.

The performance index and cases for compliance assessment listed in Table 2~Table 4

should be determined according to the situation in different countries.

Table 2 – Example table for maximum variation value of active power

Maximum variation value in 10 min Maximum variation value in 1 min

Cases

(MW) (MW)

Normal operation

Start-up

Stop

Table 3 – Example of table for performance index of set point test

Set value of active power

Control settling time Overshoot Tolerance band

(s) (%) (%)

[(P/P ) p.u.]

n

0,8 → 0,6

0,6 → 0,4

0,4 → 0,2

0,2 → 0,4

0,4 → 0,6

0,6 → 0,8

Table 4 – Example of table for performance index of frequency control response

Cases Control Control Active power Active power Tolerance

response settling time before after band

time disturbance disturbance

(s) (%)

(s)

(p.u.) (p.u.)

50 Hz → 50,2 Hz

(Active power derating to

0,2 p.u ~ 0,3 p.u.)

50 Hz → 50,2 Hz

(Active power

0,2 p.u ~ 0,3 p.u. without

derating)

50 Hz → 50,2 Hz

(Active power derating to

0.5~0.9 p.u.)

50 Hz → 50,2 Hz

( Active power 0.5~0.9p.u.

without derating)

50 Hz → 49,8 Hz

(Active power derating to

0.2 p.u ~ 0.3 p.u.)

50 Hz →49,8 Hz

( Active power

0.2 p.u. ~ 0.3 p.u. without

derating)

7.2.3 Method 2: Monitoring

The plant active power production at POC should be measured, while the control reference

signal should be monitored continuously at the same time.

If frequency control is required, the plant frequency at POC should be measured

simultaneously, while the control reference signal should be monitored continuously at the

same time.

7.2.4 Method 3: CHIL testing

CHIL is generally used for active power based control strategy testing. In CHIL testing

environment, the plant controller should be hardware based. Except that, the power plant

should be a simulation model with at least one generation unit, as well as the external grid.

The testing procedure can refer to IEC 61400-21-2.

– 18 – IEC TS 63102:2021 IEC 2021

CHIL testing should meet following conditions:

• The available active power output of the power plant should be equal to the rated power.

• Simulated frequency variation (upward and downward) should be obtained in the external

grid model.

• The testing results should be reported as 0,1 s average data.

The contents of CHIL testing include:

• frequency control functionality;

• coordination functionality of active power set point and frequency control.

Results of CHIL test should be presented in the following form:

• Figure: Time series of simulated frequency variation, active power reference and

measured active power output, see Figure 5.

Figure 5 – Example of figure for frequency control

test with simulated frequency variation

• Table: functionality assessment of frequency control, see Table 4.

• Table: frequency step value, active power set point and measured active power output in

the coordin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...