IEC TR 60068-3-12:2014

(Main)Environmental testing - Part 3-12: Supporting documentation and guidance - Method to evaluate a possible lead-free solder reflow temperature profile

Environmental testing - Part 3-12: Supporting documentation and guidance - Method to evaluate a possible lead-free solder reflow temperature profile

IEC TR 60068-3-12:2014 presents two approaches for establishing a possible temperature profile for a lead-free reflow soldering process using SnAgCu solder paste. This process covers a great variety of electronic products, including a large range of package sizes (e.g. molded active electronic components, passive components and electromechanical components). Study A addresses requirements needed in the production of high-reliability electronic control units (ECU), as for example in automotive electronics. These requirements include measurement and production tolerances. Study B represents consumer electronics products and includes reflow oven capability, board design and package sizes. This edition includes the following significant technical changes with respect to the previous edition:

- the content has been adapted to the state-of-the-art of reflow-oven technology and termination finishes;

- minor language adjustments were performed.

Essais d'environnement - Partie 3-12: Documentation d'accompagnement et guide - Méthode d'évaluation d'un profil de température possible de brasage sans plomb par refusion

L'IEC TR 60068-3-12:2014 présente deux approches pour établir un profil de température possible pour un processus de brasage sans plomb par refusion utilisant de la pâte à braser au SnAgCu. Ce processus recouvre une grande diversité de produits électroniques, incluant une large gamme de dimensions de boîtier (par exemple, des composants électroniques actifs moulés, des composants passifs et des composants électromécaniques). L'étude A traite les exigences nécessaires pour la fabrication d'unités de commande électroniques (ECU, Electronic Control Unit) de haute fiabilité, par exemple pour l'électronique automobile. Ces exigences contiennent les tolérances de mesure et de fabrication. L'étude B présente les produits électroniques grand public et inclut les caractéristiques des fours de refusion, la conception des cartes et les dimensions des boîtiers.

General Information

- Status

- Published

- Publication Date

- 16-Oct-2014

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 14-Oct-2022

- Completion Date

- 27-Aug-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC TR 60068-3-12:2014 is a pivotal technical report published by the International Electrotechnical Commission (IEC) that provides supporting documentation and guidance for evaluating a lead-free solder reflow temperature profile. This standard focuses specifically on the SnAgCu solder paste reflow process, an essential procedure in electronic assembly. It addresses the unique challenges of lead-free soldering, which requires higher temperature profiles than traditional SnPb solder paste, particularly for achieving reliable solder joints while protecting components from thermal damage.

The report presents two major approaches-Study A and Study B-that account for different electronic product categories and production requirements, covering a diverse range of package sizes, including molded active components, passive components, and electromechanical parts.

Key Topics

Lead-Free Soldering Temperature Profiles

The introduction of lead-free soldering necessitates an increase in peak reflow temperatures by approximately 20 K to 30 K compared to SnPb soldering, due to the higher melting point of SnAgCu alloy (~217 °C). IEC TR 60068-3-12:2014 outlines methods to establish temperature profiles that ensure reliable solder joints while addressing the thermal sensitivity of various electronic components.

Two Study Approaches

- Study A: Tailored for high-reliability electronic control units (ECU), such as those used in automotive electronics. This study focuses on critical measurement and production tolerances to safeguard safety- and mission-critical assemblies.

- Study B: Focuses on consumer electronics, factoring in reflow oven capabilities, board design practices, and diverse package sizes. It accounts for practical manufacturing conditions and board variability.

Temperature Tolerances and Peak Profiles

The report details how to evaluate temperature tolerances across different components during reflow. It also explains peak temperature form and duration, such as the “hat” profile with specific peak time and temperature targets, to maintain process uniformity.

Classification of Devices and Boards

IEC TR 60068-3-12 provides classification schemes for both devices and boards based on their thermal profiles and tolerance needs. This supports better selection and qualification of components and assembly boards according to their heat resistance and reliability requirements.

Practical Guidance on Profile Development

The report consolidates best practices for deriving lead-free reflow profiles that bridge the gap between ensuring solder joint reliability and protecting component integrity. Proposed profiles meet the unique demands of different product categories and manufacturing setups.

Applications

IEC TR 60068-3-12:2014 serves as a comprehensive guide for:

- Electronic manufacturers who transition from SnPb to lead-free soldering processes and require validated temperature profiles to avoid failures.

- Automotive electronics production, where stringent reliability criteria and heat impact tolerances apply.

- Consumer electronics manufacturers aiming to optimize reflow oven settings, considering board designs and component variability.

- Process engineers and quality assurance teams looking for a scientifically grounded method to evaluate and control reflow soldering parameters.

- Environmental and reliability testing of assembled electronic products, ensuring compliance with international standards.

By using the methodologies in this report, manufacturers can minimize solder joint defects, reduce thermal damage to components, and comply with regulatory directives banning lead-based solder.

Related Standards

IEC TR 60068-3-12:2014 is part of the broader IEC 60068 series on Environmental Testing, which covers various environmental influences and test methods for electrotechnical products. Key related standards include:

- IEC 60068-2 series: Specifies environmental testing procedures such as temperature cycling, humidity, and mechanical tests pertinent to electronics.

- IEC 61760: Covers termination finishes for components that can impact solderability and reflow characteristics.

- IPC standards (e.g., IPC-7351, IPC-7711/7721): Industry standards providing best practices in soldering and printed circuit board assembly, complementary for implementing IEC profiles.

- JEDEC standards on thermal profiles and component reliability testing, which often collaborate with IEC methodologies.

Understanding and integrating IEC TR 60068-3-12:2014 with these complementary standards enables a holistic approach to environmental testing, soldering process optimization, and component qualification.

This IEC technical report offers essential reference material and practical guidance for designing lead-free solder reflow temperature profiles-critical for advancing electronic assembly technology that balances reliability, manufacturing efficiency, and compliance with modern environmental requirements.

IEC TR 60068-3-12:2014 - Environmental testing - Part 3-12: Supporting documentation and guidance - Method to evaluate a possible lead-free solder reflow temperature profile Released:10/17/2014 Isbn:9782832218884

IEC TR 60068-3-12:2014 - Environmental testing - Part 3-12: Supporting documentation and guidance - Method to evaluate a possible lead-free solder reflow temperature profile

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC TR 60068-3-12:2014 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 3-12: Supporting documentation and guidance - Method to evaluate a possible lead-free solder reflow temperature profile". This standard covers: IEC TR 60068-3-12:2014 presents two approaches for establishing a possible temperature profile for a lead-free reflow soldering process using SnAgCu solder paste. This process covers a great variety of electronic products, including a large range of package sizes (e.g. molded active electronic components, passive components and electromechanical components). Study A addresses requirements needed in the production of high-reliability electronic control units (ECU), as for example in automotive electronics. These requirements include measurement and production tolerances. Study B represents consumer electronics products and includes reflow oven capability, board design and package sizes. This edition includes the following significant technical changes with respect to the previous edition: - the content has been adapted to the state-of-the-art of reflow-oven technology and termination finishes; - minor language adjustments were performed.

IEC TR 60068-3-12:2014 presents two approaches for establishing a possible temperature profile for a lead-free reflow soldering process using SnAgCu solder paste. This process covers a great variety of electronic products, including a large range of package sizes (e.g. molded active electronic components, passive components and electromechanical components). Study A addresses requirements needed in the production of high-reliability electronic control units (ECU), as for example in automotive electronics. These requirements include measurement and production tolerances. Study B represents consumer electronics products and includes reflow oven capability, board design and package sizes. This edition includes the following significant technical changes with respect to the previous edition: - the content has been adapted to the state-of-the-art of reflow-oven technology and termination finishes; - minor language adjustments were performed.

IEC TR 60068-3-12:2014 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 60068-3-12:2014 has the following relationships with other standards: It is inter standard links to IEC TR 60068-3-12:2022, IEC TR 60068-3-12:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 60068-3-12:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 60068-3-12 ®

Edition 2.0 2014-10

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Environmental testing –

Part 3-12: Supporting documentation and guidance – Method to evaluate a

possible lead-free solder reflow temperature profile

Essais d'environnement –

Partie 3-12: Documentation d'accompagnement et guide – Méthode d'évaluation

d'un profil de température possible de brasage sans plomb par refusion

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC TR 60068-3-12 ®

Edition 2.0 2014-10

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Environmental testing –

Part 3-12: Supporting documentation and guidance – Method to evaluate a

possible lead-free solder reflow temperature profile

Essais d'environnement –

Partie 3-12: Documentation d'accompagnement et guide – Méthode d'évaluation

d'un profil de température possible de brasage sans plomb par refusion

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX Q

ICS 19.040 ISBN 978-2-8322-1888-4

– 2 – IEC TR 60068-3-12:2014 IEC 2014

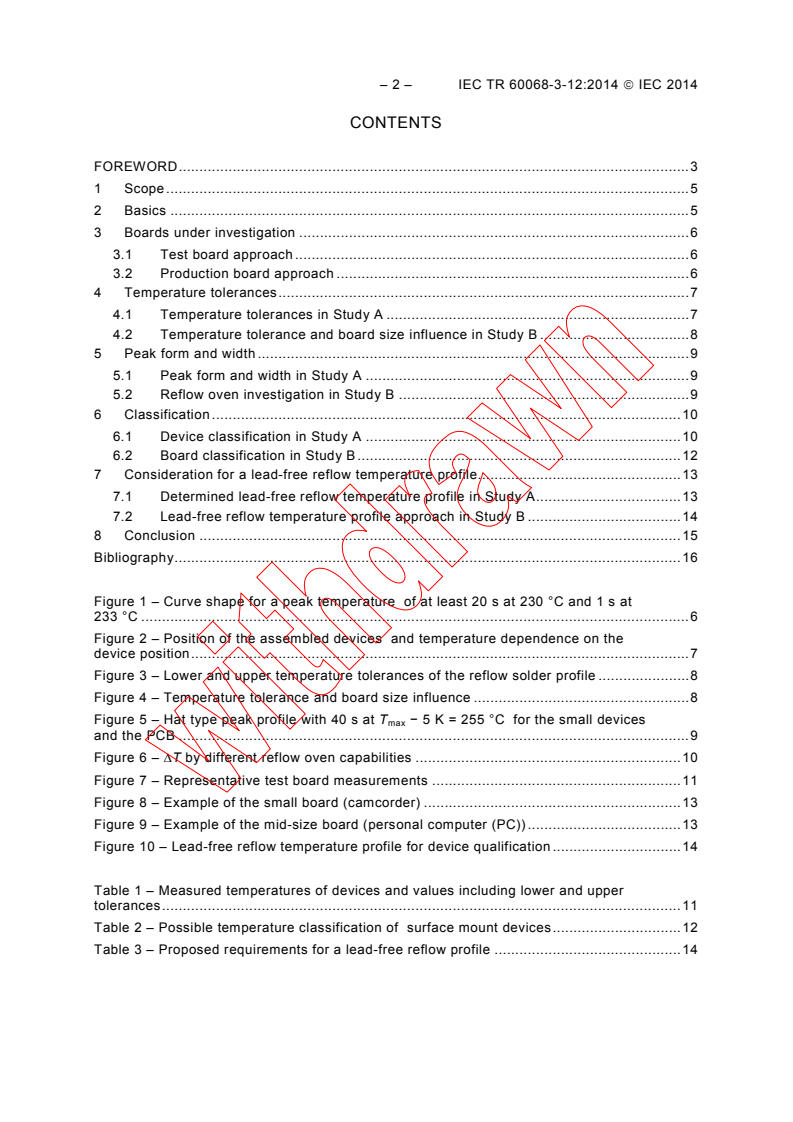

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Basics . 5

3 Boards under investigation . 6

3.1 Test board approach . 6

3.2 Production board approach . 6

4 Temperature tolerances . 7

4.1 Temperature tolerances in Study A . 7

4.2 Temperature tolerance and board size influence in Study B . 8

5 Peak form and width . 9

5.1 Peak form and width in Study A . 9

5.2 Reflow oven investigation in Study B . 9

6 Classification . 10

6.1 Device classification in Study A . 10

6.2 Board classification in Study B . 12

7 Consideration for a lead-free reflow temperature profile. 13

7.1 Determined lead-free reflow temperature profile in Study A . 13

7.2 Lead-free reflow temperature profile approach in Study B . 14

8 Conclusion . 15

Bibliography . 16

Figure 1 – Curve shape for a peak temperature of at least 20 s at 230 °C and 1 s at

233 °C . 6

Figure 2 – Position of the assembled devices and temperature dependence on the

device position . 7

Figure 3 – Lower and upper temperature tolerances of the reflow solder profile . 8

Figure 4 – Temperature tolerance and board size influence . 8

Figure 5 – Hat type peak profile with 40 s at T − 5 K = 255 °C for the small devices

max

and the PCB . 9

Figure 6 – ∆T by different reflow oven capabilities . 10

Figure 7 – Representative test board measurements . 11

Figure 8 – Example of the small board (camcorder) . 13

Figure 9 – Example of the mid-size board (personal computer (PC)) . 13

Figure 10 – Lead-free reflow temperature profile for device qualification . 14

Table 1 – Measured temperatures of devices and values including lower and upper

tolerances . 11

Table 2 – Possible temperature classification of surface mount devices . 12

Table 3 – Proposed requirements for a lead-free reflow profile . 14

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 3-12: Supporting documentation and guidance –

Method to evaluate a possible lead-free solder

reflow temperature profile

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 60068-3-12, which is a technical report, has been prepared by IEC technical

committee 91: Electronics assembly technology.

This second edition cancels and replaces the first edition published in 2007 and constitutes a

technical revision.

– 4 – IEC TR 60068-3-12:2014 IEC 2014

This edition includes the following significant technical changes with respect to the previous

edition:

• the content has been adapted to the state-of-the-art of reflow-oven technology and

termination finishes;

• minor language adjustments were performed.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

91/1158/DTR 91/1177/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60068 series, under the general title Environmental testing,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

ENVIRONMENTAL TESTING –

Part 3-12: Supporting documentation and guidance –

Method to evaluate a possible lead-free solder

reflow temperature profile

1 Scope

This part of IEC 60068, which is a technical report, presents two approaches for establishing

a possible temperature profile for a lead-free reflow soldering process using SnAgCu solder

paste.

This process covers a great variety of electronic products, including a large range of package

sizes (e.g. molded active electronic components, passive components and electromechanical

components).

Study A addresses requirements needed in the production of high-reliability electronic control

units (ECU), as for example in automotive electronics. These requirements include

measurement and production tolerances.

Study B represents consumer electronics products and includes reflow oven capability, board

design and package sizes.

2 Basics

The process temperature for SnPb solder paste has a wide margin due to the liquid

temperature of the solder alloy. During reflow soldering, temperature differences between

components exist but are not critical. The process temperature of SnAgCu solder paste is

about 20 K to 30 K higher than SnPb solder paste. Furthermore, the temperature difference

between components (∆T) becomes wider and sometimes the heat resistance temperature of

components can become critical.

To avoid soldering failures which could be very harmful in safety-related applications and also

generate higher failure costs, the capability of the soldering process is very important.

A compromise between the temperature requirements of highly reliable solder joints and the

limited solder-heat resistance of the electronic components has to be sought. In addition, the

different aspects of mass production have to be considered. To achieve a reliable solder joint,

the conventional reflow soldering process with eutectic SnPb solder paste is usually

performed at a minimum peak temperature of about 203 °C at the coldest solder joint (i.e. at

least 20 K above the liquid temperature of SnPb T = 183 °C).

liquid

The selected lead-free solder is SnAgCu with a melting point at around T = 217 °C [1] . It

liquid

is a generally preferred material for lead-free reflow and wave soldering in mass production

[2]. Using SnAgCu solder paste, it is not possible to solder the coldest solder joints at least

20 K above the liquid temperature (T = 217 °C), which would result in minimum

liquid

temperatures of 237 °C. When the coldest solder joint is 237 °C, the temperature spread

between small and large components, small semiconductor, and passive components, as well

as the printed circuit board (PCB), will be too large for the components to survive the heat

impact. Despite the aim to achieve a relatively low temperature at the coldest solder joint, the

reliability of the solder joint has to be assured.

___________

Numbers in square brackets refer to the Bibliography.

– 6 – IEC TR 60068-3-12:2014 IEC 2014

To reach this target in Study A, the temperature at the coldest solder joint is taken to be

T = 230 °C, for a minimum time of 20 s, which is just 13 K above the melting temperature.

min

Considering the peak shape (see Figure 1) this condition corresponds to 1 s at 233 °C. From

a physical point of view, the risk of insufficient solder wetting during mass production is

significantly higher if the solder joint temperature is lower than the above mentioned

temperature of 230 °C. In addition, lead-free termination finishes (like tin layers with a post-

bake process or very thin NiPdAu finishes) are known to exhibit a poorer wetting behavior

than conventional SnPb pin finishes.

Coldest solder joint

20 s at 230 °C

t, s

IEC

Figure 1 – Curve shape for a peak temperature

of at least 20 s at 230 °C and 1 s at 233 °C

The experiments had been performed under mass production conditions (850 mm/min) using

state-of-the-art reflow equipment, i.e ovens featuring multiple heating zones, full convection

and N atmosphere.

3 Boards under investigation

3.1 Test board approach

For the experiment in Study A, a special test PCB was designed. Polyimide resin with a glass

transition temperature of T = 260 °C was used as base material for the PCB. Such a test

g

board can represent the entire automotive ECU spectrum. The largest temperature difference

(∆T) between the coldest solder joint and the hottest point existing on this printed circuit

assembly (PCA) spectrum is reflected on this test board (∆T can be even larger for even more

complex PCAs). The coldest solder joint was represented by a defined thermal mass, to

represent large integrated circuits (ICs), coils or aluminium electrolytic capacitors. Its

temperature behavior was correlated with the temperatures of the coldest solder joints on

serial boards.

3.2 Production board approach

For Study B, PCB and reflow oven were taken from actual series production.

T, °C

4 Temperature tolerances

4.1 Temperature tolerances in Study A

For tolerances during temperature profiling, different systematic failures shall be considered.

First of all, there is an error associated with the temperature measurement itself. The

measurement was performed in the centre on top of the packages with a well defined and

repeatable preparation technique. Nevertheless, the failure due to preparation had to be fixed

within ±1,0 K. In addition, the thermocouple (NiCrNi), together with the evaluation unit has an

accuracy of ±1,5 K for pre-selected thermocouples. According to IEC 60584-2 [6] the NiCrNi

thermocouples, class K, tolerance class 1 are specified with a tolerance of ±1,5 K for just the

thermocouple itself without the measurement unit. Based on suppliers indication and own

measurements, the furnace tolerance based on furnace load is ±0,5 K and the furnace

tolerance for long term stability is ±2,5 K.

– Thermocouple with measurement unit:

±1,5 K

– Preparation of thermocouple:

±1,0 K

– Furnace load variation:

±0,5 K

– Long term stability of furnace:

±2,5 K

Because these variations are independent, the Gaussian error propagation can be applied,

which results in a total tolerance of ±3,0 K, due to measurement errors and variations in mass

production. The tolerance of –3,0 K results in the requirement to profile the coldest solder

joint at 236 °C, instead of 233 °C (i.e. 233 °C + 3,0 K). This tolerance is known as the “lower

tolerance”. In addition to the measurement errors and variations due to mass production, the

influences of the test board have to be considered. The measured temperatures of the

electronic components depend also on the position on the test board because of the

longitudinal and transversal temperature spread in the furnace and along the test board (see

Figure 2). These temperature differences are the result of the heat flow conditions in the

furnace and around the test board. The actual temperature of a device can be up to 3,5 K

higher than the measured values at the position where the device is mounted on the test

board. The temperature dependence on the device position was measured independently

before measuring the device temperatures on the assembled test board.

Temperature

Transversal temperature profile

Longitudinal

temperature

profile

Device position

Direction of

on test board

transportation

IEC

Figure 2 – Position of the assembled devices

and temperature dependence on the device position

The thermal mass on the test board, which represents the coldest solder joint on the serial

boards, was designed to include the relevant position-dependent tolerances. The upper

temperature tolerances consist of the position-dependent temperature tolerances of 2 K to

3,5 K and the above mentioned +3 K. This leads to a total upper tolerance of 5 K to 6,5 K.

– 8 – IEC TR 60068-3-12:2014 IEC 2014

Regarding the whole temperature window of the lead-free soldering process, a total position-

dependent temperature tolerance of 8 K to 9,5 K has to be added to the measured ∆T spread

of the devices (see Figure 3).

Upper tolerances (measurement, equipment

and position on test board 5,0 K to 6,5 K)

Measured ∆T between coldest solder joint

and hottest device within each class

∆T devices

236 °C

Lower tolerances (measurement and equipment)

3 K

233 °C

20 s at 230 °C corresponds to 1 s at 233 °C

Minimum temperature requirement; 20 s at 230 °C

20 s 230 °C

IEC

NOTE Electronic devices are divided into three temperature classes.

Figure 3 – Lower and upper temperature tolerances of the reflow solder profile

4.2 Temperature tolerance and board size influence in Study B

In the consumer board study, the measured temperature includes lower temperature tolerance

and upper temperature tolerance. Therefore at the coldest solder joint temperature of 230 °C,

the "worst-case" temperature becomes 227 °C (i.e. 230 °C – 3 K) which is still 10 K higher

than the melting point of the SnAgCu solder alloy (see Figure 4).

∆T = 20 K

∆T between coldest solder joint and hottest

∆T = 15 K

component within the board →

∆T = 10 K

230 °C →

Total tolerance 3 K

Minimum condition for high reliable soldering

227 °C min.

Temperature: 230 °C

13 K

Soldering time: 10 s to 30 s

Melting point of the SnAgCu: 217 °C →

IEC

Figure 4 – Temperature tolerance and board size influence

Small size PCB

・Digital camera

・Camcorder

Small

Mid size PCB

devices

・PC

Large

・Set top box

devices

Very large

devices

Large size PCB

・Non consumer products

5 Peak form and width

5.1 Peak form and width in Study A

The requirements were to maintain a temperature of at least 230 °C for 20 s at the coldest

solder joint, and to limit the peak package temperature of the smallest devices (e.g. SOT23,

small LQFP, TopLEDs and passive components) to T ≤ 260 °C. In order to meet these

peak

requirements, a soak-type preheating, as well as a hat type soldering peak were necessary in

the investigation. The soak-type preheating allowed the temperatures of the individual

packages to be close to each other upon entering the peak zone (see Figure 7). The hat type

form of the soldering peak was used to minimize the temperature differences between the

individual packages during reflow soldering. After conducting the experiment, it was

discovered that the hat type form of the soldering peak required a soak time of 40 s at

T − 5 K = 255 °C for the hottest devices on the PCB (see Figure 5).

max

40 s at 255 °C

PCB

LQFP 14 × 14

LQFP 20 × 20

Coldest solder joint

20 s at 230 °C

t, s

IEC

NOTE Temperature tolerances are included.

Figure 5 – Hat type peak profile with 40 s at T − 5 K = 255 °C

max

for the small devices and the PCB

5.2 Reflow oven investigation in Study B

Figure 6 shows temperature profiles on quad flat package (QFP) leads and a 1608 size

surface mounting device (SMD) resistor using the same board but different reflow ovens. The

reflow oven of Maker B, having more heating zones than the oven of Maker A, shows a wider

temperature spread ∆T in the temperature profile than the oven of Maker A. Thus, the

temperature spread ∆T does not depend primarily on the number of heating zones of the

reflow oven but on the design of the reflow oven.

The peak reflow temperature for smallest components may vary according to the reflow oven

being used. Also board size and board design are other factors affecting the peak reflow

temperature.

T, °C

– 10 – IEC TR 60068-3-12:2014 IEC 2014

Maker A

Maker B

7 zones

12 zones

∆T ≈ 15 °C

230 °C

230 °C

∆T ≈ 20 °C

QFP Lead

1608 R

IEC

Figure 6 – ∆T by different reflow oven capabilities

6 Classification

6.1 Device classification in Study A

To classify the non-hermetic solid-state surface-mount devices into temperature groups with

respect to the reflow peak, the heat capacity and heat conductivity should be taken into

consideration. To simplify the study, the component similarity with respect to the composition

(molded silicon) is taken into account and only the package volume and thickness are

considered. In Figure 7, some typical temperature measurements of molded components

using the described test board with a soak preheating and a hat-type reflow soldering peak

are shown. The transportation speed was 850 mm/min and the temperature measurements

were performed centrally on the top of the packages. In total, the temperature profiles for 19

characteristic molded package types and several passive and electromechanical devices were

measured on a multiple heating zone reflow oven with full convection. Between the coldest

solder joint and the PCB itself, a temperature difference of 13 K was measured. Small plastic

components like small connectors, switches or TopLEDs showed even higher peak package

temperatures with a temperature difference of 17 K from the coldest solder joint [3], [4].

PCB and small devices

BGA

Coldest solder joint

t, s

IEC

NOTE Temperature tolerances are included.

Figure 7 – Representative test board measurements

Table 1 shows the measured temperatures and the temperatures achieved when the lower

and upper tolerances are being added. Temperatures shown are for several characteristic

molded devices with different peak temperatures.

Table 1 – Measured temperatures of devices and values

including lower and upper tolerances

Temperature

Measured Lower Including Upper Including

Device value tolerance lower tolerance upper

tolerance tolerance

°C °C °C °C °C

Coldest solder joint 233,0 3,0 236,0 – –

Plastic leaded chip 234,0 3,0 237,0 6,0 243,0

carrier PLCC52

TO263 239,5 3,0 242,5 5,0 247,5

Ball grid array (BGA) 240,5 3,0 243,5 6,0 249,5

(24 mm x 24 mm)

Low-profile quad flat 243,5 3,0 246,5 6,0 252,5

package (LQFP) (14 mm

x 14 mm)

Small outline transistor 247,0 3,0 250,0 5,0 255,0

(SOT) devices

The upper tolerance is dependent on the position of the device on the PCB. The lower tolerance of 3,0 K

represents the value that the minimum solder joint temperature has to be raised to, due to the mentioned

measurement and process tolerances.

In these examples, the maximum temperature difference between actual measured and

tolerance corrected values was 9 K. These corrected temperatures represent the theoretically

possible maximum package temperatures for the devices during reflow soldering. Referring to

molded components (most active components) their internal structure is very similar. The

specific heat capacity and the thermal conductivity do not deviate significantly (metal-based

lead frame or interposer/silicon/mold compound). Therefore, it is possible to create

temperature classes for the solder-heat resistance referring to volume and thickness of such

molded devices. However, a similar approach is not feasible for the wide range of passive and

T, °C

– 12 – IEC TR 60068-3-12:2014 IEC 2014

electromechanical components. Some of these (non-molded) components reached peak

temperatures of 260 °C. In addition, many of the small molded components are commonly

qualified with a 260 °C peak temperature reflow profile. Therefore, the upper temperature

device group was defined as the 260 °C class. Furthermore, a class of 250 °C for large

molded components and a class of 245 °C for very large molded components was defined.

Table 2 shows a possible temperature classification of non-hermetic solid state surface mount

devices referring to volume and thickness of the devices.

Table 2 – Possible temperature classification of

surface mount devices

3 3 3 3

Thickness / Volume <350 mm 350 mm to 2 000 mm >2 000 mm

260 (– 0) °C 260 (– 0) °C 260 (– 0) °C

<1,6 mm

1,6 mm to 2,5 mm 260 (– 0) °C 250 (– 0) °C 250 (– 0) °C

260 (– 0) °C 250 (– 0) °C 245 (– 0) °C

>2,5 mm

NOTE The package volume excludes external terminals and non-integral heat sinks.

6.2 Board classification in Study B

Between the coldest solder joint and the hottest component package or PCB ∆T ranks from

1 K for small boards to 9 K for mid-size boards.

Figure 8 shows temperature profiles of the PCB surface and under the BGA on the small

board. The maximum temperature under the BGA is 229 °C with 20 s above 225 °C and the

maximum temperature of the PCB is 230 °C.

Figure 9 shows temperature profiles of the PCB surface and under the BGA on the mid-size

board. The maximum temperature under the BGA is 228 °C with 26 s above 225 °C and the

maximum temperature of the PCB is 237 °C.

From this study, ∆T between coldest solder joint and hottest component package or PCB

could be assumed as follows (refer to Figure 4):

small size board (e.g., digital camera, camcorder) 10 K;

mid-size board (e.g., personal computer (PC), set top box) 15 K;

large board (e.g., non-consumer product) 20 K.

Temperature profile

Temperature profile

- PCB surface 230 °C

- Under the BGA 229 °C

PCB surface

Under the BGA

IEC

Figure 8 – Example of the small board (camcorder)

Temperature profile

Temperature profile

- PCB surface

237 °C max.

- Under the BGA

228 °C max.

PCB surface

Under the BGA

IEC

Figure 9 – Example of the mid-size board (personal computer (PC))

7 Consideration for a lead-free reflow temperature profile

7.1 Determined lead-free reflow temperature profile in Study A

The performed measurements and the given considerations lead to a possible reflow profile,

which covers the described requirements of lead-free mass production (see Figure 10). Once

a device is qualified, using this reflow profile, it can be used in a wide range of electronic

control units. To assess the components resistance to solder heat the devices should be

subjected to a soldering simulation by subjecting them to this temperature profile at least

three times. This is necessary to ensure the reliability of the device after more than one reflow

soldering process. Soldering in mass production shall be performed below this limiting

temperature line to ensure that the device will not be stressed too much during the reflow

process. Therefore, the proposed reflow profile could help define the borders between the

– 14 – IEC TR 60068-3-12:2014 IEC 2014

device suppliers and the device assemblers. Figure 10 shows a lead-free reflow temperature

profile for device qualification regarding the solder heat resistance.

T(solid) 217 °C

Ramp down

Ramp up

from T(max.)

to 150 °C

6 K/s

3 K/s

t, s

IEC

NOTE Temperature profile not to scale.

Figure 10 – Lead-free reflow temperature profile for

device qualification

Table 3 presents proposed requirements for a lead-free device qualification reflow

temperature profile given in numbers.

Table 3 – Proposed requirements for a lead-free reflow profile

Profile features Small devices Large Very large

Pre-heat

Ramp-up rate to 150 °C 3 K/s (average value over 10 s)

Time from 190 °C to 200 °C Min. 110 s

Peak

Ramp-up rate from 200 °C to T 0,5 K/s – 3 K/s (average value over 10 s)

peak

Time above T (min. 217 °C) Min. 90 s

solidus

Peak temperature T 260 (–0) °C 250 (–0) °C 245 (–0) °C

peak

Time above T – 5 K Min. 40 s Min. 30 s Min. 30 s

peak

Cooling

Ramp-down rate from T (min. 217 °C) Up to 6 K/s (average value over 10 s) device dependent

solidus

General

Time 25 °C to T Min. 300 s

peak

7.2 Lead-free reflow temperature profile approach in Study B

The maximum temperature of the package body during the reflow process not only depends

on volume and thickness, but also depends on construction, materials used and other factors.

Therefore, the resistance to soldering heat test conditions for reflow soldering using SnAgCu,

as described in IEC 60068-2-58 [5], covers the majority of the consumer electronics,

assuming components are mounted on a large size board (∆T = 20 K).

T, °C

8 Conclusion

Based on measurements performed on state-of-the-art technology furnaces, a process for

lead-free soldering using SnAgCu solder paste was developed. The determined lead-free

temperature profile covers the requirements of mass production assembly with respect to the

solder-heat resistance. The molded (non-hermetic solid state) devices could be divided into

three maximum temperature classes of 260 °C, 250 °C and 245 °C (a classification of the

passive and electromechanical components was not achieved). For automotive ECU

applications as shown in Study A, all passive and electromechanical devices should be

considered as elements of the 260 °C class until further measurements of single parts are

performed. Using this process, most electronic control units can be soldered in compliance

with the process-capability requirements. In order to reduce the peak temperature below

260 °C, further evaluation is necessary. Improvements of the furnace technology may reduce

the position-dependent tolerances and mass production tolerances (especially the long term

stability and the longitudinal temperature spread across the board).

– 16 – IEC TR 60068-3-12:2014 IEC 2014

Bibliography

[1] MOON, BÖTTINGER, KATTNER, BIANCANIELLO, HANDWERKER: "Experimental and

Thermodynamic Assessment of Sn-Ag-Cu solder alloys", J. Electr. Mat., Vol. 29, No.

10 (2000), pp. 1122-1135

[2] NIMMO, Kay: "Second European Lead-Free Soldering Technology Roadmap",

soldertec, Feb. 2003

[3] KIRCHNER, KLEIN, BEINTNER, BRAUER, HOLZ, FEUFEL: "The Development of a

Qualification Temperature Profile for Lead-free Reflow Soldering", Proceedings of 5th

IPC JEDEC Lead-free Conference San Jose, Mar. 2004

[4] GÖRTLER, ZETTNER, SCHOTTENLOHER, KIRCHNER, KLEIN: "Reaction of Passive

and Active Electronic Components on the Heat Impact During Lead-free Reflow

Soldering", Proceedings of the 7th IPC JEDEC International Lead-free Conference,

Frankfurt, Oct. 2004

[5] IEC 60068-2-58, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

[6] IEC 60584-2, Thermocouples – Part 2: Tolerances

_____________

– 18 – IEC TR 60068-3-12:2014 IEC 2014

SOMMAIRE

AVANT-PROPOS . 19

1 Domaine d'application . 21

2 Notions fondamentales . 21

3 Cartes étudiées . 22

3.1 Approche de la carte d'essai . 22

3.2 Approche de la carte de fabrication . 23

4 Tolérances de température . 23

4.1 Tolérances de température dans l'étude A . 23

4.2 Tolérance de température et influence des dimensions de la carte dans

l'étude B . 25

5 Forme et largeur de pic de brasage . 26

5.1 Forme et largeur de pic dans l'étude A . 26

5.2 Etude du four de refusion dans l'étude B . 27

6 Classification . 28

6.1 Classification des dispositifs dans l'étude A . 28

6.2 Classification des cartes dans l'étude B . 30

7 Considérations relatives à un profil de température de refusion sans plomb . 32

7.1 Profil de température de refusion sans plomb déterminé dans l'étude A . 32

7.2 Approche du profil de température de refusion sans plomb dans l'étude B . 34

8 Conclusion . 34

Bibliographie . 35

Figure 1 – Forme de courbe pour une température de crête d'au moins 20 s à 230 °C

et 1 s à 233 °C . 22

Figure 2 – Position des dispositifs assemblés et de la dépendance de la position du

dispositif par rapport à la température . 24

Figure 3 – Tolérances de température inférieure et supérieure du profil de brasage par

refusion . 25

Figure 4 – Tolérance de température et influence des dimensions de la carte . 26

Figure 5 – Profil de crête de type chapeau avec 40 s à T – 5 K = 255 °C pour les

max

petits dispositifs et le PCB . 27

Figure 6 – ∆T pour différentes caractéristiques du four de refusion . 28

Figure 7 – Mesures de cartes d'essai représentatives . 29

Figure 8 – Exemple de petite carte (caméscope). 31

Figure 9 – Exemple de carte de taille moyenne (PC) . 32

Figure 10 – Profil de température de refusion sans plomb pour la qualification des

composants . 33

Tableau 1 – Températures mesurées des dispositifs et valeurs incluant les tolérances

inférieures et supérieures . 29

Tableau 2 – Classification en température possible des dispositifs à montage en

surface .

...

IEC TR 60068-3-12 ®

Edition 2.0 2014-10

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Environmental testing –

Part 3-12: Supporting documentation and guidance – Method to evaluate a

possible lead-free solder reflow temperature profile

Essais d'environnement –

Partie 3-12: Documentation d'accompagnement et guide – Méthode d'évaluation

d'un profil de température possible de brasage sans plomb par refusion

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC TR 60068-3-12 ®

Edition 2.0 2014-10

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

Environmental testing –

Part 3-12: Supporting documentation and guidance – Method to evaluate a

possible lead-free solder reflow temperature profile

Essais d'environnement –

Partie 3-12: Documentation d'accompagnement et guide – Méthode d'évaluation

d'un profil de température possible de brasage sans plomb par refusion

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX Q

ICS 19.040 ISBN 978-2-8322-1888-4

– 2 – IEC TR 60068-3-12:2014 IEC 2014

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Basics . 5

3 Boards under investigation . 6

3.1 Test board approach . 6

3.2 Production board approach . 6

4 Temperature tolerances . 7

4.1 Temperature tolerances in Study A . 7

4.2 Temperature tolerance and board size influence in Study B . 8

5 Peak form and width . 9

5.1 Peak form and width in Study A . 9

5.2 Reflow oven investigation in Study B . 9

6 Classification . 10

6.1 Device classification in Study A . 10

6.2 Board classification in Study B . 12

7 Consideration for a lead-free reflow temperature profile. 13

7.1 Determined lead-free reflow temperature profile in Study A . 13

7.2 Lead-free reflow temperature profile approach in Study B . 14

8 Conclusion . 15

Bibliography . 16

Figure 1 – Curve shape for a peak temperature of at least 20 s at 230 °C and 1 s at

233 °C . 6

Figure 2 – Position of the assembled devices and temperature dependence on the

device position . 7

Figure 3 – Lower and upper temperature tolerances of the reflow solder profile . 8

Figure 4 – Temperature tolerance and board size influence . 8

Figure 5 – Hat type peak profile with 40 s at T − 5 K = 255 °C for the small devices

max

and the PCB . 9

Figure 6 – ∆T by different reflow oven capabilities . 10

Figure 7 – Representative test board measurements . 11

Figure 8 – Example of the small board (camcorder) . 13

Figure 9 – Example of the mid-size board (personal computer (PC)) . 13

Figure 10 – Lead-free reflow temperature profile for device qualification . 14

Table 1 – Measured temperatures of devices and values including lower and upper

tolerances . 11

Table 2 – Possible temperature classification of surface mount devices . 12

Table 3 – Proposed requirements for a lead-free reflow profile . 14

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 3-12: Supporting documentation and guidance –

Method to evaluate a possible lead-free solder

reflow temperature profile

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 60068-3-12, which is a technical report, has been prepared by IEC technical

committee 91: Electronics assembly technology.

This second edition cancels and replaces the first edition published in 2007 and constitutes a

technical revision.

– 4 – IEC TR 60068-3-12:2014 IEC 2014

This edition includes the following significant technical changes with respect to the previous

edition:

• the content has been adapted to the state-of-the-art of reflow-oven technology and

termination finishes;

• minor language adjustments were performed.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

91/1158/DTR 91/1177/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60068 series, under the general title Environmental testing,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

ENVIRONMENTAL TESTING –

Part 3-12: Supporting documentation and guidance –

Method to evaluate a possible lead-free solder

reflow temperature profile

1 Scope

This part of IEC 60068, which is a technical report, presents two approaches for establishing

a possible temperature profile for a lead-free reflow soldering process using SnAgCu solder

paste.

This process covers a great variety of electronic products, including a large range of package

sizes (e.g. molded active electronic components, passive components and electromechanical

components).

Study A addresses requirements needed in the production of high-reliability electronic control

units (ECU), as for example in automotive electronics. These requirements include

measurement and production tolerances.

Study B represents consumer electronics products and includes reflow oven capability, board

design and package sizes.

2 Basics

The process temperature for SnPb solder paste has a wide margin due to the liquid

temperature of the solder alloy. During reflow soldering, temperature differences between

components exist but are not critical. The process temperature of SnAgCu solder paste is

about 20 K to 30 K higher than SnPb solder paste. Furthermore, the temperature difference

between components (∆T) becomes wider and sometimes the heat resistance temperature of

components can become critical.

To avoid soldering failures which could be very harmful in safety-related applications and also

generate higher failure costs, the capability of the soldering process is very important.

A compromise between the temperature requirements of highly reliable solder joints and the

limited solder-heat resistance of the electronic components has to be sought. In addition, the

different aspects of mass production have to be considered. To achieve a reliable solder joint,

the conventional reflow soldering process with eutectic SnPb solder paste is usually

performed at a minimum peak temperature of about 203 °C at the coldest solder joint (i.e. at

least 20 K above the liquid temperature of SnPb T = 183 °C).

liquid

The selected lead-free solder is SnAgCu with a melting point at around T = 217 °C [1] . It

liquid

is a generally preferred material for lead-free reflow and wave soldering in mass production

[2]. Using SnAgCu solder paste, it is not possible to solder the coldest solder joints at least

20 K above the liquid temperature (T = 217 °C), which would result in minimum

liquid

temperatures of 237 °C. When the coldest solder joint is 237 °C, the temperature spread

between small and large components, small semiconductor, and passive components, as well

as the printed circuit board (PCB), will be too large for the components to survive the heat

impact. Despite the aim to achieve a relatively low temperature at the coldest solder joint, the

reliability of the solder joint has to be assured.

___________

Numbers in square brackets refer to the Bibliography.

– 6 – IEC TR 60068-3-12:2014 IEC 2014

To reach this target in Study A, the temperature at the coldest solder joint is taken to be

T = 230 °C, for a minimum time of 20 s, which is just 13 K above the melting temperature.

min

Considering the peak shape (see Figure 1) this condition corresponds to 1 s at 233 °C. From

a physical point of view, the risk of insufficient solder wetting during mass production is

significantly higher if the solder joint temperature is lower than the above mentioned

temperature of 230 °C. In addition, lead-free termination finishes (like tin layers with a post-

bake process or very thin NiPdAu finishes) are known to exhibit a poorer wetting behavior

than conventional SnPb pin finishes.

Coldest solder joint

20 s at 230 °C

t, s

IEC

Figure 1 – Curve shape for a peak temperature

of at least 20 s at 230 °C and 1 s at 233 °C

The experiments had been performed under mass production conditions (850 mm/min) using

state-of-the-art reflow equipment, i.e ovens featuring multiple heating zones, full convection

and N atmosphere.

3 Boards under investigation

3.1 Test board approach

For the experiment in Study A, a special test PCB was designed. Polyimide resin with a glass

transition temperature of T = 260 °C was used as base material for the PCB. Such a test

g

board can represent the entire automotive ECU spectrum. The largest temperature difference

(∆T) between the coldest solder joint and the hottest point existing on this printed circuit

assembly (PCA) spectrum is reflected on this test board (∆T can be even larger for even more

complex PCAs). The coldest solder joint was represented by a defined thermal mass, to

represent large integrated circuits (ICs), coils or aluminium electrolytic capacitors. Its

temperature behavior was correlated with the temperatures of the coldest solder joints on

serial boards.

3.2 Production board approach

For Study B, PCB and reflow oven were taken from actual series production.

T, °C

4 Temperature tolerances

4.1 Temperature tolerances in Study A

For tolerances during temperature profiling, different systematic failures shall be considered.

First of all, there is an error associated with the temperature measurement itself. The

measurement was performed in the centre on top of the packages with a well defined and

repeatable preparation technique. Nevertheless, the failure due to preparation had to be fixed

within ±1,0 K. In addition, the thermocouple (NiCrNi), together with the evaluation unit has an

accuracy of ±1,5 K for pre-selected thermocouples. According to IEC 60584-2 [6] the NiCrNi

thermocouples, class K, tolerance class 1 are specified with a tolerance of ±1,5 K for just the

thermocouple itself without the measurement unit. Based on suppliers indication and own

measurements, the furnace tolerance based on furnace load is ±0,5 K and the furnace

tolerance for long term stability is ±2,5 K.

– Thermocouple with measurement unit:

±1,5 K

– Preparation of thermocouple:

±1,0 K

– Furnace load variation:

±0,5 K

– Long term stability of furnace:

±2,5 K

Because these variations are independent, the Gaussian error propagation can be applied,

which results in a total tolerance of ±3,0 K, due to measurement errors and variations in mass

production. The tolerance of –3,0 K results in the requirement to profile the coldest solder

joint at 236 °C, instead of 233 °C (i.e. 233 °C + 3,0 K). This tolerance is known as the “lower

tolerance”. In addition to the measurement errors and variations due to mass production, the

influences of the test board have to be considered. The measured temperatures of the

electronic components depend also on the position on the test board because of the

longitudinal and transversal temperature spread in the furnace and along the test board (see

Figure 2). These temperature differences are the result of the heat flow conditions in the

furnace and around the test board. The actual temperature of a device can be up to 3,5 K

higher than the measured values at the position where the device is mounted on the test

board. The temperature dependence on the device position was measured independently

before measuring the device temperatures on the assembled test board.

Temperature

Transversal temperature profile

Longitudinal

temperature

profile

Device position

Direction of

on test board

transportation

IEC

Figure 2 – Position of the assembled devices

and temperature dependence on the device position

The thermal mass on the test board, which represents the coldest solder joint on the serial

boards, was designed to include the relevant position-dependent tolerances. The upper

temperature tolerances consist of the position-dependent temperature tolerances of 2 K to

3,5 K and the above mentioned +3 K. This leads to a total upper tolerance of 5 K to 6,5 K.

– 8 – IEC TR 60068-3-12:2014 IEC 2014

Regarding the whole temperature window of the lead-free soldering process, a total position-

dependent temperature tolerance of 8 K to 9,5 K has to be added to the measured ∆T spread

of the devices (see Figure 3).

Upper tolerances (measurement, equipment

and position on test board 5,0 K to 6,5 K)

Measured ∆T between coldest solder joint

and hottest device within each class

∆T devices

236 °C

Lower tolerances (measurement and equipment)

3 K

233 °C

20 s at 230 °C corresponds to 1 s at 233 °C

Minimum temperature requirement; 20 s at 230 °C

20 s 230 °C

IEC

NOTE Electronic devices are divided into three temperature classes.

Figure 3 – Lower and upper temperature tolerances of the reflow solder profile

4.2 Temperature tolerance and board size influence in Study B

In the consumer board study, the measured temperature includes lower temperature tolerance

and upper temperature tolerance. Therefore at the coldest solder joint temperature of 230 °C,

the "worst-case" temperature becomes 227 °C (i.e. 230 °C – 3 K) which is still 10 K higher

than the melting point of the SnAgCu solder alloy (see Figure 4).

∆T = 20 K

∆T between coldest solder joint and hottest

∆T = 15 K

component within the board →

∆T = 10 K

230 °C →

Total tolerance 3 K

Minimum condition for high reliable soldering

227 °C min.

Temperature: 230 °C

13 K

Soldering time: 10 s to 30 s

Melting point of the SnAgCu: 217 °C →

IEC

Figure 4 – Temperature tolerance and board size influence

Small size PCB

・Digital camera

・Camcorder

Small

Mid size PCB

devices

・PC

Large

・Set top box

devices

Very large

devices

Large size PCB

・Non consumer products

5 Peak form and width

5.1 Peak form and width in Study A

The requirements were to maintain a temperature of at least 230 °C for 20 s at the coldest

solder joint, and to limit the peak package temperature of the smallest devices (e.g. SOT23,

small LQFP, TopLEDs and passive components) to T ≤ 260 °C. In order to meet these

peak

requirements, a soak-type preheating, as well as a hat type soldering peak were necessary in

the investigation. The soak-type preheating allowed the temperatures of the individual

packages to be close to each other upon entering the peak zone (see Figure 7). The hat type

form of the soldering peak was used to minimize the temperature differences between the

individual packages during reflow soldering. After conducting the experiment, it was

discovered that the hat type form of the soldering peak required a soak time of 40 s at

T − 5 K = 255 °C for the hottest devices on the PCB (see Figure 5).

max

40 s at 255 °C

PCB

LQFP 14 × 14

LQFP 20 × 20

Coldest solder joint

20 s at 230 °C

t, s

IEC

NOTE Temperature tolerances are included.

Figure 5 – Hat type peak profile with 40 s at T − 5 K = 255 °C

max

for the small devices and the PCB

5.2 Reflow oven investigation in Study B

Figure 6 shows temperature profiles on quad flat package (QFP) leads and a 1608 size

surface mounting device (SMD) resistor using the same board but different reflow ovens. The

reflow oven of Maker B, having more heating zones than the oven of Maker A, shows a wider

temperature spread ∆T in the temperature profile than the oven of Maker A. Thus, the

temperature spread ∆T does not depend primarily on the number of heating zones of the

reflow oven but on the design of the reflow oven.

The peak reflow temperature for smallest components may vary according to the reflow oven

being used. Also board size and board design are other factors affecting the peak reflow

temperature.

T, °C

– 10 – IEC TR 60068-3-12:2014 IEC 2014

Maker A

Maker B

7 zones

12 zones

∆T ≈ 15 °C

230 °C

230 °C

∆T ≈ 20 °C

QFP Lead

1608 R

IEC

Figure 6 – ∆T by different reflow oven capabilities

6 Classification

6.1 Device classification in Study A