IEC 62321-9:2021

(Main)Determination of certain substances in electrotechnical products - Part 9: Hexabromocyclododecane in polymers by gas chromatography-mass spectrometry (GC-MS)

Determination of certain substances in electrotechnical products - Part 9: Hexabromocyclododecane in polymers by gas chromatography-mass spectrometry (GC-MS)

IEC 62321-9:2021 specifies two techniques for the determination of hexabromocyclododecane (HBCDD) in polymers of electrotechnical products.

The gas chromatography-mass spectrometry (GC-MS) test method is described in the normative part of this document. The GC-MS method is suitable for the determination of hexabromocyclododecane (HBCDD).

A method using high-pressure liquid chromatography-mass spectrometry (HPLC-MS) is given.

These test methods have been evaluated for use with EPS (expanded polystyrene foam), XPS (extruded polystyrene foam) and ABS (acrylonitrile butadiene styrene) within the concentration ranges as specified. The use of this method for other types of materials or concentration ranges outside those specified below has not been evaluated.

This document has the status of a horizontal standard in accordance with IEC Guide 108.

Détermination de certaines substances dans les produits électrotechniques - Partie 9: Hexabromocyclododécane dans les polymères par chromatographie en phase gazeuse-spectrométrie de masse (GC-MS)

L'IEC 62321-9:2021 spécifie deux techniques pour la détermination de l’hexabromocyclododécane (HBCDD) dans les polymères des produits électrotechniques.

La méthode d’essai par chromatographie en phase gazeuse-spectrométrie de masse (GC-MS) est décrite dans la partie normative du présent document. La méthode GC-MS convient à la détermination de l’hexabromocyclododécane (HBCDD).

L’Annexe A informative spécifie une méthode utilisant la chromatographie en phase liquide sous haute pression-spectrométrie de masse (HPLC-MS).

Ces méthodes d’essai ont été évaluées pour une utilisation avec une mousse EPS (polystyrène expansé), XPS (polystyrène extrudé) et de l’ABS (acrylonitrile-butadiène-styrène) dans les plages de concentrations spécifiées. L’utilisation de ces méthodes pour d’autres types de matériaux ou des plages de concentrations en dehors de celles spécifiées ci-dessous n’a pas été évaluée.

Le présent document a le statut d'une norme horizontale conformément au Guide IEC 108.

General Information

- Status

- Published

- Publication Date

- 29-Aug-2021

- Technical Committee

- TC 111 - Environmental standardization for electrical and electronic products and systems

- Drafting Committee

- WG 3 - TC 111/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Aug-2021

- Completion Date

- 30-Jul-2021

Overview

IEC 62321-9:2021 is an international standard established by the International Electrotechnical Commission (IEC) that specifies analytical methods for the determination of hexabromocyclododecane (HBCDD) in polymers used in electrotechnical products. This standard focuses primarily on the use of gas chromatography-mass spectrometry (GC-MS) as the normative method for detecting and quantifying HBCDD in polymers such as expanded polystyrene foam (EPS), extruded polystyrene foam (XPS), and acrylonitrile butadiene styrene (ABS).

The standard also provides an informative method using high-pressure liquid chromatography-mass spectrometry (HPLC-MS) for the same purpose. IEC 62321-9:2021 serves as a horizontal standard aligned with IEC Guide 108, facilitating worldwide harmonization of test procedures related to the hazardous flame retardant HBCDD in electronic and electrical product polymers.

Key Topics

- Hexabromocyclododecane (HBCDD) Detection: Identifies and quantifies the presence of HBCDD, a brominated flame retardant, in plastic components of electrotechnical products.

- GC-MS Method: Provides detailed procedures for sample preparation, extraction, instrumental parameters, calibration, calculation of concentration, and quality controls for HBCDD measurement using gas chromatography-mass spectrometry.

- HPLC-MS Alternative: Includes an ancillary method using liquid chromatography coupled with mass spectrometry for laboratories preferring this analytical technique.

- Material Scope: Evaluated primarily for polymers EPS, XPS, and ABS within specified concentration ranges; applicability for other materials or outside these ranges remains unevaluated.

- Quality Assurance: Emphasizes precision, method detection limits (MDL), repeatability, reproducibility, and internal controls for reliable and validated test results.

- Standardized Reporting: Specifies comprehensive guidelines for test reporting to ensure consistency across labs and compliance with international regulations.

Applications

IEC 62321-9:2021 is essential for manufacturers, testing laboratories, and regulatory bodies involved in:

- Environmental Compliance: Verifying compliance with regulations restricting hazardous substances, including HBCDD, in electrotechnical and electronic equipment.

- Product Safety: Ensuring that polymer materials used in electronic products meet safety standards related to harmful flame retardants.

- Quality Control: Facilitating standardized laboratory testing for accurate, reproducible measurement of HBCDD concentrations during product development and manufacturing.

- Material Screening: Screening polymers such as EPS, XPS, and ABS for contamination by HBCDD to guide material selection or recycling decisions.

- Regulatory Reporting: Supporting documentation and certification processes required under international environmental and chemical safety directives.

Related Standards

IEC 62321-9:2021 is part of the IEC 62321 series that addresses the Determination of Certain Substances in Electrotechnical Products. Other relevant parts include:

- IEC 62321-1: Overview and general principles for the determination of restricted substances.

- IEC 62321-4: For the determination of cadmium, lead, mercury, and chromium VI.

- IEC 62321-5: Determination methods for certain phthalates.

- IEC 62321-7-1 and 7-2: Methods for polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE).

- IEC Guide 108: Guidance on environmental standardization related to electrical and electronic products.

Together, these standards provide a comprehensive framework for testing and controlling restricted hazardous substances in electrical and electronic equipment in compliance with global environmental mandates.

Keywords: IEC 62321-9, hexabromocyclododecane, HBCDD, polymers, electrotechnical products, GC-MS, gas chromatography-mass spectrometry, HPLC-MS, flame retardants testing, environmental compliance, EPS, XPS, ABS, hazardous substances, electrical and electronic equipment standards.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Sponsored listings

Frequently Asked Questions

IEC 62321-9:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Determination of certain substances in electrotechnical products - Part 9: Hexabromocyclododecane in polymers by gas chromatography-mass spectrometry (GC-MS)". This standard covers: IEC 62321-9:2021 specifies two techniques for the determination of hexabromocyclododecane (HBCDD) in polymers of electrotechnical products. The gas chromatography-mass spectrometry (GC-MS) test method is described in the normative part of this document. The GC-MS method is suitable for the determination of hexabromocyclododecane (HBCDD). A method using high-pressure liquid chromatography-mass spectrometry (HPLC-MS) is given. These test methods have been evaluated for use with EPS (expanded polystyrene foam), XPS (extruded polystyrene foam) and ABS (acrylonitrile butadiene styrene) within the concentration ranges as specified. The use of this method for other types of materials or concentration ranges outside those specified below has not been evaluated. This document has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-9:2021 specifies two techniques for the determination of hexabromocyclododecane (HBCDD) in polymers of electrotechnical products. The gas chromatography-mass spectrometry (GC-MS) test method is described in the normative part of this document. The GC-MS method is suitable for the determination of hexabromocyclododecane (HBCDD). A method using high-pressure liquid chromatography-mass spectrometry (HPLC-MS) is given. These test methods have been evaluated for use with EPS (expanded polystyrene foam), XPS (extruded polystyrene foam) and ABS (acrylonitrile butadiene styrene) within the concentration ranges as specified. The use of this method for other types of materials or concentration ranges outside those specified below has not been evaluated. This document has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-9:2021 is classified under the following ICS (International Classification for Standards) categories: 13.020.01 - Environment and environmental protection in general; 29.140.10 - Lamp caps and holders; 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62321-9:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62321-9 ®

Edition 1.0 2021-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

HORIZONTAL PUBLICATION

PUBLICATION HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 9: Hexabromocyclododecane in polymers by gas chromatography-mass

spectrometry (GC‑MS)

Détermination de certaines substances dans les produits électrotechniques –

Partie 9: Hexabromocyclododécane dans les polymères par chromatographie

en phase gazeuse-spectrométrie de masse (GC‑MS)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 18 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 000 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 16 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC online collection - oc.iec.ch

IEC 62321-9 ®

Edition 1.0 2021-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

HORIZONTAL PUBLICATION

PUBLICATION HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 9: Hexabromocyclododecane in polymers by gas chromatography-mass

spectrometry (GC‑MS)

Détermination de certaines substances dans les produits électrotechniques –

Partie 9: Hexabromocyclododécane dans les polymères par chromatographie

en phase gazeuse-spectrométrie de masse (GC‑MS)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.020.01; 43.040.10 ISBN 978-2-8322-9960-9

– 2 – IEC 62321-9:2021 © IEC 2021

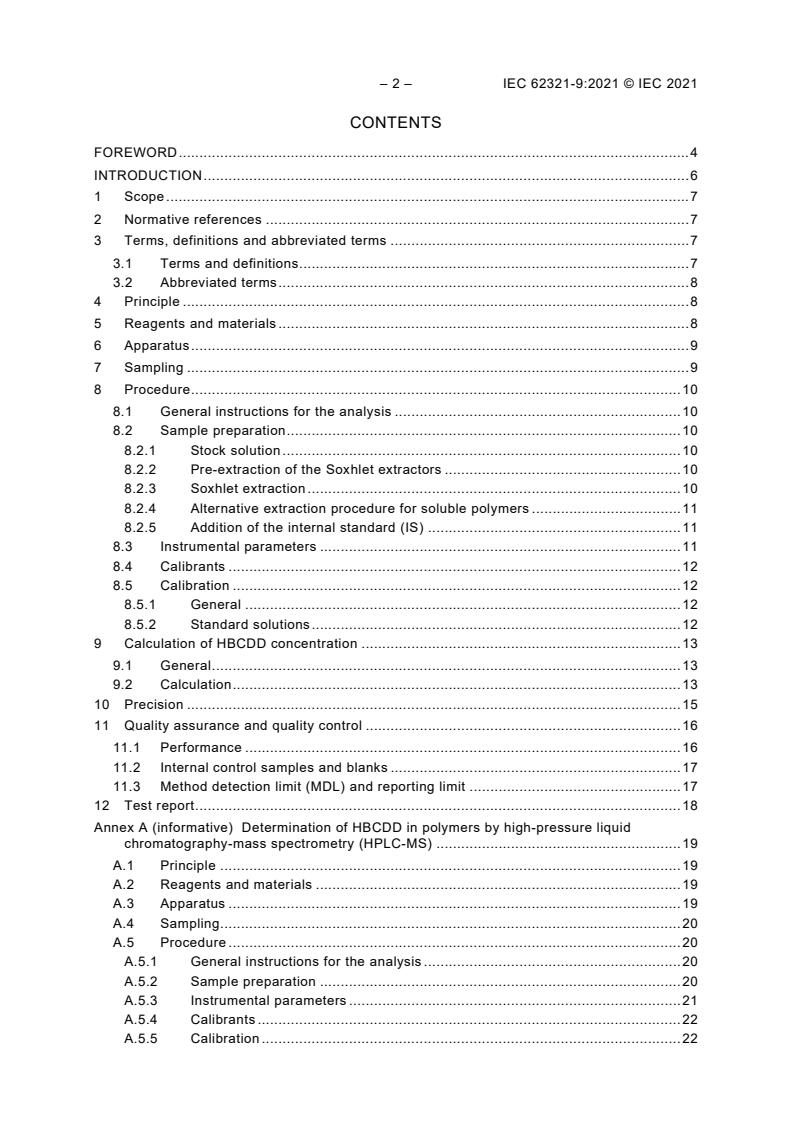

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviated terms . 7

3.1 Terms and definitions . 7

3.2 Abbreviated terms . 8

4 Principle . 8

5 Reagents and materials . 8

6 Apparatus . 9

7 Sampling . 9

8 Procedure . 10

8.1 General instructions for the analysis . 10

8.2 Sample preparation . 10

8.2.1 Stock solution . 10

8.2.2 Pre-extraction of the Soxhlet extractors . 10

8.2.3 Soxhlet extraction . 10

8.2.4 Alternative extraction procedure for soluble polymers . 11

8.2.5 Addition of the internal standard (IS) . 11

8.3 Instrumental parameters . 11

8.4 Calibrants . 12

8.5 Calibration . 12

8.5.1 General . 12

8.5.2 Standard solutions . 12

9 Calculation of HBCDD concentration . 13

9.1 General . 13

9.2 Calculation . 13

10 Precision . 15

11 Quality assurance and quality control . 16

11.1 Performance . 16

11.2 Internal control samples and blanks . 17

11.3 Method detection limit (MDL) and reporting limit . 17

12 Test report . 18

Annex A (informative) Determination of HBCDD in polymers by high-pressure liquid

chromatography-mass spectrometry (HPLC-MS) . 19

A.1 Principle . 19

A.2 Reagents and materials . 19

A.3 Apparatus . 19

A.4 Sampling. 20

A.5 Procedure . 20

A.5.1 General instructions for the analysis . 20

A.5.2 Sample preparation . 20

A.5.3 Instrumental parameters . 21

A.5.4 Calibrants . 22

A.5.5 Calibration . 22

A.6 Calculation of HBCDD concentration . 23

A.6.1 General . 23

A.6.2 Calculation . 23

A.7 Precision . 24

A.8 Quality assurance and quality control . 25

A.8.1 Performance . 25

A.8.2 Method detection limit (MDL) and reporting limit . 25

A.9 Test report . 26

Annex B (informative) Examples of chromatograms at suggested conditions . 27

Annex C (informative) Results of international interlaboratory study (IIS 9) . 29

Bibliography . 31

Figure B.1 – Total ion chromatogram of HBCDD by GC‑MS analysis. 27

Figure B.2 – Mass spectrum of HBCDD by GC‑MS analysis . 27

Figure B.3 – Total ion chromatogram of HBCDD isomers (α-, β-, γ-HBCDD) by HPLC-

MS analysis . 28

Table 1 – Tested concentration ranges for HBCDD by GC‑MS in various materials . 7

Table 2 – Reference masses for the quantification of HBCDD . 12

Table 3 – Commercially available HBCDD reference materials considered suitable for

GC-MS analysis . 12

Table 4 – Calibration solutions of HBCDD . 13

Table 5 – IIS 9 repeatability and reproducibility . 16

Table A.1 – HPLC-MS liquid phase . 21

Table A.2 – Commercially available HBCDD reference materials considered suitable

for HPLC-MS analysis . 22

Table A.3 – Calibration solutions of HBCDD . 23

Table A.4 – IIS 9 repeatability and reproducibility . 25

Table C.1 – Mean results and recovery rates for HBCDD using GC‑MS . 29

Table C.2 – Statistical data for GC‑MS . 29

Table C.3 – Mean results and recovery rates for HBCDD using HPLC-MS . 29

Table C.4 – Statistical data for HPLC-MS . 30

– 4 – IEC 62321-9:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 9: Hexabromocyclododecane in polymers

by gas chromatography-mass spectrometry (GC‑MS)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62321-9 has been prepared by IEC technical committee 111: Environmental

standardization for electrical and electronic products and systems. It is an International

Standard.

The text of this International Standard is based on the following documents:

FDIS Report on voting

111/620/FDIS 111/631/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 62321 series, published under the general title Determination of

certain substances in electrotechnical products, can be found on the IEC website

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 62321-9:2021 © IEC 2021

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries this has resulted in the adoption of regulations affecting

wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd) and polybrominated diphenyl

ethers (PBDEs) in electrotechnical products is a source of concern in current and proposed

regional legislation.

The purpose of this document is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

WARNING – Persons using this document should be familiar with normal laboratory

practice. This document does not purport to address all of the safety problems, if any,

associated with its use. It is the responsibility of the user to establish appropriate safety

and health practices and to ensure compliance with any national regulatory conditions.

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 9: Hexabromocyclododecane in polymers

by gas chromatography-mass spectrometry (GC‑MS)

1 Scope

This part of IEC 62321 specifies two techniques for the determination of

hexabromocyclododecane (HBCDD) in polymers of electrotechnical products.

The gas chromatography-mass spectrometry (GC-MS) test method is described in the

normative part of this document. The GC-MS method is suitable for the determination of

hexabromocyclododecane (HBCDD).

A method using high-pressure liquid chromatography-mass spectrometry (HPLC-MS) is given

in informative Annex A.

These test methods have been evaluated for use with EPS (expanded polystyrene foam),

XPS (extruded polystyrene foam) and ABS (acrylonitrile butadiene styrene) within the

concentration ranges as specified in Table 1. The use of this method for other types of materials

or concentration ranges outside those specified below has not been evaluated.

Table 1 – Tested concentration ranges for HBCDD by GC‑MS in various materials

Substance or element HBCDD

Medium or material tested

Unit of

Parameter

measurement ABS

EPS/XPS

mg/kg

Concentration range tested 6 080 to 11 940 1 000 to 10 000

This document has the status of a horizontal standard in accordance with IEC Guide 108.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1:2013, Determination of certain substances in electrotechnical products – Part 1:

Introduction and overview

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62321-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

– 8 – IEC 62321-9:2021 © IEC 2021

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.2 Abbreviated terms

ABS acrylonitrile butadiene styrene

API-ES atmospheric pressure-electrospray

BFR brominated flame retardant

BSA N,O-Bis(trimethylsilyl)acetamide

BSTFA N,O-Bis(trimethylsilyl)trifluoroacetamide

CCC continuing calibration check

C-IC combustion-ion chromatography

EI electron ionization

EPS expanded polystyrene foam

HBCDD hexabromocyclododecane

HPLC-MS high-pressure liquid chromatography-mass spectrometry

ID internal diameter

IS internal standard

GC‑MS gas chromatography-mass spectrometry

LOD limit of detection

LOQ limit of quantification

MDL method detection limit

PTFE polytetrafluoroethylene

QC quality control

RSD relative standard deviation

SIM single (or "selected") ion monitoring

THF tetrahydrofuran

TIF tentatively identified compound

XPS extruded polystyrene foam

XRF X-ray fluorescence

UV ultraviolet

4 Principle

HBCDD is determined using ultrasonic or Soxhlet extraction followed by gas chromatography

separation and mass spectrometry determination. This technique is suitable to determinate total

HBCDD instead of separated HBCDD isomers.

NOTE The thermal stability of HBCDD is poor. The results can be influenced by the temperature testing conditions.

5 Reagents and materials

All reagent chemicals shall be tested for contamination and blank values prior to application.

a) toluene (guaranteed reagent, purity of greater than a volume fraction of 99 %);

b) tetrahydrofuran (THF) (guaranteed reagent, purity of greater than a volume fraction of 99 %);

c) acetonitrile (guaranteed reagent, purity of greater than a volume fraction of 99 %);

d) methanol (guaranteed reagent, purity of greater than a volume fraction of 99 %);

e) mixed solvent solution (tetrahydrofuran and acetonitrile or methanol),

– add 500 ml tetrahydrofuran and 1 000 ml acetonitrile or methanol to a 2 000 ml beaker

and mix;

f) calibrants hexabromocyclododecane (guaranteed reagent, purity of greater than a volume

fraction of 99 %): see 8.4;

g) helium (purity of greater than a volume fraction of 99,999 %);

h) internal standard used to correct for injection errors (e.g. CB 209 (2,2’,3,3’,4,4’,5,5’,6,6’-

decachlorobiphenyl)).

6 Apparatus

The following items shall be used for the analysis:

a) analytical balance capable of measuring accurately to 0,000 1 g;

b) 10 ml, 20 ml, 500 ml, 1 000 ml volumetric flasks;

c) Soxhlet device, Soxhlet extractor of 200 ml or suitable volume;

d) extraction thimble;

e) heating jackets;

f) funnel (non plastic);

g) aluminium foil;

h) ultrasonic bath;

i) Pasteur pipette;

j) glass wool;

k) 1,5 ml sample vials with 100 µl glass insert and a screw cap with polytetrafluoroethylene

(PTFE) gasket or, depending on the analytical system, a comparable sample receptacle;

l) a gas chromatograph with a capillary column coupled to a mass spectrometric detector

(electron ionization, EI). The mass spectrometric detector shall be able to perform selective

ion monitoring. The use of an autosampler is strongly recommended to ensure repeatability.

A column length of approximately 30 m is suitable for sufficient separation efficiency for

HBCDD;

m) rotary evaporator with water bath;

n) milling equipment;

o) 0,45 µm PTFE filter membrane.

p) No. 5A filter paper.

7 Sampling

As described in IEC 62321-2, unless indicated otherwise, the following procedure a) is

recommended.

a) Cut samples approximately to a size of 2 mm × 2 mm, and mix them well.

NOTE 1 When using the alternative ultrasonic dissolution procedure for polymers that are difficult to dissolve,

cryogenic grinding with liquid nitrogen cooling is necessary. The samples are ground to pass through a 500 µm

sieve.

NOTE 2 Contact with polymer material are avoided during sampling.

– 10 – IEC 62321-9:2021 © IEC 2021

8 Procedure

8.1 General instructions for the analysis

The following general instructions shall be followed:

In order to reduce blank values, ensure the cleanliness of all glass equipment (excluding

volumetric flasks) and deactivate the glass wool by subjecting it to 450 °C for at least 30 min.

To avoid decomposition and/or debromination of HBCDD by UV light during extraction and

analysis, glass equipment made from brown or amber glass shall be used.

NOTE If no brown or amber glass is available, aluminium foil can be used for protection from light.

If the amount of Br in the sample (determined by XRF, C-IC or other means) is considerably

above the 0,1 % range, it will be necessary to carry out the analysis using an adjusted sample

size or by repeating the analysis using an extract that has been appropriately diluted prior to

internal standard addition.

8.2 Sample preparation

8.2.1 Stock solution

a) Standard mixture solution: Prepare a standard mixture solution containing α, β, γ-HBCDD

in an organic solvent at a concentration of 10 µg/ml made from each 100 µg/ml standard

solution.

b) Internal standard (to correct for injection error): 50 µg/ml in toluene or an organic solvent

(e.g. CB 209).

8.2.2 Pre-extraction of the Soxhlet extractors

To clean the Soxhlet extractors (Clause 6, c)), a 2 h pre-extraction is carried out with 70 ml of

toluene. The washing solvent is discarded.

8.2.3 Soxhlet extraction

The following steps shall be followed for sample extraction:

a) Weigh 0,5 g of the crushed sample to the nearest 0,000 1 g. The sample is transferred

through a funnel into the extraction thimble. Put the extraction thimble into the Soxhlet

extractor. Toluene shall be used as the extraction solvent.

b) In order to ensure a quantitative transfer, the funnel is rinsed with approximately 10 ml of

extraction solvent.

c) In order to prevent the sample from floating, the extraction thimble is closed with glass wool

(Clause 6, j)). Approximately 80 ml of solvent is placed in the 200 ml round-bottomed flask,

the equipment is covered with aluminium foil to exclude light and the sample is extracted

for at least 2 h with each cycle being approximately 2 min to 3 min.

NOTE Sample amount and volume of extraction can be reduced in the same ratio to keep the same cycle rate.

d) After Soxhlet extraction, allow it to cool down at room temperature.

e) Evaporate the extracted solution in the round-bottomed flask on a rotary evaporator until

approximately 10 ml remains.

f) Transfer the contents into a 20 ml volumetric flask and then bring to volume using solvent.

g) Filter the sample solution through a 0,45 µm syringe filter (Clause 6, o)) and transfer into a

vial for GC‑MS analysis.

8.2.4 Alternative extraction procedure for soluble polymers

As an alternative to Soxhlet extraction, an ultrasonic dissolution procedure is applicable for

polymers soluble in tetrahydrofuran as described in the following steps:

a) Weigh 0,5 g of the sample to the nearest 0,000 1 g into a suitable glass vessel.

b) Quantitatively add 30 ml of tetrahydrofuran, and put the sample in an ultrasonic bath at

40 °C for approximately one hour or until dissolved.

c) Slowly add 70 ml of methanol dropwise to precipitate the polymer resin portion of the

polymer from the solution.

d) Allow the solution and sample mixture to stand for 30 min at room temperature (the

precipitated polymer resin will settle in the solution). Filter with No. 5A filter paper.

e) Evaporate the extracted solution in the round-bottomed flask on a rotary evaporator until

approximately 10 ml remains.

f) Transfer the contents into a 20 ml volumetric flask and then bring to volume using solvent.

g) Filter the sample solution through a 0,45 µm syringe filter (Clause 6, o)) and transfer into a

vial for GC‑MS analysis.

8.2.5 Addition of the internal standard (IS)

Prepare a 1 ml aliquot of each sample and standard to be analysed and place it in an

appropriate sample vial. Add 20 µl of internal standard solution (8.2.1, b)) to the vial and cap

the vial. Invert the vial twice to mix.

Inject 1 µl of the sample solution into the GC‑MS and analyse it according to the parameters

described in 8.3.

8.3 Instrumental parameters

Different conditions might be necessary to optimize a specific GC‑MS system to achieve

effective separation of all calibration congeners and meet the QC and MDL requirements. The

following parameters have been found suitable and are provided as an example:

a) GC column: non-polar (phenyl-arylene-polymer equivalent to 5 % phenyl-methyl-

polysiloxane), length 30 m; internal diameter 0,25 mm; film thickness 0,25 µm;

b) injector liner: 4 mm single taper glass liner with glass wool (deactivated);

c) carrier: helium (5 g), 1,0 ml/min, constant flow;

d) oven temperature: 70 °C for 2 min, 20 °C/min to 300 °C for 5 min;

e) injection temperature: 250 °C;

f) transfer line: 300 °C;

g) injection volume: 1 µl;

h) injection mode: split (10:1);

i) ionization method: electron ionization (EI);

j) solvent delay time: 4 min;

k) ion source temperature: 250 °C;

l) scan range: m/z 50 ~ m/z 1 000 ;

m) dwell time: 80 ms.

Table 2 shows reference masses for confirmation ions and a quantification ion of HBCDD.

– 12 – IEC 62321-9:2021 © IEC 2021

Table 2 – Reference masses for the quantification of HBCDD

Confirmation ions Quantification ion

(m/z) (m/z)

HBCDD 319, 401, 561 319

NOTE 1 α-, β-, γ-HBCDD isomers are not separated by GC and therefore appear as a single peak. This is sufficient

for quantification.

NOTE 2 In GC analysis, degradation of HBCDD occurs with an oven temperature above 160 °C, resulting in the

formation of the degradation products, pentabromocyclododecane and tetrabromocyclododecadiene. The three

isomers, α-, β-, γ-HBCDD, were detected on the same retention time. Therefore, they cannot be clearly separated in

the mixed HBCDD peak.

The chromatogram in Annex B (see Figure B.1 and Figure B.2) gives an example of GC-MS

analysis.

8.4 Calibrants

Reference materials are used as calibrants to make stock solutions of 100 µg/ml each in toluene.

Table 3 shows recommended HBCDD reference materials suitable for GC-MS analysis.

Table 3 – Commercially available HBCDD reference

materials considered suitable for GC-MS analysis

Compound name CAS Number

α-Hexabromocyclododecane 134237-50-6

β-Hexabromocyclododecane 134237-51-7

γ-Hexabromocyclododecane 134237-52-8

25637-99-4

Mix standards of α-, β-,γ-Hexabromocyclododecane

and 3194-55-6

8.5 Calibration

8.5.1 General

Wherever possible, the solvent used for the sample and standard solutions shall be the same

to avoid any potential solvent effects. A calibration curve shall be developed for quantitative

analysis. At least five calibration solutions shall be prepared in equidistant concentration steps.

Quantification is made on the basis of the measurement of the peak areas. The linear regression

fit of each calibration curve is required to have a relative standard deviation (RSD) of less than

or equal to 15 % of the linear calibration function.

NOTE If the limiting value of the RSD of 15 % is exceeded, from the point of view of quality assurance, 2nd order

curve fitting does not guarantee any significantly better adjustment. Only statistical tests such as the F-test fulfil

these requirements by comparing linear or 2nd order. That means that although the RSD value is exceeded, the

calibration is linear.

8.5.2 Standard solutions

Stock solutions of HBCDD listed in Table 3 are used to prepare the calibration solution

concentrations shown in Table 4 using the mixed solvent solution (Clause 5, e)) as a diluent.

Table 4 – Calibration solutions of HBCDD

Final concentration of Volume of internal

HBCDD standard

Standard solution No.

(μg/ml) (μl)

1 0,5 20

2 1,0 20

3 2,5 20

4 5,0 20

5 10 20

A linear regression is carried out using Equation (1):

AC

=ab×+ (1)

AC

IS IS

where

A is the peak area of HBCDD in the calibration solution;

A is the peak area of the internal standard;

IS

C is the concentration of HBCDD (μg/ml);

C is the concentration of the internal standard (μg/ml);

IS

a is the slope of the calibration curve;

b is the intercept on the y-axis of the calibration curve.

The internal standard is used for the correction of the injection error. Therefore, the evaluation

of the response factor or ratio is carried out by A/A .

IS

To produce the calibration straight lines the response A/A is plotted against the concentration

IS

ratio C/C .

IS

9 Calculation of HBCDD concentration

9.1 General

In the event that there is no HBCDD compound detected in the sample, HBCDD shall be

reported as a function of the compound with the highest method detection limits.

9.2 Calculation

The final concentration of HBCDD in the sample can be calculated by using Equation (2):

For a linear fit, the equation takes the form of:

y = ax + b (2)

where

y is the response factor or ratio (A/A ) for the HBCDD in the sample;

IS

a is the slope of the line that best fits the calibration obtained in Equation (1);

– 14 – IEC 62321-9:2021 © IEC 2021

x is the instrumental result (C/C where C commonly equals 1) in µg/ml (the concentration

IS IS

of the congener in the extract);

b is the y intercept or the concentration when the response factor equals 0, obtained from

Equation (1).

For a quadratic fit the equation takes the form of Equation (3):

y = ax + bx + c (3)

where

y is the response factor or ratio (A/A ) for the HBCDD in the sample;

IS

a and b are constants that correspond to the curve that best fits the calibration;

x is the instrument result in µg/ml (the concentration of the HBCDD in the extract);

c is the y intercept or the concentration when the response factor equals 0.

If the concentration of HBCDD in a sample does not fall within the range of its respective

calibrants, a serial sample dilution shall be prepared that will bring the concentration of the

HBCDDs to failing within the calibration. Analyse the dilution and use the dilution factor to

quantify the concentration of those HBCDD that were not within the calibration range in the

original analysis. The dilution factor (D) can be calculated by dividing the final volume of the

dilution by volume of the aliquot, per Equation (4):

V

f

(4)

D=

V

a

where

D is the dilution factor;

V is the final volume in ml;

f

V is the volume of the aliquot in ml.

a

Equation (2), which is in the form of a linear equation, can be rewritten in the form of

Equation (5):

A C

IS

Cb−×

(5)

Aa

IS

where

A is the peak area of HBCDD;

A is the peak area of the internal standard;

IS

C is the (intermediate) concentration of HBCDD in µg/ml;

C is the concentration of the internal standard in µg/ml.

IS

a is the slope of the line that best fits the calibration obtained in Equation (2);

b is the y intercept or the concentration when the response factor equals 0, obtained from

Equation (2).

Equation (5) does not give the final concentration; as the volume of the organic solvent, the

mass of the sample and the volume of the extract and any dilution factor needs to be taken into

account. A conversion factor (F) to convert the units from ng to µg is also needed. The final

concentration of HBCDD in the sample can be calculated by using Equation (6):

=

A C V

IS

Cb−× ×

(6)

final

A aM

IS

where

C is the concentration of HBCDD in the sample in µg/g;

final

V is the final extraction volume (100 ml);

M is the mass of the sample in grams.

NOTE The calculation example shown above is for linear regression calibration only. A separate calculation can be

required if polynomial regression calibration is utilized.

The HBCDD can be calculated by the measured concentrations of signals identified as an

HBCDD. The HBCDD result shall include the signal with appropriate mass, retention time and

ion ratios for HBCDD.

The calibration solutions can be used to establish an average response factor for each degree

of bromination within the HBCDD. The average response factors can then be used in the

calculation of the measured concentration in the sample that are not included in the calibration

(e.g. tentatively identified compounds or "TICs"). Automatic integration of signals meeting the

criteria for HBCDD is a common function of software used in GC‑MS trace analysis.

The HBCDD isolated from the sample extraction (8.2.3) are quantified by adding the internal

standard (CB 209) (8.2.1, b)) to an extract aliquot, injecting the solution into the GC‑MS,

measuring the area of the analyte peak(s) and the area of the CB 209 peak, and calculating the

concentration of the analyte according to Equations (5) and (6).

10 Precision

When the values of two independent single test results, obtained using the same method on

identical test material in the same laboratory by the same operator using the same equipment

within a short interval of time, lie within the range of the mean values cited in Table 5 below,

the absolute difference between the two test results obtained shall not exceed the repeatability

limit r deduced by statistical analysis of the international interlaboratory study (IIS 9) results in

more than 5 % of cases.

When the values of two single test results, obtained using the same method on identical test

material in different laboratories by different operators using different equipment, lie within the

range of the values cited in Table 5 below, the absolute difference between the two results shall

not be greater than the reproducibility limit R by statistical analysis of the international

interlaboratory study (IIS 9) results in more than 5 % of cases.

=

– 16 – IEC 62321-9:2021 © IEC 2021

Table 5 – IIS 9 repeatability and reproducibility

m r R

Parameter N

mg/kg mg/kg mg/kg

HBCDD 36 4 513,2 881,17 4 427,02

HBCDD 24 10 623,71 3 421,82 7 942,11

HBCDD 24 9 924,00 1 882,62 5 203,60

HBCDD 12 811,83 254,32 616,22

HBCDD 15 7 991,13 2 588,69 4 599,88

Key

N number of test results taken into calculation

m mean value in mg/kg

r repeatability

R reproducibility

See Annex C (results of the international interlaboratory study (IIS 9)) for supporting data.

11 Quality assurance and quality control

11.1 Performance

The following steps are taken for the quality control:

a) One reagent blank shall be extracted with each sequence of samples. The reagent blank is

60 ml of only solvent taken through the entire extraction procedure according to 8.2.3 or

8.2.4. The concentration of HBCDD compounds found in the method blank shall be less than

the method detection limits for each compound.

b) One sample per sequence or one every ten samples, depending on the sample load, shall

be spiked with 10 µg of HBCDD in the matrix spiking solution (see 8.2.1).

Equation (7) shall be used for the calculation:

CC−

m

HR ×100 (7)

C

s

where

HR is the recovery of HBCDD in %;

is the concentration of HBCDD in the matrix spike in µg/ml;

C

m

C is the concentration of HBCDD in the original sample in µg/ml;

C is the concentration of HBCDD spike solution in µg/ml.

s

The percent recovery for HBCDD shall be between 50 % and 150 %. The percent recovery

for each matrix spike shall be recorded and tracked in a spreadsheet to determine possible

matrix effects in the analysis.

c) After every tenth sample run and at the end of each sample set, analyse a continuing

calibration check (CCC) standard. A CCC is an unextracted mid-range calibrant that is

analysed as a sample. The percent recovery for HBCDD shall be between 70 % and 130 %.

If the percent recovery for HBCDD in the CCC standard falls outside of this range, the CCC

standard shall be reinjected within 12 h. If the recovery is still out of range after re-injection

of the CCC standard, the analysis is stopped and maintenance shall be performed on the

system to return it to optimal operating conditions. All samples injected before the last

successful CCC standard may be reported, but all samples after the failing CCC standard

shall be re-analysed with a new calibration.

=

d) The surrogate recovery shall be monitored for each sample. Percent (%) surrogate recovery

shall be calculated by Equation (8):

M

s

SR ×100 (8)

10 µg

where

SR is the surrogate re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...