IEC 62899-502-2:2019

(Main)Printed electronics - Part 502-2: Quality assessment - Organic light emitting diode (OLED) elements - Combined mechanical and environmental stress test methods for flexible OLED elements

Printed electronics - Part 502-2: Quality assessment - Organic light emitting diode (OLED) elements - Combined mechanical and environmental stress test methods for flexible OLED elements

IEC 62899-502-2:2019(E) specifies the combined mechanical and environmental stress test methods for flexible OLED (organic light emitting diode) elements fabricated using the printing method. Mechanical stress tests include the static and cycling vending test, and the dynamic and static rolling test.

General Information

- Status

- Published

- Publication Date

- 23-Jul-2019

- Technical Committee

- TC 119 - Printed Electronics

- Drafting Committee

- WG 5 - TC 119/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Jul-2019

- Completion Date

- 23-Aug-2019

Overview

IEC 62899-502-2:2019 - Printed electronics, Part 502-2 - defines combined mechanical and environmental stress test methods for flexible OLED elements fabricated by printing processes. The standard provides methods to subject printed, flexible organic light emitting diode (OLED) elements to mechanical deformation (bending and rolling) together with environmental exposure, and to measure the resulting optical, electrical and mechanical performance changes.

Key points:

- Applies to flexible OLED elements made using printing methods.

- Specifies combined mechanical (deformation) and environmental stress tests.

- Focuses on reliability and quality assessment for foldable, rollable or conformable printed OLED devices.

Key Topics and Technical Requirements

The standard organizes testing and measurement to enable repeatable quality assessment. Main technical topics include:

- Mechanical stress tests

- Cyclic bending (cyclic bending test)

- Static bending (static bending test)

- Dynamic and static rolling (rolling tests)

- Combined mechanical + environmental testing

- Procedures for subjecting samples to deformation while controlling temperature and atmospheric conditions

- Recovery and operating condition definitions

- Measurements and analysis

- Sample preparation for optical and electrical measurements

- Visual inspection and mechanical status assessment

- IVL (current‑voltage‑luminance) characteristics and luminous flux measurements

- Test apparatus and configuration

- Structure of measuring equipment and examples of apparatus for bending and rolling tests

- Standard and referee atmospheric/operating conditions

- Guidance on standard conditions for repeatable referee measurements and tests

- Normative annexes

- Annex A: IVL measurement methods

- Annex B: Luminous flux measurement methods

Note: IEC 62899-502-2 references related IEC standards for measuring methods, environmental testing, and flexible display mechanical tests.

Practical Applications and Who Uses This Standard

IEC 62899-502-2 is intended for stakeholders involved in the development, manufacturing and evaluation of printed flexible OLED products:

- OLED manufacturers and process engineers - to validate printed device robustness under bending/rolling and environmental stress.

- Quality control and reliability labs - to implement standardized test procedures for batch acceptance and failure analysis.

- Product designers and OEMs - to verify design durability for foldable, rollable or conformable lighting and display applications.

- Test houses and certification bodies - to provide objective, repeatable test reports for supplier qualification and compliance.

- R&D and material suppliers - to compare material/process choices and characterize deformation-related failure modes.

Related Standards

Normative references cited in IEC 62899-502-2 include (selection):

- IEC 60068-1:2013 (Environmental testing - General)

- IEC 60068-2-2 (Dry heat)

- IEC 62341 series (OLED display measurement methods)

- IEC 62715 series (Flexible display measurement and mechanical tests)

- IEC 62899-502-1 (Mechanical stress testing of OLED elements)

- IEC 62922 (OLED panels for general lighting)

Keywords: IEC 62899-502-2, flexible OLED, printed electronics, mechanical stress test, cyclic bending, rolling test, environmental stress testing, IVL, luminous flux, OLED quality assessment.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62899-502-2:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Printed electronics - Part 502-2: Quality assessment - Organic light emitting diode (OLED) elements - Combined mechanical and environmental stress test methods for flexible OLED elements". This standard covers: IEC 62899-502-2:2019(E) specifies the combined mechanical and environmental stress test methods for flexible OLED (organic light emitting diode) elements fabricated using the printing method. Mechanical stress tests include the static and cycling vending test, and the dynamic and static rolling test.

IEC 62899-502-2:2019(E) specifies the combined mechanical and environmental stress test methods for flexible OLED (organic light emitting diode) elements fabricated using the printing method. Mechanical stress tests include the static and cycling vending test, and the dynamic and static rolling test.

IEC 62899-502-2:2019 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 29.035.01 - Insulating materials in general; 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62899-502-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62899-502-2 ®

Edition 1.0 2019-07

INTERNATIONAL

STANDARD

colour

inside

Printed electronics –

Part 502-2: Quality assessment – Organic light emitting diode (OLED) elements –

Combined mechanical and environmental stress test methods for flexible OLED

elements

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62899-502-2 ®

Edition 1.0 2019-07

INTERNATIONAL

STANDARD

colour

inside

Printed electronics –

Part 502-2: Quality assessment – Organic light emitting diode (OLED) elements –

Combined mechanical and environmental stress test methods for flexible OLED

elements

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.035.01; 31.260 ISBN 978-2-8322-7220-6

– 2 – IEC 62899-502-2:2019 IEC 2019

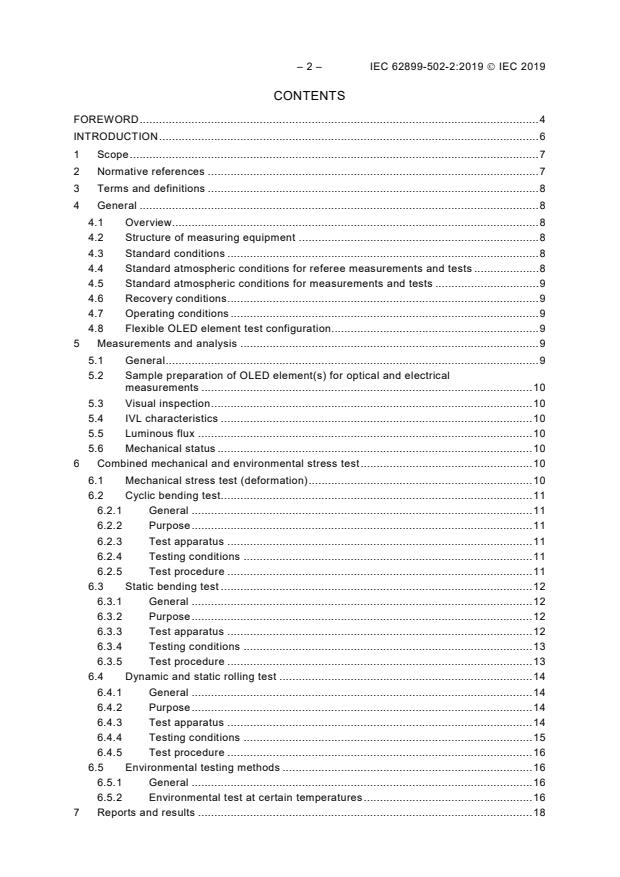

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 General . 8

4.1 Overview. 8

4.2 Structure of measuring equipment . 8

4.3 Standard conditions . 8

4.4 Standard atmospheric conditions for referee measurements and tests . 8

4.5 Standard atmospheric conditions for measurements and tests . 9

4.6 Recovery conditions . 9

4.7 Operating conditions . 9

4.8 Flexible OLED element test configuration. 9

5 Measurements and analysis . 9

5.1 General . 9

5.2 Sample preparation of OLED element(s) for optical and electrical

measurements . 10

5.3 Visual inspection . 10

5.4 IVL characteristics . 10

5.5 Luminous flux . 10

5.6 Mechanical status . 10

6 Combined mechanical and environmental stress test . 10

6.1 Mechanical stress test (deformation) . 10

6.2 Cyclic bending test . 11

6.2.1 General . 11

6.2.2 Purpose . 11

6.2.3 Test apparatus . 11

6.2.4 Testing conditions . 11

6.2.5 Test procedure . 11

6.3 Static bending test . 12

6.3.1 General . 12

6.3.2 Purpose . 12

6.3.3 Test apparatus . 12

6.3.4 Testing conditions . 13

6.3.5 Test procedure . 13

6.4 Dynamic and static rolling test . 14

6.4.1 General . 14

6.4.2 Purpose . 14

6.4.3 Test apparatus . 14

6.4.4 Testing conditions . 15

6.4.5 Test procedure . 16

6.5 Environmental testing methods . 16

6.5.1 General . 16

6.5.2 Environmental test at certain temperatures . 16

7 Reports and results . 18

Annex A (normative) IVL measurement methods . 19

A.1 General . 19

A.2 Measurement method . 19

A.2.1 General . 19

A.2.2 Measurement apparatus . 19

A.2.3 Measurement procedure . 19

A.2.4 Acceptance . 19

A.2.5 Items for the relevant specification . 19

Annex B (normative) Luminous flux measurement methods . 21

B.1 General . 21

B.2 Measurement method . 21

B.2.1 General . 21

B.2.2 Measurement apparatus . 21

B.2.3 Measurement procedure . 22

B.2.4 Acceptance . 23

B.2.5 Terms for additional definition . 23

Bibliography . 24

Figure 1 – Apparatus for cyclic bending test . 12

Figure 2 – Apparatus for static bending test . 13

Figure 3 – Example of apparatus for rolling test . 15

Figure A.1 – Layout of luminous measurement system . 20

Figure B.1 – Example of measurement apparatus for luminous flux using an integral

sphere . 22

Table 1 – Standard conditions for referee measurements and tests . 8

Table 2 – Examples of the test conditions . 17

– 4 – IEC 62899-502-2:2019 IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRINTED ELECTRONICS –

Part 502-2: Quality assessment –

Organic light emitting diode (OLED) elements –

Combined mechanical and environmental stress

test methods for flexible OLED elements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62899-502-2 has been prepared by IEC technical committee 119:

Printed Electronics.

The text of this International Standard is based on the following documents:

FDIS Report on voting

119/271/FDIS 119/278/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62899 series, published under the general title Printed electronics,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62899-502-2:2019 IEC 2019

INTRODUCTION

Electronic devices made by printing processes have very unique characteristics, as they are

flexible, with foldable, rollable and/or conformable capabilities, compared to the electronic

devices made through conventional non-printing processes that are mostly rigid. Given these

characteristics, these devices can show different phenomena from those by non-printing

processes under some conditions. In order to evaluate these phenomena, several unique

evaluation methods are used for these devices made by the printing process. This document

will provide one of them.

PRINTED ELECTRONICS –

Part 502-2: Quality assessment –

Organic light emitting diode (OLED) elements –

Combined mechanical and environmental stress

test methods for flexible OLED elements

1 Scope

This part of IEC 62899 specifies the combined mechanical and environmental stress test

methods for flexible OLED (organic light emitting diode) elements fabricated using the printing

method. Mechanical stress tests include the static and cycling vending test, and the dynamic

and static rolling test.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1:2013, Environmental testing – Part 1: General and guidance

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 62341-6-1, Organic light emitting diode (OLED) displays – Part 6-1: Measuring methods

of optical and electro-optical parameters

IEC 62341-6-2, Organic light emitting diode (OLED) displays – Part 6-2: Measuring methods

of visual quality and ambient performance

IEC 62341-6-3, Organic light emitting diode (OLED) displays – Part 6-3: Measuring methods

of image quality

IEC 62715-5-1, Flexible display devices – Part 5-1: Measuring methods of optical

performance

IEC 62715-5-3, Flexible display devices – Part 5-3: Visual assessment of image quality and

defects

IEC 62715-6-1, Flexible display devices – Part 6-1: Mechanical test methods – Deformation

tests

IEC 62899-502-1, Printed electronics – Part 502-1: Quality assessment – Organic light

emitting diode (OLED) elements – Mechanical stress testing of OLED elements formed on

flexible substrates

IEC 62922, Organic light emitting diode (OLED) panels for general lighting – Performance

requirements

– 8 – IEC 62899-502-2:2019 IEC 2019

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62899-502-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General

4.1 Overview

The flexible OLED elements can show some level of property variation applied by mechanical

stress in certain environmental conditions such as a hot or cool atmosphere. In order to

evaluate adequately these variations, environmental test conditions combined with a

mechanical test are introduced.

4.2 Structure of measuring equipment

The system diagrams and/or operating conditions of the measuring equipment shall comply

with the structure specification of each item.

4.3 Standard conditions

The standard testing conditions shall be as follows:

– temperature: 25 °C

– atmosphere: 101,3 kPa

If the parameters to be measured depend on temperature and/or pressure, and their

dependence on temperature and pressure is known, the parameter values can be measured

under the conditions specified in 4.5 and corrected by calculation to the standard reference

atmosphere above.

4.4 Standard atmospheric conditions for referee measurements and tests

If the parameters to be measured depend on temperature, pressure and humidity and their

dependence on temperature, pressure and humidity is unknown, the atmospheres to be

specified shall be selected from the following values, as shown in Table 1. The selected

values shall be noted in the relevant specifications.

Table 1 – Standard conditions for referee measurements and tests

a b b

Temperature Relative humidity Air pressure

°C % RH kPa

20 ± 1 (close)/ ± 2 (wide) 63 to 67 (close), 60 to 70 (wide) 86 to 106

25 ± 1 (close)/ ± 2 (wide) 48 to 52 (close), 45 to 55 (wide) 86 to 106

30 ± 1 (close)/ ± 2 (wide)

45 to 75 86 to 106

35 ± 1 (close)2/ ± 2 (wide)

a

The close tolerances may be used for the referee measurements. The wider tolerances

may be used only when allowed by the relevant specification.

b

Inclusive values.

4.5 Standard atmospheric conditions for measurements and tests

Unless otherwise specified, all tests and measurements shall be carried out under standard

atmospheric conditions:

– temperature: (25 ± 5) °C

– relative humidity: (60 ± 15) %

– atmospheric pressure: (96 ± 10) kPa

4.6 Recovery conditions

The recovery conditions specified in IEC 60068-1:2013, 4.4 shall be applied.

The OLED element shall be subjected to the recovery procedure in the chamber or otherwise

as appropriate.

The OLED element shall then remain under standard atmospheric conditions for recovery for

a period adequate for the attainment of temperature stability, for a minimum of 1 h.

If required by the relevant specification, the element shall be switched on or loaded and

measured continuously during the recovery period.

If the standard conditions given above are not appropriate for the device to be tested, the

relevant specification may call for other recovery conditions.

4.7 Operating conditions

Apply the proper driving current and voltage to the OLED element to provide luminosity at

normal intended operation.

4.8 Flexible OLED element test configuration

Unless otherwise specified, the OLED element shall be tested in a state that is ready for

normal operation without any protective elements added, nor voltage applied.

5 Measurements and analysis

5.1 General

Both before and after the combined stress testing in Clause 6, the following measurements on

the electrical, optical and mechanical characteristics of OLED element(s) shall be performed

in the standard environmental conditions defined in Clause 4. Measurement samples shall be

prepared according to 5.2 before the measurements defined in 5.3 and 5.4. Both IEC 62922

and IEC 62341-6-1 are applied to measure the optical and electro-optical parameters.

a) Visual inspection (see 5.3): Visual inspection shall be performed according to IEC 62715-

5-3.

b) IVL (intensity of electric current, voltage, luminance) characteristics (see 5.4).

c) Luminous flux (see 5.5): Optical performance measurement shall refer to IEC 62715-5-1.

d) Mechanical status (5.6).

e) Image quality: Image quality measurement shall refer to IEC 62341-6-2 and IEC 62341-6-3.

Depending on the purpose of the test, only one, some, or all of the methods shall be used.

The measuring frequency and evaluation criteria shall be specified in the detailed

specifications.

– 10 – IEC 62899-502-2:2019 IEC 2019

NOTE Measurements of luminous intensity distribution and maintenance of luminous flux are important

parameters for OLED elements, however these measurements, in particular for maintenance of luminous flux, can

cause degradation of OLED elements which will disturb evaluation of the mechanical stress testing of OLED

elements. Since these measurements would be applicable for an evaluation as a final product, but not practically

suitable for an evaluation as an element for this case, they are eliminated for evaluating the OLED elements both

before and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...