IEC 61779-1:1998

(Main)Electrical apparatus for the detection and measurement of flammable gases - Part 1: General requirements and test methods

Electrical apparatus for the detection and measurement of flammable gases - Part 1: General requirements and test methods

Specifies general requirements for construction and testing and describes the test methods that apply to portable, transportable and fixed apparatus for the detection and measurement of flammable gas or vapour concentrations with air. The apparatus, or parts thereof, are intended for use in potentially explosive atmospheres and in mines susceptible to firedamp.

General Information

- Status

- Replaced

- Publication Date

- 22-Apr-1998

- Technical Committee

- TC 31 - Equipment for explosive atmospheres

- Drafting Committee

- MT 60079-29 - TC 31/MT 60079-29

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-Aug-2007

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61779-1:1998 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical apparatus for the detection and measurement of flammable gases - Part 1: General requirements and test methods". This standard covers: Specifies general requirements for construction and testing and describes the test methods that apply to portable, transportable and fixed apparatus for the detection and measurement of flammable gas or vapour concentrations with air. The apparatus, or parts thereof, are intended for use in potentially explosive atmospheres and in mines susceptible to firedamp.

Specifies general requirements for construction and testing and describes the test methods that apply to portable, transportable and fixed apparatus for the detection and measurement of flammable gas or vapour concentrations with air. The apparatus, or parts thereof, are intended for use in potentially explosive atmospheres and in mines susceptible to firedamp.

IEC 61779-1:1998 is classified under the following ICS (International Classification for Standards) categories: 17.060 - Measurement of volume, mass, density, viscosity; 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61779-1:1998 has the following relationships with other standards: It is inter standard links to IEC 60079-29-1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61779-1:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL

IEC

STANDARD

61779-1

First edition

1998-04

Electrical apparatus for the detection

and measurement of flammable gases –

Part 1:

General requirements and test methods

Appareils électriques de détection et de mesure

des gaz combustibles –

Partie 1:

Règles générales et méthodes d’essai

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken by

the technical committee which has prepared this publication, as well as the list of

publications issued, is to be found at the following IEC sources:

• IEC web site*

• Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter

symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL

IEC

STANDARD

61779-1

First edition

1998-04

Electrical apparatus for the detection

and measurement of flammable gases –

Part 1:

General requirements and test methods

Appareils électriques de détection et de mesure

des gaz combustibles –

Partie 1:

Règles générales et méthodes d’essai

IEC 1998 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http: //www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

XA

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 61779-1 © IEC:1998(E)

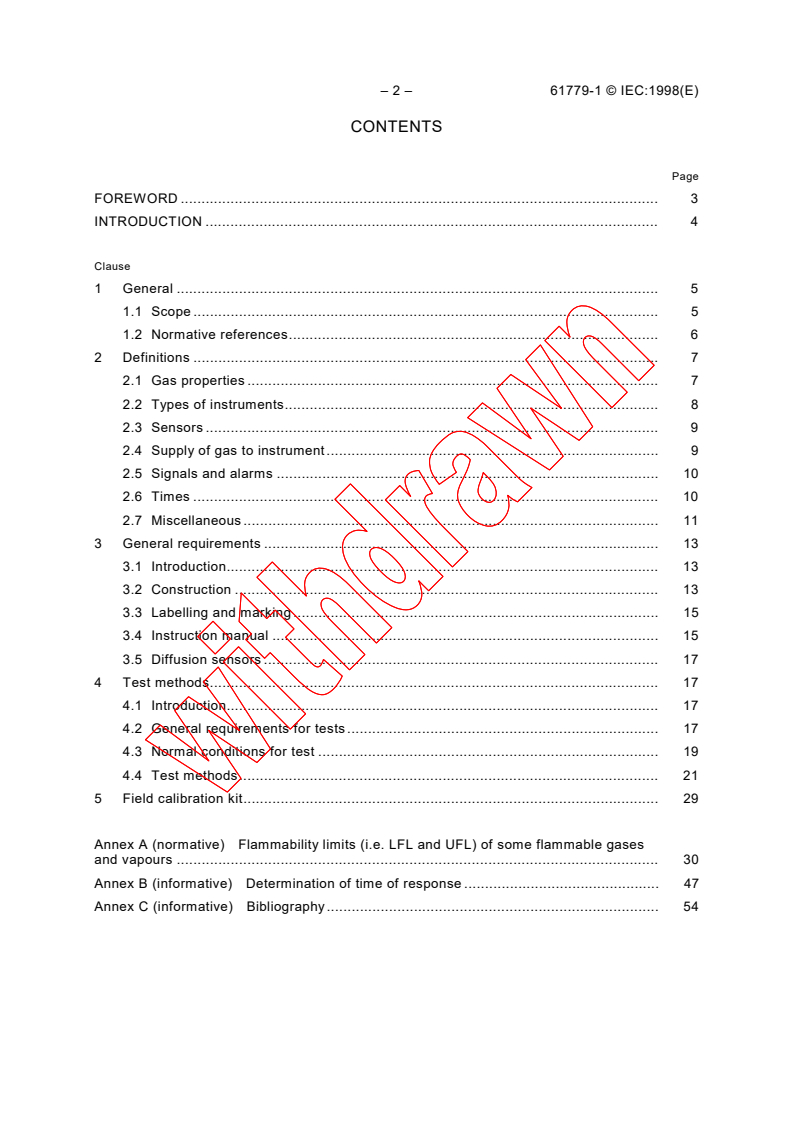

CONTENTS

Page

FOREWORD . 3

INTRODUCTION . 4

Clause

1 General. 5

1.1 Scope. 5

1.2 Normative references. 6

2 Definitions. 7

2.1 Gas properties. 7

2.2 Types of instruments. 8

2.3 Sensors. 9

2.4 Supply of gas to instrument. 9

2.5 Signals and alarms . 10

2.6 Times. 10

2.7 Miscellaneous. 11

3 General requirements. 13

3.1 Introduction. 13

3.2 Construction. 13

3.3 Labelling and marking . 15

3.4 Instruction manual. 15

3.5 Diffusion sensors. 17

4 Test methods. 17

4.1 Introduction. 17

4.2 General requirements for tests . 17

4.3 Normal conditions for test . 19

4.4 Test methods. 21

5 Field calibration kit. 29

Annex A (normative) Flammability limits (i.e. LFL and UFL) of some flammable gases

and vapours . 30

Annex B (informative) Determination of time of response . 47

Annex C (informative) Bibliography. 54

61779-1 © IEC:1998(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

ELECTRICAL APPARATUS FOR THE DETECTION

AND MEASUREMENT OF FLAMMABLE GASES –

Part 1: General requirements and test methods

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61779-1 has been prepared by subcommittee 31L: Electrical

apparatus for the detection of flammable gases, of IEC technical committee 31: Electrical

apparatus for explosive atmospheres.

The text of this standard is based on the following documents:

FDIS Report on voting

31L/47/FDIS 31L/52/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

Annex A forms an integral part of this standard.

Annexes B and C are for information only.

A bilingual version of this standard may be issued at a later date.

– 4 – 61779-1 © IEC:1998(E)

INTRODUCTION

Guidance for the selection, installation, use and maintenance of gas detecting apparatus are

set out in IEC 61779-6: Electrical apparatus for the detection and measurement of flammable

1)

gases – Part 6: Guidelines for the selection, installation, use and maintenance .

___________

1)

To be published.

61779-1 © IEC:1998(E) – 5 –

ELECTRICAL APPARATUS FOR THE DETECTION

AND MEASUREMENT OF FLAMMABLE GASES –

Part 1: General requirements and test methods

1 General

1.1 Scope

1.1.1 This part of IEC 61779 specifies general requirements for construction and testing and

describes the test methods that apply to portable, transportable and fixed apparatus for the

detection and measurement of flammable gas or vapour concentrations with air. The

apparatus, or parts thereof, are intended for use in potentially explosive atmospheres (see

2.1.8) and in mines susceptible to firedamp. This standard is supplemented by the following

standards, concerning the specific requirements for the performance of the various types of

apparatus:

IEC 61779-2: Performance requirements for group I apparatus indicating up to a volume

fraction of 5 % methane in air

IEC 61779-3: Performance requirements for group I apparatus indicating up to a volume

fraction of 100 % methane in air

IEC 61779-4: Performance requirements for group II apparatus indicating up to a volume

fraction of 100 % lower explosive limit

IEC 61779-5: Performance requirements for group II apparatus indicating up to a volume

fraction of 100 % gas

NOTE 1 – IEC 61779-1, in association with the standards referred to above, is intended to provide for the supply of

apparatus giving a level of safety and performance suitable for general purpose applications. However, for specific

applications, a prospective purchaser (or an appropriate authority) may additionally require the apparatus to be

submitted to particular tests or approval. For example, group I apparatus (i.e. apparatus to be used in mines

susceptible to firedamp) may not be permitted to be used without the additional, prior approval of the relevant

authority in mines under its jurisdiction. Such particular tests/approval are to be regarded as additional to and

separate from the provisions of the standards referred to above and do not preclude certification to or compliance

with these standards.

NOTE 2 – Group I and group II apparatus indicating up to a volume fraction of 100 % methane and group II

apparatus indicating up to a volume fraction of 100 % gas are suitable for use only with the specific gases for which

they have been calibrated.

NOTE 3 – For the purpose of this standard, the terms "lower flammable limit (LFL)" and "lower explosive limit (LEL)"

are deemed to be synonymous, and likewise the terms "upper flammable limit (UFL)" and "upper explosive limit

(UEL)" are deemed to be synonymous. For ease of reference, the two abbreviations LFL and UFL may be used

hereinafter to denote these two sets of terms. It should be recognized that particular authorities having jurisdiction

may have overriding requirements that dictate the use of one of these sets of terms and not the other.

1.1.2 This standard is applicable when an apparatus manufacturer makes any claims

regarding any special features of construction or superior performance that exceed these

minimum requirements. All such claims shall be verified and the test procedures shall be

extended or supplemented, where necessary, to verify the claimed performance. The additional

tests shall be agreed between the manufacturer and test laboratory.

1.1.3 This standard is applicable to flammable gas detection apparatus intended to provide an

indication, alarm or other output function, the purpose of which is to give a warning of a

potential explosion hazard and, in some cases, to initiate automatic or manual protective

action(s).

– 6 – 61779-1 © IEC:1998(E)

1.1.4 This standard is applicable to apparatus, including the integral sampling systems of

aspirated apparatus, intended to be used for commercial and industrial safety applications.

1.1.5 This standard does not apply to external sampling systems, or to apparatus of

laboratory or scientific type, or to apparatus used only for process control purposes.

1.2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 61779. At the time of publication, the editions indicated

were valid. All normative documents are subject to revision, and parties to agreements based

on this part of IEC 61779 are encouraged to investigate the possibility of applying the most

recent editions of the normative documents indicated below. Members of IEC and ISO maintain

registers of currently valid International Standards.

IEC 60050(351):1975, International Electrotechnical Vocabulary (IEV) – Chapter 351:

Automatic control

IEC 60079-0:1983, Electrical apparatus for explosive gas atmospheres – Part 0: General

requirements

IEC 60079-1:1990, Electrical apparatus for explosive gas atmospheres – Part 1: Construction

and verification test of flameproof enclosures of electrical apparatus

IEC 60079-2:1983, Electrical apparatus for explosive gas atmospheres – Part 2: Electrical

apparatus – type of protection "p"

IEC 60079-5:1967, Electrical apparatus for explosive gas atmospheres – Part 5: Sand-filled

apparatus

IEC 60079-6:1995, Electrical apparatus for explosive gas atmospheres – Part 6: Oil immersion "o"

IEC 60079-7:1990, Electrical apparatus for explosive gas atmospheres – Part 7: Increased

safety "e"

IEC 60079-10:1986, Electrical apparatus for explosive gas atmospheres – Part 10:

Classification of hazardous areas

IEC 60079-11:1991, Electrical apparatus for explosive gas atmospheres – Part 11: Intrinsic

safety "i"

IEC 60079-13:1982, Electrical apparatus for explosive gas atmospheres – Part 13:

Construction and use of rooms or buildings protected by pressurization

IEC 60079-14:1984, Electrical apparatus for explosive gas atmospheres – Part 14: Electrical

installations in explosive gas atmospheres (other than mines)

IEC 60079-15:1987, Electrical apparatus for explosive gas atmospheres – Part 15: Electrical

apparatus, with type of protection "n"

IEC 60079-18:1992, Electrical apparatus for explosive gas atmospheres – Part 18:

Encapsulation "m"

IEC 60079-19:1993, Electrical apparatus for explosive gas atmospheres – Part 19: Repair and

overhaul for apparatus used in explosive atmospheres (other than mines or explosives)

61779-1 © IEC:1998(E) – 7 –

IEC 60079-20:1996, Electrical apparatus for explosive gas atmospheres – Part 20: Data for

flammable gases and vapours, relating to the use of electrical apparatus

IEC 61000-4-1:1992, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 1: Overview of immunity tests – Basic EMC publication

IEC 61000-4-3:1995, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 3: Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4:1995, Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques – Section 4: Electrical fast transient/burst immunity test – Basic EMC publication

ISO 2738:1987, Permeable sintered metal materials – Determination of density, oil content, and

open porosity

ISO 4003:1977, Permeable sintered metal materials – Determination of bubble test pore size

ISO 4022:1987, Permeable sintered metal materials – Determination of fluid permeability

ISO 6142:1981, Gas analysis – Preparation of calibration gas mixtures – Weighing methods

ISO 6145-1:1986, Gas analysis – Preparation of calibration gas mixtures – Dynamic volumetric

methods – Part 1: Methods of calibration

ISO 6145-3:1986, Gas analysis – Preparation of calibration gas mixtures – Dynamic volumetric

methods – Part 3: Periodic injections into a flowing gas stream

ISO 6145-4:1986, Gas analysis – Preparation of calibration gas mixtures – Dynamic volumetric

methods – Part 4: Continuous injection method

ISO 6145-6:1986, Gas analysis – Preparation of calibration gas mixtures – Dynamic volumetric

methods – Part 6: Sonic orifices

ISO 6147:1979, Gas analysis – Preparation of calibration gas mixtures – Saturation method

2 Definitions

For the purpose of this part of IEC 61779, and of the standards listed in 1.1.1, the following

definitions apply:

2.1 Gas properties

2.1.1

ambient air

normal atmosphere surrounding the apparatus

2.1.2

clean air

air that is free of flammable gases and interfering or contaminating substances

2.1.3

explosive gas atmosphere

mixture with air, under normal atmospheric conditions, of flammable material in the form of gas

or vapour, in which, after ignition, combustion spreads throughout the unconsumed mixture

– 8 – 61779-1 © IEC:1998(E)

NOTE 1 – This definition specifically excludes dusts and fibres in suspension in air. Mists are not covered by this

standard.

NOTE 2 – Although a mixture that has a concentration above the upper flammable limit (see 2.1.9) is not an

explosive atmosphere, in certain cases for area classification purposes, it is advisable to consider it as an explosive

gas atmosphere.

NOTE 3 – Normal atmospheric conditions include variations above and below the reference levels of 101,3 kPa and

20 °C provided the variations have a negligible effect on the explosive properties of the flammable materials.

2.1.4

firedamp

flammable gas, consisting mainly of methane, found naturally in mines

2.1.5

flammable gas

gas or vapour which, when mixed with air in a certain proportion, will form an explosive

atmosphere

NOTE – For the purpose of this standard the term "flammable gas" includes flammable vapours.

2.1.6

lower flammable limit (LFL)

volume ratio of flammable gas or vapour in air below which an explosive gas atmosphere will

not be formed

2.1.7

poisons (of sensors)

substances which lead to temporary or permanent loss of sensitivity of the sensors

2.1.8

potentially explosive atmosphere

atmosphere that could become explosive (The danger is a potential one.)

2.1.9

upper flammable limit (UFL)

volume ratio of flammable gas or vapour in air above which an explosive gas atmosphere will

not be formed (see also note 2 to 2.1.3)

2.1.10

volume ratio (v/v)

ratio of the volume of a component gas to the volume of the gas mixture under specified

conditions of temperature and pressure

2.1.11

zero gas

gas which is free of flammable gases, and interfering and contaminating substances, the

purpose of which is calibration/adjustment of the apparatus zero

2.2 Types of instruments

2.2.1

alarm-only apparatus

apparatus having an alarm but not having a meter or other indicating device that would allow

measurement of the deviations permitted by the requirements of the appropriate standards

listed in 1.1.1

2.2.2

aspirated apparatus

combustible gas detecting apparatus that obtains the gas by drawing it to the gas sensor – for

example, by means of a hand-operated or electric pump

61779-1 © IEC:1998(E) – 9 –

2.2.3

continuous duty apparatus

combustible gas detecting apparatus that is powered for long periods of time, but may have

either continuous or intermittent sensing

2.2.4

diffusion apparatus

apparatus in which the transfer of gas from the atmosphere to the gas sensor takes place by

random molecular movement, i.e. under conditions in which there is no aspirated flow

2.2.5

fixed apparatus

apparatus that is intended to have all parts permanently installed at a given location

2.2.6

group I apparatus

electrical apparatus for mines susceptible to firedamp

2.2.7

group II apparatus

electrical apparatus for places with a potentially explosive atmosphere, other than mines

susceptible to firedamp

2.2.8

portable apparatus

spot-reading or continuous duty apparatus that has been designed to be carried readily from

place to place and to be used while it is being carried. A portable apparatus is battery powered

and includes, but is not limited to

a) a hand-held apparatus, typically less than 1 kg, suitable for one-handed operation without

accessories (such as sampling probes, sample lines), fitted,

b) personal monitors, similar in size and mass to the hand-held apparatus, that are

continuously operating (but not necessarily continuously sensing) while they are attached to

the user, and

c) another apparatus that can be operated by the user while it is carried either by hand, or by

means of a shoulder strap or carrying harness, and which may or may not have a

hand-directed probe.

2.2.9

spot-reading apparatus

apparatus intended to operate for periods of only a few minutes for irregular intervals

2.2.10

transportable apparatus

apparatus not intended to be portable, but which can be moved readily from one place to

another

2.3 Sensors

2.3.1

remote sensor

sensor that is not integral to the main body of the apparatus

2.3.2

sensor

assembly in which the sensing element is housed and which may also contain associated

circuit components

– 10 – 61779-1 © IEC:1998(E)

2.4 Supply of gas to instrument

2.4.1

sample line

pipeline by means of which the gas being sampled is conveyed to the sensor

2.4.2

sampling probe

separate sample line which is attached to the apparatus as required, that may or may not be

supplied with the apparatus. It is usually short (e.g. in the order of 1 m) and rigid (although it

may be telescopic), but it may be connected by a flexible tube to the apparatus

2.5 Signals and alarms

2.5.1

alarm set point

fixed or adjustable setting of the apparatus that is intended to preset the level of concentration

at which the apparatus will automatically initiate an indication, alarm or other output function

2.5.2

fault signal

audible, visible or other type of output different from the alarm signal, permitting, directly or

indirectly, a warning or indication that the apparatus is not working satisfactorily

2.5.3

latching alarm

alarm that, once activated, requires deliberate action to be deactivated

2.6 Times

2.6.1

drift

variation in the apparatus indication with time, at any fixed gas concentration level (including

clean air)

2.6.2

final indication

indication given by the apparatus after stabilization

2.6.3

minimum time of operation (spot-reading apparatus)

time interval between the initiation of a measurement procedure and the time when the

apparatus indication reaches a stated percentage of the final indication

2.6.4

measuring span

algebraic difference between the upper and lower limits of the measuring range [IEV 351-05-39

modified]

2.6.5

stabilization

state when three successive readings of an apparatus, taken at two minute intervals, indicates

no changes greater than ±1 % of the measuring range

61779-1 © IEC:1998(E) – 11 –

2.6.6

time of response t(x) (not applicable to spot-reading apparatus)

time interval, with the apparatus in a warmed-up condition, between the time when an

instantaneous variation in volume ratio is produced at the apparatus inlet and the time when

the response reaches a stated percentage (x) of the final indication

2.6.7

warm-up time (not applicable to spot-reading apparatus)

time interval, with the apparatus in a stated atmosphere, between the time when the apparatus

is switched on and the time when the indication reaches and remains within the stated

tolerances (see figures 1 and 2)

2.7 Miscellaneous

2.7.1

nominal supply voltage

voltage that is given by manufacturers as the recommended operating voltage of their gas

detection apparatus

2.7.2

special tool

tool required to gain access to, or to adjust, controls. The design of the tool is intended to

discourage unauthorized interference with the apparatus

2.7.3

type of protection

measures applied in the construction of electrical apparatus to prevent ignition of the

surrounding explosive atmosphere by such apparatus (see 3.1.2)

– 12 – 61779-1 © IEC:1998(E)

Indication

Power off in Power on in

clean air clean air

Specified

Apparatus

0 tolerance band

}

zero

on zero indication

Time

0 Warm-up time

IEC 629/98

(see 2.6.7)

Figure 1 – Warm-up time in clean air (typical)

Indication

Power off Power on

in standard in standard

test gas test gas

Volume ratio

Specified

of standard

tolerances of

}

test gas

the indication

Zero in

clean air 0 Time

0 Warm-up time

IEC 630/98

(see 2.6.7)

Figure 2 – Warm-up time in standard test gas (typical)

61779-1 © IEC:1998(E) – 13 –

3 General requirements

3.1 Introduction

3.1.1 The apparatus shall comply with both the requirements of this standard and the

appropriate standard(s) listed in 1.1.1.

Where an apparatus manufacturer makes any claims regarding any special features of

construction or superior performance that exceed these minimum requirements, all such claims

shall be verified and the test procedures shall be extended or supplemented, where necessary,

to verify the claimed performance.

3.1.2 Electrical assemblies and components shall comply with the construction and test

requirements of 3.2, 3.5 and clause 4, where applicable. In addition, parts of the flammable gas

detection apparatus intended for use in hazardous areas shall employ materials, and comply

with the construction and explosion protection as specified in the appropriate standards listed

in 1.1.1 and in the appropriate standards of IEC 60079. The appropriate standards are the

following:

IEC 60079-0

IEC 60079-1

IEC 60079-2

IEC 60079-5

IEC 60079-6

IEC 60079-7

IEC 60079-11

IEC 60079-13

IEC 60079-15

IEC 60079-18

3.1.3 For group I apparatus any electrical circuits to be installed in the same area as the

sensor, including those within the sensor, shall be intrinsically safe ("ia"); the sensing elements

shall be intrinsically safe, or their enclosures shall comply with the safety requirements

specified in 1.1.1.

3.1.4 In the design of software-controlled apparatus, the risks arising from faults in the

programme shall be taken into account.

NOTE – No specific test requirements have been developed but they are under consideration.

3.2 Construction

3.2.1 General

Gas detection apparatus or parts thereof (e.g. remote sensors) specifically intended for use in

the presence of corrosive vapours or gases, or which may produce corrosive by-products as a

result of the detection process (e.g. catalytic oxidation or other chemical process) shall be

constructed of materials known to be resistant to corrosion by such substances.

All apparatus shall be constructed to facilitate regular accuracy checks.

All materials and components used in the construction of the apparatus shall be used within the

manufacturer's ratings or limitations, unless otherwise specified by appropriate safety

standards.

– 14 – 61779-1 © IEC:1998(E)

3.2.2 Indicating devices

3.2.2.1 An indication shall be provided to show that the apparatus is energized.

NOTE – The indication can be shown at the central unit.

3.2.2.2 For alarm-only apparatus or apparatus where the resolution of the read-out device is

inadequate to demonstrate compliance with this standard, the manufacturer shall identify

suitable points for connecting indicating or recording devices for the purpose of testing the

compliance of the apparatus with this standard.

3.2.2.3 Where a read-out device is inadequate in this way, it shall be of sufficient quality as

not to contradict the results obtained by additional indicating or recording devices.

3.2.2.4 If the apparatus has more than one measuring range, the range selected shall be

clearly identified.

3.2.2.5 If individual coloured indicating lights are provided, they shall be coloured as follows:

a) alarms indicating the presence of a gas concentration above an alarm set point shall be

coloured RED;

b) equipment fault indicators shall be coloured YELLOW;

c) power supply indicators shall be coloured GREEN.

3.2.2.6 In addition to the colour requirements, the indicator lights shall be adequately labelled

to show their functions.

3.2.3 Alarm or output functions

3.2.3.1 Continuous duty apparatus

If alarm devices, output contacts or alarm signal outputs are provided as part of fixed or

continuous duty portable apparatus and are intended to operate when a potentially hazardous

gas concentration is detected, they shall be of a latching type requiring a deliberate manual

action to reset. Where the outputs are connected to an integrated or auxiliary system the

means of latching and resetting may be incorporated into these systems. If two or more set or

alarm positions are provided, the lower may be non-latching - based on user preference.

NOTE The integral or latching device may reside in software.

3.2.3.2 Group II portable apparatus indicating up to 100 % LFL

Alarm devices provided as part of a gas detection apparatus shall not be set to operate above

60 % LFL.

NOTE 1 – For other group II apparatus, it is recommended that alarm devices should be set to operate at a gas

volume ratio not higher than 60 % LFL.

NOTE 2 – In addition, it is also permissible to fit group II apparatus with an alarm which is designed to indicate

when full scale has been exceeded and which is, therefore, set to operate at 100 % LFL.

3.2.4 Fault signals

Fixed and transportable apparatus shall provide a fault signal in the event of failure of power to

the apparatus, of loss of continuity in one or more of the wires to any sensor, or of loss of

electrical continuity of any gas sensing system. A short circuit or open circuit in connections to

any sensor shall be indicated by a fault signal.

61779-1 © IEC:1998(E) – 15 –

Automatically aspirated apparatus shall be provided:

a) in the case of fixed and transportable apparatus: with an integral flow-indicating device that

produces a fault signal in the event of flow failure,

b) in the case of portable apparatus: with a means of verifying the air flow.

3.2.5 Adjustments

All adjustment devices shall be designed so as to discourage unauthorized or inadvertent

interference with the apparatus. Examples would include procedural devices, in the case of a

keyboard instrument, or mechanical devices such as a cover requiring the use of a tool.

Fixed explosion-protected apparatus housed in explosion-protected enclosures shall be

designed so that, if any facilities for adjustment are necessary for routine recalibration and for

resetting or like functions, these facilities shall be externally accessible. The means for making

adjustments shall not degrade the explosion protection of the apparatus.

The adjustments of the zero and signal amplification shall be so designed that adjustment of

one will not affect the other.

3.2.6 Battery-powered apparatus

Apparatus powered with integral batteries shall be provided with an indication of low battery

condition, and the nature and purpose of this indication shall be explained in the manual

(see 3.4 j)). All battery-powered apparatus shall be so constructed that, when the apparatus is

tested according to 4.4.19, it shall comply with the requirements of the appropriate standards

listed in 1.1.1.

3.3 Labelling and marking

The apparatus shall comply with the marking requirements contained in the relevant IEC 60079

standards covering electrical apparatus for explosive atmospheres referred to in 3.1.2, as

applicable.

The apparatus shall be marked with the number of the IEC 60079 standard (i.e. part 1, part 2,

part 3, part 4 or part 5) with which the performance is claimed to comply. The marking shall be

adjacent to that required by the standards referred to in 3.1.2. Where the apparatus

incorporates flame arresting devices complying with 3.5 of this standard, the marking shall

include the symbol "s" in accordance with 25.6 of IEC 60079-0.

All equipment and protective systems shall be marked legibly and indelibly with the following

minimum requirements:

a) name and address of the manufacturer;

b) certification marking;

c) designation of series or type;

d) serial number, if any;

e) specific marking describing the type of explosive protection.

Fixed group II apparatus with remote sensors shall carry a label, on each sensor, indicating the

calibration gas.

3.4 Instruction manual

Each apparatus shall be provided with an instruction manual that includes the following

information:

– 16 – 61779-1 © IEC:1998(E)

a) complete instructions, drawings and diagrams for safe and proper operation, installation and

servicing of the apparatus;

b) operating instructions and adjustment procedures;

c) recommendations for initial checking and calibration of the apparatus on a routine basis,

including instructions for the use of the field calibration kit, if provided (see also clause 5);

NOTE – Users are referred to IEC 61779-6.

d) details of operational limitations including, where applicable, the following:

1) gases for which the apparatus is suitable and the relative sensitivities of the instrument

to these gases,

2) information that describes the sensitivities to other gases to which the apparatus is

responsive,

3) temperature limits,

4) humidity ranges,

5) supply voltage limits,

6) relevant characteristics and construction details of required interconnecting cables,

7) battery data,

8) pressure limits,

9) sample flow rate,

10) warm-up time,

11) stabilization time;

e) details of storage life and limitations for the apparatus, replacement parts and accessories,

including, where applicable, the following:

1) temperature,

2) humidity,

3) time,

4) pressure;

f) bases used for converting test and calibration gas concentrations from % LFL to % volume

fraction;

g) information on the adverse effects of poisons and interfering gases or substances and

oxygen-enriched or deficient atmospheres on the proper performance (and, in the case of

oxygen-enriched atmospheres, on electrical safety) of the apparatus;

h) for aspirated apparatus, indication of the minimum and maximum flow rates and pressure;

also, tubing type, maximum length and size for proper operation;

i) for aspirated apparatus, instructions for ensuring that the sample lines are intact and that

proper flow is established (see 3.2.4);

j) statements of the nature and significance of all alarms and fault signals, the duration of

such alarms and signals (if time-limited or non-latching), and any provisions that may be

made for silencing or resetting such alarms and signals, as applicable;

k) details of any method for the determination of the possible sources of a malfunction and any

corrective procedures (i.e. trouble-shooting procedures);

l) a statement that alarm devices, outputs or contacts are of the non-latching types, where

applicable (see 3.2.3.1);

m) for battery-operated apparatus, installation and maintenance instructions for the batteries;

n) a recommended replacement parts list;

o) where optional accessories (e.g. collecting cones, weather-protecting devices) are supplied,

the manufacturer shall list such accessories and state their effects on the instrument

characteristics (including response time and sensitivity), and provide means for their

identification (e.g. part numbers included in manual);

p) details of certification and marking, and any special conditions of service;

61779-1 © IEC:1998(E) – 17 –

q) storage life and recommended storage conditions for replacement parts and accessories,

where critical;

r) where the special nature of the apparatus (such as non-linear responses) requires

additional instructions or special information that are alternative to, or in addition to, the

requirements of 3.3 and 3.4 a) to q), the instructions or information shall be provided.

3.5 Diffusion sensors

1)

NOTE – Requirements for diffusion sensors are being prepared.

4 Test methods

4.1 Introduction

The test methods and procedures described in 4.2 to 4.4 are intended as a basis for

establishing whether the apparatus conforms with the supplementary requirements for

performance given in the appropriate standards listed in 1.1.1.

4.2 General requirements for tests

4.2.1 Samples and sequence of tests

4.2.1.1 For the purpose of type testing, the tests shall be carried out on one apparatus.

Another apparatus may be used for tests according to 4.2.1.2.

4.2.1.2 The apparatus shall be subjected to all of the tests applicable to that type of

apparatus, as described in 4.4. The test sequence detailed below shall be followed. However,

test items 4) and 5) may be carried out to a schedule agreed upon between the manufacturer

and the test laboratory.

One apparatus shall successfully complete all the tests, 1) to 7) inclusive. Another apparatus

may be used for tests 8) and 9).

1) Unpowered storage (4.4.2)

2) Preparation and verification

Calibration and adjustment (4.4.3)

Alarm set point(s) (4.4.6)

Flow rate (4.4.11)

Warm-up time (4.4.15)

Time of response (4.4.16)

Minimum time of operation (4.4.17)

Addition of sampling probe (4.4.22)

Field calibration kit (clause 5)

3) Short-term stability (4.4.4.1)

Test on spot-reading apparatus (4.4.5)

4) Mechanical

Vibration (4.4.13)

Drop test (4.4.14)

5) Electrical battery capacity (4.4.19)

___________

1)

The review is conducted by a working group.

– 18 – 61779-1 © IEC:1998(E)

Power supply variations (4.4.20)

Power supply interruptions, voltage transients and step changes of voltage (4.4.21)

Electromagnetic interference (4.4.25)

6) Orientation (4.4.12)

7) Climatic

Temperature (4.4.7)

Pressure (4.4.8)

Humidity (4.4.9)

Air velocity (4.4.10)

8) Stability

Long-term tests for continuous duty apparatus (4.4.4.2 to 4.4.4.5)

9) Environmental

High gas concentration (4.4.18)

Dust (4.4.23)

Poisons (4.4.24)

4.2.1.3 Tests shall also be carried out, where applicable, to ensure that the apparatus

satisfies the construction requirements of 3.2. The requirements for these tests are generally

self-evident, except that for short-circuit requirements in 3.2.4, ballast resistors shall be

substituted for each wire connecting the instrument to any remote sensor. The values of these

resistors shall be those declared, in the instruction manual (see 3.4 d)), to be the maximum

lead resistances allowing satisfactory compliance with the standard. The device used for the

short circuit shall be of negligible resistance and shall be applied to convenient points in the

circuit, at the sensor ends of the ballast resistors.

4.2.1.4 For apparatus having more than one selectable range or scale for the same or

different gases or vapours, each range shall be tested. For the second and subsequent ranges

the necessary amount of testing shall be agreed upon between the manufacturer and the test

laboratory.

4.2.2 Preparation of apparatus before testing

The apparatus shall be prepared and mounted as near to typical service as possible, in

accordance with the instruction manual – including all necessary interconnections, initial

adjustments and initial calibrations. Adjustments may be made, where appropriate, at the

beginning of each test.

In particular, the following points shall be noted:

a) Apparatus having remote sensors

For the purpose of the tests in 4.4, where reference is made to exposure of the sensor to

the test conditions, the entire remote sensor (including any or all normally attached

protective mechanical parts) shall be exposed.

For apparatus having connection facilities for more than one remote sensor, only one

remote sensor needs to be subjected to the tests. The replacement of all but one sensor

by "dummy" impedances yielding the worst case load conditions for the test in question

shall be permitted. The worst case load conditions shall be determined by the testing

laboratory within the limits specified in the instruction manual (see 3.4 d)).

61779-1 © IEC:1998(E) – 19 –

For apparatus having remote sensor(s), all tests shall be performed with resistances

(with temperature coefficients similar to those of the recommended interconnecting wire)

connected in the detector circuit to simulate the maximum line resistance specified by the

apparatus producer, except where minimum line resistance offers a more stringent test in

the judgement of the test laboratory.

b) Apparatus having self-contained sensors

The entire apparatus shall be exposed to the test conditions without removal of any normally

attached parts, including any sampling probe for tests 4.4.11, 4.4.15, 4.4.16 and 4.4.17.

c) Alarm-only apparatus

For alarm-only apparatus, readings shall be taken using an external meter connected to the

test points described in 3.2.2.2.

In all cases, optional parts shall be either attached or removed according to which condition will

give the most unfavourable result (at the discretion of the testing laboratory) for the test being

conducted.

4.2.3 Mask for calibration and tests

When a mask is used for calibration or for the injection of test gas into the sensor, the design

and operation of the mask used by the testing laboratory – in particular the pressure and

velocity inside the mask – shall not inadmissibly influence the response of the apparatus or the

results obtained.

NOTE – It is recommended that the testing laboratory should consult with the manufacturer in determining the

design of the calibration mask. The manufacturer may provide a suitable calibration mask together with details of

suggested pressure or flow for application of calibration gases with the apparatus.

4.3 Normal conditions for test

4.3.1 General

The test conditions specified in 4.3.2 to 4.3.10 shall be used for all tests, unless otherwise

stated.

4.3.2 Test gas(es)

The flammable gas(es) to be used in a mixture with clean air for initial and all subsequent tests

shall be selected in accordance with a) or b) below.

a) Methane for apparatus intended for sensing methane or firedamp, or intended for general

purpose flammable gas detection that includes the detection of methane.

b) The actual specific gas or a representative gas for apparatus intended for sensing a specific

flammable gas or a specific family of chemica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...