EN 10216-3:2002

(Main)Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy fine grain steel tubes

Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy fine grain steel tubes

This Part of EN 10216 specifies the technical delivery conditions in two categories for seamless tubes of circular cross section, made of weldable alloyed fine grained steel.

Nahtlose Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 3: Rohre aus legierten Feinkornbaustählen

Dieser Teil der EN 10216 enthält die technischen Lieferbedingungen für nahtlose Rohre mit kreisförmigem Querschnitt aus schweißbaren legierten Feinkornbaustählen und legt dafür zwei Prüfkategorien fest.

Tubes sans soudure en acier pour service sous pression - Conditions techniques de livraison - Partie 3: Tubes en acier allié à grain fin

La présente partie de l'EN 10216 spécifie les conditions techniques de livraison, selon deux catégories d'essai, pour les tubes sans soudure à section circulaire en acier allié soudable à grain fin.

Nevarjene jeklene cevi za tlačne posode - Tehnični dobavni pogoji - 3. del: Legirane jeklene cevi z drobnozrnato mikrostrukturo

General Information

- Status

- Withdrawn

- Publication Date

- 21-May-2002

- Withdrawal Date

- 10-Dec-2013

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 29/SC 1 - Tubes for pressure purposes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Dec-2013

- Completion Date

- 11-Dec-2013

Relations

- Effective Date

- 15-Apr-2009

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Frequently Asked Questions

EN 10216-3:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy fine grain steel tubes". This standard covers: This Part of EN 10216 specifies the technical delivery conditions in two categories for seamless tubes of circular cross section, made of weldable alloyed fine grained steel.

This Part of EN 10216 specifies the technical delivery conditions in two categories for seamless tubes of circular cross section, made of weldable alloyed fine grained steel.

EN 10216-3:2002 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10216-3:2002 has the following relationships with other standards: It is inter standard links to EN 10216-3:2013, EN ISO 8493:2004, EN 546-1:2006, CEN/TR 10261:2023, EN 12952-2:2011, EN 13445-2:2009, EN 1092-1:2007, EN 13480-2:2017, EN 10216-3:2002/A1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10216-3:2002 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10216-3:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Nahtlose Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 3: Rohre aus legierten FeinkornbaustählenTubes sans soudure en acier pour service sous pression - Conditions techniques de livraison - Partie 3: Tubes en acier allié a grain finSeamless steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy fine grain steel tubes77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 10216-3:2002SIST EN 10216-3:2003en01-april-2003SIST EN 10216-3:2003SLOVENSKI

STANDARD

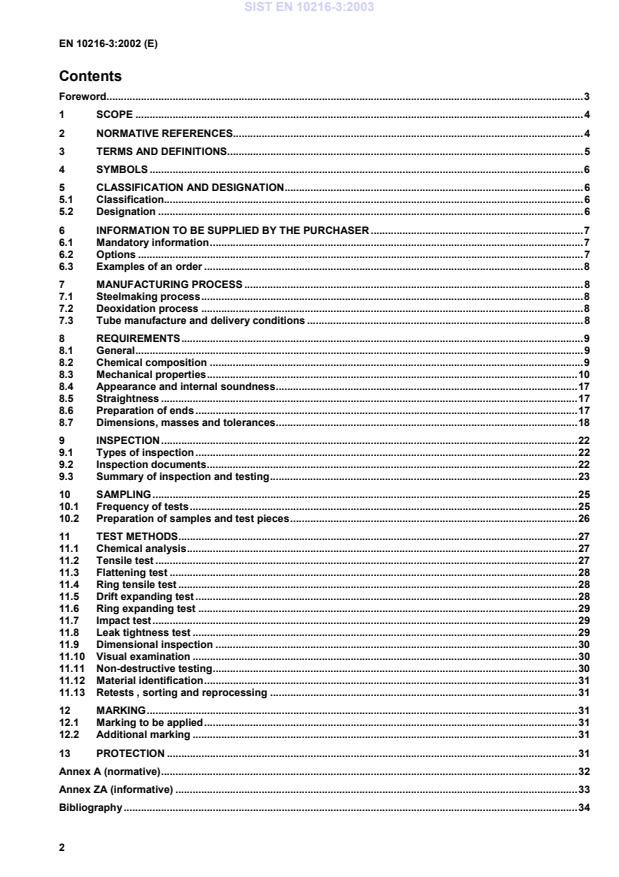

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10216-3May 2002ICS 23.040.10; 77.140.75English versionSeamless steel tubes for pressure purposes - Technical deliveryconditions - Part 3: Alloy fine grain steel tubesTubes sans soudure en acier pour service sous pression -Conditions techniques de livraison - Partie 3: Tubes enacier allié à grain finNahtlose Stahlrohre für Druckbeanspruchungen -Technische Lieferbedingungen - Teil 3: Rohre aus legiertenFeinkornbaustählenThis European Standard was approved by CEN on 25 April 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10216-3:2002 ESIST EN 10216-3:2003

of steel tubes Part 1 : Automatic electromagnetic testing of seamlessand welded (except submerged arc welded) ferromagnetic steel tubes for verification of hydraulic leak-tightness.EN 10246-5, Non-Destructive Testing

of steel tubes – Part 5: Automatic full peripheral magnetictransducer/flux leakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steeltubes for the detection of longitudinal imperfections.EN 10246-6, Non-Destructive

Testing of steel tubes - Part 6: Automatic full peripheral ultrasonic testing ofseamless steel tubes for the detection of transverse imperfections.EN 10246-7, Non-Destructive Testing

of steel tubes - Part 7 : Automatic full peripheral ultrasonic testing ofseamless and welded (except submerged arc welded) steel tubes for the detection of longitudinalimperfections.SIST EN 10216-3:2003

supplier or a third party organisation providing Non-Destructive Testing (NDT) services.3.3fine grain steelsteel having a ferritic grain size equal to or finer than 6 in accordance with EURONORM 103

1)In preparation; until this document is published as a European Standard, the corresponding national standard(s)should be agreed at the time of enquiry and order.2)Until this EURONORM is transformed into an a European Standard, it can be implemented or the correspondingnational standard may

be agreed at the time of enquiry and order.SIST EN 10216-3:2003

specified inside diameter; dminspecified minimum inside diameter; Tminspecified minimum wall thickness; Dccalculated outside diameter; dccalculated inside diameter; Tccalculated wall thickness; TCtest category5 CLASSIFICATION AND DESIGNATION5.1 Classification5.1.1This Part of EN 10216 covers steel grades in four qualities (see Tables 2 and 4): the basic quality (P . N, Q); the elevated temperature quality (P . NH, QH); the low temperature quality (P . NL1, QL, QL1); the special low temperature quality (P . NL2, QL2).5.1.2In accordance with the classification system in EN 10020, the steel grades P275NL1, P355N,P355NH and P355NL1 are classified as alloy quality steels and the other steel grades are classified as alloyspecial steels.5.2 Designation5.2.1For the tubes covered by this Part of EN 10216 steel the designation consists of: the number of this Part of EN 10216;plus either: the steel name in accordance with EN 10027-1 and CR 10260;or : the steel number allocated in accordance with EN 10027-2.5.2.2The steel name is designated by: the capital letter P for pressure purposes; the indication of the specified minimum yield strength for the lowest applicable wall thickness groupexpressed in megapascals, (Table 4); one of the additional symbols N, NH, NL1, NL2, Q, QH, QL, QL1 or QL2 (see 5.1.1, Tables 2 and 4).SIST EN 10216-3:2003

made of steel grade P355N, test category 1, with a 3.1.C inspection certificate inaccordance with EN 10204:500 m – Tube – 168,3 x 4,5 – EN 10216-3 – P355N – TC1 – Option 12: 3.1.C7 MANUFACTURING PROCESS7.1 Steelmaking processThe steelmaking process is at the discretion of the manufacturer.7.2 Deoxidation processSteels shall be fully killed and be made to a fine grain practice (see 3.3).7.3 Tube manufacture and delivery conditions7.3.1All NDT activities shall be carried out by qualified and competent level 1,2 and/or 3 personnelauthorised to operate by the employer.The qualification shall be in accordance with EN 10256 or, at least, an equivalent to it.It is recommended that the level 3 personnel be certified in accordance with EN 473 or, at least, anequivalent to it.The operating authorisation issued by the employer shall be in accordance with a written procedure.NDT operations shall be authorised by level 3 NDT individual approved by the employer.NOTEThe definition of level 1, 2 and 3 can be found in appropriate Standards, e.g. EN 473 and EN 102567.3.2 The tubes shall be manufactured by a seamless process.Unless option 1 is specified, the tubes may be either hot or cold finished at the discretion of themanufacturer. The terms “ hot finished “ and “ cold finished “ apply to the condition of the tube before it isheat treated in accordance with 7.3.3.Option 1: The tubes shall be cold finished before heat treatment.7.3.3The tubes shall be supplied in the relevant heat treatment conditions as specified in Table 1 andTable 4.Table 1 — Forming operation

and delivery conditionFormingoperationHeat treatmentconditionSymbolfor the delivery conditionNormalised a b+NHot finishedQuenched and tempered+QTNormalised b+NHot rolled + cold finishedQuenched and tempered+QTa See 7.3.4b See 7.3.5SIST EN 10216-3:2003

= Tdoftoleranced22minmin(2)dc = 2minmindoftoleranced(3)Tc = 2minminToftoleranceT(4)For tolerance see Tables 10, 11 and 12.8.2 Chemical composition8.2.1 Cast analysisThe cast analysis reported by the steel producer shall apply and conform to the requirements of Table 2.NOTEWhen welding tubes produced in accordance with this Part of EN 10216, account should be taken of the factthat the behaviour of the steel during and after welding is dependent not only on the steel, but also on the applied heattreatment and the conditions of preparing for and carrying out the welding.8.2.2 Product analysisOption 3: A product analysis for the tubes shall be supplied.Table 3 specifies the permissible deviations of the product analysis from the specified limits on cast analysisgiven in Table 2.SIST EN 10216-3:2003

Elevated temperature properties given in Tables 5 and 6 shall be verified for NH-grades at 400°C.The properties at elevated temperature given in Tables 5 and 6 for steel grades P355NH, P460NH, P620QHand P690QH, apply for the corresponding low and special low temperature quality steels if option 5 isspecified.The properties at the elevated temperature given in Annex A for steel grades P275NL1 and P275NL2 apply,if option 5 is specifiedOption 5: Elevated temperature properties given in Tables 5, 6 and Annex A shall be verified for NL- andQL-grades at the highest temperature for which a value is given.SIST EN 10216-3:2003

2, if nitrogen is fixed by niobium, titanium or vanadium the requirements for Altot and Al/N do not apply.cThe sum of the percentage by mass of the three elements chromium, copper and molybdenum shall not exceed 0,45 %.dOption 2: In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.eIf the percentage by mass of copper exceeds 0,30 %, the percentage by mass of nickel shall be at least half the percentage by mass of copper.SIST EN 10216-3:2003

1,70+ 0,10- 0,05P

0,025+ 0,005 0,015+ 0,003S 0,015

0,020+ 0,005Al 0,020- 0,005 0,30+ 0,05Cr> 0,30 to

1,50+ 0,10Cu 0,70+ 0,05

0,35+ 0,03Mo> 035 to

0,70+ 0,04N 0,020+ 0,002Nb

0,06+ 0,005Ni

2,50+ 0,05Ti

0,05+ 0,01V 0,10+ 0,01 0,10

to

0,20+

0,02SIST EN 10216-3:2003

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...