EN 10088-5:2009

(Main)Stainless steels - Part 5: Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes

Stainless steels - Part 5: Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes

1.1 The scope of this part of EN 10088 is to specify the technical delivery conditions for hot or cold formed bars, rods, wire, sections and bright products of standard and special grades of corrosion resisting stainless steels for construction purposes in addition to the general technical delivery conditions specified in EN 10021.

1.2 This European Standard does not apply to components manufactured by further processing of the product forms listed in 1.1 with quality characteristics altered as a result of such further processing.

Nichtrostende Stähle - Teil 5: Technische Lieferbedingungen für Stäbe, Walzdraht, gezogenen Draht, Profile und Blankstahlerzeugnisse aus korrosionsbeständigen Stählen für das Bauwesen

1.1 Dieser Teil der EN 10088 enthält die technischen Lieferbedingungen für warm oder kalt umgeformte

Stäbe, Walzdraht, gezogenen Draht, Profile und Blankstahlerzeugnisse aus Standardgüten und Sondergüten

korrosionsbeständiger nichtrostender Stähle für das Bauwesen in Ergänzung zu den in EN 10021 festgelegten

allgemeinen technischen Lieferbedingungen.

1.2 Diese Europäische Norm gilt nicht für die durch Weiterverarbeitung der in 1.1 genannten Erzeugnisformen

hergestellten Teile mit fertigungsbedingt abweichenden Gütemerkmalen.

Aciers inoxydables - Partie 5 : Conditions techniques des livraisons pour les barres, fils tréfilés, profils et produits transformés à froid en acier résistant à la corrosion pour usage de construction

1.1 Le domaine d’application de la présente partie de l’EN 10088 vise à spécifier les conditions techniques de livraison des barres laminées à chaud ou à froid, du fil machine, des profils et des produits laminés à froid produits dans des nuances standardisées et dans des nuances spéciales d’aciers inoxydables résistant à la corrosion pour usage de construction, en plus des conditions générales techniques de livraison spécifiées dans l’EN 10021.

1.2 La présente Norme européenne ne s'applique pas aux composants fabriqués par transformation ultérieure des produits énumérés en 1.1, avec les modifications des caractéristiques de qualité qui en résultent.

Nerjavna jekla - 5. del: Tehnični dobavni pogoji za drogove, palice, žico, profile in svetle izdelke iz nerjavnih konstrukcijskih jekel

General Information

- Status

- Published

- Publication Date

- 24-Mar-2009

- Withdrawal Date

- 30-Dec-2010

- Technical Committee

- SC 13 - Stainless steels

- Drafting Committee

- ECISS/TC 23/SC 1 - Stainless steels

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 12-Aug-2025

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10306:2001 - Iron and steel - Ultrasonic testing of H beams with parallel flanges and IPE beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10088-5:2009 - "Stainless steels - Part 5: Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes" (CEN) specifies the technical delivery conditions for hot- or cold-formed stainless steel product forms intended for construction use. It complements the general delivery requirements of EN 10021 and applies to standard and special corrosion‑resisting grades (steels with at least 10.5% Cr and max 1.20% C where corrosion resistance is a primary concern). It does not apply to components whose properties are altered by further processing.

Key topics and requirements

- Product forms covered: bars, rods, wire, sections and bright (cold‑finished) products intended for construction.

- Delivery conditions: process routes and treatment conditions (hot worked, cold worked, heat treated) are referenced and specified for each grade and product form.

- Chemical composition: cast‑analysis limits for listed grades and permitted deviations for product analysis are defined.

- Corrosion properties: requirements for resistance to intergranular corrosion (referencing EN ISO 3651‑2) for ferritic, austenitic and duplex grades; notes on testing limitations for martensitic and precipitation‑hardening steels.

- Mechanical properties: tensile, hardness and other mechanical property requirements by condition (hot/cold/heat treated) including rules for simulated heat treatments and cold‑work hardened bars.

- Dimensions & tolerances: references to applicable dimensional standards and tolerances for shape, size and mass.

- Surface quality & internal soundness: surface finish classes and non‑destructive testing options (ultrasonic testing references).

- Inspection & testing: required inspection documents (EN 10204), factory production control (FPC), initial type testing and retest provisions.

- Marking & regulatory: marking, traceability and relationship to the Construction Products Directive (Annex ZA) and dangerous substances declarations.

Applications and who uses it

EN 10088-5 is used by:

- Steel manufacturers and mill producers specifying technical delivery conditions for stainless steel bars, rods and wire.

- Architects, structural and civil engineers who specify corrosion‑resistant stainless steels for building and infrastructure projects.

- Fabricators and metalwork contractors who need compatible mechanical, corrosion and dimensional characteristics for forming, welding and assembly.

- Procurement and quality managers requiring inspection certificates (EN 10204) and compliance evidence.

- Testing and inspection bodies implementing sampling, mechanical tests and non‑destructive evaluation.

Typical applications include structural fasteners, reinforcing bars, architectural profiles, tension rods, wire ropes and other construction components where durability and corrosion resistance are essential.

Related standards

- EN 10021 (general technical delivery requirements)

- EN 10088‑1, ‑3, ‑4 (other parts of the EN 10088 series)

- EN 10204 (inspection documents)

- EN ISO 3651‑2 (intergranular corrosion testing)

- EN ISO 9001 (quality management)

- Relevant dimensional and NDT standards referenced within EN 10088‑5

Keywords: EN 10088-5:2009, stainless steels, technical delivery conditions, corrosion resisting steels, bars rods wire sections, construction stainless steel, inspection and testing, EN 10021.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10088-5:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Stainless steels - Part 5: Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes". This standard covers: 1.1 The scope of this part of EN 10088 is to specify the technical delivery conditions for hot or cold formed bars, rods, wire, sections and bright products of standard and special grades of corrosion resisting stainless steels for construction purposes in addition to the general technical delivery conditions specified in EN 10021. 1.2 This European Standard does not apply to components manufactured by further processing of the product forms listed in 1.1 with quality characteristics altered as a result of such further processing.

1.1 The scope of this part of EN 10088 is to specify the technical delivery conditions for hot or cold formed bars, rods, wire, sections and bright products of standard and special grades of corrosion resisting stainless steels for construction purposes in addition to the general technical delivery conditions specified in EN 10021. 1.2 This European Standard does not apply to components manufactured by further processing of the product forms listed in 1.1 with quality characteristics altered as a result of such further processing.

EN 10088-5:2009 is classified under the following ICS (International Classification for Standards) categories: 77.140.20 - Stainless steels; 77.140.50 - Flat steel products and semi-products; 77.140.65 - Steel wire, wire ropes and link chains. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10088-5:2009 has the following relationships with other standards: It is inter standard links to EN 10027-2:2015, EN ISO 14284:2022, EN ISO 6892-1:2019, EN ISO 3651-2:1998, EN ISO 9001:2015, EN 10052:1993, EN 10308:2001, EN 10163-3:2004, EN 10204:2004, EN 10079:2007, EN 10168:2004, EN 10021:2006, EN 10306:2001, EN 10088-1:2005, EN ISO 377:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10088-5:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/120. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10088-5:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Nichtrostende Stähle - Teil 5: Technische Lieferbedingungen für Stäbe, Walzdraht, gezogenen Draht, Profile und Blankstahlerzeugnisse aus korrosionsbeständigen Stählen für das BauwesenAciers inoxydables -

Partie 5: Conditions techniques de livraison pour les barres, fils machines, fil, profils et produits blanc en acier de résistance a la corrosion pour usage de construction.Stainless steels - Part 5: Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes77.140.65Jeklene žice, jeklene vrvi in verigeSteel wire, wire ropes and link chains77.140.60Jeklene palice in drogoviSteel bars and rods77.140.20Visokokakovostna jeklaStainless steelsICS:Ta slovenski standard je istoveten z:EN 10088-5:2009SIST EN 10088-5:2009en,fr,de01-junij-2009SIST EN 10088-5:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10088-5March 2009ICS 77.140.20; 77.140.50; 77.140.65 English VersionStainless steels - Part 5: Technical delivery conditions for bars,rods, wire, sections and bright products of corrosion resistingsteels for construction purposesAciers inoxydables - Partie 5 : Conditions techniques deslivraisons pour les barres, fils tréfilés, profils et produitstransformés à froid en acier résistant à la corrosion pourusage de constructionNichtrostende Stähle - Teil 5: TechnischeLieferbedingungen für Stäbe, Walzdraht, gezogenen Draht,Profile und Blankstahlerzeugnisse auskorrosionsbeständigen Stählen für das BauwesenThis European Standard was approved by CEN on 21 February 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10088-5:2009: ESIST EN 10088-5:2009

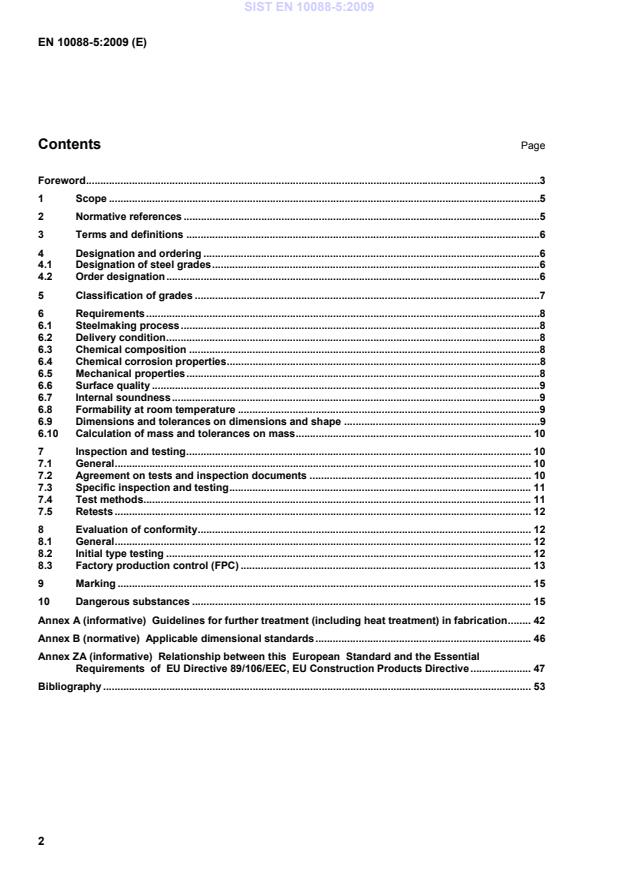

Guidelines for further treatment (including heat treatment) in fabrication . 42 Annex B (normative)

Applicable dimensional standards . 46 Annex ZA (informative)

Relationship between this

European

Standard and the Essential Requirements

of

EU Directive 89/106/EEC, EU Construction Products Directive . 47 Bibliography . 53

Part 1: List of stainless steels (including a table of European Standards, in which these stainless steels are further specified, see Annex D); Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes; Part 3: Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes; Part 4: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for construction purposes; Part 5: Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes. The European Organisation for Standardisation (CEN) draws attention to the fact that it is claimed that compliance with this document may involve the use of patents concerning two steel grades. CEN takes no position concerning the evidence, validity and scope of these patent rights. The holder of these patent rights has assured CEN that they are willing to negotiate licenses, under reasonable and non-discriminatory terms and conditions, with applicants throughout the world. In this respect, the statements of the holders of these patent rights are registered with CEN. Information may be obtained from: Sandvik AB SE-811 81 SANDVIKEN Sweden for grade 1.4477 Outokumpu Stainless AB SE-77480 AVESTA Sweden for grade 1.4162

This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EC Directive(s). For relationship with EC Directive(s), see informative Annex ZA, which is an integral part of this document. SIST EN 10088-5:2009

grades with a relatively good availability and a wider range of application

3.6 special grades

grades for special use and/or with limited availability

4 Designation and ordering 4.1 Designation of steel grades The steel names and steel numbers (see Tables 2 to 5) are allocated in accordance with EN 10027-1 and EN 10027-2 respectively.

4.2 Order designation The complete designation for ordering a product according to this European Standard shall contain the following information: a) the desired quantity; SIST EN 10088-5:2009

EN ISO 3651-2 shall not be not applicable for testing martensitic and precipitation hardening steels. NOTE The corrosion resistance of stainless steels is very dependent on the type of environment and can therefore not always be clearly ascertained through laboratory tests. It is therefore advisable to draw on the available experience of the use of the steels. 6.5 Mechanical properties 6.5.1 The mechanical properties at room temperature as specified in Tables 8 to 12 shall apply for hot worked products of every condition, condition 1U excluded, for cold processed products in condition 2D (excluding wire), and for each specified heat treatment condition. For cold processed products of every specified condition, condition 2D and wire excluded, and each specified heat treatment condition, the mechanical properties at room temperature as specified in Tables 13 to 17 shall apply. For these products, the condition is the prime property with the mechanical properties secondary. If the products are to be supplied in a non-heat-treated condition, the mechanical properties specified in Tables 8 to 17 shall be obtained from reference test pieces which have received the appropriate heat treatment (simulated heat treatment). For wire, the properties as specified in Table 18 shall apply. For bars which are intentionally cold work hardened in order to increase their tensile strength to a specified level, the mechanical properties at room temperature as specified in Table 20 shall apply. For these products, the mechanical properties are prime, with the condition a secondary property. SIST EN 10088-5:2009

that surface. b The order can require that the product shall be delivered with a surface being technically defect free by manufacture. In this case,

also the maximum % of delivered weight in excess of permissible depth of discontinuities shall be agreed.

For further information, e.g. roughness in conditions 2G and 2P, see Table 7. 6.7 Internal soundness

The products shall be free of internal defects which would exclude them from being used for their intended purpose. If verification of internal soundness is required, ultrasonic testing of H-beams with parallel flanges and IPE-beams shall be in accordance with EN 10306 and ultrasonic testing of steel bars shall be in accordance with EN 10308. 6.8 Formability at room temperature

Cold formability may be verified by elongation in the tensile test. 6.9 Dimensions and tolerances on dimensions and shape Dimensions and tolerances on dimensions and shape shall be declared by reference to the appropriate European Standard (see Annex B). Dimensions and tolerances on dimensions and shape not covered by European SIST EN 10088-5:2009

When calculating the nominal mass from the nominal dimensions the values given in

EN 10088-1 shall be used as a basis for the density of the steel concerned. 6.10.2

If the tolerances on mass are not specified in the dimensional standard listed in Table 7 or the normative references, they may be agreed at the time of enquiry and order. 7 Inspection and testing 7.1 General The process control, inspection and testing shall be carried out according to 8.3 to ensure that the product complies with the requirements of both this European Standard and the order.

This includes the following: a) A suitable frequency of verification of the dimensions of the products; b) An adequate intensity of visual examination of the surface quality of the products; c) An appropriate frequency and type of test to ensure that the correct grade of steel is used. The nature and frequency of these verifications, examinations and tests shall be in accordance with the manufacturer's written procedures in compliance with 8.3. 7.2 Agreement on tests and inspection documents Products declaring compliance with this European Standard shall be delivered with an inspection certificate 3.1 or 3.2 as specified in EN 10204. The type of certificate shall be agreed upon at the time of enquiry and order. If the order does not contain any specification of this type, inspection certificate 3.1 shall be issued.

The specific inspection described in 7.3 shall be carried out and confirmed together with the following information in the inspection certificate with the code numbers and details required by EN 10168:2004. a) the information groups A, B and Z of EN 10168:2004; b) the results of the cast analysis in accordance with the code numbers C71 to C92 in EN 10168:2004; c) the results of the tests marked in Table 21, second column, by 'm'; d) the results of any optional test or inspections agreed at the time of enquiry and order; e) the regulatory information (see Annex ZA). SIST EN 10088-5:2009

in accordance with the rules for families and/or direct or extended application of test results. 8.2.2 Characteristics All characteristics of Clause 6 shall be subject to initial type testing, with following exceptions: a) Weldability is covered by chemical composition; b) Durability is covered by chemical composition; SIST EN 10088-5:2009

The specifications of all incoming raw materials shall be documented, as shall the inspection scheme for ensuring their conformity. The verification of conformity of the raw material with the specification shall be in accordance with EN ISO 9001:2008, 7.4.3. 8.3.3.4 In-process control The manufacturer shall plan and carry out production under controlled conditions. Compliance with EN ISO 9001:2008, 7.5.1 and 7.5.2 shall be deemed to satisfy the requirements of this sub-clause. 8.3.3.5 Traceability and marking Individual steel products shall be identifiable and traceable with regard to their production origin. The manufacturer shall have written procedures ensuring that processes related to affixing traceability codes and/or markings (see Clause 9) are inspected regularly. Compliance with EN ISO 9001:2008, 7.5.3 shall be deemed to satisfy the requirements of this sub-clause. 8.3.3.6 Non-conforming products The manufacturer shall have written procedures which specify how non-conforming products shall be dealt with. Any such events shall be recorded as they occur and these records shall be kept for the period defined in the manufacturer’s written procedures. Compliance with EN ISO 9001:2008, 8.3 shall be deemed to satisfy the requirements of this sub-clause. SIST EN 10088-5:2009

Type of test Round cross-section productsRectangular cross-section products

Tensile

Impact a

a

For products of a round cross-section, the axis of the notch is parallel to a diameter; for products with a rectangular

cross-section, the axis of the notch is perpendicular to the greatest rolled surface. b

Samples of product may alternatively be tested unmachined, in accordance with EN ISO 377. Figure 1 — Position of test pieces for steel bars and rods ≤ 160 mm diameter or thickness

(longitudinal test pieces) SIST EN 10088-5:2009

Key tr transverse NOTE The axis of the notch on the impact test pieces should be radial in the case of round steel bars, and perpendicular to the nearest rolled surface for rectangular bars. Figure 2 — Position of test pieces for steel bars > 160 mm diameter or thickness (transverse test pieces)

KEY 1 Location of sample NOTE The axis of the notch on the impact test pieces should be perpendicular to the outside surface of the section. a By agreement, the sample can be taken from the web, at a quarter of the total height. Figure 3 — Position of test pieces for beams, channels, angles, T sections and Z sectionsSIST EN 10088-5:2009

All precautions shall be taken to avoid the addition of such elements not quoted in the table from scrap and other materials used in production which would impair

mechanical properties and the suitability of the steel. a Particular ranges of sulphur content can provide improvement of particular properties. For machinability a controlled sulphur content of 0,015 % to 0,030 % is recommended.

For weldability, a controlled sulphur content of 0,008 % to 0,015 % is recommended. For polishability, a controlled sulphur content of 0,015 % max. is recommended.

Si max. Mn max. P max. S max. Cr Cu Mo Ni Others Standard grades (Martensitic steels) X12Cr13 1.4006 0,08 to 0,15 1,00 1,50 0,040 0,030a 11,5 to 13,5 - - ≤ 0,75 - X20Cr13 1.4021 0,16 to 0,25 1,00 1,50 0,040 0,030a 12,0 to 14,0 - - - - X17CrNi16-2 1.4057 0,12 to 0,22 1,00 1,50 0,040 0,030a 15,0 to 17,0 - - 1,50 to 2,50 - X4CrNiMo16-5-1 1.4418 ≤ 0,06 0,70 1,50 0,040 0,030a 15,0 to 17,0 - 0,80 to 1,50 4,0 to 6,0 N: ≥ 0,020 Standard grades (Precipitation hardening steels) X5CrNiCuNb16-4 1.4542 ≤ 0,07 0,70 1,50 0,040 0,030a 15,0 to 17,0 3,0 to 5,0 ≤ 0,60 3,0 to 5,0 Nb: 5xC to 0,45 X7CrNiAI17-7 1.4568 ≤ 0,09 0,70 1,00 0,040 0,015 16,0 to 18,0 - - 6,5 to 7,8b AI: 0,70 to 1,50

All precautions shall be taken to avoid the addition of such elements not quoted in the table from scrap and other materials used in production which would impair mechanical

properties and the suitability of the steel. a Particular ranges of sulphur content can provide improvement of particular properties. For machinability a controlled sulphur content of 0,015 % to 0,030 % is recommended. For

weldability, a controlled sulphur content of 0,008 % to 0,015 % is recommended. For polishability, a controlled sulphur content of 0,015 % max. is recommended. b For better cold deformability, the upper limit may be increased to 8,3 %.

1.4401≤ 0,07 ≤ 1,00≤ 2,000,045≤ 0,030a ≤ 0,1016,5 to 18,5-2,00 to 2,50-10,0 to 13,0- X6CrNiMoTi17-12-2 1.4571≤ 0,08 ≤ 1,00≤ 2,000,045≤ 0,030a -16,5 to 18,5-2,00 to 2,50-10,5 to 13,5b Ti: 5 x C to 0,70 X2CrNiMo17-12-3 1.4432≤ 0,030 ≤ 1,00≤ 2,000,045≤ 0,030a ≤ 0,1016,5 to 18,5-2,50 to 3,00-10,5 to 13,0- X2CrNiMoN17-13-3 1.4429≤ 0,030 ≤ 1,00≤ 2,000,045≤ 0,0150,12 to 0,2216,5 to 18,5-2,50 to 3,00-11,0 to 14,0b- X3CrNiMo17-13-3 1.4436≤ 0,05 ≤ 1,00≤ 2,000,045≤ 0,030a≤ 0,1016,5 to 18,5-2,50 to 3,00-10,5 to 13,0 - X2CrNiMo18-14-3 1.4435≤ 0,030 ≤ 1,00≤ 2,000,045≤ 0,030a ≤ 0,1017,0 to 19,0-2,50 to 3,00-12,5 to 15,0- X2CrNiMoN17-13-5 1.4439≤ 0,030 ≤ 1,00≤ 2,000,045≤ 0,015 0,12 to 0,2216,5 to18,5-4,0 to 5,0-12,5 to 14,5- X3CrNiCu18-9-4 1.4567≤ 0,04 ≤ 1,00≤ 2,000,045≤ 0,030a ≤ 0,1017,0 to 19,03,0 to 4,0--8,5 to 10,5- X1NiCrMoCu25-20-5 1.4539≤ 0,020 ≤ 0,70≤2,000,030≤ 0,010≤ 0,1519,0 to 21,01,20 to 2,004,0 to 5,0-24,0 to 26,0- Special gradesX6CrNiNb18-10 1.4550≤ 0,08 ≤ 1,00≤ 2,000,045≤ 0,015-17,0 to 19,0--10 x C to 1,009,0 to 12,0b - X1CrNiMoN25-22-2 1.4466≤ 0,020 ≤ 0,70≤ 2,000,025≤ 0,0100,10 to 0,1624,0 to 26,0-2,00 to 2,50-21,0 to 23,0- X2CrNiMo18-15-4 1.4438≤ 0,030 ≤ 1,00≤ 2,000,045≤ 0,030a ≤ 0,1017,5 to 19,5-3,0 to 4,0-13,0 to 16,0b - X12CrMnNiN17-7-5 1.4372≤ 0,15 ≤ 1,005,5 to 7,50,045≤ 0,0150,05 to 0,2516,0 to 18,0---3,5 to 5,5- X3CrNiCuMo17-11-3-2 1.4578≤ 0,04 ≤ 1,00≤ 1,000,045≤ 0,015≤ 0,1016,5 to 17,53,0 to 3,52,00 to 2,50-10,0 to 11,0- X1NiCrMoCu31-27-4 1.4563≤ 0,020 ≤ 0,70≤ 2,000,030≤ 0,010≤ 0,1026,0 to 28,00,70 to 1,503,0 to4,0-30,0 to 32,0- X1CrNiMoCuN20-18-7 1.4547≤ 0,020 ≤ 0,70≤ 1,000,030≤ 0,0100,18 to 0,2519,5 to 20,50,50 to 1,006,0 to 7,0-17,5 to 18,5- X1NiCrMoCuN25-20-7 1.4529≤ 0,020 ≤ 0,50≤ 1,000,030≤ 0,0100,15 to 0,2519,0 to 21,00,50 to 1,506,0 to 7,0-24,0 to 26,0- X2CrNiMnMoN25-18-6-51.4565≤ 0,030 ≤ 1,005,0 to 7,00,030≤ 0,0150,30 to 0,6024,0 to 26,0-4,0 to 5,0≤ 0,1516,0 to 19,0-

All precautions shall be taken to avoid the addition of such elements not quoted in the table from scrap and other materials used in production which would impair mechanical

properties and the suitability of the steel. SIST EN 10088-5:2009

sulphur content of 0,008 % to 0,015 % is recommended. For polishability, a controlled sulphur content of 0,015 % max. is recommended. b Where for special reasons, e.g. hot workability for the fabrication of seamless tubes where it is necessary to minimize the delta ferrite content, or with the aim of low magnetic permeability, the maximum

Ni content may be increased by the following amounts:

0,50 % (by mass): 1.4571

1,00 % (by mass): 1.4306, 1.4406, 1.4429, 1.4438, 1.4541, 1.4550

1,50 % (by mass): 1.4404. SIST EN 10088-5:2009

Steel designati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...