EN 1012-3:2013

(Main)Compressors and vacuum pumps - Safety requirements - Part 3: Process compressors

Compressors and vacuum pumps - Safety requirements - Part 3: Process compressors

This European Standard is applicable to process gas compressors and process gas compressor units having an operating pressure greater than 0,5 bar (gauge), an input shaft power greater than 0,5 kW and designed to compress all gases other than air, nitrogen or inert gases which are covered in Part 1. This document deals with all significant hazards, hazardous situations and events relevant to the design, installation, operation, maintenance, dismantling and disposal of process gas compressors and process gas compressor units, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This part of EN 1012 includes under the general term compressor units those machines which comprise:

- the compressor;

- a drive system including the prime mover;

- any component or device supplied which is necessary for operation.

This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN.

The requirements of this European Standard do not take into account the interaction between the compressor/compressor unit and other processes carried out on site.

Excluded are:

- refrigerant compressors used in refrigerating systems or heat pumps for which the safety requirements are given in EN 60335-2-34 or EN 12693;

- the specification of performance levels and/or safety integrity levels for safety related parts of control systems.

Performance levels and/or safety integrity levels are an important aspect of compressor design and should be determined by the manufacturer and the user based on a risk assessment (see Introduction).

This European Standard does not cover those safety aspects of road transport dealt with by EC legislation for trailers.

Kompressoren und Vakuumpumpen - Sicherheitsanforderungen - Teil 3: Prozesskompressoren

Diese Europäische Norm gilt für Prozessgaskompressoren und Prozessgaskompressoranlagen, die einen Arbeitsdruck von mehr als 0,5 bar (Überdruck) haben, eine Leistungsaufnahme an der Antriebswelle von mehr als 0,5 kW haben und so konstruiert wurden, dass sie alle Gase außer Luft, Stickstoff oder inerte Gase, die im Teil 1 behandelt werden, verdichten können. Dieses Dokument befasst sich mit allen signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignissen, die sich auf die Konstruktion, das Aufstellen, den Betrieb, die Wartung, das Demontieren und die Entsorgung von Prozessgaskompressoren und Prozessgaskompressoranlagen beziehen, wenn sie bestimmungsgemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen verwendet werden (siehe Abschnitt 4).

Dieser Teil von EN 1012 enthält unter dem allgemeinen Begriff Kompressoranlagen Maschinen, die Folgendes umfassen:

den Kompressor;

ein Antriebssystem einschließlich der Antriebsmaschine;

alle mitgelieferten Bauteile oder Geräte, die für den Betrieb notwendig sind.

Dieser Teil von EN 1012 gilt nicht für Kompressoren, die vor dem Datum der Veröffentlichung dieses Dokuments durch das CEN hergestellt wurden.

Die Anforderungen dieser europäischen Norm berücksichtigen nicht die Wechselwirkungen zwischen dem Kompressor/der Kompressoranlage und anderen vor Ort ausgeführten Prozessen.

Ausgenommen sind:

Kältemittelverdichter in Kälteanlagen oder Wärmepumpen, deren Sicherheitsanforderungen in EN 60335-2-34 oder EN 12693 enthalten sind;

die Festlegung von Performance Level und/oder Sicherheits-Integritätslevel für sicherheitsbezogene Teile von Steuerungssystemen.

Performance Level und/oder Sicherheits-Integritätslevel stellen einen wichtigen Aspekt der Kompressor-konstruktion dar und sollten vom Hersteller und Anwender auf Grundlage einer Risikobeurteilung bestimmt werden (siehe Einleitung).

Diese Europäische Norm behandelt nicht die gleichen Sicherheitsaspekte im Straßenverkehr wie das EU-Recht für Anhänger.

Compresseurs et pompes à vide - Prescriptions de sécurité - Partie 3: Compresseurs de procédé

La présente Norme européenne est applicable aux compresseurs pour gaz de procédé et aux unités de compression pour gaz de procédé ayant une pression de service supérieure à 0,5 bar (manomètre), une puissance à l'arbre d'entrée supérieure à 0,5 kW, et conçus pour utiliser tous les gaz autres que l'air, l'azote ou les gaz inertes, qui sont traités dans la Partie 1. Le présent document traite de tous les phénomènes dangereux, situations et événements dangereux significatifs spécifiques à la conception, à l'installation, au fonctionnement, à la maintenance, au démontage et à la mise au rebut des compresseurs pour gaz de procédé et unités de compression pour gaz de procédé, lorsqu'ils sont utilisés normalement et dans les conditions prévues par le fabricant (voir Article 4).

La présente partie de l'EN 1012 englobe sous le terme général « unités de compression » les machines qui comprennent :

le compresseur ;

un système d'entraînement, y compris la machine motrice ;

tout composant ou dispositif fourni nécessaire au fonctionnement.

La présente partie de l'EN 1012 ne s'applique pas aux compresseurs qui ont été construits avant la date de publication du présent document par le CEN.

Les prescriptions de la présente norme Européenne ne tiennent pas compte de l'interaction entre le compresseur/l'unité de compression et les autres procédés effectués sur le site.

sont exclus :

les compresseurs frigorifiques utilisés dans les systèmes de réfrigération ou pompes à chaleur, dont les prescriptions de sécurité sont données dans l'EN 60335-2-34 ou l'EN 12693 ;

la spécification des niveaux de performance et/ou des niveaux d'intégrité de sécurité pour les parties des systèmes de commande relatives à la sécurité.

Les niveaux de performance et/ou les niveaux d'intégrité de sécurité sont un aspect important de la conception des compresseurs, et il convient qu'ils soient déterminés par le fabricant et par l'utilisateur sur la base de l'appréciation du risque (voir l'Introduction).

La présente norme Européenne ne traite pas des aspects liés à la sécurité du transport routier, qui sont couverts par la législation de la CE concernant les remorques.

Kompresorji in vakuumske črpalke - Varnostne zahteve - 3. del: Procesni kompresorji

Ta evropski standard se uporablja za procesne plinske kompresorje in procesne plinske kompresorske enote, katerih obratovalni tlak je večji od 0,5 bara, moč pogonske osi kompresorja je večja od 0,5 kW, zasnovani pa so za stiskanje vseh plinov, razen zraka, dušika ali inertnih plinov, ki so zajeti v 1. delu. Ta evropski standard obravnava vse pomembne nevarnosti, nevarne razmere in dogodke v zvezi z zasnovo, namestitvijo, delovanjem, vzdrževanjem, razstavljanjem ali odstranjevanjem procesnih plinskih kompresorjev in procesnih plinskih kompresorskih enot, kadar se uporabljajo v skladu s svojim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določa proizvajalec. Ta del standarda EN 1012 pod splošnim izrazom kompresorske enote vključuje vse stroje, ki jih sestavlja: – kompresor; – pogonski sistem, vključno s pogonskim strojem; – katera koli komponenta ali naprava, ki je potrebna za delovanje. Ta del standarda EN 1012 se ne uporablja za kompresorje, proizvedene, preden je CEN objavil ta standard. Zahteve tega evropskega standarda ne upoštevajo medsebojnega vpliva kompresorja/kompresorske enote in ostalih procesov, ki se izvajajo na mestu. Izključeni so: – hladilni kompresorji, ki se uporabljajo za hladilne sisteme ali toplotne črpalke, za katere so varnostne zahteve opredeljene v standardu EN 60335-2-34 ali EN 12693; – specifikacija ravni delovanja in/ali specifikacija ravni varnostne celovitosti za dele krmilnih sistemov, povezane z varnostjo. Ravni delovanja in/ali ravni varnostne celovitosti so pomemben del zasnove kompresorjev ter bi jih morala določiti proizvajalec in uporabnik na podlagi ocene tveganja (glej uvod). Ta evropski standard ne zajema varnostnih vidikov cestnega prometa, ki so obravnavani v zakonodaji ES za priklopna vozila.

General Information

- Status

- Published

- Publication Date

- 12-Nov-2013

- Technical Committee

- CEN/TC 232 - Compressors - Safety

- Drafting Committee

- CEN/TC 232 - Compressors - Safety

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Mar-2025

- Completion Date

- 04-Mar-2025

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

EN 1012-3:2013 (EN 1012-3) - Compressors and vacuum pumps - Safety requirements - Part 3: Process compressors - sets European safety requirements for process gas compressors and compressor units. It applies to machines with an operating pressure > 0.5 bar (gauge) and input shaft power > 0.5 kW used to compress gases other than air, nitrogen or inert gases (those are covered in Part 1). The standard addresses all significant hazards during design, installation, operation, maintenance, dismantling and disposal, including reasonably foreseeable misuse. A “compressor unit” in this standard includes the compressor, drive system (including the prime mover) and any supplied components necessary for operation.

Key topics and technical requirements

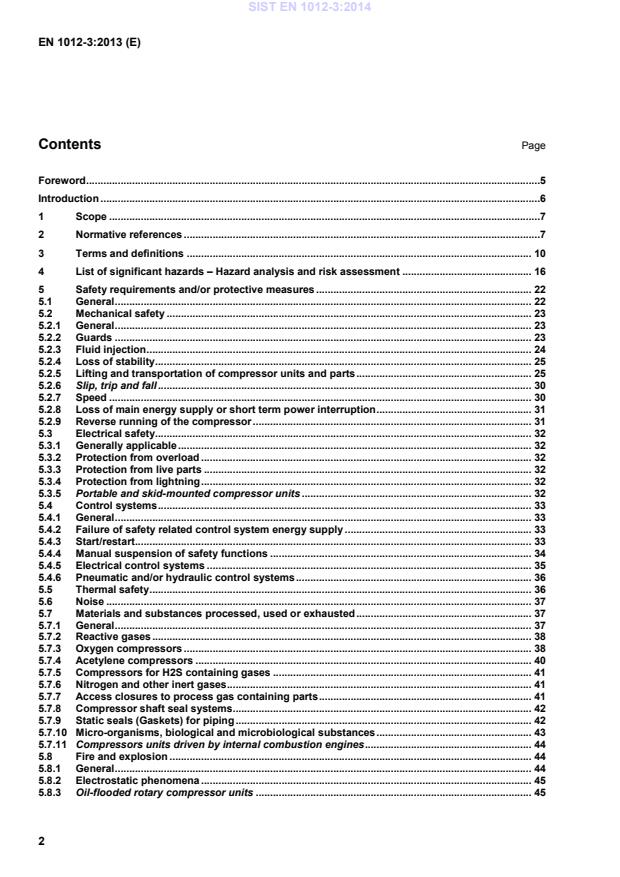

The standard provides detailed safety requirements, protective measures and verification procedures covering areas such as:

- Hazard analysis and risk assessment - identification and management of significant hazards for process compressors.

- Mechanical safety - guards, lifting/transportation, stability, reverse running, loss of energy and speed considerations.

- Control systems and functional safety - start/restart logic, monitoring, manual overrides and guidance for applying functional safety standards (see informative Annex C). The standard does not set SIL/PL values; manufacturers and users determine these by risk assessment.

- Electrical safety - overload protection, live-part protection and installation checks.

- Thermal, noise and ergonomic safety - thermal protection, noise emission guidance and manual handling requirements.

- Materials and process gases - special provisions for reactive gases, oxygen, acetylene, H2S and biological agents; shaft seals and gasket considerations.

- Fire, explosion and electrostatic risk - design and mitigation measures for flammable or hazardous process gases.

- Pressure limiting devices and verification - specifications and installation rules for relief devices, pressure testing and leak-tightness testing.

- Information for use - required documentation, operating and service manuals, markings, warnings and commissioning instructions.

Practical applications and who uses this standard

SIST EN 1012-3 is used by:

- Compressor manufacturers and OEMs (design, CE marking and technical documentation)

- Process and plant engineers (specification, installation and integration)

- Safety engineers and risk assessors (hazard analysis, SIL/PL allocation)

- Maintenance teams and service providers (inspection, testing and documentation)

- Procurement and certification bodies (compliance checks and acceptance testing)

Typical applications include chemical, petrochemical, oil & gas, pharmaceutical and industrial plants where process gas compressors are integral to operations.

Related standards

- EN 1012-1 (air, nitrogen and inert gases) - companion part for non-process gases

- EN 60335-2-34 and EN 12693 - for refrigerant compressors and heat pumps (excluded from Part 3)

- Functional safety standards (e.g., IEC/EN series) - referenced in Annex C for applying SIL/PL principles; manufacturers/users perform risk-based determination.

Keywords: EN 1012-3:2013, EN 1012-3, process compressors, compressor safety, process gas compressors, functional safety, pressure limiting devices, risk assessment.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1012-3:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Compressors and vacuum pumps - Safety requirements - Part 3: Process compressors". This standard covers: This European Standard is applicable to process gas compressors and process gas compressor units having an operating pressure greater than 0,5 bar (gauge), an input shaft power greater than 0,5 kW and designed to compress all gases other than air, nitrogen or inert gases which are covered in Part 1. This document deals with all significant hazards, hazardous situations and events relevant to the design, installation, operation, maintenance, dismantling and disposal of process gas compressors and process gas compressor units, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This part of EN 1012 includes under the general term compressor units those machines which comprise: - the compressor; - a drive system including the prime mover; - any component or device supplied which is necessary for operation. This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN. The requirements of this European Standard do not take into account the interaction between the compressor/compressor unit and other processes carried out on site. Excluded are: - refrigerant compressors used in refrigerating systems or heat pumps for which the safety requirements are given in EN 60335-2-34 or EN 12693; - the specification of performance levels and/or safety integrity levels for safety related parts of control systems. Performance levels and/or safety integrity levels are an important aspect of compressor design and should be determined by the manufacturer and the user based on a risk assessment (see Introduction). This European Standard does not cover those safety aspects of road transport dealt with by EC legislation for trailers.

This European Standard is applicable to process gas compressors and process gas compressor units having an operating pressure greater than 0,5 bar (gauge), an input shaft power greater than 0,5 kW and designed to compress all gases other than air, nitrogen or inert gases which are covered in Part 1. This document deals with all significant hazards, hazardous situations and events relevant to the design, installation, operation, maintenance, dismantling and disposal of process gas compressors and process gas compressor units, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This part of EN 1012 includes under the general term compressor units those machines which comprise: - the compressor; - a drive system including the prime mover; - any component or device supplied which is necessary for operation. This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN. The requirements of this European Standard do not take into account the interaction between the compressor/compressor unit and other processes carried out on site. Excluded are: - refrigerant compressors used in refrigerating systems or heat pumps for which the safety requirements are given in EN 60335-2-34 or EN 12693; - the specification of performance levels and/or safety integrity levels for safety related parts of control systems. Performance levels and/or safety integrity levels are an important aspect of compressor design and should be determined by the manufacturer and the user based on a risk assessment (see Introduction). This European Standard does not cover those safety aspects of road transport dealt with by EC legislation for trailers.

EN 1012-3:2013 is classified under the following ICS (International Classification for Standards) categories: 23.140 - Compressors and pneumatic machines; 23.160 - Vacuum technology. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1012-3:2013 has the following relationships with other standards: It is inter standard links to EN 61511-1:2017, EN 61508-4:2010, EN 61511-2:2017, EN 61508-2:2010, EN 61508-6:2010, EN IEC 60079-0:2018, EN 61511-3:2017, EN 61508-3:2010, EN 61508-7:2010, EN 61310-2:2008, EN IEC 61000-6-2:2019, EN 61508-5:2010, EN 61508-1:2010, EN IEC 60079-14:2024, EN IEC 60204-11:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1012-3:2013 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1012-3:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.RFHVQLNRPSUHVRUMLKompressoren und Vakuumpumpen - Sicherheitsanforderungen - Teil 3: ProzesskompressorenCompresseurs et pompes à vide - Prescriptions de sécurité - Partie 3: Compresseurs de procédéCompressors and vacuum pumps - Safety requirements - Part 3: Process compressors23.160Vakumska tehnologijaVacuum technology23.140VWURMLCompressors and pneumatic machinesICS:Ta slovenski standard je istoveten z:EN 1012-3:2013SIST EN 1012-3:2014en,fr,de01-januar-2014SIST EN 1012-3:2014SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1012-3

November 2013 ICS 23.140; 23.160 English Version

Compressors and vacuum pumps - Safety requirements - Part 3: Process compressors

Compresseurs et pompes à vide - Prescriptions de sécurité - Partie 3: Compresseurs de procédé

Kompressoren und Vakuumpumpen - Sicherheitsanforderungen - Teil 3: Prozesskompressoren This European Standard was approved by CEN on 8 September 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1012-3:2013 ESIST EN 1012-3:2014

Graphical symbols . 71 Annex B (informative)

Measure to ensure a safety function while testing a safety device (example) . 78 B.1 Shutdown Override Switches . 78 B.2 Monitoring . 78 Annex C (informative)

Guide to the application of current standards to the functional safety on safety related control of process compressors or compressor units . 79 C.1 Introduction . 79 C.2 Scope . 79 C.3 Standard and code references . 79 C.4 Standard abbreviations . 80 C.5 Risk reduction process and functional safety. 81 SIST EN 1012-3:2014

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 101 Bibliography . 102

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document. When provisions of this type C standard are different from those which are stated in type A and B standards, the provisions of this type C standard take precedence over the provisions of the other standards for machines that have been designed and built according to the provisions of this type C standard. When published in 1996, Part 1 of EN 1012 applied to all types of compressor. The standard is now divided into 3 parts with Part 1 addressing compressors for compressed air, nitrogen and inert gases and Part 3 addressing compressors for process gases. Part 2 continues to address vacuum pumps. Separating requirements for process gas compressors from those for compressors for air, nitrogen and other inert gases was considered a practical move so that the requirements for one type of compressor could be changed without affecting the complete standard.

Where texts parts of EN 1012-3 are identical with EN 1012-1:2010, these are identified and formatted in italics. If common requirements for functional safety would be applied to all process compressors, the variety in the application of process compressors may cause significantly different levels of residual risk. Therefore, in addition to the requirements of this standard, the application of risk assessment may be required for safety related control systems in the case of particular applications to specify performance levels and/or safety integrity levels for related aspects of functional safety.

Informative Annex C has been included to provide guidance on risk assessment for related aspects of functional safety, including the determination of safety integrity levels and/or performance levels. The manufacturer of the compressor is responsible for carrying out such a risk assessment and applying appropriate preventive measures. These tasks are outside the scope of this standard. SIST EN 1012-3:2014

a drive system including the prime mover;

any component or device supplied which is necessary for operation. This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN. The requirements of this European Standard do not take into account the interaction between the compressor/compressor unit and other processes carried out on site. Excluded are: refrigerant compressors used in refrigerating systems or heat pumps for which the safety requirements are given in EN 60335-2-34 or EN 12693; the specification of performance levels and/or safety integrity levels for safety related parts of control systems. Performance levels and/or safety integrity levels are an important aspect of compressor design and should be determined by the manufacturer and the user based on a risk assessment (see Introduction). This European Standard does not cover those safety aspects of road transport dealt with by EC legislation for trailers. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 626-1:1994+A1:2008, Safety of machinery Reduction of risks to health from hazardous substances emitted by machinery Part 1: Principles and specifications for machinery manufacturers EN 764-7:2002, Pressure equipment Part 7: Safety systems for unfired pressure equipment EN 837-2, Pressure gauges Part 2: Selection and installation recommendations for pressure gauges

EN 953:1997+A1:2009, Safety of machinery Guards General requirements for the design and construction of fixed and movable guards SIST EN 1012-3:2014

EN 1005-3, Safety of machinery Human physical performance Part 3: Recommended force limits for machinery operation EN 1127-1, Explosive atmospheres Explosion prevention and protection Part 1: Basic concepts and methodology EN 12021, Respiratory protective devices Compressed air for breathing apparatus EN 12195-1, Load restraining on road vehicles Safety Part 1: Calculation of securing forces EN 13001-2, Crane safety General design Part 2: Load actions EN 13155, Cranes Safety Non-fixed load lifting attachments EN 13309, Construction machinery Electromagnetic compatibility of machines with internal power supply EN 13445-5:2009, Unfired pressure vessels Part 5: Inspection and testing EN 13445-6, Unfired pressure vessels Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron EN 13463-1, Non-electrical equipment for use in potentially explosive atmospheres Part 1: Basic method and requirements EN 15198, Methodology for the risk assessment of non-electrical equipment and components for intended use in potentially explosive atmospheres EN 60079-0, Explosive atmospheres Part 0: Equipment General requirements (IEC 60079-0:2011, modified) EN 60079-1, Explosive atmospheres Part 1: Equipment protection by flameproof enclosures "d" (IEC 60079-1) EN 60079-14, Explosive atmospheres Part 14: Electrical installations design, selection and erection (IEC 60079-14) EN 60204-1:20061), Safety of machinery Electrical equipment of machines Part 1: General requirements (IEC 60204-1:2005, modified) EN 60204-11, Safety of machinery Electrical equipment of machines Part 11: Requirements for HV equipment for voltages above 1 000 V a.c. or 1 500 V d.c. and not exceeding 36 kV (IEC 60204-11) EN 61000-6-2, Electromagnetic compatibility (EMC) Part 6-2: Generic standards Immunity for industrial environments (IEC 61000-6-2) EN 61000-6-4, Electromagnetic compatibility (EMC) Part 6-4: Generic standards Emission standard for industrial environments (IEC 61000-6-4) EN 61310-2:2008, Safety of machinery Indication, marking and actuation Part 2: Requirements for marking (IEC 61310-2:2007)

1) EN 60204-1:2006 is impacted by the stand-alone amendment EN 60204-1:2006/A1:2009 (IEC 60204-1:2005/A1:2008). SIST EN 1012-3:2014

(IEC 61508-2:2010) EN 61508-3, Functional safety of electrical/electronic/programmable electronic safety-related systems Part 3: Software requirements (IEC 61508-3) EN 61508-4, Functional safety of electrical/electronic/programmable electronic safety-related systems Part 4: Definitions and abbreviations (IEC 61508-4) EN 61508-5, Functional safety of electrical/electronic/programmable electronic safety-related systems Part 5: Examples of methods for the determination of safety integrity levels (IEC 61508-5) EN 61508-6, Functional safety of electrical/electronic/programmable electronic safety-related systems Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3 (IEC 61508-6) EN 61508-7, Functional safety of electrical/electronic/programmable electronic safety-related systems Part 7: Overview of techniques and measures (IEC 61508-7) EN 61511-1, Functional safety Safety instrumented systems for the process industry sector Part 1: Framework, definitions, system, hardware and software requirements (IEC 61511-1) EN 61511-2, Functional safety Safety instrumented systems for the process industry sector Part 2: Guidelines for the application of IEC 61511-1 (IEC 61511-2) EN 61511-3, Functional safety Safety instrumented systems for the process industry sector Part 3: Guidance for the determination of the required safety integrity levels (IEC 61511-3) EN 62061, Safety of machinery Functional safety of safety-related electrical, electronic and programmable electronic control systems (IEC 62061) EN ISO 2151:2008, Acoustics Noise test code for compressors and vacuum pumps Engineering method (Grade 2) (ISO 2151:2004) EN ISO 4126-1, Safety devices for protection against excessive pressure Part 1: Safety valves

(ISO 4126-1) EN ISO 4413:2010, Hydraulic fluid power General rules and safety requirements for systems and their components (ISO 4413:2010) EN ISO 4414:2010, Pneumatic fluid power General rules and safety requirements for systems and their components (ISO 4414:2010) EN ISO 11688-1, Acoustics Recommended practice for the design of low-noise machinery and equipment Part 1: Planning (ISO/TR 11688-1) EN ISO 12100:2010, Safety of machinery General principles for design Risk assessment and risk reduction (ISO 12100:2010) EN ISO 13849-1:2008, Safety of machinery Safety-related parts of control systems Part 1: General principles for design (ISO 13849-1:2006) EN ISO 13850:2008, Safety of machinery Emergency stop Principles for design (ISO 13850:2006) SIST EN 1012-3:2014

ISO 3857-2, Compressors, pneumatic tools and machines Vocabulary Part 2: Compressors ISO 8573-1, Compressed air Part 1: Contaminants and purity classes ISO 8573-2, Compressed air Part 2: Test methods for oil aerosol content ISO 8573-3, Compressed air Part 3: Test methods for measurement of humidity ISO 8573-4, Compressed air Part 4: Test methods for solid particle content IEC 60417 (2002-10), Graphical symbols for use on equipment 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 apply.

Definitions specifically needed for compressors are listed below and in the standards ISO 3857-1 and ISO 3857-2. 3.1 General terms 3.1.1 compressor part of a compressor unit that compresses a gas or vapour media to a pressure higher than that at the inlet 3.1.2 compressor unit unit that comprises the compressor, a drive system and any component or device which is necessary for operation SIST EN 1012-3:2014

depressurisation reduction of the pressure difference between the inside of a pressure containing part and its environment to zero EXAMPLE Stopping a compressor may lead to higher pressures on the suction side. In such cases, achieving a safe state may include depressurizing. 3.1.4 drive system system that consists of a prime mover and coupling mechanism Note 1 to entry: Prime mover may be an electric motor, steam engine (turbine), etc. Note 2 to entry: Coupling mechanism may be a drive belt, shaft, gears, etc. 3.1.5 harm physical injury or damage to health [SOURCE: EN ISO 12100:2010, definition 3.5] 3.1.6 hazard potential source of harm [SOURCE: EN ISO 12100:2010, definition 3.6] 3.1.6.1

hazard zone danger zone space within and/or around machinery in which a person can be exposed to a hazard [SOURCE: EN ISO 12100:2010, definition 3.11] 3.1.6.2

hazardous event event that can cause harm Note 1 to entry: A hazardous event can occur over a short period of time or over an extended period of time. 3.1.6.3 hazardous situation circumstance in which a person is exposed to at least one hazard Note 1 to entry: The exposure can result in harm immediately or over a period of time. [SOURCE: EN ISO 12100:2010, definition 3.10] 3.1.6.4

hazardous gas or vapour gas or vapour with chemical, radioactive or biological properties (such as flammable, explosive, unstable, pyrogenic, corrosive, caustic, toxic, carcinogenic), which generate hazards by reactions inside the compressor or through dispersal or through reactions with the environment Note 1 to entry: A hazardous gas may be a mixture of gases with these properties. SIST EN 1012-3:2014

The unit bar for pressure is used. 1 bar = 100 kPa. 3.1.15 rated power maximum permitted power (mechanical or electrical)

Note 1 to entry: Nominal power is a synonym for rated power. 3.1.16 risk combination of the probability of occurrence of harm and the severity of that harm [SOURCE: EN ISO 12100:2010, definition 3.12] SIST EN 1012-3:2014

SIS control device that carries out one or more safety function(s) Note 1 to entry: This definition corresponds to safety instrumented system (SIS) according to EN 61511-1. 3.1.20 shutdown stopping of all prime movers of a compressor 3.1.20.1 automatic shutdown automatically initiated stopping of a compressor initiated by limiting device or safety device Note 1 to entry: Automatic shutdown is commonly denoted as “tripping”. Note 2 to entry: This definition describes the way of initiating a normal, safety related controlled or emergency shutdown. 3.1.20.2

normal shutdown manually or automatically initiated stopping of a compressor which may include full sequential actuation of auxiliary equipment and drive system 3.1.20.3

safety related controlled shutdown manually or automatically initiated stopping of a compressor which includes a reduced (compared to normal shutdown) sequential actuation of auxiliary equipment and drive system Note 1 to entry: This type of shutdown is initiated by a safety related function. Note 2 to entry: Reduced sequential actuation means a reduced number and/or duration of steps of the sequence. Note 3 to entry: After a normal shutdown the energy to the prime movers can be cut off or not (see stop category 1 or 2 of 9.2.2 of EN 60204-1:2006). Note 4 to entry: Manually initiated stopping of a compressor which includes a reduced (compared to normal shutdown) sequential actuation of auxiliary equipment and drive system is often denoted as emergency stop. SIST EN 1012-3:2014

emergency shutdown manually or automatically initiated stopping of a compressor with immediate cut of the energy to the prime mover Note 1 to entry: This type of shutdown is initiated by a safety related function. Note 2 to entry: This shutdown definition is related to the stop category 0 of 9.2.2 of EN 60204-1:2006. 3.1.21 unexpected start-up unintended start-up start-up which, because of its unexpected nature, generates a hazard by, for example: a start command which is the result of a failure in, or an external influence on, the control system; a start command generated by inopportune action on a start control or other parts of the machine as, e.g., a sensor or a power control element; restoration of the power supply after an interruption; external / internal influences (e.g. gravity, wind, self-ignition in internal combustion engines) on parts of the machine. Note 1 to entry: Machine start-up during the normal sequence of an automatic cycle is not unintended, but can be considered to be unexpected from the point of view of the operator. Prevention of accidents in this case involves the use of safeguarding measures (see EN ISO 12100-2:2010, Clause 5). [SOURCE: EN ISO 12100:2010, 3.31]

3.2 Specific terms 3.2.1 acetylene compressor compressor intended for handling technically pure acetylene Note 1 to entry: For mixtures of acetylene with other gases or liquids the applicability of the relevant acetylene specifications will be decided on a case by case basis. 3.2.2

air compressor compressor intended for compression of air, nitrogen or inert gases 3.2.3 auxiliary energy supply energy which forces auxiliary systems (e.g. oil systems, cooling system or valves) to operate 3.2.4

compressor assembly assembly of compressor units and ancillary equipment to provide a compression facility that functions as an integrated whole Note 1 to entry: The limits of the assembly are as defined by the manufacturer.

3.2.5 control energy supply

energy supply for the control system (e.g. control voltage) SIST EN 1012-3:2014

3.2.14.1 portable compressor unit compressor unit which is wheel-mounted and can be towed on and off-site 3.2.14.2 skid-mounted compressor unit compressor unit which is mounted on skids and which is intended to be towed short distances on-site or transported on-site 3.2.14.3 gross mass maximum specified mass of the skid mounted or portable compressor unit (including tools, equipment and fuel)

Note 1 to entry: Tools and equipment includes for example concrete breakers, picks and hoses likely to be carried for a typical working application. SIST EN 1012-3:2014

NOTE Basis of the risk assessment is EN ISO 12100. SIST EN 1012-3:2014

By design or guarding Information for use 1 Mechanical hazards due to:

1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...