EN 1012-1:2010

(Main)Compressors and vacuum pumps - Safety requirements - Part 1: Air compressors

Compressors and vacuum pumps - Safety requirements - Part 1: Air compressors

This part of EN 1012 is applicable to compressors and compressor units having an operating pressure greater than 0,5 bar and designed to compress air, nitrogen or inert gases. This document deals with all significant hazards, hazardous situations and events relevant to the design, installation, operation, maintenance, dismantling and disposal of compressors and compressor units, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This part of EN 1012 includes under the general term compressor units those machines which comprise:

- the compressor;

- a drive system;

- any component or device which is necessary for operation.

This part also covers the general requirements relating to process gas compressors; for specific requirements see prEN 1012-3 which applies.

This part covers compressors driven by any power media, including battery powered and which are fitted in or used with motor vehicles.

This part of EN 1012 does not cover requirements for compressors used in potentially explosive atmospheres.

This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN.

Kompressoren und Vakuumpumpen - Sicherheitsanforderungen - Teil 1: Kompressoren

Dieser Teil von EN 1012 gilt für Kompressoren und Kompressoranlagen, die einen Arbeitsdruck von mehr als

0,5 bar haben und so konstruiert wurden, dass sie Luft, Stickstoff oder inerte Gase verdichten können. Diese

Norm befasst sich mit allen wesentlichen Gefährdungen, Gefährdungssituationen und Vorkommnissen, die

sich auf die Konstruktion, das Aufstellen, den Betrieb, die Wartung, das Demontieren und die Entsorgung von

Kompressoren und Kompressoranlagen beziehen, wenn sie wie beabsichtigt verwendet werden sowie unter

Bedingungen einer unsachgemäßen Verwendung, die vom Hersteller vernünftigerweise vorhersehbar sind

(siehe Abschnitt 4).

Dieser Teil von EN 1012 enthält unter dem allgemeinen Begriff Kompressoranlagen Maschinen, die

Folgendes umfassen:

⎯ den Kompressor;

⎯ eine Antriebsmaschine;

⎯ jedes Bauteil oder Gerät, das für den Betrieb notwendig ist.

Dieser Teil deckt auch die allgemeinen Anforderungen für Prozessgaskompressoren ab; bei besonderen

Anforderungen gilt dann prEN 1012-3.

Dieser Teil von EN 1012 deckt alle kraftbetriebenen Kompressoren ab, einschließlich batteriegespeister

Kompressoren und in Kraftfahrzeugen befestigte oder mit Kraftfahrzeugen verwendete Kompressoren.

Dieser Teil von EN 1012 deckt keine Anforderungen an Kompressoren ab, die in explosionsgefährdeten

Bereichen eingesetzt werden.

Dieser Teil von EN 1012 gilt nicht für Kompressoren, die vor dem Zeitpunkt der Herausgabe dieses Dokumentes

durch CEN gefertigt worden sind.

Compresseurs et pompes à vide - Prescriptions de sécurité - Partie 1 : Compresseurs d'air

La présente partie de l'EN 1012 est applicable aux compresseurs et aux unités de compression ayant une

pression de service supérieure à 0,5 bar et conçus pour utiliser de l'air, de l'azote ou des gaz inertes. Le

présent document traite tous les phénomènes dangereux, situations et événements dangereux significatifs

spécifiques à la conception, à l'installation, au fonctionnement, à la maintenance, au démontage et à la mise

au rebut des compresseurs et unités de compression, lorsqu'ils sont utilisés normalement et dans les

conditions prévues par le fabricant (voir Article 4).

La présente partie de l'EN 1012 englobe sous le terme général « unités de compression » les machines qui

comprennent :

- le compresseur ;

- un système d'entraînement ;

- tout composant ou dispositif nécessaire au fonctionnement.

La présente partie couvre les prescriptions générales relatives aux compresseurs pour gaz de procédé ; pour

les prescriptions spécifiques, voir le prEN 1012-3 qui s'applique.

La présente partie couvre les compresseurs entraînés par tout moyen de transmission de puissance, y

compris les compresseurs alimentés par batterie, qui sont intégrés ou utilisés avec des véhicules à moteur.

La présente partie de l'EN 1012 ne couvre pas les prescriptions relatives aux compresseurs utilisés dans les

atmosphères explosibles.

La présente partie de l'EN 1012 ne s'applique pas aux compresseurs qui ont été construits avant la date de

publication du présent document par le CEN.

Kompresorji in vakuumske črpalke - Varnostne zahteve - 1. del: Kompresorji za zrak

Ta del EN 1012 velja za kompresorje in kompresorske enote, ki imajo obratovalni tlak večji od 0,5 bara in so zasnovani za stiskanje zraka, dušika ali žlahtnih plinov. Ta dokument obravnava vse velike nevarnosti, nevarne situacije in primere, ki so pomembni pri načrtovanju, namestitvi, obratovanju, vzdrževanju, razstavljanju in odstranjevanju kompresorjev in kompresorskih enot, kadar se uporabljajo, kot je predvideno, in pod pogoji napačne uporabe, ki jih razumno predvidi proizvajalec (glej Klavzulo 4). Ta del EN 1012 pod splošnim izrazom kompresorske enote vključuje stroje, ki zajemajo: - kompresor; - pogonski sistem; - vsak sestavni del ali napravo, ki je potrebna za obratovanje. Ta del zajema tudi splošne zahteve, ki se nanašajo na procesne kompresorje plina; za natančne zahteve glej veljavni prEN 1012-3. Ta del zajema kompresorje, ki jih poganja kakršnokoli napajanje, vključno z baterijskim napajanjem, in ki so nameščeni v motornih vozilih ali se uporabljajo z njimi. Ta del EN 1012 ne zajema zahtev za kompresorje, ki se uporabljajo v potencialno eksplozivni atmosferi. Ta del EN 1012 ne velja za kompresorje, ki so bili izdelani pred datumom, ko je CEN objavil ta dokument.

General Information

- Status

- Published

- Publication Date

- 21-Sep-2010

- Withdrawal Date

- 21-Sep-2012

- Technical Committee

- CEN/TC 232 - Compressors - Safety

- Drafting Committee

- CEN/TC 232 - Compressors - Safety

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 22-Sep-2010

- Due Date

- 18-Oct-2010

- Completion Date

- 22-Sep-2010

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

EN 1012-1:2010 - Overview

EN 1012-1:2010 is the CEN (European) safety standard for air compressors and compressor units with an operating pressure greater than 0.5 bar, intended to compress air, nitrogen or inert gases. It covers the full lifecycle - design, installation, operation, maintenance, dismantling and disposal - and addresses hazards and reasonably foreseeable misuse. The standard applies to complete compressor units (compressor, drive system and any necessary components), including battery-powered and motor-vehicle‑fitted compressors, but excludes use in potentially explosive atmospheres and units manufactured before publication.

Key Topics and Requirements

The standard sets out safety requirements and verification measures across technical domains, including:

- Hazard analysis & risk assessment - identification of significant hazards and required protective measures.

- Mechanical safety - guarding, prevention of liquid shock, structural integrity and fragmentation protection.

- Electrical safety - safe electrical equipment and wiring in line with EN 60204 series.

- Control systems & safety-related parts - requirements for emergency stop, control reliability and functional safety (see EN ISO 13849-1).

- Thermal safety - protection against hot/cold surfaces and related ergonomic concerns.

- Noise - emission assessment and mitigation (engineering methods per ISO/EN 2151 and EN ISO 11688).

- Materials & processed substances - guidance on compressed-air quality (see ISO 8573 series) and handling of hazardous fluids.

- Fire/explosion - prevention measures where applicable (note: explosive-atmosphere compressors excluded).

- Pressure relief & testing - pressure testing, relief devices and verification of maximum allowable pressure.

- Information for use - required markings, instruction manuals, service and dismantling instructions, warning labels.

Practical Applications - Who Uses This Standard

EN 1012-1:2010 is used by:

- Compressor manufacturers and OEMs to design and certify safe compressor units.

- Design engineers specifying safety features, guards and controls.

- Test laboratories and notified bodies performing pressure, noise and stability verification.

- Maintenance teams and safety officers to follow prescribed service, inspection and dismantling procedures.

- Procurement and compliance teams to ensure machinery conforms with the Machinery Directive (see Annex ZA).

This standard helps reduce operational risk, ensures regulatory compliance across Europe, and supports safer installation and servicing of air compressors and compressor assemblies.

Related Standards

- EN 1012-2 (vacuum pumps) and prEN 1012-3 (process compressors) - related parts of the EN 1012 series.

- Key normative references used alongside EN 1012-1: EN 60204-1, EN ISO 12100, EN ISO 13849-1, EN ISO 2151, ISO 8573 series.

Keywords: EN 1012-1:2010, air compressor safety standard, compressor safety, CEN standard, pressure testing, noise testing, compressor units, risk assessment.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1012-1:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Compressors and vacuum pumps - Safety requirements - Part 1: Air compressors". This standard covers: This part of EN 1012 is applicable to compressors and compressor units having an operating pressure greater than 0,5 bar and designed to compress air, nitrogen or inert gases. This document deals with all significant hazards, hazardous situations and events relevant to the design, installation, operation, maintenance, dismantling and disposal of compressors and compressor units, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This part of EN 1012 includes under the general term compressor units those machines which comprise: - the compressor; - a drive system; - any component or device which is necessary for operation. This part also covers the general requirements relating to process gas compressors; for specific requirements see prEN 1012-3 which applies. This part covers compressors driven by any power media, including battery powered and which are fitted in or used with motor vehicles. This part of EN 1012 does not cover requirements for compressors used in potentially explosive atmospheres. This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN.

This part of EN 1012 is applicable to compressors and compressor units having an operating pressure greater than 0,5 bar and designed to compress air, nitrogen or inert gases. This document deals with all significant hazards, hazardous situations and events relevant to the design, installation, operation, maintenance, dismantling and disposal of compressors and compressor units, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This part of EN 1012 includes under the general term compressor units those machines which comprise: - the compressor; - a drive system; - any component or device which is necessary for operation. This part also covers the general requirements relating to process gas compressors; for specific requirements see prEN 1012-3 which applies. This part covers compressors driven by any power media, including battery powered and which are fitted in or used with motor vehicles. This part of EN 1012 does not cover requirements for compressors used in potentially explosive atmospheres. This part of EN 1012 is not applicable to compressors which are manufactured before the date of publication of this document by CEN.

EN 1012-1:2010 is classified under the following ICS (International Classification for Standards) categories: 23.080 - Pumps; 23.140 - Compressors and pneumatic machines; 23.160 - Vacuum technology. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1012-1:2010 has the following relationships with other standards: It is inter standard links to EN 1012-1:1996, EN IEC 60204-11:2019, ISO 8573-1:2010, EN 61310-2:2008, EN ISO 13732-1:2008, EN ISO 4126-1:2013, EN 837-2:1997, EN 13445-6:2021, EN 12021:2014, EN ISO 15667:2000, EN 983:1996+A1:2008, EN ISO 10555-5:1997/A1:2000, EN 1678:1998+A1:2010, EN 13445-5:2009, EN 547-1:1996+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1012-1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1012-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.]UDNKompressoren und Vakuumpumpen - Sicherheitsanforderungen - Teil 1: KompressorenCompresseurs et pompes a vide - Prescriptions de sécurité - Partie 1: Compresseurs d'airCompressors and vacuum pumps - Safety requirements - Part 1: Air compressors23.160Vakumska tehnologijaVacuum technology23.140VWURMLCompressors and pneumatic machinesICS:Ta slovenski standard je istoveten z:EN 1012-1:2010SIST EN 1012-1:2010en,fr01-december-2010SIST EN 1012-1:2010SLOVENSKI

STANDARDSIST EN 1012-1:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1012-1

September 2010 ICS 23.080; 23.140; 23.160 Supersedes EN 1012-1:1996English Version

Compressors and vacuum pumps - Safety requirements - Part 1: Air compressors

Compresseurs et pompes à vide - Prescriptions de sécurité - Partie 1 : Compresseurs d'air

Kompressoren und Vakuumpumpen - Sicherheitsanforderungen - Teil 1: Kompressoren This European Standard was approved by CEN on 30 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1012-1:2010: ESIST EN 1012-1:2010

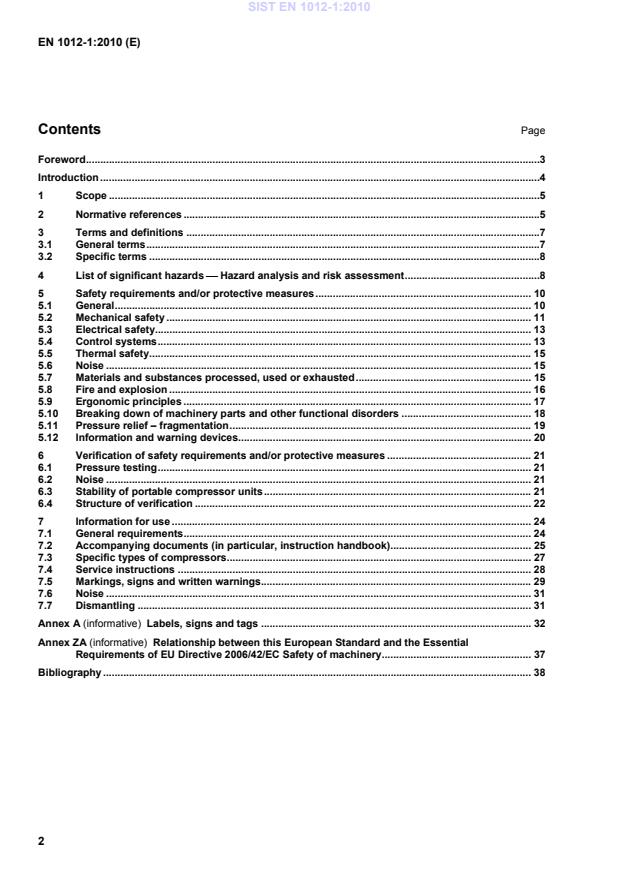

Labels, signs and tags . 32Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC Safety of machinery . 37Bibliography . 38 SIST EN 1012-1:2010

(ISO 4126-1:2004) EN ISO 11688-1, Acoustics Recommended practice for the design of low-noise machinery and equipment Part 1: Planning

(ISO/TR 11688-1:1995) EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) EN ISO 13732-1, Ergonomics of the thermal environment Methods for the assessment of human responses to contact with surfaces Part 1: Hot surfaces (ISO 13732-1:2006) EN ISO 13732-3, Ergonomics of the thermal environment Methods for the assessment of human responses to contact with surfaces Part 3: Cold surfaces (ISO 13732-3:2005) EN ISO 13849-1:2008, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design (ISO 13849-1:2006) EN ISO 13850:2008, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006) EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008) EN ISO 14121-1, Safety of machinery — Risk assessment — Part 1: Principles (ISO 14121-1:2007) EN ISO 14122-1, Safety of machinery — Permanent means of access to machinery — Part 1: Choice of fixed means of access between two levels (ISO 14122-1:2001) EN ISO 14122-2, Safety of machinery — Permanent means of access to machinery — Part 2: Working platforms and walkways (ISO 14122-2:2001) EN ISO 14122-3, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs, stepladders and guard-rails (ISO 14122-3:2001) EN ISO 14122-4, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed ladders (ISO 14122-4:2004) EN ISO 14163, Acoustics Guidelines for noise control by silencers (ISO 14163:1998) EN ISO 15667, Acoustics Guidelines for noise control by enclosures and cabins (ISO 15667:2000) ISO 3857-1:1977, Compressors, pneumatic tools and machines — Vocabulary — Part 1: General ISO 3857-2:1977, Compressors, pneumatic tools and machines — Vocabulary — Part 2: Compressors SIST EN 1012-1:2010

ISO 3857-2:1977. 3.1 General terms 3.1.1 compressor part of a compressor unit that compresses a gas or vapour media to a pressure higher than that at the inlet 3.1.2 compressor unit unit that comprises the compressor, a drive system and any component or device which is necessary for operation 3.1.3 drive system system that consists of a prime mover and coupling mechanism NOTE 1 Prime mover may be an electric motor, steam engine (turbine), etc. NOTE 2 Coupling mechanism may be a drive belt, shaft, gears, etc. 3.1.4 inert gas chemically inactive gas which retains this characteristic even at elevated pressures 3.1.5 pressure pressure relative to atmospheric pressure, i.e. gauge pressure NOTE 1 In many cases, this is referred to as effective pressure. NOTE 2 The unit bar for pressure is used. 1 bar = 100 kPa. 3.1.6 liquid shock excessive force resulting from an attempt to compress incompressible media 3.1.7 maximum allowable pressure maximum pressure for which the compressor or compressor unit is designed, as specified by the manufacturer

1) IEC 60417 is available only as a database which can be accessed, if necessary, by subscription through the IEC Website (see http://www.graphical-symbols.info/graphical-symbols/equipment/db1.nsf/welcome?OpenPage); those symbols relevant to this standard can be found in Annex A. SIST EN 1012-1:2010

The limits of the assembly are as defined by the manufacturer. 3.2.3

portable and skid mounted compressor

3.2.3.1 portable compressor unit compressor unit which is wheel-mounted and can be towed on- and off-site 3.2.3.2 skid-mounted compressor unit compressor unit which is mounted on skids and which can be towed short distances on-site or transported 3.2.3.3 gross mass maximum specified mass of a skid-mounted or portable compressor unit (including tools, equipment and fuel) NOTE Tools and equipment includes for example concrete breakers, picks and hoses likely to be carried for a typical working application. 3.2.4 process compressor compressor intended for compression of all gases other than air, nitrogen or inert gases 3.2.5 water-injected compressor compressor design in which the compressed media and the water are mixed 4 List of significant hazards Hazard analysis and risk assessment To provide the suitable level of safety taking into consideration the design, guarding and the provision of information, the appropriate risk assessment procedure shall be adopted in accordance with the principles identified in EN ISO 12100-1, EN ISO 12100-2 and EN ISO 14121-1. Hazards listed in Table 1 are related to all compressors/compressor units within the scope of this standard. SIST EN 1012-1:2010

By design or guarding Information for use1 Mechanical hazards due to:

1.1 Machine parts or work-pieces, e.g.:

a) shape;

5.10.1

b) mass and stability (potential energy of elements which maymove under the effect of gravity);

7.3.2 a) & d), 7.5.4.1

c) mass and velocity (kinetic energy of elements in controlled oruncontrolled motion);

7.3.2 a)

d) inadequacy of mechanical strength;

1) accumulation of energy inside the machinery 5.10.1

e) liquids and gases under pressure 5.10.1., 5.11.1, 5.11.2, 5.12 7.2.1.4 c), d) & g), 7.2.2 m) 1.2

Cutting or severing hazard friction or abrasion hazard 5.2.1.1 7.2.1.4 n), 7.2.2 a) 1.3 Drawing-in or trapping hazard

5.2.1.2 7.3.3 1.4 Impact hazard stabbing or puncture hazard

7.2.1.4 o) 1.5

High pressure fluid injection or ejection hazard

5.2.2 7.2.1.4 o) 2

Electrical hazards due to:

2.1

Contact of persons with live parts (direct contact)

7.2.1.3.2, 7.4.2 2.2

Contact of persons with parts which have become live under faultyconditions (indirect contact)

7.4.2 2.3 Lack of isolation of energy source

7.2.1.3.2 2.4

Electrostatic phenomena

5.8.1

Thermal hazards, resulting in:

3.1 Burns, scalds and other injuries by a possible contact of personswith objects or materials with an extreme high or low temperature,by flames or explosions and also by the radiation of heat sources 5.5 7.2.1.4 k). 7.2.2 d) 4 Hazards generated by noise, resulting in:

4.1 Hearing loss (deafness), other physiological disorders (e.g. loss ofbalance, loss of awareness) 5.6 7.2.2 a), 7.5.1, 7.6.2 5 Hazards generated by materials and substances (and theirconstituent elements) processed or used by the machinery

5.1

Hazards from contact with or inhalation of harmful fluids, gases,mists, fumes, and dusts 5.2.2, 5.7.2, 5.10.1 7.2.2 e), 7.3.2 e), f) 5.2

Fire or explosion hazard

5.8 7.2.1.4 j), m), 7.2.2 f) 5.3

Biological or microbiological (viral or bacterial) hazards 5.7.1 7.2.2 i) 6 Hazards generated by neglecting ergonomic principles inmachinery design as, e.g. hazards from:

By design or guarding Information for use6.1

Inadequate design, location or identification of manual controls 5.9

7 Unexpected start-up, unexpected over-run/over-speed (or any similar malfunction) from:

7.1

Failure/disorder of the control system

7.2.2 b) 7.2

External influences on electrical equipment

5.4.5

8 Failure of the power supply

7.2.1.3.1 9 Failure of the control circuit

5.4 7.2.2 b) 10 Errors of fitting

11 Break-up during operation

5.10, 5.11.1 7.2.1.4 i) 12 Falling or ejected objects or fluids

7.3.2 b), h) 13 Loss of stability / overturning of machinery 5.2.3 7.2.2 l) 14 Slip, trip and fall of persons (related to machinery) 5.2.4 7.4.2 Additional hazards, hazardous situations and hazardous events due to mobility

15 Linked to the work position (including driving station) on the machine

15.1

Exhaust gases/lack of oxygen at the work position

7.2.2 e) & h), 7.3.2, e) & f) 15.2

Noise at the operator's position

6.2.1, 7.6 16 From handling the machine (lack of stability) 5.9.2 b) & c) 7.3.2 d) 17 Due to the power source and to the transmission of power

17.1

Hazards from the engine and the batteries

5.3.2

17.2

Hazards from coupling and towing

5.9.2 b), 5.9.3 7.3.2 a), g) 18 From/to third persons

18.1

Lack or inadequacy of visual or acoustic warning means

7.5 19 Insufficient instructions for the driver/operator

7.3.2 20 Unhealthy postures or excessive effort

5.9.3

5 Safety requirements and/or protective measures 5.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 (all parts) for relevant but not significant hazards, which are not dealt with by this document. When choices are necessary for the application of type B standards referred to in this European Standard, i.e. listed in Clause 2, the manufacturer shall carry out an appropriate risk assessment for making these choices. The measures adopted to comply with the requirements of this clause shall take account of the state-of-the-art when more effective technical means become available. SIST EN 1012-1:2010

A safe system of work shall also be identified in accordance with 7.4.1. 5.2.2 Fluid injection The risk of fluid (gas or liquid) injection into the human body shall be minimized by: designing and supporting integral pipework, hoses and auxiliaries to withstand vibration, thermal expansion and their own mass, foreseeable external forces, influence of contaminants and external chemical substances; ensuring that all piping which is in a position likely to be damaged is protected, robust and sufficiently supported, but shall be free to move with changing temperature; ensuring that the design of oil/coolant filler plugs does not allow the dangerous release of fluid, e.g. by means of preventing the removal of the filler plug under pressure or an effective warning system; the design and location of pressure vents and drains, shall take account of the velocity of air, gas, vapour or liquid likely to be discharged. 5.2.3 Loss of stability 5.2.3.1 Generally applicable Compressor units shall be in accordance with 4.6 of EN ISO 12100-2:2003. 5.2.3.2 Portable and skid-mounted compressor units The centre of gravity, mainly associated with the engine/compressor combination shall be low enough to ensure that the compressor unit remains stable, without tipping or slipping, when used within intended limits. The provisions of 7.3.2 d) shall be applied to indicate the intended limits. Tyres of a portable compressor unit shall be rated to carry the maximum gross mass of the portable compressor unit at the highest towing speed the compressor unit is intended for. All tyres shall be of the same construction. The support leg or jockey wheel shall be capable of supporting the gross nose weight of the portable compressor unit as defined in the instruction handbook. It shall be possible to securely lock it in the support and towing positions by, for example, a clamping system or removable pin in locating holes. The jockey wheel device shall be positively retained in the draw bar in the event of the operator leaving it unlocked. NOTE Portable compressor units used on-road are also subject to regulations related to motor vehicles and their trailers. 5.2.4 Slip, trip and fall If access to elevated areas around a compressor unit is necessary and is an integral part of a compressor unit then these access areas shall be in accordance with 5.5.6 of EN ISO 12100-2:2003. Where such access is SIST EN 1012-1:2010

EN 60204-1:2006 and EN ISO 13849-1. 5.4.2 Emergency stop The need for and provision of an emergency stop shall be in accordance with 5.5.2 of EN ISO 12100-2:2003. A manual emergency stop shall be in accordance with Clause 5 of EN ISO 13849-1:2008 and specifically in 5.2.1 of that standard. SIST EN 1012-1:2010

In order to avoid 'hot-spots' the immersion heaters used for heating the lubricant shall have power dissipation not greater than 25 kW/m2. The heaters used shall be totally immersed in the oil at all times. To avoid the risk of fire hot piping shall not be in contact with wood or flammable material. 5.6 Noise Design considerations shall be given to noise reduction in particular at the source, see EN ISO 11688-1, EN ISO 14163, and EN ISO 15667. Design shall be such that continuous full load operation is possible at the maximum specified ambient temperature, with all noise attenuating devices and measures in place including all doors and access covers closed. NOTE EN ISO 11688-2 gives useful information on noise generation mechanisms in machinery. 5.7 Materials and substances processed, used or exhausted 5.7.1 Micro-organisms, biological and microbiological substances 5.7.1.1 Condensate Drainage facilities shall be provided to minimize the accumulation of stagnant liquid, which may promote the growth of micro-organisms. The drainage systems may be either manual or automatic types and shall allow for removal of accumulated liquid from piping and accessories such as water jackets, coolers, pulsation dampers and air receivers. The provisions of 7.2.2 i), j) and k) shall be applied. The compressor unit shall be equipped with, for example, drain traps to allow containment of condensate fluids and subsequent safe draining and disposal. 5.7.1.2 Water-injected compressor units The choice of materials in the compressor unit should be designed to prevent the growth of bacteria in the water. 5.7.2 Breathing difficulties 5.7.2.1 Compressor units driven by internal combustion engines The relationship between the location of the exhaust outlet and the compressor inlet shall be such that in normal operation the exposure of the compressor inlet to exhaust fumes is minimized. In addition to this requirement the provisions of 7.2.2 d) and 7.3.2 e) and f) shall also apply. SIST EN 1012-1:2010

The following types of shut-down devices are acceptable: temperature sensing device acting via an electronic/electrical control or; temperature indicator/gauge switch. The temperature measurement sensor shall be located in the discharge air stream such that the correct oil/air mixture temperature measurement is assured. SIST EN 1012-1:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...