EN 14227-2:2013

(Main)Hydraulically bound mixtures - Specifications - Part 2: Slag bound granular mixtures

Hydraulically bound mixtures - Specifications - Part 2: Slag bound granular mixtures

This European Standard specifies slag bound granular mixtures for, roads, airfields, and other trafficked areas, and specifies the requirements for their constituents, composition and laboratory performance classification. In this European Standard slag refers to slag from the iron and steel industry.

Hydraulisch gebundene Gemische - Anforderungen - Teil 2: Schlackengebundene Gemische

Diese Europäische Norm enthält Festlegungen für schlackengebundene Gemische für Straßen, Flugplätze und weitere Verkehrsflächen und legt die Anforderungen an ihre Bestandteile und Zusammensetzung sowie an die Klassifizierung des im Labor bestimmten Gebrauchsverhaltens fest. In dieser Eur

Mélanges traités aux liants hydrauliques - Spécifications - Partie 2: Mélanges granulaires traités au laitier

La présente Norme européenne spécifie les mélanges granulaires traités au laitier pour les routes, les

aéroports et autres zones de circulation, et précise les exigences relatives à leurs constituants, à leur

composition et à leur classification selon les performances mesurées en laboratoire. Dans la présente Norme

européenne, le laitier se rapporte au laitier de l'industrie du fer et de l'acier.

Hidravlično vezane zmesi - Specifikacije - 2. del: Vezane zmesi z žlindro

Ta evropski standard določa vezane zmesi z žlindro za ceste, letališča in druge prometne površine in določa zahteve za njihove sestavine, sestavo in klasifikacijo usposobljenosti laboratorija. V tem evropskem standardu se žlindra nanaša na žlindro pri pridobivanju železa in jekla.

General Information

- Status

- Published

- Publication Date

- 30-Apr-2013

- Withdrawal Date

- 29-Nov-2013

- Technical Committee

- CEN/TC 227 - Road materials

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 14-Feb-2022

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 14227-2:2004 - Hydraulically bound mixtures - Specifications - Part 2: Slag bound mixtures - Effective Date

- 08-May-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14227-2:2013 - Hydraulically bound mixtures: Part 2 - Slag bound granular mixtures is a European Standard published by CEN that specifies requirements for slag bound granular mixtures used in roads, airfields and other trafficked areas. In this standard, slag refers specifically to by‑products from the iron and steel industry (e.g., granulated blast furnace slag). The standard covers constituents, mix composition, laboratory performance classification and production control for these hydraulically bound pavement materials.

Key Topics and Technical Requirements

- Constituents: Requirements for aggregates, granulated blast furnace slag (GGBFS), partially ground and ground slag, water and chemical activators.

- Mixture types: Defines several slag bound granular mixture types (Mixture 1 to Mixture 5) with guidance on composition, grading and dry density.

- Mix design parameters:

- Proportioning of constituents and target grading

- Water content and workability period

- Compacity and immediate bearing index for fresh mixes

- Laboratory performance classification:

- Classification by California Bearing Ratio (CBR)

- Classification by compressive strength

- Tensile performance: direct tensile, indirect tensile and combined Rt, E methods

- Strength after immersion in water and other durability checks

- Testing methods referenced: EN 13286 series for laboratory density and compaction methods, EN 13286-40/41/42 for direct tensile, compressive and indirect tensile testing.

- Production control & quality management: Requirements for documentation, sampling, testing frequency, inspection, non‑conformity procedures and marking/labeling of mixtures.

- Normative and informative annexes: Include hydraulic activity of slag, examples of mixtures, compacity and CBR test procedures, and production control guidance.

Applications and Users

Practical uses and primary audiences:

- Road and pavement engineers specifying base and subbase layers for highways and airfields

- Contractors and asphalt/aggregate suppliers producing hydraulically bound granular mixtures

- Materials laboratories performing CBR, compressive and tensile testing

- Designers seeking sustainable alternatives using industrial slag (granulated blast furnace slag)

- Public agencies and consultants developing procurement specifications and quality control plans

Benefits:

- Promotes reuse of iron/steel industry slag in infrastructure

- Provides harmonized test and classification methods to ensure performance and durability

- Supports design decisions for trafficked areas requiring hydraulically bound base/subbase layers

Related Standards

- EN 14227 series (other parts: Part 1 cement bound, Part 3 fly ash bound, etc.)

- EN 13286 (laboratory reference density and compaction methods)

- EN 13286-40/41/42 (tensile, compressive and indirect tensile test methods)

- EN 459-1, EN 933-1, EN 1097 series (referenced aggregate and material test standards)

Keywords: EN 14227-2:2013, hydraulically bound mixtures, slag bound granular mixtures, granulated blast furnace slag, road construction materials, CBR, compressive strength, CEN, pavement materials.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 14227-2:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Hydraulically bound mixtures - Specifications - Part 2: Slag bound granular mixtures". This standard covers: This European Standard specifies slag bound granular mixtures for, roads, airfields, and other trafficked areas, and specifies the requirements for their constituents, composition and laboratory performance classification. In this European Standard slag refers to slag from the iron and steel industry.

This European Standard specifies slag bound granular mixtures for, roads, airfields, and other trafficked areas, and specifies the requirements for their constituents, composition and laboratory performance classification. In this European Standard slag refers to slag from the iron and steel industry.

EN 14227-2:2013 is classified under the following ICS (International Classification for Standards) categories: 01.040.93 - Civil engineering (Vocabularies); 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14227-2:2013 has the following relationships with other standards: It is inter standard links to EN 14227-2:2004, EN 13286-1:2021, EN 13286-40:2003, EN 1097-7:2022, EN 13286-43:2003, EN 13286-5:2003, EN 933-1:2012, EN 15167-1:2006, EN 13286-44:2003, EN 13286-50:2004, EN 13286-4:2021, EN 1097-6:2000, EN 13286-47:2021, EN 13286-42:2003, EN 459-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14227-2:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Hydraulisch gebundene Gemische - Anforderungen - Teil 2: Schlackengebundene GemischeMélanges traités aux liants hydrauliques - Spécifications - Partie 2: Mélanges granulaires traités au laitierHydraulically bound mixtures - Specifications - Part 2: Slag bound mixtures93.080.20Materiali za gradnjo cestRoad construction materialsICS:Ta slovenski standard je istoveten z:EN 14227-2:2013SIST EN 14227-2:2013en,fr,de01-julij-2013SIST EN 14227-2:2013SLOVENSKI

STANDARDSIST EN 14227-2:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14227-2

May 2013 ICS 93.080.20 Supersedes EN 14227-2:2004English Version

Hydraulically bound mixtures - Specifications - Part 2: Slag bound granular mixtures

Mélanges traités aux liants hydrauliques - Spécifications - Partie 2: Mélanges granulaires traités au laitier

Hydraulisch gebundene Gemische - Anforderungen - Teil 2: Schlackengebundene Gemische This European Standard was approved by CEN on 1 March 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14227-2:2013: ESIST EN 14227-2:2013

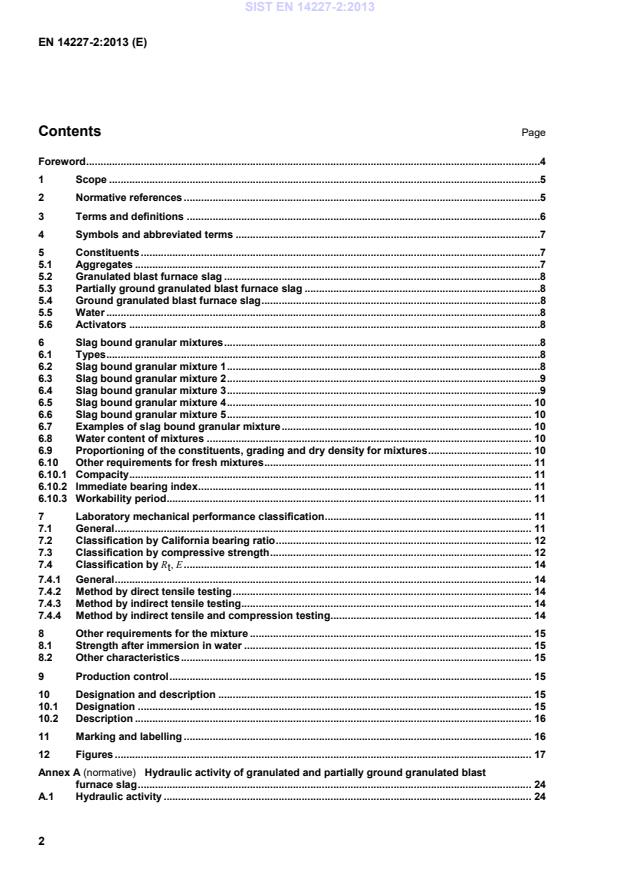

Hydraulic activity of granulated and partially ground granulated blast furnace slag . 24 A.1 Hydraulic activity . 24 SIST EN 14227-2:2013

Examples of slag bound granular mixtures . 26 Annex C (normative)

Compacity of a slag bound granular mixture 2 . 27 Annex D (normative)

CBR value of slag bound granular mixtures . 28 D.1 Sampling and preparation of the test samples . 28 D.2 Specimen manufacture and curing . 28 D.3 Calculation and expression of results . 28 Annex E (informative)

Production control for slag bound granular mixtures . 29 E.1 General . 29 E.2 Quality manual . 29 E.3 Organisation . 29 E.3.1 Responsibility and authority . 29 E.3.2 Management representative . 29 E.3.3 Internal audits . 29 E.3.4 Management review . 30 E.3.5 Sub-contract services . 30 E.3.6 Records . 30 E.3.7 Training. 30 E.4 Control procedures . 30 E.4.1 Production management . 30 E.4.2 Composition of the mixture . 31 E.4.3 Constituents . 31 E.4.4 Process control . 31 E.4.5 Inspection, calibration and control of process equipment . 31 E.4.6 Handling and delivery . 32 E.5 Inspection and testing of constituents and mixtures during production . 32 E.5.1 General . 32 E.5.2 Characteristics that require control during production . 32 E.5.3 Frequency of sampling the mixture . 33 E.6 Inspection and testing equipment . 33 E.6.1 General . 33 E.6.2 Measuring and testing equipment . 33 E.6.3 Measuring and testing equipment in the process . 33 E.6.4 Measuring and testing equipment in laboratory . 33 E.7 Non-conformity . 34 E.7.1 General . 34 E.7.2 Non-conformity of constituents . 34 E.7.3 Non-conformity of the mixture . 34 Bibliography . 35

Note 1 to entry:

The mixture may include an activator.

3.3 air-cooled blast furnace slag aggregate made mainly of crystalline silicates and aluminosilicates of calcium and magnesium, obtained by slow air cooling of molten blast furnace slag Note 1 to entry:

The cooling process may be assisted by the controlled application of water. Air-cooled blast furnace slag hardens by hydraulic reaction and carbonation. 3.4 air-cooled steel slag aggregate made mainly of crystalline calcium silicates and calcium ferrites comprising CaO, SiO2, MgO and iron oxides, obtained by slow air cooling of molten steel slag Note 1 to entry:

The cooling process may be assisted by the controlled application of water. Air-cooled steel slag hardens mainly by carbonatic reactions. 3.5 granulated blast furnace slag vitrified sandy material made up mainly of CaO, SiO2, Al2O3 and MgO, produced generally by rapid water quenching of molten blast furnace slag Note 1 to entry:

Granulated blast furnace slag hardens by hydraulic reaction. Note 2 to entry:

Pelletised and dry granulated blast-furnace slag may have similar hydraulic properties. SIST EN 14227-2:2013

The α coefficient characterises the reactivity of a fresh vitrified blast furnace slag used for road construction (see EN 13286-44). 4 Symbols and abbreviated terms For the purpose of this document, the following symbols and abbreviated terms apply. CBR is the California bearing ratio, expressed in percent (%) Rc is the compressive strength, expressed in megapascals (MPa) Ri is the compressive strength after immersion, expressed in megapascals (MPa) Rt is the direct tensile strength, expressed in megapascals (MPa) Rit is the indirect tensile strength, expressed in megapascals (MPa) E is the modulus of elasticity, expressed in megapascals (MPa) EC is the E determined by compressive strength, expressed in megapascals (MPa) Et is the E determined in direct tension, expressed in megapascals (MPa) Eit is the E determined in indirect tension, expressed in megapascals (MPa) 5 Constituents 5.1 Aggregates Aggregates shall comply with EN 13242. SIST EN 14227-2:2013

5.2 Granulated blast furnace slag When required, the content of SiO2, Al2O3, CaO, MgO and the C.A category in accordance with Annex A (normative) shall be declared.

When required, the alpha coefficient category shall be declared in accordance with Annex A. 5.3 Partially ground granulated blast furnace slag When required, the content of SiO2, Al2O3, CaO, MgO and the C.A category in accordance with Annex A shall be declared. When required, the fines content category shall be declared in accordance with Annex A. When required, the alpha coefficient category (measured before grinding) shall be declared in accordance with Annex A. 5.4 Ground granulated blast furnace slag Ground granulated blast furnace slag shall conform to EN 15167-1. 5.5 Water Water shall not contain components that adversely affect the hardening and performance of the slag bound mixture. 5.6 Activators Activators include quick lime, hydrated lime, gypsum, air-cooled steel slag or other similar products containing lime and/or sulfate.

Quick lime (CaO) or hydrated lime [Ca(OH)2] shall be type CL90 or CL80 in conformity with EN 459-1.

Quick lime shall comply with reactivity R4 or R5 and particle size distribution P1, P2, P3 or P4. 6 Slag bound granular mixtures 6.1 Types Using the constituents specified in Clause 5, slag bound granular mixture shall be selected from the types and sub-types described in 6.2 to 6.7 and shall conform to the specified requirements for the selected mixture.

6.2 Slag bound granular mixture 1

Granular mixture that contains granulated (or ground or partially ground granulated) blast furnace slag. The grading of the mixture, determined in accordance with EN 933-1, shall comply with Table 1. SIST EN 14227-2:2013

6.3 Slag bound granular mixture 2

Granular mixture with compacity requirement that contains granulated (or ground or partially ground granulated) blast furnace slag. The grading of the selected sub-type, determined in accordance with EN 933-1, shall comply with Table 2.

Either category G1 or category G2 of the grading envelopes in Figures 4 to 6 shall be specified. Compacity shall comply with 6.10.1. Mixture 2 - 0/10 shall satisfy the immediate bearing index requirement stated in 6.10.2. Table 2 — Grading of slag bound granular mixture 2 Column 1 2 3 Line Slag bound granular mixture Grading category Grading envelopes 1 2 – 0/20 G1 or G2

Figure 4 2 2 – 0/14 G1 or G2

Figure 5 3 2 – 0/10 G1 or G2

Figure 6

6.4 Slag bound granular mixture 3

Granular mixture that contains granulated (or ground or partially ground granulated) blast furnace slag with a maximum nominal size of D equal or less than 6,3 mm and with an immediate bearing index requirement. Slag bound granular mixture 3 shall be a mixture with a maximum nominal size of D equal or less than 6,3 mm with an immediate bearing index requirement. The grading of the mixture, determined in accordance with EN 933-1, shall comply with Table 3. The immediate bearing index category shall be selected from 6.10.2. Table 3 — Grading of slag bound granular mixture 3 Column 1 2 3 4 Line Sieve

mm 2D D 0,063 1 Percentage of mixture passing by mass 100 ≥85 ≤35

Granular mixture with manufacturer declared value for the grading including declared upper and lower limits and, when required, an immediate bearing index category selected from Table 5. The grading of the mixture shall be determined in accordance with EN 933-1.

6.6 Slag bound granular mixture 5

Granular mixture that contains granulated (or ground or partially ground granulated) blast furnace slag. The grading of the mixture when tested in accordance with EN 933-1 shall comply with Table 4. When required, the immediate bearing index category shall be selected from Table 5. Table 4 — Grading of slag bound granular mixture 5 Sieve mm Percentage of mixture passing by mass Minimum Maximum 45 100 100 31,5 75 100 16 50 100 8 35

100 4 25 100 2 15 100 0,5 5 75 0,25 3 60 0,063 0 25

6.7 Examples of slag bound granular mixture Examples of slag bound granular mixtures are given in Annex B. NOTE The examples are not exhaustive, nor the proportions intended to be restrictive, but they illustrate the current use in Europe. 6.8 Water content of mixtures The water content shall be selected to permit compaction on site by rolling and to optimise the mechanical performance of the mixture. The water content shall be determined by the Proctor test or other method in accordance with EN 13286-1, EN 13286-2, EN 13286-3, EN 13286-4 and EN 13286-5 ,and limits set to give a workable range of water content on site compatible with the compaction and the desired mechanical performance of the mixture. 6.9 Proportioning of the constituents, grading and dry density for mixtures The proportioning of the constituents, expressed as a percentage by dry mass of the total dry mass of the mixture, the target grading, including lower and upper limits, if required, and the dry density of the mixture, shall be declared. The declared proportions shall be based on the laboratory mixture design and/or practical experiences with mixtures produced with the same constituents and under the same conditions in a way that the mixture complies with the requirements of this European Standard. SIST EN 14227-2:2013

6.10.2 Immediate bearing index Mixture 2-0/10 shall comply with immediate bearing index category IPI50 from Table 5.

For mixture 3, and when required for mixtures 4 and 5, the appropriate IPI category shall be selected from Table 5.

The immediate bearing index of the mixture shall be determined in accordance with EN 13286-47 using modified Proctor compaction.

Table 5 — Immediate bearing index categories Column 1 2 Line Immediate bearing index requirement Immediate bearing index category 1 Declared value IPIDV 2 ≥ 50 IPI50 3 ≥ 40 IPI40 4 ≥ 25 IPI25 5 No requirement IPINR

Mixtures with an immediate bearing index less than 40 may not support immediate trafficking and should be used with care.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...