SIST EN 1011-7:2004

(Main)Welding - Recommendations for welding of metallic materials - Part 7: Electron beam welding

Welding - Recommendations for welding of metallic materials - Part 7: Electron beam welding

This document may be used for the electron beam welding (process no. 51 according to EN ISO 4063) of weldable metallic materials according to CR ISO 15608. It does not contain data on permissible stresses on weld seams or on the testing and evaluation of weld seams. Such data can either be seen from the relevant user documents or should be separately agreed between the contracting parties.

A requirement for the application of this document is that the recommendations should be used by appropriately trained and experienced personnel.

Schweißen - Empfehlungen zum Schweißen metallischer Werkstoffe - Teil 7: Elektronenstrahlschweißen

Dieses Dokument kann für das Elektronenstrahlschweißen (Prozess-Nr. 51 nach EN ISO 4063) schweißgeeigneter Werkstoffe nach CR ISO 15608 angewendet werden. Es enthält keine Angaben über zulässige Beanspruchungen an Schweißnähten oder über das Prüfen und Bewerten von Schweißnähten. Diese sind entweder den entsprechenden Anwendungsnormen zu entnehmen oder sind zwischen den Vertragsparteien gesondert zu vereinbaren.

Für das Anwenden dieses Dokumentes wird vorausgesetzt, dass die Empfehlungen von entsprechend geschultem und erfahrenem Personal berücksichtigt werden.

Soudage - Recommandations pour le soudage des matériaux métalliques - Partie 7 : Soudage par faisceau d'électrons

Le présent document peut être utilisé pour le soudage par faisceau d'électrons (procédé 51 selon l'EN ISO 4063) des matériaux métalliques soudables selon le CR ISO 15608. Elle ne contient aucune information relative aux contraintes admissibles par les joints soudés ou en ce qui concerne les essais et l'évaluation des joints soudés. De telles informations peuvent être obtenues à partir des normes d'application adéquates ou il convient aux parties contractantes de se mettre d'accord à ce sujet.

Une exigence pour l'application du présent document est qu'il convient de mettre en �uvre les recommandations qu'elle contient par du personnel expérimenté ayant été formé de manière appropriée.

Varjenje – Priporočila za varjenje kovinskih materialov – 7. del: Varjenje z elektronskim snopom

General Information

- Status

- Published

- Publication Date

- 31-Oct-2004

- Technical Committee

- VAR - Welding

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Nov-2004

- Due Date

- 01-Nov-2004

- Completion Date

- 01-Nov-2004

Overview

EN 1011-7:2004 - published by CEN - is the European guidance document for electron beam welding (EBW, process no. 51 according to EN ISO 4063) of weldable metallic materials (grouping per CR ISO 15608). It provides practical recommendations for applying EBW in production, covering quality requirements, joint design, equipment, procedures and personnel qualification. The standard does not provide permissible stresses for weld seams or rules for testing/evaluation of weld seams - those are found in relevant application standards or by agreement between contracting parties. A precondition for use is appropriately trained and experienced personnel.

Key Topics and Requirements

- Scope and purpose: Guidance specific to EBW (deep penetration, high power density) to achieve low heat input, low shrinkage/distortion and high welding speeds.

- Quality requirements: Definitions of acceptable imperfection levels and process control expectations (references to EN ISO 13919 series for quality levels).

- Equipment and facilities: Recommendations for EBW machines, vacuum/evacuation considerations and acceptance inspection principles (referencing EN ISO 14744 series).

- Personnel and qualification: Requirements for qualification and competence of EBW operators and welders.

- Welding procedure documentation:

- Welding Procedure Specification (WPS) and procedure test guidance (see EN ISO 15609-3 and EN ISO 15614-11 for formal procedure specification and qualification).

- Joint preparation and design: Machining, cleaning, demagnetisation, assembly, longitudinal and circular joint details, evacuation holes, tack welds and cosmetic passes.

- Thermal treatment and handling: Advice on pre/post heat treatment, storage and handling of parent metals and consumables.

- Troubleshooting and materials guidance: Annexes summarising weldability of steels, aluminium, copper, nickel, titanium, refractory/reactive metals, dissimilar joins and causes/prevention of weld imperfections.

Applications

EN 1011-7:2004 is targeted where EBW advantages are required:

- Welding of dissimilar or reactive metals

- Applications needing low heat input, low distortion and deep penetration welds

- High-speed, automated production joining very thin or very thick sections or combinations thereof Typical users include welding engineers, fabricators, design engineers, quality managers and procurement/specification teams working in sectors such as aerospace, energy, medical devices and precision engineering.

Related Standards

- EN 1011-1 (general welding guidance)

- EN ISO 15609-3 / EN ISO 15614-11 (WPS and procedure qualification for EBW)

- EN ISO 13919-1/-2 (quality levels for imperfections)

- EN ISO 14744-1 to -6 (acceptance inspection of EBW machines)

EN 1011-7:2004 is a practical, process-specific supplement to general welding guidance and normative procedure standards for safe, controlled and repeatable electron beam welding.

Frequently Asked Questions

SIST EN 1011-7:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Welding - Recommendations for welding of metallic materials - Part 7: Electron beam welding". This standard covers: This document may be used for the electron beam welding (process no. 51 according to EN ISO 4063) of weldable metallic materials according to CR ISO 15608. It does not contain data on permissible stresses on weld seams or on the testing and evaluation of weld seams. Such data can either be seen from the relevant user documents or should be separately agreed between the contracting parties. A requirement for the application of this document is that the recommendations should be used by appropriately trained and experienced personnel.

This document may be used for the electron beam welding (process no. 51 according to EN ISO 4063) of weldable metallic materials according to CR ISO 15608. It does not contain data on permissible stresses on weld seams or on the testing and evaluation of weld seams. Such data can either be seen from the relevant user documents or should be separately agreed between the contracting parties. A requirement for the application of this document is that the recommendations should be used by appropriately trained and experienced personnel.

SIST EN 1011-7:2004 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1011-7:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Schweißen - Empfehlungen zum Schweißen metallischer Werkstoffe - Teil 7: ElektronenstrahlschweißenSoudage

- Recommandations pour le soudage des matériaux métalliques - Partie 7 : Soudage par faisceau d'électronsWelding - Recommendations for welding of metallic materials - Part 7: Electron beam welding25.160.10Varilni postopki in varjenjeWelding processesICS:Ta slovenski standard je istoveten z:EN 1011-7:2004SIST EN 1011-7:2004en01-november-2004SIST EN 1011-7:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1011-7July 2004ICS 25.160.10English versionWelding - Recommendations for welding of metallic materials -Part 7: Electron beam weldingSoudage

- Recommandations pour le soudage desmatériaux métalliques - Partie 7 : Soudage par faisceaud'électronsSchweißen - Empfehlungen zum Schweißen metallischerWerkstoffe - Teil 7: ElektronenstrahlschweißenThis European Standard was approved by CEN on 30 April 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1011-7:2004: ESIST EN 1011-7:2004

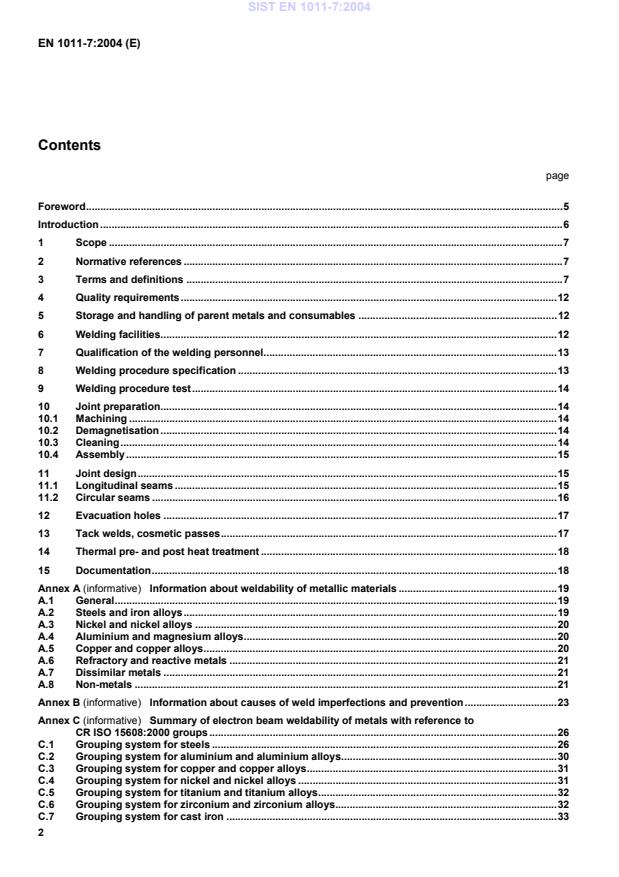

Information about weldability of metallic materials.19 A.1 General.19 A.2 Steels and iron alloys.19 A.3 Nickel and nickel alloys.20 A.4 Aluminium and magnesium alloys.20 A.5 Copper and copper alloys.20 A.6 Refractory and reactive metals.21 A.7 Dissimilar metals.21 A.8 Non-metals.21 Annex B (informative)

Information about causes of weld imperfections and prevention.23 Annex C (informative)

Summary of electron beam weldability of metals with reference to CR ISO 15608:2000 groups.26 C.1 Grouping system for steels.26 C.2 Grouping system for aluminium and aluminium alloys.30 C.3 Grouping system for copper and copper alloys.31 C.4 Grouping system for nickel and nickel alloys.31 C.5 Grouping system for titanium and titanium alloys.32 C.6 Grouping system for zirconium and zirconium alloys.32 C.7 Grouping system for cast iron.33 SIST EN 1011-7:2004

Examples of preparation of circular joints.34 Bibliography.41

Figures Figure 1 — Terms of electron beam oscillation.8 Figure 2 — Definition of working distance and focusing distance.9 Figure 3 — Definition for termination of circular seams.10 Figure 4 — Welding with interlayer material.11 Figure 5 — Welding of dissimilar metals with transition material.12 Figure 6 — Example of preparation of surface treated work pieces.14 Figure 7 — Normal square butt weld.15 Figure 8 — Square butt weld with spigot or integral backing.16 Figure 9 — Square butt weld with detached backing.16 Figure 10 — Work piece with run-on and run-off plate for separating the weld start and weld end.16 Figure 11 — Machining-related cavities.17 Figure 12 — Weldment with additional hole for evacuating the cavity.17 Figure A.1 — Sensitivity of hot cracks depending of alloy contents in aluminium.22 Figure D.1 — Various types of radial joints with centring.34 Figure D.2 — Work piece with radial joint, centred using a welding jig.35 Figure D.3 — Work pieces with unsuitable and better positions for radial weld.35 Figure D.4 — Various types of axial joints.36 Figure D.5 — Example of an axial weld with a depth of fusion zone adapted to suit the strength requirement (not welded through the full thickness of the joint).36 Figure D.6 — Improved joint detail for axial welds with reduced stress concentration.37 Figure D.7 — Deterioration of joint fit-up that occurs when welding axial joints assembled with a clearance fit.37 Figure D.8 — Effect of the method of manufacture on the dimensions of gear wheels.38 Figure D.9 — Example of a gear wheel with an unsuitable located axial joint. The joint is too close to the central bore.38 Figure D.10 — Better positioned axial joint compared with figure D.9. The joint is further from the central bore and the wall thickness has been adapted to suit the required weld strength.39 Figure D.11 — Better positioned axial joint compared with figure D.9. The slot has been included to accommodate radial shrinkage.39 Figure D.12 — Example of a difficult to access electron beam weld.39 SIST EN 1011-7:2004

1 Scope This document may be used for the electron beam welding (process no. 51 according to EN ISO 4063) of weldable metallic materials according to CR ISO 15608. It does not contain data on permissible stresses on weld seams or on the testing and evaluation of weld seams. Such data can either be seen from the relevant application standards or should be separately agreed between the contracting parties. A requirement for the application of this document is that the recommendations should be used by appropriately trained and experienced personnel. 2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1011-1, Welding — Recommendations for welding of metallic materials — Part 1: General guidance for arc welding EN ISO 13919-1:1996, Welding — Electron and laser beam welded joints — Guidance on quality levels for imperfections — Part 1: Steel (ISO 13919-1:1996) EN ISO 13919-2:2001, Welding — Electron and laser beam welded joints — Guidance on quality levels for imperfections — Part 2: Aluminium and its weldable alloys (ISO 13919-2:2001) EN ISO 14744-1:2000, Welding — Acceptance inspection of electron beam welding machines — Part 1: Principles and acceptance conditions (ISO 14744-1:2000) EN ISO 14744-2, Welding — Acceptance inspection of electron beam welding machines — Part 2: Measurement of accelerating voltage characteristics (ISO 14744-2:2000) EN ISO 14744-3, Welding — Acceptance inspection of electron beam welding machines — Part 3: Measurement of beam current characteristics (ISO 14744-3:2000) EN ISO 14744-4, Welding — Acceptance inspection of electron beam welding machines — Part 4: Measurement of welding speed (ISO 14744-4:2000) EN ISO 14744-5, Welding — Acceptance inspection of electron beam welding machines — Part 5: Measurement of run-out accuracy (ISO 14744-5:2000) EN ISO 14744-6, Welding — Acceptance inspection of electron beam welding machines — Part 6: Measurement of stability of spot position (ISO 14744-6:2000) EN ISO 15614-11:2002, Specification and qualification of welding procedures for metallic materials — Welding procedure test — Part 11: Electron and laser beam welding (ISO 15614-11:2002) EN ISO 15609-3:2004, Specification and qualification of welding procedures for metallic materials — Welding procedure specification — Part 3: Electron beam welding (ISO 15609-3:2004) 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 15609-3:2004,

EN ISO 13919-1:1996, EN ISO 13919-2:2003, EN ISO 14744-1:2000, and EN ISO 15614-11:2002 and the following apply. SIST EN 1011-7:2004

Key 1 Oscillation width 2 Initial position of the beam 3 Oscillation length Figure 1 — Terms of electron beam oscillation 3.4 cosmetic pass superficial remelting of the weld in order to enhance its appearance NOTE This pass is usually made with a defocused or oscillating beam. 3.5 defocusing deviation from the normal focus position (e. g. focus on work piece surface) 3.6 focusing distance distance between the focusing lens plane and beam focus position SIST EN 1011-7:2004

Key 1 Work piece 2 Working distance 3 Heat protection 4 Focusing lens 5 Focusing distance6 Beam focus 7 Beam spot Figure 2 — Definition of working distance and focusing distance 3.7 working distance distance between the surface of the work piece and a standard reference point on the equipment which is traceable to the true focusing lens plane NOTE See Figure 2. 3.8 lens current current IL which flows through the electromagnetic focusing lens 3.9 slope down controlled decrease of the beam power at the end of welding. The slope down region is the region on the work piece in which the effects of slope down occur NOTE See Figure 3. The slope down region can consist of one or two areas, depending on the selected welding mode: a) in partial penetration welding: a region where penetration decreases continuously. b) in full penetration welding: a region where beam penetration is still complete; a region where penetration is partial or decreasing. SIST EN 1011-7:2004

a) Partial penetration welding (with overlap)

b) Full penetration welding (without overlap)

c) Typical beam current IB profile for a circular weld with overlap Key 1 Work piece (welded zone) 2 Delay between control starting and weld beginning 3 Slope-up region 4 Overlapping region 5 Electron beam 6 Remelted zone 7 Slope-down region 8 Direction of work piece motion 9 Work piece (unwelded zone) IB

Beam current l

Weld length t

Weld time Figure 3 — Definition for termination of circular seams SIST EN 1011-7:2004

Joint prepared

Joint welded Key 1 Parent material A 2 Interlayer material 3 Parent material A or B 4 Fusion zone Figure 4 — Welding with interlayer material 3.15 transition material buffer material insert employed to allow welding of metallurgically incompatible materials NOTE See Figure 5. SIST EN 1011-7:2004

Joint prepared

Joint welded Key 1 Parent material A 2 Transition material 3 Parent material B 4 Fusion zone Figure 5 — Welding of dissimilar metals with transition material 4 Quality requirements The quality requirements should be given in the design specification prior to the beginning of welding work. They should be based on EN 729-1 and EN 729-2 or EN 729-3 or EN 729-4 and EN ISO 13919-1 or EN ISO 13919-2, unless relevant application standards are available. 5 Storage and handling of parent metals and consumables In order to avoid contact corrosion, foreign metal inclusions etc., parent metals and consumables of dissimilar classes of materials (according to CR ISO 15608) should not be stored and processed jointly. 6 Welding facilities Welding facilities include the electron beam-welding machine, workshop, tools, clamping devices, demagnetisation devices, and cleaning facilities. In the following, only those facilities, which are of particular significance for electron beam welding, will be described in more detail. The electron beam welding machine should be installed so that environmental conditions, such as mechanical vibrations, noise and dirt from neighbouring machines, electric and magnetic fields do not influence the quality of welds. Moreover, noise control regulations pursuant to the equipment safety act should be observed for the vacuum pumps. In larger workshops, the machine operators' and machine setters' workplace should be shielded against disturbances from manufacturing operations (e.g. by means of partition walls). The exhaust gases generated during evacuation of the working chamber shall only be released into the environment in accordance with the relevant emission regulations. Where particularly high demands are placed, on weld quality it is recommended that filtered air or inert gas be used to vent the working chamber. The supply voltage for the electron beam welding machine shall not vary by more than ± 10 % and care should be taken to ensure that the welding machine has a satisfactory earth connection. The electron beam welding machine shall be subjected to an acceptance inspection according to EN ISO 14744-1 to EN ISO 14744-6 as part of an internal quality management upon commissioning or in the case of displacement, modifications and repairs of major welding machine components. In this acceptance inspection the short and long-term consistency as well as the reproducibility of the most important welding parameters and compliance with particular characteristic data deviations will be measured and verified according to given deviation limits. SIST EN 1011-7:2004

EN ISO 13919-21). 10 Joint preparation 10.1 Machining It is recommended that all joint preparations be produced by machining or high precision cutting. The objective is to prepare clean metal surfaces with a minimum gap when assembled. Where components have surface layers produced by carburising, anodising, cadmium plating, nitriding, phosphating, galvanising etc. these are to be removed preferentially by machining in and adjacent to the weld joint region as shown in Figure 6.

Key 1 Boundary-layer-treated work piece 2 Boundary-layer removed for welding 3 Electron beam 4 3 x upper bead width Figure 6 — Example of preparation of surface treated work pieces 10.2 Demagnetisation Components containing ferromagnetic materials should be checked for residual magnetism and demagnetised if necessary. 10.3 Cleaning The quality of electron beam welding relies on accuracy and cleanliness of the joint preparation.

1) EN ISO 13919-1 and EN ISO 13919-2 are covered steel and aluminium. For other materials these standards can be used, if possible. SIST EN 1011-7:2004

Key t Work piece thickness Figure 7 — Normal square butt weld

Key t Work piece thickness s Weld penetration c and d Lengths to be defined Figure 8 — Square butt weld with spigot or integral backing

Key t Work piece thickness s Weld penetration Figure 9 — Square butt weld with detached backing

Key 1 Run-on plate 2 Work piece 3 Run-off plate 4 Start of weld 5 End of weld Figure 10 — Work piece with run-on and run-off plate for separating the weld start and weld end 11.2 Circular seams For welding circular components a spigot preparation, which facilitates alignment positioning of the components, can be used. Rotation-angle- or time-dependent control of the beam power and possib

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...