SIST EN 13852-3:2021

(Main)Cranes - Offshore cranes - Part 3: Light offshore cranes

Cranes - Offshore cranes - Part 3: Light offshore cranes

This document applies to light offshore cranes including their supporting pedestals and structures.

NOTE Supporting pedestal and structures such as columns and boom rests, are covered by this document to the extent where their main purpose is to support the crane.

This document is applicable to light offshore cranes, whose structures are made of steel, and fulfil all of the following characteristics:

- maximum rated capacity 15 tonnes or maximum static load moment 3 000 kNm;

- limitation for off-board lifting operation up to Hs = 2,0 m and wind speed 15 m/s (3 s gust);

- maximum number of working cycles class U1 (C ≤ 3,15 × 104) according to EN 13001-1.

This document provides requirements for all significant hazards, hazardous situations and events relevant to light offshore cranes for lifting of goods and lifting of persons, when used as intended and under conditions foreseen by the risk assessment (see Clause 4).

This document is applicable to light offshore cranes, which are manufactured after the date of approval by CEN of this document.

This document is not applicable for:

a) transportation, assembly, disabling, scrapping, installation or erecting of the crane;

b) any item attached to the hook, such as loads, non-fixed load lifting attachments, lifting accessories, baskets, carriers and containers;

c) lifting operations in ambient temperatures below −20 °C;

d) lifting operations in ambient temperatures above 45 °C;

e) lifting operations involving more than one crane;

f) accidental loads as result of collisions, earthquakes, explosions, etc., which are not covered by exceptional loads defined in Table B.7;

g) emergency personnel rescue operations (except training);

h) subsea lifting operations;

i) general purpose offshore cranes (covered by EN 13852-1), floating cranes and motion compensated cranes.

Krane - Offshore-Krane - Teil 3: Offshore-Krane mit kleiner Kapazität

Dieses Dokument ist anwendbar für Offshore-Krane mit kleiner Kapazität, einschließlich deren unterstützenden Tragsäulen und Fundamentstrukturen.

ANMERKUNG Unterstützende Tragsäulen und Fundamentstrukturen, wie z. B. Kranmast- und Auslegerstützen, werden in diesem Dokument behandelt, soweit ihre Hauptaufgabe darin besteht, den Kran abzustützen.

Dieses Dokument ist anwendbar für Offshore-Krane mit kleiner Kapazität, deren Kranstrukturen aus Stahl gefertigt sind und die alle der folgenden Merkmale aufweisen:

- maximale Tragfähigkeit von 15 Tonnen oder maximales statisches Lastmoment von 3 000 kNm;

- Begrenzung von Hebevorgängen außerhalb der Offshore-Anlage bis Hs = 2,0 m bei einer Windgeschwindigkeit von 15 m/s (bei 3 s Böenwind);

- maximale Gesamtzahl von Arbeitsspielen entsprechend Klasse U1 (C ≤ 3,15 × 104 Arbeitsspiele) nach EN 13001 1.

Dieses Dokument enthält Anforderungen im Hinblick auf alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Offshore-Krane mit kleiner Kapazität für das Heben von Gütern und das Heben von Personen zutreffen, wenn sie bestimmungsgemäß und unter den durch die Risikobeurteilung vorhergesehenen Bedingungen verwendet werden (siehe Abschnitt 4).

Dieses Dokument ist anwendbar für Offshore-Krane mit kleiner Kapazität, die nach dem Datum der Annahme dieses Dokument durch CEN hergestellt wurden.

Dieses Dokument ist nicht anwendbar für:

a) den Transport, die Montage, die Außerbetriebnahme, die Verschrottung, den Aufbau oder die Aufstellung des Krans;

b) beliebige am Haken angebrachte Objekte wie Lasten, lose Lastaufnahmemittel, Anschlagmittel, Personenaufnahmekörbe, Tragmittel und Container;

c) Hebevorgänge bei Umgebungstemperaturen unter −20 °C;

d) Hebevorgänge bei Umgebungstemperaturen über 45 °C;

e) Hebevorgänge , an denen mehr als ein Kran beteiligt ist;

f) unbeabsichtigte Lasten aufgrund von Kollisionen, Erdbeben, Explosionen usw., die nicht durch die außergewöhnlichen Lasten nach Tabelle B.7 abgedeckt sind;

g) Personenrettungsmaßnahmen in Notfällen (ausgenommen Training);

h) Unterwasser-Hebevorgänge;

i) Offshore-Krane für allgemeine Verwendung (in EN 13852-1 behandelt), schwimmende Krane und Krane mit Bewegungsfolgeeinrichtung.

Appareils de levage à charge suspendue - Grues off-shore - Partie 3 : Grues off-shore légères (potence off-shore)

Le présent document s’applique aux grues off-shore légères (potence off-shore), y compris à leurs socles et structures d’appui.

NOTE Le socle et les structures d’appui comme les colonnes et supports de flèche sont couverts par le présent document dans la mesure où leur objectif principal est de soutenir la grue.

Le présent document s’applique aux grues off-shore légères, dont les structures sont en acier, et répondant à toutes les caractéristiques suivantes :

- charge nominale maximale 15 tonnes, moment de charge statique maximal 3 000 kNm ;

- limite pour les opérations de levage hors-bord jusqu’à Hs = 2,0 m et vitesse de vent 15 m/s (rafale de 3 s) ;

- nombre maximal de cycles de travail classe U1 (C ≤ 3,15 × 104) conformément à l’EN 13001-1.

Le présent document spécifie les prescriptions relatives à l'ensemble des phénomènes dangereux, situations dangereuses et événements dangereux majeurs relatifs aux grues off-shore légères, pour le transport de marchandises et le levage de personnes, lorsque celles-ci sont utilisées comme prévu et dans les conditions prévues par l'appréciation du risque (voir Article 4).

Le présent document s’applique aux grues off-shore légères fabriquées après la date d'approbation du présent document par le CEN.

Le présent document ne s’applique pas :

a) au transport, au montage, au démontage, à la mise au rebut ou à l’installation de la grue ;

b) à tout article fixé au crochet, tel que les charges, les accessoires de levage amovibles, les accessoires de levage, les nacelles, les supports et les conteneurs ;

c) aux opérations de levage à des températures ambiantes inférieures à −20 °C ;

d) aux opérations de levage à des températures ambiantes supérieures à 45 °C ;

e) aux opérations de levage impliquant plus d'un appareil de levage à charge suspendue ;

f) aux charges accidentelles résultant de collisions, de tremblements de terre, d'explosions, etc., qui ne sont pas couvertes par les charges exceptionnelles définies dans le Tableau B.7 ;

g) aux opérations de sauvetage de personnel (hors entraînement) ;

h) aux opérations de levage sous-marines ;

i) aux grues off-shore pour usage général (couvertes par l’EN 13852-1), aux grues flottantes et aux grues à compensation de mouvement.

Dvigala (žerjavi) - Dvigala na plavajočih objektih - 3. del: Lahka dvigala na plavajočih objektih

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Nov-2018

- Publication Date

- 09-May-2021

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Apr-2021

- Due Date

- 07-Jun-2021

- Completion Date

- 10-May-2021

Overview

EN 13852-3:2021 (CEN) is the European standard for light offshore cranes. It sets safety, design and verification requirements for steel-structured cranes used offshore - including their supporting pedestals and immediate structures where the main purpose is to support the crane. The standard covers light offshore cranes built after its CEN approval and is intended to help manufacturers and users meet essential health and safety requirements (e.g., Machinery Directive).

Key scope limits:

- Maximum rated capacity: 15 tonnes or maximum static load moment 3 000 kNm

- Off‑board lifting limit: up to H = 2.0 m and wind speed 15 m/s (3 s gust)

- Duty class: max working cycles class U1 (C ≤ 3.15 × 10^4) per EN 13001‑1

- Exclusions include subsea lifts, multi‑crane lifts, floating/motion‑compensated cranes, extreme temperatures (< −20 °C or > 45 °C), and hook‑attached accessories

Key Topics

This standard addresses the primary safety and technical requirements for light offshore crane design and use:

- Hazard identification and risk assessment: requirements for identifying significant hazards, hazardous situations and events relevant to lifting goods and persons

- Strength & stability: structural design and limit state considerations for steel crane components and pedestals

- Mechanical & electrical systems: safe design of drives, brakes, controls and electrical equipment for offshore conditions

- Limiting, indicating & protection devices: load moment indicators, limit switches, emergency stop and safety systems

- Verification & testing: procedures for verification, inspection and functional testing of safety features

- Information for use: operator instructions, maintenance guidance and marking requirements

- Normative and informative annexes covering environmental influences, failure mode analyses, control arrangements, brake requirements, hazardous‑area equipment and a typical crane data sheet

Applications / Who Uses It

EN 13852-3:2021 is relevant to:

- Crane manufacturers and designers developing light offshore cranes and supporting pedestals

- Offshore operators and fleet owners specifying equipment for topside and near‑deck lifting (goods and qualified personnel lifts)

- Classification societies, notified bodies and certifiers assessing conformity to EU directives

- Safety engineers and maintenance teams implementing testing, inspection and operator training regimes

Practical benefits include safer offshore lifting operations, compliance with European legal requirements, and clear guidance on design limits and verification for light offshore crane installations.

Related Standards

- EN 13852 series: Part 1 (general purpose offshore cranes) and Part 2 (floating cranes)

- EN 13001 (general crane design principles and load actions) and other crane‑related EN standards referenced for wire ropes, brakes, controls and access

- Machinery Directive and relevant EU normative annexes (see Annex ZA/ZB in the standard)

Keywords: EN 13852-3:2021, light offshore cranes, offshore crane safety, crane design, CEN, lifting of persons, lifting operations, crane pedestals, risk assessment.

Frequently Asked Questions

SIST EN 13852-3:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cranes - Offshore cranes - Part 3: Light offshore cranes". This standard covers: This document applies to light offshore cranes including their supporting pedestals and structures. NOTE Supporting pedestal and structures such as columns and boom rests, are covered by this document to the extent where their main purpose is to support the crane. This document is applicable to light offshore cranes, whose structures are made of steel, and fulfil all of the following characteristics: - maximum rated capacity 15 tonnes or maximum static load moment 3 000 kNm; - limitation for off-board lifting operation up to Hs = 2,0 m and wind speed 15 m/s (3 s gust); - maximum number of working cycles class U1 (C ≤ 3,15 × 104) according to EN 13001-1. This document provides requirements for all significant hazards, hazardous situations and events relevant to light offshore cranes for lifting of goods and lifting of persons, when used as intended and under conditions foreseen by the risk assessment (see Clause 4). This document is applicable to light offshore cranes, which are manufactured after the date of approval by CEN of this document. This document is not applicable for: a) transportation, assembly, disabling, scrapping, installation or erecting of the crane; b) any item attached to the hook, such as loads, non-fixed load lifting attachments, lifting accessories, baskets, carriers and containers; c) lifting operations in ambient temperatures below −20 °C; d) lifting operations in ambient temperatures above 45 °C; e) lifting operations involving more than one crane; f) accidental loads as result of collisions, earthquakes, explosions, etc., which are not covered by exceptional loads defined in Table B.7; g) emergency personnel rescue operations (except training); h) subsea lifting operations; i) general purpose offshore cranes (covered by EN 13852-1), floating cranes and motion compensated cranes.

This document applies to light offshore cranes including their supporting pedestals and structures. NOTE Supporting pedestal and structures such as columns and boom rests, are covered by this document to the extent where their main purpose is to support the crane. This document is applicable to light offshore cranes, whose structures are made of steel, and fulfil all of the following characteristics: - maximum rated capacity 15 tonnes or maximum static load moment 3 000 kNm; - limitation for off-board lifting operation up to Hs = 2,0 m and wind speed 15 m/s (3 s gust); - maximum number of working cycles class U1 (C ≤ 3,15 × 104) according to EN 13001-1. This document provides requirements for all significant hazards, hazardous situations and events relevant to light offshore cranes for lifting of goods and lifting of persons, when used as intended and under conditions foreseen by the risk assessment (see Clause 4). This document is applicable to light offshore cranes, which are manufactured after the date of approval by CEN of this document. This document is not applicable for: a) transportation, assembly, disabling, scrapping, installation or erecting of the crane; b) any item attached to the hook, such as loads, non-fixed load lifting attachments, lifting accessories, baskets, carriers and containers; c) lifting operations in ambient temperatures below −20 °C; d) lifting operations in ambient temperatures above 45 °C; e) lifting operations involving more than one crane; f) accidental loads as result of collisions, earthquakes, explosions, etc., which are not covered by exceptional loads defined in Table B.7; g) emergency personnel rescue operations (except training); h) subsea lifting operations; i) general purpose offshore cranes (covered by EN 13852-1), floating cranes and motion compensated cranes.

SIST EN 13852-3:2021 is classified under the following ICS (International Classification for Standards) categories: 47.020.40 - Lifting and cargo handling equipment; 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13852-3:2021 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, EUR-PUB; Standardization Mandates: M/396, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13852-3:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2021

Dvigala (žerjavi) - Dvigala na plavajočih objektih - 3. del: Lahka dvigala na

plavajočih objektih

Cranes - Offshore cranes - Part 3: Light offshore cranes

Krane - Offshore-Krane - Teil 3: Offshore-Krane mit kleiner Kapazität

Appareils de levage à charge suspendue - Grues off-shore - Partie 3 : Grues off-shore

légères (potence off-shore)

Ta slovenski standard je istoveten z: EN 13852-3:2021

ICS:

47.020.40 Dvigalna oprema in oprema Lifting and cargo handling

za pretovor equipment

53.020.20 Dvigala Cranes

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13852-3

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2021

EUROPÄISCHE NORM

ICS 47.020.40; 53.020.20

English Version

Cranes - Offshore cranes - Part 3: Light offshore cranes

Appareils de levage à charge suspendue - Grues off- Krane - Offshore-Krane - Teil 3: Offshore-Krane mit

shore - Partie 3 : Grues off-shore légères (potence off- kleiner Kapazität

shore)

This European Standard was approved by CEN on 8 February 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13852-3:2021 E

worldwide for CEN national Members.

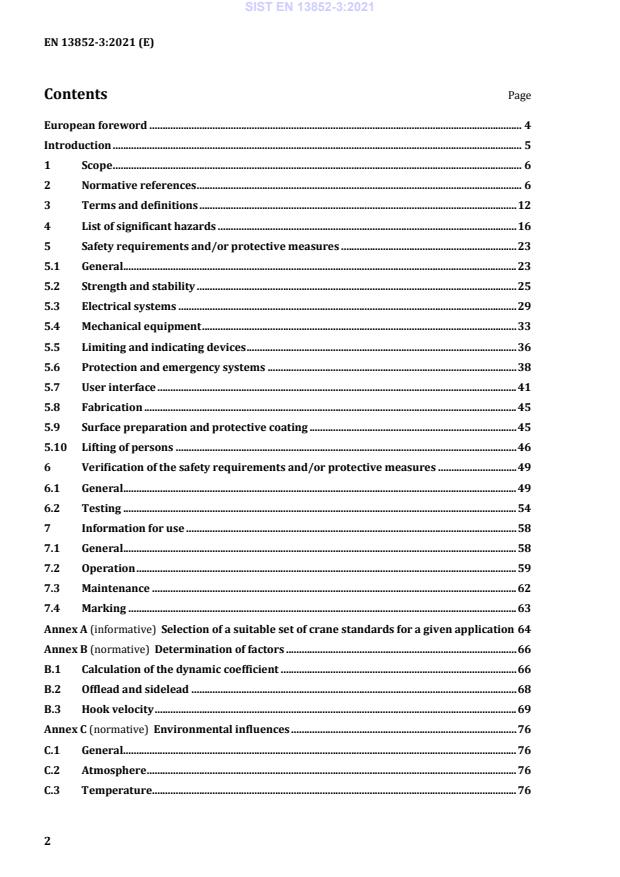

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 12

4 List of significant hazards . 16

5 Safety requirements and/or protective measures . 23

5.1 General . 23

5.2 Strength and stability . 25

5.3 Electrical systems . 29

5.4 Mechanical equipment . 33

5.5 Limiting and indicating devices . 36

5.6 Protection and emergency systems . 38

5.7 User interface . 41

5.8 Fabrication . 45

5.9 Surface preparation and protective coating . 45

5.10 Lifting of persons . 46

6 Verification of the safety requirements and/or protective measures . 49

6.1 General . 49

6.2 Testing . 54

7 Information for use . 58

7.1 General . 58

7.2 Operation . 59

7.3 Maintenance . 62

7.4 Marking . 63

Annex A (informative) Selection of a suitable set of crane standards for a given application 64

Annex B (normative) Determination of factors . 66

B.1 Calculation of the dynamic coefficient . 66

B.2 Offlead and sidelead . 68

B.3 Hook velocity . 69

Annex C (normative) Environmental influences . 76

C.1 General . 76

C.2 Atmosphere . 76

C.3 Temperature . 76

C.4 Wind . 77

C.5 Installation motions. 77

C.6 Ice and snow loads . 79

Annex D (normative) Failure mode analyses . 80

D.1 General . 80

D.2 Failure mode charts . 80

Annex E (normative) Arrangement of controls . 82

E.1 Control station (permanent location) . 82

E.2 Control console (permanent location or remote) . 82

Annex F (normative) Requirements for brakes . 83

Annex G (normative) Ranking of safety functions . 85

Annex H (normative) Safety functions and required performance levels . 86

Annex I (informative) Typical light offshore cranes and their terminology . 87

Annex J (normative) Excursion envelopes . 91

Annex K (normative) Equipment for use in a hazardous area . 92

K.1 General . 92

K.2 Avoidance or reduction of ignition sources . 92

K.3 Electrical equipment . 92

K.4 Non-electrical equipment . 93

K.5 Electrostatic discharge . 93

Annex L (informative) Light offshore crane data sheet . 94

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 102

Annex ZB (informative) Relationship between this European Standard and the Essential

requirements of EU Directive 2014/34/EU . 106

Bibliography . 110

European foreword

This document (EN 13852-3:2021) has been prepared by Technical Committee CEN/TC 147 “Cranes -

safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2021, and conflicting national standards

shall be withdrawn at the latest by September 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and

the European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA or ZB, which are integral parts of this

document.

This document is one part of EN 13852. The parts are the following ones:

— Part 1: General purpose offshore cranes;

— Part 2: Floating cranes;

— Part 3: Light offshore cranes.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey

and the United Kingdom.

Introduction

This document is a type C standard as defined in EN ISO 12100.

This document has been prepared to provide one means for light offshore cranes to conform to the

essential health and safety requirements of the Machinery Directive.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered and are indicated in the scope of this document (see Clause 1).

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type C

standard.

1 Scope

This document applies to light offshore cranes including their supporting pedestals and structures.

NOTE Supporting pedestal and structures such as columns and boom rests, are covered by this document

to the extent where their main purpose is to support the crane.

This document is applicable to light offshore cranes, whose structures are made of steel, and fulfil all

of the following characteristics:

— maximum rated capacity 15 tonnes or maximum static load moment 3 000 kNm;

— limitation for off-board lifting operation up to H = 2,0 m and wind speed 15 m/s (3 s gust);

s

— maximum number of working cycles class U (C ≤ 3,15 × 10 ) according to EN 13001-1.

This document provides requirements for all significant hazards, hazardous situations and events

relevant to light offshore cranes for lifting of goods and lifting of persons, when used as intended and

under conditions foreseen by the risk assessment (see Clause 4).

This document is applicable to light offshore cranes, which are manufactured after the date of approval

by CEN of this document.

This document is not applicable for:

a) transportation, assembly, disabling, scrapping, installation or erecting of the crane;

b) any item attached to the hook, such as loads, non-fixed load lifting attachments, lifting accessories,

baskets, carriers and containers;

c) lifting operations in ambient temperatures below −20 °C;

d) lifting operations in ambient temperatures above 45 °C;

e) lifting operations involving more than one crane;

f) accidental loads as result of collisions, earthquakes, explosions, etc., which are not covered by

exceptional loads defined in Table B.7;

g) emergency personnel rescue operations (except training);

h) subsea lifting operations;

i) general purpose offshore cranes (covered by EN 13852-1), floating cranes and motion

compensated cranes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology

and general principles

EN 614-2:2000+A1:2008, Safety of machinery — Ergonomic design principles — Part 2: Interactions

between the design of machinery and work tasks

EN 795:2012, Personal fall protection equipment — Anchor devices

EN 842:1996+A1:2008, Safety of machinery — Visual danger signals — General requirements, design

and testing

EN 894-1:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 1: General principles for human interactions with displays and control

actuators

EN 894-2:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 2: Displays

EN 894-3:2000+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 3: Control actuators

EN 1127-1:2019, Explosive atmospheres — Explosion prevention and protection — Part 1: Basic

concepts and methodology

EN 1837:2020, Safety of machinery — Integral lighting of machines

EN 10204:2004, Metallic products — Types of inspection documents

EN 12077-2:1998+A1:2008, Cranes safety — Requirements for health and safety — Part 2: Limiting and

indicating devices

EN 12385-1:2002+A1:2008, Steel wire ropes — Safety — Part 1: General requirements

EN 12385-2:2002+A1:2008, Steel wire ropes — Safety — Part 2: Definitions, designation and

classification

EN 12385-3:2020, Steel wire ropes — Safety — Part 3: Information for use and maintenance

EN 12385-4:2002+A1:2008, Steel wire ropes — Safety — Part 4: Stranded ropes for general lifting

applications

EN 12464-2:2014, Light and lighting — Lighting of work places — Part 2: Outdoor work places

EN 12644-1:2001+A1:2008, Cranes — Information for use and testing — Part 1: Instructions

EN 12644-2:2000+A1:2008, Cranes — Information for use and testing — Part 2: Marking

EN 13001-1:2015, Cranes — General design — Part 1: General principles and requirements

EN 13001-2:2014, Crane safety — General design — Part 2: Load actions

EN 13001-3-1:2012+A2:2018, Cranes — General design — Part 3-1: Limit states and proof of

competence of steel structure

EN 13001-3-2:2014, Cranes — General design — Part 3-2: Limit states and proof of competence of wire

ropes in reeving systems

EN 13001-3-3:2014, Cranes — General design — Part 3-3: Limit states and proof of competence of

wheel/rail contacts

EN 13001-3-4:2018, Cranes — General design — Part 3-4: Limit states and proof of competence of

machinery bearings

EN 13001-3-5:2016, Cranes — General design — Part 3-5: Limit states and proof of competence of forged

hooks

EN 13001-3-6:2018, Cranes — General design — Part 3-6: Limit states and proof of competence of

machinery — Hydraulic cylinders

EN 13135:2013+A1:2018, Cranes — Safety — Design — Requirements for equipment

EN 13557:2003+A2:2008, Cranes — Controls and control stations

EN 13586:2020, Cranes — Access

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 14118:2018, Safety of machinery — Prevention of unexpected start-up (ISO 14118:2017)

EN 14502-1:2010, Cranes — Equipment for the lifting of persons — Part 1: Suspended baskets

EN IEC 60079-0:2018, Explosive atmospheres — Part 0: Equipment — General requirements

(IEC 60079-0:2017)

EN 60079-1:2014, Explosive atmospheres — Part 1: Equipment protection by flameproof enclosures “d”

(IEC 60079-1:2014)

EN 60079-2:2014, Explosive atmospheres — Part 2: Equipment protection by pressurized enclosure “p”

(IEC 60079-2:2014)

EN 60079-5:2015, Explosive atmospheres — Part 5: Equipment protection by powder filling “q”

(IEC 60079-5:2015)

EN 60079-6:2015, Explosive atmospheres — Part 6: Equipment protection by liquid immersion “o”

(IEC 60079-6:2015)

EN 60079-7:2015, Explosive atmospheres — Part 7: Equipment protection by increased safety “e”

(IEC 60079-7:2015)

EN 60079-11:2012, Explosive atmospheres — Part 11: Equipment protection by intrinsic safety “i”

(IEC 60079-11:2011)

This document is impacted by EN 60079-1:2014/AC:2018-09.

This document is impacted by EN 60079-7:2015/A1:2018.

EN 60079-14:2014, Explosive atmospheres — Part 14: Electrical installations design, selection and

erection (IEC 60079-14:2013)

EN 60079-18:2015, Explosive atmospheres — Part 18: Equipment protection by encapsulation “m”

(IEC 60079-18:2014)

EN 60079-25:2010, Explosive atmospheres — Part 25: Intrinsically safe electrical systems

(IEC 60079-25:2010)

EN 60204-32:2008, Safety of machinery — Electrical equipment of machines — Part 32: Requirements

for hoisting machines (IEC 60204-32:2008)

EN IEC 61000-6-2:2019, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards —

Immunity for industrial environments (IEC 61000-6-2:2016)

EN IEC 61000-6-4:2019, Electromagnetic compatibility (EMC) — Part 6-4: Generic standards —

Emission standard for industrial environments (IEC 61000-6-4:2018)

EN ISO 898-1:2013, Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1:

Bolts, screws and studs with specified property classes — Coarse thread and fine pitch thread

(ISO 898-1:2013)

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744:2010)

EN ISO 3834-1:2005, Quality requirements for fusion welding of metallic materials — Part 1: Criteria for

the selection of the appropriate level of quality requirements (ISO 3834-1:2005)

EN ISO 3834-2:2005, Quality requirements for fusion welding of metallic materials — Part 2:

Comprehensive quality requirements (ISO 3834-2:2005)

EN ISO 3834-3:2005, Quality requirements for fusion welding of metallic materials — Part 3: Standard

quality requirements (ISO 3834-3:2005)

EN ISO 4413:2010, Hydraulic fluid power — General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 4414:2010, Pneumatic fluid power — General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 7731:2008, Ergonomics — Danger signals for public and work areas — Auditory danger signals

(ISO 7731:2003)

This document is impacted by EN 60079-18:2010/A1:2017 and EN 60079-18:2010/AC:2018-09.

This document is impacted by EN 60079-25:2010/AC:2013.

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of

emission sound pressure levels at a work station and at other specified positions in an essentially free field

over a reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery — Emergency stop function — Principles for design

(ISO 13850:2015)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

EN ISO 15614-1:2017, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

(ISO 15614-1:2017, Corrected version 2017-10-01)

EN ISO 15614-11:2002, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 11: Electron and laser beam welding (ISO 15614-11:2002)

EN ISO 15614-12:2014, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 12: Spot, seam and projection welding (ISO 15614-12:2014)

EN ISO 15614-13:2012, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 13: Upset (resistance butt) and flash welding (ISO 15614-13:2012)

EN ISO 19353:2019, Safety of machinery — Fire prevention and fire protection (ISO 19353:2019)

EN ISO 80079-36:2016, Explosive atmospheres — Part 36: Non-electrical equipment for explosive

atmospheres — Basic method and requirements (ISO 80079-36:2016)

EN ISO 80079-37:2016, Explosive atmospheres — Part 37: Non-electrical equipment for explosive

atmospheres — Non-electrical type of protection constructional safety “c”, control of ignition sources “b”,

liquid immersion “k” (ISO 80079-37:2016)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for

visual, acoustic and tactile signals (IEC 61310-1:2007)

EN 61310-2:2008, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for

marking (IEC 61310-2:2007)

As impacted by EN60529:1991/AC:2006-12, EN60529:1991/A1:2000, EN60529:1991/A2:2013 and

EN60529:1991/A2:2013/AC:2019-02.

EN 61310-3:2008, Safety of machinery — Indication, marking and actuation — Part 3: Requirements for

the location and operation of actuators (IEC 61310-3:2007)

ISO 3864-1:2011, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for

safety signs and safety markings

ISO 3864-2:2016, Graphical symbols — Safety colours and safety signs — Part 2: Design principles for

product safety labels

ISO 3864-3:2012, Graphical symbols — Safety colours and safety signs — Part 3: Design principles for

graphical symbols for use in safety signs

ISO 3864-4:2011, Graphical symbols — Safety colours and safety signs — Part 4: Colorimetric and

photometric properties of safety sign materials

ISO 5817:2014, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections

ISO 7010:2019, Graphical symbols — Safety colours and safety signs — Registered safety signs

ISO 9927-1:2013, Cranes — Inspections — Part 1: General

ISO 12478-1:1997, Cranes — Maintenance manual — Part 1: General

ISO 12480-1:1997, Cranes — Safe use — Part 1: General

ISO 12482:2014, Cranes — Monitoring for crane design working period

EN ISO 12944-1:2017, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 1: General introduction (ISO 12944-1:2017)

EN ISO 12944-2:2017, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 2: Classification of environments (ISO 12944-2:2017)

EN ISO 12944-3:2017, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 3: Design considerations (ISO 12944-3:2017)

EN ISO 12944-4:2017, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 4: Types of surface and surface preparation (ISO 12944-4:2017)

EN ISO 12944-5:2019, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 5: Protective paint systems (ISO 12944-5:2019)

EN ISO 12944-6:2018, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 6: Laboratory performance test methods (ISO 12944-6:2018)

EN ISO 12944-7:2017, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 7: Execution and supervision of paint work (ISO 12944-7:2017)

EN ISO 12944-8:2017, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 8: Development of specifications for new work and maintenance (ISO 12944-

8:2017)

EN ISO 12944-9:2018, Paints and varnishes — Corrosion protection of steel structures by protective

paint systems — Part 9: Protective paint systems and laboratory performance test methods for offshore

and related structures (ISO 12944-9:2018)

ISO 17635:2016, Non-destructive testing of welds — General rules for metallic materials

ISO 20332:2016, Cranes — Proof of competence of steel structures

ISO 23815-1:2007, Cranes —Maintenance — Part 1: General

3 Terms and definitions

For the purposes of this document, the terms and definitions in EN ISO 12100 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following locations:

— IEC Electropedia: available at http://www.electropedia.org

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

actual hook load

total static weight of the load including any equipment placed between the load and the hook

3.2

automatic overload protection system

AOPS

system that automatically safeguards and protects the crane during overload in off-board lifts by

allowing the hook to be pulled away from the crane, without causing significant damage to the crane

3.3

component

single part or assembly of parts of a crane, which is subjected to load effects

Note 1 to entry: Examples of components are wire ropes, pendant bars, rope sheaves, axles, gears, couplings,

brakes, hoists, hydraulic cylinders, shafts, shackles, swivels and pins.

3.4

primary component

component (usually in the main load path) which is essential for the mechanical and structural

integrity of the crane

Note 1 to entry: Examples of primary components are boom section, slewing bearing, hoist rope and hook.

3.5

secondary component

component that is not a primary component

Note 1 to entry: Examples of secondary components are walkways and their supports.

3.6

crane stiffness

value representing the rigidity of the crane in terms of a vertical force applied at the hook divided by

the resulting vertical deflection at the hook

3.7

dynamic coefficient

ɸ

2n

ratio between the maximum dynamic load at the hook and the actual hook load for any given

configuration or operating condition

3.8

emergency operation system

EOS

back-up system for limited operation of the crane, if the normal system of operation is out-of-service

3.9

folding

motion to fold or unfold a knuckle boom assembly

3.10

light offshore crane

smaller, low class working cycle, offshore crane for sporadic use and long inactive periods without

attendance or maintenance

3.11

hazardous area

area in which an explosive gas atmosphere is present or may be expected to be present, in quantities

such as to require special precautions for the construction, installation and use of the equipment

3.12

hoisting

moving the hook in vertical direction

3.13

load chart

diagram or table showing the rated capacity relative to the radius, configuration, environmental

conditions, out of plane influences and type of operation

Note 1 to entry: An example is given in Figure 1 showing rated capacity for off-board lifts to and from the deck

of supply vessels.

Key

X radius

Y rated capacity

R rated capacity for on-board lifts

R rated capacity for off-board lifts in significant wave height H = 1 m

1 s

R rated capacity for off-board lifts in significant wave height H = 2 m

2 s

Figure 1 — Load chart

3.14

luffing

motion where the boom is raised or lowered

3.15

emergency load lowering

ELL

system activated by the crane operator, to lower the load down to the load supporting deck to avoid

hazardous situations

3.16

off-board lift

lifting operation between the offshore installation and a floating unit or the sea surface

3.17

offlead load

horizontal load at the boom tip caused by a radial displacement of the hook

3.18

offshore crane

crane mounted on an offshore installation and used for on-board and off-board lifts

3.19

offshore installation

structure supported by the seabed or floating unit, exposed to an offshore marine environment

3.20

on-board lift

lifting operation within the physical boundaries of the offshore installation where the crane is installed

3.21

overload

condition where the actual hook load exceeds the rated capacity for on-board lift

3.22

lifting of persons

lifting operation where persons are moved by the crane from one location to another using equipment

attached to the crane hook

3.23

radius

horizontal distance between the crane vertical axis of slewing and a vertical line through the hook

when there is no offlead or sidelead

3.24

rated capacity

R , R or R

0 n p

maximum actual hook load that the crane is designed to lift for a given operational condition (e.g. lifting

mode, reeving arrangement, radius, significant wave height, wind, heel/trim)

Note 1 to entry: Rated capacity R refers to on-board lifts, R refers to off-board lift and R refers to lifting of

0 n p

persons. Rated capacity corresponds to hoist load as defined in EN 13001-2 and Safe Working Load (SWL) as

used by ILO conventions.

3.25

rated capacity limiter

RCL

device or system that automatically safeguards and protects the crane against overload during on-

board lifts and lifting of persons

3.26

sidelead load

horizontal load at the boom tip caused by the tangential displacement of the hook

3.27

failure load

calculated overload at the hook that causes the most probable first loss of the load carrying capacity of

a primary component

Note 1 to entry: Examples of failure loads:

a) result in components exceeding their yield strength, e.g. by forming partly plastic cross-sections;

b) result in components exceeding their ultimate tensile strength or minimum breaking loads, e.g. wire

ropes;

c) result in immediate buckling of any component;

d) cause mechanical components to fail to fulfil their primary function, e.g. torque transmitting

components.

3.28

significant wave height

H

s

average height of the highest one third of the individual wave heights in a shortterm constant state of

sea, typically 3 h

3.29

slewing

motion where the crane is rotating about its vertical axis

3.30

telescoping

motion where the boom is extended or retracted

3.31

travelling

motion where the wire rope suspension for the hook is moved along the boom

3.32

davit type offshore crane

light offshore crane with a maximum rated capacity up to 2 tonne and a fixed working radius up to 7 m

3.33

emergency shutdown

ESD

safety system on an offshore installation which limits or prevents abnormal events to develop into a

major accident

3.34

significant damage

state of loading that represents 80 % of the failure load

3.35

user

organization (owner, operator, buyer) which owns and utilizes the crane

4 List of significant hazards

Table 1 contains all the significant hazards, hazardous situations and events, as far as they are dealt

with by this document, identified as significant for this type of machinery, and which require action to

eliminate or reduce the risk.

The significant hazards are based upon EN ISO 12100. Also shown are the sub clause references to the

safety requirements and/or protective measures in this document.

A risk assessment of each light offshore crane design shall be carried out by the manufacturer to check

that the hazards identified Table 1 and any other relevant hazards not identified in Table 1 are dealt

with. Any significant hazards identified as a result of the risk assessment in addition to the generic

hazards as given in Table 1, shall be taken into consideration.

Table 1 — List of significant hazards, hazardous situations, hazardous events, their relation to

the Essential Requirements of the Machinery Directive 2006/42/EC, and associated

requirements in this document

Group Significant hazard in Directive 2006/42/EC, Associated

accordance with Annex I requirements in this

EN ISO 12100:2010, Table B.1 document

1 Mechanical hazards

1.1 Due to machine parts or 1.3.3 Risks due to falling or 5.2.8, 5.4.1, 5.7.12,

workpieces, e.g. ejected objects 5.8, 5.9

— by potential energy (falling

objects, height from the ground,

gravity)

— by kinetic energy 1.3.7 Risks related to 5.2.8, 5.7.9.2, 5.8, 5.9

(acceleration, deceleration, moving parts

moving/rotating elements)

— by mechanical strength 1.1.3 Materials and 5.2, 5.4, 5.8, 5.9

(break-up) products

1.3.2 Risk of break-up

during operation

1.2 by stored energy, e.g.: 1.3.9 Risks of uncontrolled 5.1.4, 5.4.8, 5.4.9

movements

— elastic elements (springs)

1.5.3 Energy supply other

than electricity

1.6.3 Isolation of energy

sources

1.3 Crushing 1.3 Protection against 5.7.9.2

mechanical hazards

Group Significant hazard in Directive 2006/42/EC, Associated

accordance with Annex I requirements in this

EN ISO 12100:2010, Table B.1

document

1.4 Shearing 1.3 Protection against 5.7.9.2

mechanical hazards

1.5 Cutting or severing 1.3.4 Risks due to surfaces, 5.7.1, 5.7.9

edges or angles

1.6 Entanglement 1.3 Protection against 5.7.1, 5.7.9

mechanical hazards

1.7 Drawing-in or trapping 1.3 Protection against 5.7.1, 5.7.9

mechanical hazards

1.8 Impact 1.3 Protection against 5.7.1, 5.7.9

mechanical hazards

1.9 Stabbing or puncture 1.3 Protection against 5.7.1, 5.7.9

mechanical hazards

1.10 Friction or abrasion 1.3.4 Risks due to surfaces, 5.7.1, 5.7.9

edges or angles

1.11 Injection 1.3.2 Risk of break-up 5.7.1, 5.7.9

during operation

1.12 Slipping, tripping and falling 1.5.15 Risk of slipping, 5.7.5

tripping or falling

1.13 Instability 1.1.5 Design of machinery 5.1.3

to facilitate its

handling

1.3.1 Risk of loss of

stability

2 Electrical hazards

2.1 Touching live parts 1.5.1 Electricity supply 5.3.1

1.6.3 Isolation of energy

sources

2.2 Parts which have become live 1.5.1 Electricity supply 5.3.1

under fault conditions

2.3 Not enough distance to live 1.5.1 Electricity supply 5.3.1

parts under high voltage

1.6.3 Isolation of energy

sources

2.4 Electrostatic phenomena 1.5.2 Static electricity 5.3.1

2.5 Electromagnetic phenomena 1.2.1 Safety and reliability 5.3.2.6

of control systems

2.7 Short-circuit 1.5.1 Electricity supply 5.3.1

2.8 Overload 1.5.1 Electricity supply 5.1.4

2.9 Thermal radiation 1.5.1 Electricity supply 5.1.4

Group Significant hazard in Directive 2006/42/EC, Associated

accordance with Annex I requirements in this

EN ISO 12100:2010, Table B.1

document

3 Thermal hazards

3.1 Burn, scald 1.5.5 Extreme 5.7.10

temperatures

1.5.6 Fire

1.5.7 Explosion

4 Noise hazards

4.1 Permanent hearing loss, tinnitus 1.5.8 Noise 5.7.8

6.2.4

6 Radiation hazards

6.2 Radio frequency 1.5.10 Radiation 5.3.2.6

electromagnetic radiation

1.5.11 External radiation

7 Material/ substance hazards

7.1 Hazards from contact with 1.1.3 Materials and 5.7.1

inhalation of harmful fluids, products

gases, mists, fumes and dusts

1.5.13 Emissions of

hazardous materials

and substances

1.6.5 Cleaning of internal

parts

7.2 Fire 1.5.6 Fire 5.6.5

7.3 Explosion 1.5.7 Explosion 5.3.4, 5.6.5

8 Ergonomic hazards

8.1 Unhealthy postures or excessive 1.1.5 Design of machinery 5.7.13.3, 5.7.1

effort to facilitate its

handling

1.1.6 Ergonomics

8.3 Insufficient means for 1.1.7 Operating positions 5.7.5

evacuation/emergency exit

8.4 Inadequate local lighting 1.1.4 Lighting 5.7.7

8.5 Design or location of indicators 1.7.1 Information and 5.5.1, 5.7.2

and visual displays units warnings on the

machinery

8.6 Design, location or identification 1.2.2 Control devices 5.7.3

of control devices

Group Significant hazard in Directive 2006/42/EC, Associated

accordance with Annex I requirements in this

EN ISO 12100:2010, Table B.1

document

8.9 Human error during operation 1.1.6 Ergonomics 5.7.1, 5.7.2, 5.7.3,

5.7.4

1.2.1 Safety and reliability

of control systems

Control devices

1.2.5 Selection of control

or operating modes

1.5.4 Errors of fitting

information

9 Hazards associated with the environment in which the machine is used

9.1 Lightning 1.5.16 Lightning 5.3.1

9.2 Moisture 1.1.3 Material and 5.1.3, 5.3.1.4, 5.3.1.5

products

1.2.1 Safety and

reliability of control

systems

1.1.7 Operating positions

9.4 Snow, water, wind, temperature 1.1.3 Material and 5.1.1, 5.1.2, 5.1.3,

products 5.2.8, 5.3.1, 5.3.2

1.2.1 Safety and

reliability of control

systems

1.1.7 Operating positions

10 Combination of hazards

10.1 Failure/disorder of the control 1.2.1 Safety and reliability 5.3.1.8, 5.3.2, 5.6.4

system and control circuits of control systems

1.2.3 Starting

1.2.4 Stopping

1.2.5 Selection of control

or operating modes

1.6.3 Isolation of energy

sources

10.2 Restoration of energy supply 1.2.3 Starting 5.3.2, 5.3.1.8

after an interruption

1.2.6 Failure of the power

supply

10.3 Software error 1.2.1 Safety and reliability 5.3.2.3

of control systems

10.4 Failure of the power supply 1.2.6 Failure of the power 5.3.1.8

supply

Group Significant hazard in Directive 2006/42/EC, Associated

accordance with Annex I requirements in this

EN ISO 12100:2010, Table B.1

document

12 Hazards due to:

assembly and installation

setting

cleaning

fault-finding

maintenance

12.1 Maintenance 1.6.1 Machinery 5.7.13.4

maintenance

12.2 Insufficient means of access 1.6.2 Access to operating 5.7.13.1

during use, setting and positions and

maintenance servicing points

12.3 Cleaning inside the machine 1.6.4 Operator 5.7.13.4

intervention

12.4 Being trapped in a machine 1.5.14 Risk of being 5.7.5

trapped in a machine

17 Hazards linked to work position (including driving station) on the machine

17.1 Fall of persons during access to 3.4.5 Means of access 5.7.5

or at/from the work position

3.4.7 Transmission of

power between self-

propelled machinery

(or tractor) and

recipient machinery

17.2 Fire (lack of extinguishing 3.5.2 Fire 5.6.5

means)

17.3 Mechanical hazards at the 3.2.1 Driving position 5.7.9, 5.7.12

work position, such as:

3.4.3 Roll-over and tip-

contact with the wheels over

rollover and overturning 3.4.5 Means of access

slipping during access 3.4.4 Falling objects

fall of objects, penetration by 3.3.4 Movement of

objects pedestrian-controlled

machinery

contact of persons with machine

parts or tools (pedestrian

controlled machines

17.4 Insufficient visibility from the 3.2.1 Driving position 5.3.2.9

work position

Group Significant hazard in Directive 2006/42/EC, Associated

accordance with Annex I requirements in this

EN ISO 12100:2010, Table B.1

document

18 Hazards due to the control system

18.1 Inadequa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...