ISO 14532:2014

(Main)Natural gas — Vocabulary

Natural gas — Vocabulary

ISO 14532:2014 establishes the terms, definitions, symbols, and abbreviations used in the field of natural gas. The terms and definitions have been reviewed and studied in order to cover all aspects of any particular term with input from other sources such as European Standards from CEN (The European Committee for Standardization), national standards, and existing definitions in the IGU Dictionary of the Gas Industry. The definitive intention of ISO 14532:2014 is to incorporate the reviewed definitions into the ISO/TC 193 source standards.

Gaz naturel — Vocabulaire

L'ISO 14532:2014 a pour objet de donner les définitions, symboles et abréviations utilisés dans le domaine du gaz naturel. Les termes et définitions ont été étudiés et revus de manière à couvrir toutes les acceptations particulières des termes provenant également d'autres sources telles que les normes européennes du CEN (Comité Européen de Normalisation), les normes nationales et les définitions existantes dans le dictionnaire U.I.I.G de l'industrie du gaz. L'intention définitive de ce document est d'intégrer les définitions révisées dans les normes source de l'ISO/TC 193.

General Information

- Status

- Published

- Publication Date

- 11-Jun-2014

- Technical Committee

- ISO/TC 193 - Natural gas

- Drafting Committee

- ISO/TC 193 - Natural gas

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 03-Jul-2023

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 07-May-2011

Overview

ISO 14532:2014, titled Natural Gas - Vocabulary, is an international standard published by ISO that establishes a comprehensive set of terms, definitions, symbols, and abbreviations related to the natural gas industry. This second edition consolidates and harmonizes terminology used across various standards, ensuring consistency and clarity in communication within this vital sector. Developed by ISO/TC 193 and integrating inputs from European and national standards, along with the IGU Dictionary of the Gas Industry, ISO 14532:2014 covers all aspects of natural gas terminology.

This standard is essential for professionals involved in natural gas production, processing, measurement, distribution, and quality management, fostering understanding and interoperability in technical documentation and operations worldwide.

Key Topics

ISO 14532:2014 covers a broad range of specialized vocabulary arranged by industry-related topics:

General Conditions: Definitions of natural gas types such as raw gas, substitute natural gas (SNG), manufactured gas, lean gas, rich gas, wet gas, sour gas, dry gas, compressed natural gas (CNG), liquefied natural gas (LNG), biogas, biomethane, and biomass. This section clarifies gas composition, origin, and energy content distinctions.

Pipeline Network: Terms describing pipeline infrastructure components like pipeline grids, local distribution systems (LDS), custody transfer points, and transfer stations, essential for understanding natural gas transmission and distribution logistics.

Measurement Methods: Definitions related to methods for measuring natural gas properties, including absolute measurement, direct and indirect measurement, relative measurement, and related concepts such as lower and upper range values, and span. Specific measurement techniques like gas chromatography and potentiometric methods provide detailed analysis tools.

Sampling and Analytical Systems: Vocabulary covering sampling approaches and the analytical instruments used for gas analysis ensures clarity in quality determination.

Physical and Chemical Properties: Standardized terms for physical and chemical characteristics of natural gas help unify descriptions across industries.

Interchangeability and Odorization: Definitions related to the suitability of substitute gases for pipeline use and the addition of odorants for safety and detection.

Thermodynamic Properties: Terms related to the energy and thermodynamic behavior of natural gas under different conditions, critical for processing and transportation.

Annexes include comprehensive indices, symbols, units, and a bibliography supporting reference and study.

Applications

ISO 14532:2014 serves as a foundational reference for a variety of practical uses within the natural gas industry:

Standardization of Technical Documentation: Ensures all stakeholders use uniform terminology in manuals, instruction booklets, technical publications, and educational materials.

Quality Management and Compliance: Helps industry professionals comprehend and evaluate gas quality attributes and measurement results accurately.

Training and Education: Provides an authoritative vocabulary for universities, technical colleges, and professional development courses concerning natural gas.

Cross-Border Trade and Operations: Facilitates international collaboration and legal compliance by standardizing language across national and regional natural gas standards.

Product and Process Development: Assists engineers and scientists in clear communication when designing natural gas processing, storage, and transportation systems.

Related Standards

ISO 14532:2014 complements and integrates with other standards and documents relevant to natural gas:

ISO/TC 193 Source Standards: All natural gas-related international standards developed by the ISO Technical Committee 193, covering gas analysis, measurement, and quality.

CEN Standards: European standards harmonizing natural gas terminology and testing methods.

IGU Dictionary of the Gas Industry: An authoritative glossary used in the international gas community.

ISO 18453: Related to water content and dew point in natural gas, referenced for moisture content description.

ISO/IEC Directives: Governing the development and maintenance of international standards, ensuring consistent editorial and procedural rules.

ISO 14532:2014 is a critical tool for fostering clear, uniform communication about natural gas, enhancing safety, efficiency, regulatory compliance, and international cooperation in a globally significant industry. By standardizing terminology spanning general definitions to measurements and thermodynamic properties, this vocabulary standard supports professionals throughout the natural gas value chain.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 14532:2014 is a standard published by the International Organization for Standardization (ISO). Its full title is "Natural gas — Vocabulary". This standard covers: ISO 14532:2014 establishes the terms, definitions, symbols, and abbreviations used in the field of natural gas. The terms and definitions have been reviewed and studied in order to cover all aspects of any particular term with input from other sources such as European Standards from CEN (The European Committee for Standardization), national standards, and existing definitions in the IGU Dictionary of the Gas Industry. The definitive intention of ISO 14532:2014 is to incorporate the reviewed definitions into the ISO/TC 193 source standards.

ISO 14532:2014 establishes the terms, definitions, symbols, and abbreviations used in the field of natural gas. The terms and definitions have been reviewed and studied in order to cover all aspects of any particular term with input from other sources such as European Standards from CEN (The European Committee for Standardization), national standards, and existing definitions in the IGU Dictionary of the Gas Industry. The definitive intention of ISO 14532:2014 is to incorporate the reviewed definitions into the ISO/TC 193 source standards.

ISO 14532:2014 is classified under the following ICS (International Classification for Standards) categories: 01.040.75 - Petroleum and related technologies (Vocabularies); 75.060 - Natural gas. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 14532:2014 has the following relationships with other standards: It is inter standard links to ISO 14532:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 14532:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14532

NORME

Second edition

Deuxième édition

INTERNATIONALE 2014-06-15

Natural gas — Vocabulary

Gaz naturel — Vocabulaire

Reference number

Numéro de référence

©

ISO 2014

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2014

The reproduction of the terms and definitions contained in this International Standard is permitted in teaching manuals, in-

struction booklets, technical publications and journals for strictly educational or implementation purposes. The conditions for

such reproduction are: that no modifications are made to the terms and definitions; that such reproduction is not permitted for

dictionaries or similar publications offered for sale; and that this International Standard is referenced as the source document.

With the sole exceptions noted above, no other part of this publication may be reproduced or utilized otherwise in any form or

by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior writ-

ten permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of the

requester.

La reproduction des termes et des définitions contenus dans la présente Norme internationale est autorisée dans les manuels

d’enseignement, les modes d’emploi, les publications et revues techniques destinés exclusivement à l’enseignement ou à la mise

en application. Les conditions d’une telle reproduction sont les suivantes: aucune modification n’est apportée aux termes et

définitions; la reproduction n’est pas autorisée dans des dictionnaires ou publications similaires destinés à la vente; la présente

Norme internationale est citée comme document source.

À la seule exception mentionnée ci-dessus, aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque

forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie, l’affichage sur l’internet ou sur un

Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent être adressées à l’ISO à l’adresse ci-après ou au

comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland/Publié en Suisse

ii © ISO 2014 – All rights reserved/Tous droits réservés

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Terms and definitions . 1

2.1 General conditions . 1

2.2 Measurement methods . 4

2.3 Sampling . 6

2.4 Analytical systems . 8

2.5 Analysis.11

2.6 Physical and chemical properties .20

2.7 Interchangeability .24

2.8 Odorization .25

2.9 Thermodynamic properties .26

Annex A (informative) Indices, symbols, and units .27

Annex B (informative) Alphabetical index .30

Bibliography .36

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 193, Natural gas.

This second edition cancels and replaces the first edition (ISO 14532:2001/Cor. 1:2002).

iv © ISO 2014 – All rights reserved/Tous droits réservés

Introduction

ISO/TC 193 Natural Gas was established in May, 1989, with the task of creating new standards and

updating existing standards relevant to natural gas. This includes gas analysis, direct measurement of

properties, quality designation, and traceability.

In these activities, a comprehensive and uniform review of the definitions, symbols, and abbreviations

used in the standards was not previously systematically pursued. The development of standards

with terminology created to suit specific purposes often resulted in the detriment of uniformity and

cohesiveness between standards.

Thus, there is the need for a work of harmonization of the terminology used in the standards pertaining

to natural gas. The intention of this International Standard is to incorporate the reviewed definitions

into the ISO/TC 193 source International Standard.

As the aim is to create a coherent body of standards which support each other with regard to their

definitions, common and unambiguous terms and definitions used throughout all International

Standards is the starting point for the understanding and application of every International Standard.

The presentation of this International Standard has been arranged to facilitate its use as follows:

— Major headings pertain to specific fields of the natural gas industry. All definitions that fall under

these headings, as gleaned from ISO International Standards issued through ISO/TC 193, are listed

under that heading. A review of the contents will serve to facilitate finding specific terms.

— Notes are given under numerous definitions where it was deemed important to give informative

guidance for a given definition. The Notes are not considered a part of the definition.

INTERNATIONAL STANDARD ISO 14532:2014(E/F)

Natural gas — Vocabulary

1 Scope

This International Standard establishes the terms, definitions, symbols, and abbreviations used in the

field of natural gas.

The terms and definitions have been reviewed and studied in order to cover all aspects of any particular

term with input from other sources such as European Standards from CEN (The European Committee for

Standardization), national standards, and existing definitions in the IGU Dictionary of the Gas Industry.

The definitive intention of this document is to incorporate the reviewed definitions into the

ISO/TC 193 source standards.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1 General conditions

2.1.1 Natural gas

2.1.1.1

natural gas

NG

complex gaseous mixture of hydrocarbons, primarily methane, but generally includes ethane, propane

and higher hydrocarbons, and some non-combustible gases such as nitrogen and carbon dioxide

Note 1 to entry: Natural gas can also contain components or containments such as sulfur compounds and/or other

chemical species.

2.1.1.2

raw gas

unprocessed gas taken from well heads, through gathering lines, to processing or treating facilities

Note 1 to entry: Raw gas can also be partially processed well-head gas taken from basic upstream processing

,

facilities.

2.1.1.3

substitute natural gas

SNG

gas from non-fossil origin which is interchangeable in its properties with natural gas

2.1.1.4

manufactured gas

synthetic gas

gas which has been treated and can contain components that are not typical of natural gas

Note 1 to entry: Manufactured (synthetic) gases can contain substantial amounts of chemical species that are not

typical of natural gases or common species found in atypical proportions as in the case of wet and sour gases.

Note 2 to entry: Manufactured gases fall into two distinct categories, as follows:

a) those that are intended as synthetic or substitute natural gases, and that closely match true natural gases in

both composition and properties;

b) those that, whether or not intended to replace or enhance natural gas in service, do not closely match natural

gases in composition.

Case b) includes gases such as town gas, coke oven gas (undiluted), and LPG/air mixtures. None of which

is compositionally similar to a true natural gas (even though, in the latter case, it can be operationally

interchangeable with natural gas).

2.1.1.5

lean gas

natural gas having a relatively low energy content, close to or lower than that of pure methane

Note 1 to entry: Lean gas typically contains high amounts of nitrogen and carbon dioxide.

2.1.1.6

rich gas

natural gas having a relatively high energy content, higher than that of pure methane

Note 1 to entry: Rich gas typically contains high amounts of ethane or propane or higher.

2.1.1.7

wet gas

gas which falls short of qualifying as pipeline quality natural gas by the inclusion of undesirable

components such as free water, water vapour and/or high hydrocarbons in such amounts that they can

condense at pipeline conditions

2.1.1.8

sour gas

gas containing significant amount of acid gases such as carbon dioxide and sulphur compounds

Note 1 to entry: The presence of acid compounds is more detrimental in wet gases.

Note 2 to entry: Typically, wet and sour gases can be unprocessed (well head) or partially-processed natural

gases and can also contain condensed hydrocarbons, traces of carbonyl sulphide, and process fluid vapours such

as methanol or glycols.

Note 3 to entry: Carbon dioxide in the presence of free water can be an important cause of corrosion damage to

pipelines.

2.1.1.9

dry natural gas

natural gas containing a mole fraction of water of no more than 0,005 % [50 ppm (molar)] in the vapour

phase

Note 1 to entry: Water vapour content in natural gas can also be expressed in terms of water concentration

(mg/m ).

[17]

Note 2 to entry: The correlation between water content and water dew point is given in ISO 18453.

2.1.1.10

saturated gas

natural gas that at the specified conditions of temperature and pressure is at its water dew-point

2.1.1.11

compressed natural gas

CNG

natural gas that has been compressed after processing for storage and transportation purposes

Note 1 to entry: CNG is mainly used as a fuel for vehicles, typically compressed up to 20 000 kPa in the gaseous

state.

2 © ISO 2014 – All rights reserved/Tous droits réservés

2.1.1.12

liquefied natural gas

LNG

natural gas that has been liquefied after processing for storage or transportation purposes

Note 1 to entry: Liquid natural gas is revaporized and introduced into pipelines for transmission and distribution

as natural gas.

2.1.1.13

gas quality

attribute of natural gas defined by its composition and its physical properties

2.1.1.14

biogas

generic term used to refer to gases produced by anaerobic fermentation or digestion of organic matter,

and without further upgrading nor purification

Note 1 to entry: This can take place in a landfill site to produce landfill gas or in an anaerobic digester to produce

biogas. Sewage gas is biogas produced by the digestion of sewage sludge. Biogases comprise mainly methane and

carbon dioxide.

2.1.1.15

biomethane

methane rich gas derived from biogas or from gasification of biomass by upgrading with the properties

similar to natural gas

2.1.1.16

biomass

mass defined from a scientific and technical point of view as material of biological origin excluding

material embedded in geological formations and/or transformed to fossil

Note 1 to entry: Biomass is organic material that is plant-based or animal-based, including but not limited to

dedicated energy crops, agricultural crops and trees, food, feed and fibre crop residues, aquatic plants, alga,

forestry and wood residues, agricultural wastes, processing by-products and other non-fossil organic matter.

Note 2 to entry: See also herbaceous biomass, fruit biomass, and woody biomass.

2.1.2 Pipeline network

2.1.2.1

pipeline grid

system of interconnected pipelines, both national and international that serve to transmit and distribute

natural gas

2.1.2.2

local distribution system

LDS

gas mains and services that supply natural gas directly to consumers

2.1.2.3

custody transfer point

location between two pipeline systems where the quantity of energy of the natural gas has to be

accounted for

Note 1 to entry: At such location a change of pressure regime can also occur.

2.1.2.4

transfer station

system of pipelines, measurement and regulation (pressure control), and ancillary devices at a custody

transfer point necessary to account for the quantity of gases transferred and the adaptation to the

possible different pressure regimes of the networks

2.2 Measurement methods

2.2.1 General definitions

2.2.1.1

absolute measurement

measurement of a property from fundamental metrological quantities

Note 1 to entry: For example, fundamental metrological quantities are length, mass, and time.

Note 2 to entry: For example, the determination of the mass of a gas using certified masses.

2.2.1.2

direct measurement

measurement of a property from quantities that, in principle, define the property

Note 1 to entry: For example, the determination of the calorific value of a gas using the thermometric measurement

of the energy released in the form of heat during the combustion of a known amount of gas.

2.2.1.3

indirect measurement

measurement of a property from quantities that, in principle, do not define the property, but have a

known relationship with the property

Note 1 to entry: For example, the determination of the calorific value from measurements of the air-to-gas ratio

required to achieve stoichiometric combustion that is related linearly to the calorific value.

2.2.1.4

lower range value

lowest value of a quantity to be measured (measurand) that a measuring system or transmitter is

adjusted to measure

2.2.1.5

upper range value

highest value of a quantity to be measured(measurand) that a measuring system or transmitter is

adjusted to measure

2.2.1.6

span

algebraic difference between the upper and lower range values

2.2.1.7

relative measurement

measurement of a property by means of comparison with a value of the property taken from an accepted

standard, for example, reference material

Note 1 to entry: For example, determining gas density from the quotient of the mass of gas contained in a given

volume to that of air contained in the same volume at the same temperature and pressure, and multiplying by the

density of air at that temperature and pressure.

2.2.2 Specific methods

2.2.2.1

gas chromatographic method

method of analysis by which the components of a gas mixture are separated using gas chromatography

Note 1 to entry: The sample is passed in a stream of carrier gas through a column that has different retention

properties relative to the components of interest. Different components pass through the column at different

rates and are detected as they elute from the column at different times.

4 © ISO 2014 – All rights reserved/Tous droits réservés

2.2.2.2

potentiometric method

method of analysis by which a known quantity of gas is first passed through a solution, where a specific

gas component or a group of components is (are) selectively absorbed, then the absorbed analyte(s) in

the solution is (are) evaluated by potentiometric titration

Note 1 to entry: The result is a titration curve showing the potentiometric end points for the components being

sought versus the titration solutions required. From this data, the concentrations of the various components can

be calculated.

2.2.2.3

potentiometric titration

method where the amount of titrant consumed for reaction of the gas component with the titrant is

proportional to the gas component concentration, and the endpoint of reaction is determined by the

variation of potential inside the cell

Note 1 to entry: The volume increments of titrant (titration solution) added determine the difference in potential

to be measured. Different volume increments of titrant, specifically smaller volume increments close to end

points, can permit a better evaluation of the end points.

2.2.2.4

turbidimetric titration

method to determine the content of sulfate ions whereby a barium salt solution is added to an absorption

solution and the turbidity caused by the formation of any insoluble barium sulfate detected

Note 1 to entry: This method is valid for solutions having a total sulfur content below 0,1 mg.

Note 2 to entry: A photometer with galvanometer readout is employed with the titration procedure to determine

the inflection point. From these data, the total sulfur content in mg/m can be calculated.

2.2.2.5

combustion method

method by which a gas sample undergoes total combustion and the specific combustion products are

measured to determine the total concentration of an element in the sample, e.g. sulfur

Note 1 to entry: Wickbold method: the Wickbold combustion method uses the combustion and complete thermal

decomposition of compounds at a high temperature in a hydrogen/oxygen flame. It is performed with a special

[2]

instrument (see ISO 4260 ).

Note 2 to entry: Lingener method: the Lingener combustion method uses air, and it is performed using a special

[8]

instrument (see ISO 6326-5 ).

2.2.2.6

absorption

extraction of one or more components from a mixture of gases when brought into contact with a liquid

Note 1 to entry: The assimilation or extraction process causes (or is accompanied by) a physical or chemical

change, or both, in the sorbent material.

Note 2 to entry: The gaseous components are retained by capillary, osmotic, chemical, or solvent action.

EXAMPLE Removal of water from natural gas using glycol.

2.2.2.7

adsorption

retention, by physical or chemical forces of gas molecules, dissolved substances, or liquids by the surfaces

of solids or liquids with which they are in contact

Note 1 to entry: For example, retention of methane by carbon.

2.2.2.8

desorption

removal of a sorbed substance by the reverse process of adsorption or absorption

2.3 Sampling

2.3.1 Sampling methods

2.3.1.1

direct sampling

sampling in situations where there is a direct connection between the natural gas to be sampled and the

analytical unit

2.3.1.2

indirect sampling

sampling in situations where there is no direct connection between the natural gas to be sampled and

the analytical unit

2.3.1.3

in-line instrument

instrument whose active element is installed inside the pipeline and makes measurements under

pipeline conditions

2.3.1.4

on-line instrument

instrument that samples gas directly from the pipeline, but is installed externally to the pipeline

2.3.1.5

off-line instrument

instrument that has no direct connection to the pipeline

2.3.1.6

spot sample

sample of specified volume taken at a specified place at a specified time from a stream of gas

2.3.2 Sampling devices

2.3.2.1

floating piston cylinder

container that has a moving piston separating the sample from a buffer gas. The pressures are in balance

on both sides of the piston

2.3.2.2

incremental sampler

sampler that accumulates a series of spot samples into one composite sample

2.3.2.3

flow-proportional incremental sampler

sampler that collects a series of spot samples over a period of time with the spot samples taken in such a

manner as to ensure the incremental sample is proportional to the incremental totalised flow

Note 1 to entry: This is normally achieved by varying the frequency of extraction of a constant volume spot sample

(grab).

2.3.2.4

sample container

container that is used to collect a representative sample and maintain the sample in a representative

condition

Note 1 to entry: The sample container should not alter the gas composition in any way or affect the proper

collection of the gas sample. The materials, valves, seals, and other components of the sample container shall be

specified to maintain this principle.

6 © ISO 2014 – All rights reserved/Tous droits réservés

2.3.2.5

sample line

conduit to transfer a sample of gas from the sample place to the analytical unit or sample container

Note 1 to entry: Another word used for sample line is transfer line.

2.3.2.6

sample probe

device inserted into the gas pipeline so that a representative sample of the flowing gas can be taken.

The sample probe will have a conduit to convey the sample from the flowing gas to a point external to

the pipeline

2.3.2.7

hot loop

sampling configuration that returns the sample to the pipeline

Note 1 to entry: The loop requires a pressure differential from collection point to discharge so as to ensure a

constant and steady flowrate through the sampling equipment located in the loop.

2.3.2.8

vent line

section of the sampling system that diverts a portion of the sampled gas away from the analyser/instrument

or sample container

Note 1 to entry: The flowrate and pressure loss in the open-ended line need to be controlled so as to ensure that

sample accuracy cannot be affected from any cooling and condensation.

2.3.2.9

fast loop

sampling system that takes more sample from the process than is needed to make the measurement so

as to reduce the residence time

2.3.3 Conditioning device

2.3.3.1

condenser

apparatus used to transform the condensable fraction (consisting of water vapour and/or of the higher

hydrocarbons) of the vapour phase present in natural gas into a liquid phase by cooling

2.3.3.2

liquid separator

unit, in the sample line, used to collect liquid fall-out

2.3.3.3

pressure reducer

device used to reduce gas pressure immediately downstream of its installed position

Note 1 to entry: It has the ability to maintain a near constant outlet pressure within its design parameters

regardless of changes in pressure or flow in other parts of the system.

2.3.3.4

back-pressure regulator

device used to control/maintain gas pressure immediately upstream of its installed position

Note 1 to entry: It has the ability to maintain a near constant inlet pressure within design parameters, regardless

of pressure or flow fluctuations in other parts of the system.

2.3.3.5

heating device

device to ensure that the sample gas remains at a temperature sufficient to avoid a change of its

composition due to condensation of some compounds

Note 1 to entry: Heating elements can be installed on the sample probe and sample lines. In some cases, heating

the sample cylinder is also required. It is particularly important where Joule-Thomson cooling occurs as a result

of pressure reduction.

Note 2 to entry: Heating devices are also used to maintain “wetted surface areas” at near constant temperatures to

avoid changes in gas sorption coefficients when measuring components that are prone to strong sorption effects.

2.3.4 Other definitions

2.3.4.1

purging time

residence time plus the time to insure that the sample in the sampling system is representative of the

gas stream

Note 1 to entry: The purging time can be much longer than the residence time and will be multiples of the residence

time in poorly designed sampling systems.

2.3.4.2

representative sample

sample having the same composition as the natural gas sample when the latter is considered as a

homogeneous whole

2.3.4.3

residence time

time it takes for a sample to flow through a piece of equipment

2.3.4.4

sampling point

point in the gas stream or vessel where a representative sample can be taken

2.3.4.5

sampling place

location of a sampling point along a stream, or the location of the vessel

2.3.4.6

gas sorption effects

physical processes whereby some gases are adsorbed onto or desorbed from the surfaces of a solid

without transformation of the molecules

Note 1 to entry: The force of attraction between some gases and solids is purely physical and depends on the

nature of the participating material. Natural gas can contain several components that exhibit strong sorption

effects. Special care should be taken when determining trace concentrations of heavy hydrocarbons, water, sulfur

compounds, and hydrogen.

2.4 Analytical systems

2.4.1

measuring system

complete set of measuring instruments and other equipment assembled to carry out specified

measurements

Note 1 to entry: System comprising, in general, a sample transfer and introduction unit, a separation unit, a

detector and an integrator or a data processing system.

8 © ISO 2014 – All rights reserved/Tous droits réservés

2.4.2

introduction unit

unit for introducing a constant, or a measured amount of material to be analysed into the analyser

Note 1 to entry: Gas chromatographic analysers are comparative rather than absolute. Therefore, the introduction

of equal quantities of a calibration mixture and of sample allows quantitative measurement of sample components.

Note 2 to entry: In gas analysis, the introduction device is frequently a multi-port valve, in which a fixed volume

of a calibration mixture or sample is isolated, and by operation of the valve, passed into the analyser.

Note 3 to entry: Equimolar quantities can be obtained by controlling the pressure and temperature of the

introduction device.

2.4.3

gas chromatograph

device that physically separates components of a mixture in the gaseous phase and measures them

individually with a detector whose signal is processed

Note 1 to entry: A chromatograph consists of the following main parts: an introduction unit, a separation unit,

and a detector. The separation unit consists of one or more chromatographic columns through which carrier gas

flows and into which samples are introduced. Under defined and controlled operating conditions, components

can be qualitatively identified by their retention time, and quantitatively measured by comparing their detector

response to that of the same or a similar component in a calibration mixture.

Note 2 to entry: In gas analysis, the range of components and their properties frequently cause more than

one separation mechanism to be required. These can be and often are combined in a single separation unit or

chromatograph.

Note 3 to entry: A gas chromatograph capable of temperature programming is a chromatograph whose columns

are placed in an oven whose temperature is programmable in a defined and repeatable manner over the period

of analysis.

2.4.4

carrier gas

pure gas introduced so as to transport a sample through the separation unit of a gas chromatograph for

analytical purposes

Note 1 to entry: Typical carrier gases are hydrogen, nitrogen, helium, and argon.

2.4.5

auxiliary gases

gases required for detector operation, e.g. hydrogen and air for flame detectors

2.4.6

chemiluminescence detector

CD

detector that uses a reducing reaction in which molecules give rise to characteristic luminous emissions

that are measured by a photomultiplier and the associated electronic devices

Note 1 to entry: A chemiluminescence detector is used in gas chromatography mainly to detect components that

contain particular elements, e.g. nitrogen (N) and sulfur (S).

2.4.7

electrochemical detector

ED

detector consisting of an electrochemical cell that responds to certain substances contained in the

carrier gas eluting from the column

Note 1 to entry: The electrochemical process can be an oxidation, reduction, or a change in conductivity. The

detection can be very specific depending on the electrochemical process involved.

2.4.8

flame ionization detector

FID

detector in which hydrocarbons are burned in a hydrogen-air flame and the electrical current caused by

the resulting ions is measured between two electrodes

Note 1 to entry: The flame ionization detector is used in gas chromatography mainly to detect hydrocarbon

compounds.

2.4.9

thermal conductivity detector (TCD)

hot wire detector (HWD)

detector that measures the difference in thermal conductivity between two gas streams when a sample

(gas mixture) passes through the sample channel

Note 1 to entry: The HWD is a dual channel detector, requiring a reference flow of pure carrier gas through the

reference channel.

Note 2 to entry: The use of helium or hydrogen is recommended as carrier gas except when the sample contains

either of these two substances to be measured.

Note 3 to entry: The detector consists of a bridge circuit; the change in resistance in the sample channel during the

passage of the sample produces an out-of-balance signal that is the basis of the detection. The detector responds

to all components except the carrier gas and it is non-destructive.

2.4.10

flame photometric detector

FPD

detector that uses a reducing flame in which individual elements give rise to characteristic colours that

are measured by a photomultiplier

Note 1 to entry: The detector is used in gas chromatography mainly to detect components that contain particular

elements, e.g. phosphorous (P) and sulfur (S).

2.4.11

integrator

device that quantitatively measures the response signal of a detector to a component in a mixture

Note 1 to entry: By comparing the integrator output to the same component in a calibration mixture and in a

sample, the concentration in the sample can be calculated. If the detector response has a temporal dimension, as

in chromatography, then the instantaneous response is integrated with respect to time.

2.4.12

photometry

determination of the concentration of a dissolved substance in a solution by using the absorption of light

by this substance

2.4.13

absorption cell

device put into the light path of the photometer

Note 1 to entry: The lower the concentration of the dissolved substance, the greater path length of the absorption

cell has to be.

10 © ISO 2014 – All rights reserved/Tous droits réservés

2.5 Analysis

2.5.1 Calibration and quality control

2.5.1.1

calibration

operation, that under specified conditions in a first step establishes a relation between the quantity

values with measurement uncertainties provided by measurement standards and corresponding

indications with associated measurement uncertainties and, in a second step uses this information to

establish a relation for obtaining a measurement result from an indication

Note 1 to entry: A calibration can be expressed by a statement, calibration function, calibration diagram,

calibration curve, or calibration table. In some cases, it consists of an additive or multiplicative correction of the

indication with associated measurement uncertainty.

Note 2 to entry: Calibration should not be confused with adjustment of a measuring system, often mistakenly

called “self-calibration”, nor with verification of calibration.

Note 3 to entry: Often, the first step alone in the above definition is perceived as being calibration.

2.5.1.2

adjustment of a measuring instrument

operation of bringing a measuring instrument into a state of performance suitable for its use

Note 1 to entry: Adjustment can be automatic, semi-automatic, or manual.

2.5.1.3

volumetric conversion

determination of the volume at reference conditions from the volume at operating conditions

2.5.1.4

correction

value added algebraically to the uncorrected result of a measurement to compensate for systematic

error

Note 1 to entry: The correction is equal to the negative of the estimated systematic error.

Note 2 to entry: Since the systematic error cannot be known perfectly, the correction cannot be complete.

2.5.1.5

correction factor

numerical factor by which the uncorrected result of a measurement is multiplied to compensate for

systematic error

Note 1 to entry: Since the systematic error cannot be known perfectly, the correction cannot be complete.

2.5.1.6

calibration interval

period between routine calibrations over which the performance of the analyser meets specified

requirements

2.5.1.7

working range

range of parameters for which the calibration function has been developed and validated

2.5.1.8

extended working range

range of parameters for which the correlation has been developed, but outside the range for which the

calibration function has been validated

2.5.1.9

single-point calibration

establishment of the calibration function using one (only) calibration point

Note 1 to entry: This is a calibration in which the response of the analyser to a measured component maintains an

exact proportion to the concentration of the component over the entire working range.

Note 2 to entry: The response can be described as being linear through the origin. A plot of the analyser response

against the concentration of the component would show a straight line intercepting the (0,0) point of the plot. In

such circumstances, the use of a single calibration mixture containing the component at a concentration within

the working range (single-point calibration) is appropriate, as the ratio of response to concentration remains

constant at all points.

Note 3 to entry: Where a more complex response function, first order not passing through the origin or second or

third order polynomial, has been defined by the use of multiple calibration mixtures, and the different elements

of this function, e.g. the coefficient of the polynomial, have been shown to maintain a constant relationship to each

other, then a single-point calibration can be used to adjust all the elements of the function on a short-term basis

(for example, daily).

2.5.1.10

bracketing

method consisting in principle in reducing the interval over which the linearity of the calibration

function is assumed as much as possible

Note 1 to entry: This leads to surrounding the value of the unknown quantity by two values of reference materials

(RMs) as tightly as possible (or bracketing).

2.5.1.11

multi-point calibration

establishment of a calibration function using more than two calibration points

Note 1 to entry: In multi-point (also called “multi-level”) calibrations, the response curves of the detector are

determined for each component over the ranges to be analysed using a series of certified reference gas mixtures.

Note 2 to entry: To define the response curves, it is necessary to obtain results at a number of different concentration

levels for each component. The number of concentration levels needed depends on the order of the polynomial

(response curve) that has to be fitted. For first order, the minimum number of concentration levels needed is

three, for second order is five, and for third order is seven. In most cases, the order of fit of the response curves is

unknown beforehand, in which cases; it is advisable to perform the analysis of at least seven concentration levels

so as to detect third order detector behaviour with a high degree of detection sensitivity. Where the order of fit

is known, then the corresponding number of concentration levels can be used. For polynomical order one, these

concentration levels should be equally spaced across the specified working range of each component. The lowest

concentration level should be slightly below the lowest concentration level of the working range, and the highest

concentration level should be slightly higher than the highest concentration level of the working range.

2.5.1.12

verification

provision of objective evidence that a given item fulfils specified requirements

EXAMPLE Confirmation that performance properties or legal requirements of a measuring system are

achieved.

Note 1 to entry: When applicable, measurement uncertainty should be taken into consideration.

Note 2 to entry: The item can be, e.g. a process, measurement procedure, material, compound, or measuring

system.

Note 3 to entry: The specified requirements can be, e.g. that a manufacturer’s specifications are met.

[20]

Note 4 to entry: Verification in legal metrology as defined in VIM 2007 and in conformity assessment in general,

pertains to the examination and marking and/or issuing of a verification certificate for a measuring system.

Note 5 to entry: Verification should not be confused with calibration; not every verification is a validation.

12 © ISO 2014 – All rights reserved/Tous droits réservés

Note 6 to entry: In chemistry, verification of the identity of the entity involved, or of activity, requires a description

of the structure or properties of that entity or activity.

2.5.1.13

analytical quality control

monitoring of the measurement system on a regular basis so as to detect quickly when the method has

deteriorated, or the calibration shifted, or both

2.5.1.14

control chart

plot in which component mole fraction values from each analysis of the control gas are compared with

the mean value and the lines for ±2 standard deviations and ±3 standard deviations obtained from the

results of the initial analyses of the control gas

2.5.2 Gas analysis

2.5.2.1 General definitions

2.5.2.1.1

mass (volume)

(mole) fraction

quotient of the mass [volume (under specified conditions of pressure and temperature)] (amount of

substance) of a component A to the sum of the masses [sum of the volumes (intended prior to mixing

under specified conditions of pressure and temperature)] (sum of the amounts of substances) of all

components of the gas mixture

2.5.2.1.2

mass (molar)(volume)

concentration

quotient of the mass [volume (under specified conditions of pressure and temperature)] (amount of

substance) of each component to the volume of the gas mixture under specified conditions of pressure

and temperature

Note 1 to entry: The mass, molar, and volume concentrations depend on the pressure and temperature of the gas

mixture.

2.5.2.1.3

gas composition

fractions or concentrations of all the components determined from natural gas analysis

2.5.2.1.4

gas analysis

measurement methods and techniques for determining the gas composition

2.5.2.1.5

direct measurement of components

measurement in which individual components or group of components are determined by comparison

with identical components in the reference gas mixture

Note 1 to entry: Main and associated components are usually determined using direct measurement.

2.5.2.1.6

indirect measurement of components

measurement in which individual components or groups of components are determined using relative

response factors to a reference component in the reference gas mixture

Note 1 to entry: Trace components are mostly determined using indirect measurement.

2.5.2.2 Analysed components

2.5.2.2.1

main component

major component

component whose content influences physical properties

Note 1 to entry: Main components of natural gases generally include: nitrogen, carbon dioxide, and saturated

hydrocarbons from methane through pentane.

2.5.2.2.2

associated component

minor component

component whose content does not significantly influence physical properties

Note 1 to entry: Associated components generally include: helium, hydrogen, argon, and oxygen.

2.5.2.2.3

trace component

trace constituent

component present at very low levels

Note 1 to entry: Trace components generally include hydrocarbons or groups of hydrocarbons above n-pentane

and the components listed in 2.5.2.3.

2.5.2.2.4

group of components

components with similar properties whose mole fractions are so low, that their measurement as

individuals would be difficult or require excessive time, and measured as a group

Note 1 to entry: The property of the group, rather than each individual property, is used to evaluate the properties

of the mixture.

Note 2 to entry: The group can be physically combined as a result of the analytical procedure, as with backflushing

in chromatography, or individually measured and combined by calculation. If they a

...

МЕЖДУНАРОДНЫЙ ISO

СТАНДАРТ 14532

Второе издание

2014-06-15

Газ природный. Словарь

Natural gas — Vocabulary

Ссылочный номер

©

ISO 2014

R/E

ДОКУМЕНТ ЗАЩИЩЕН АВТОРСКИМ ПРАВОМ

© ISO 2014

Воспроизведение терминов и определений, содержащихся в данном Международном Стандарте, разрешается в учебных

руководствах, инструкциях технических изданиях и журналах, с исключительно образовательными целями или целями

внедрения. Условия такого воспроизведения следующие: термины и определения не подвергаются никакой модификации;

воспроизведение не допускается для словарей или других подобных изданий, предлагаемых на продажу; данный

Международный стандарт указывается как источник

За единственным указанным выше исключением, никакая часть этой публикации не может быть воспроизведена или

использована в какой бы то ни было форме, как электронными, так и механическими средствами, в том числе

фотокопированием или на микрофильмах, без письменного согласия либо со стороны ISO, расположенного по указанному ниже

адресу, либо со стороны органа-члена ISO в стране, где находится подающий заявку

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Опубликовано в Швейцарии

ii © ISO 2014 – Все права сохраняются

R/E

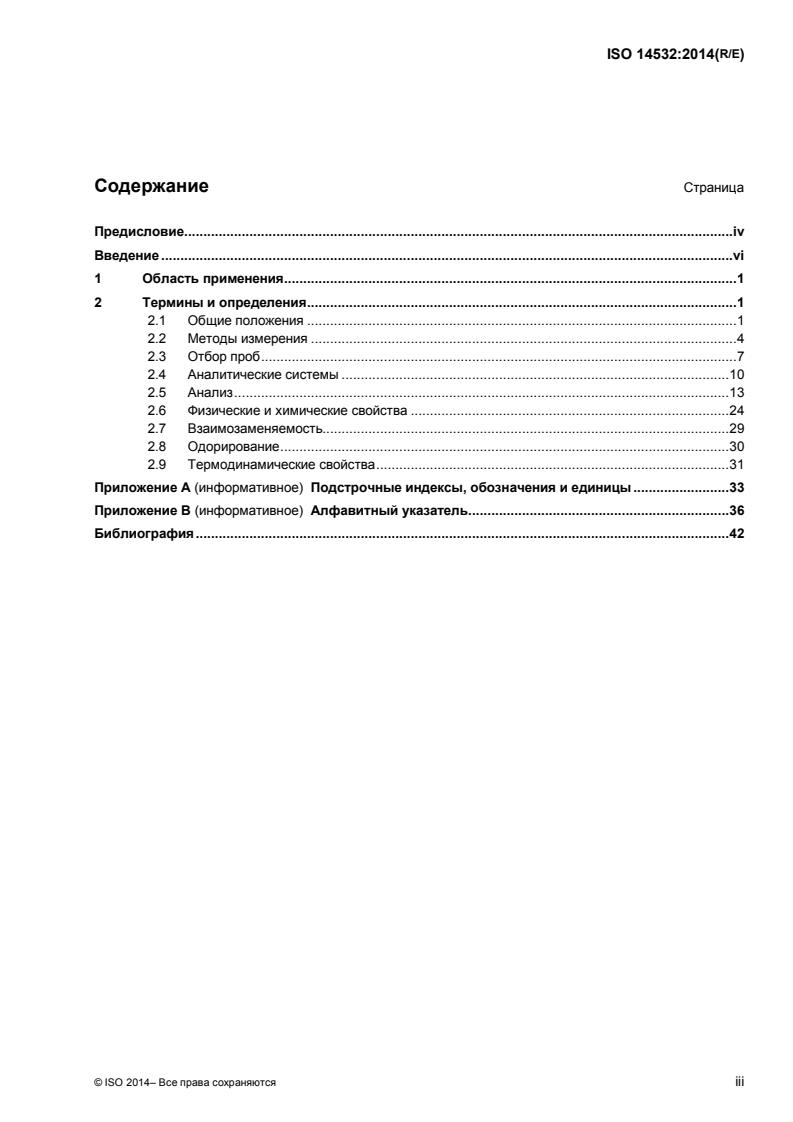

Содержание Страница

Предисловие .iv

Введение .vi

1 Область применения .1

2 Термины и определения .1

2.1 Общие положения .1

2.2 Методы измерения .4

2.3 Отбор проб .7

2.4 Аналитические системы . 10

2.5 Анализ . 13

2.6 Физические и химические свойства . 24

2.7 Взаимозаменяемость. 29

2.8 Одорирование . 30

2.9 Термодинамические свойства . 31

Приложение А (информативное) Подстрочные индексы, обозначения и единицы . 33

Приложение В (информативное) Алфавитный указатель. 36

Библиография . 42

R/E

Предисловие

Международная организация по стандартизации (ISO) всемирная федерация национальных органов

по стандартизации (комитеты-члены ISO). Работа по подготовке международных стандартов обычно

ведется через технические комитеты ISO. Каждый комитет-член ISO, проявляющий интерес к

тематике, по которой учрежден технический комитет, имеет право быть представленным в этом

комитете. Международные организации, государственные и негосударственные, имеющие связи с ISO,

также принимают участие в работе. ISO тесно сотрудничает с Международной электротехнической

комиссией (IEC) по всем вопросам стандартизации в области электротехники.

Процедуры, используемые для разработки данного документа, и процедуры, предусмотренные для его

дальнейшего ведения, описаны в Директивах ISO/IEC Directives, Part 1. В частности, следует отметить

различные критерии утверждения, требуемые для различных типов документов ISO. Проект данного

документа был разработан в соответствии с редакционными правилами Директив ISO/IEC Directives,

Part 2 (см. www.iso.org/directives ).

Необходимо обратить внимание на возможность того, что ряд элементов данного документа могут

быть предметом патентных прав. Международная организация ISO не должна нести ответственность

за идентификацию таких прав, частично или полностью. Сведения о патентных правах,

идентифицированных при разработке документа, будут указаны во Введении и/или в перечне

полученных ISO объявлениях о патентном праве (см. www.iso.org/patents ).

Любое торговое название, использованное в данном документе, является информацией,

предоставляемой для удобства пользователей, а не свидетельством в пользу того или иного товара

или той или иной компании.

Для пояснения значений конкретных терминов и выражений ISO, относящихся к оценке соответствия, а

также информация о соблюдении Международной организацией ISO принципов ВТО по техническим

барьерам в торговле (TБT), см. следующий унифицированный локатор ресурса (URL): Foreword -

Supplementary information

Технический комитет, несущий ответственность за данный документ, ISO/TC 193, Природный газ.

Настоящее второе издание отменяет и заменяет первое издание (ISO 14532:2001/Cor.1:2002).

iv © ISO 2013– Все права сохраняются

R/E

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of

ISO documents should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any patent

rights identified during the development of the document will be in the Introduction and/or on the ISO list of

patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO's adherence to the WTO principles in the Technical Barriers to Trade (TBT)

see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 193, Natural gas.

This second edition cancels and replaces the first edition (ISO 14532:2001/Cor. 1:2002).

R/E

Введение

Технический комитет ISO 193, Природный газ, был создан в мае 1989 года, в его задачу входила

подготовка новых и актуализация существующих стандартов, относящихся к природному газу. Сюда

входят анализ газа, прямое измерение свойств, определение качества и прослеживаемость.

В данной области ранее не проводилось исчерпывающей и единой систематизации определений,

обозначений и сокращений, используемых в стандартах. Разработка стандартов с терминологией,

приспособленной к конкретным нуждам, часто приводила к нарушению единообразия и

согласованности между разными стандартами.

Таким образом, возникла необходимость в гармонизации терминологии, используемой в стандартах,

касающихся природного газа. Цель данного Международного стандарта — включить пересмотренные

определения в первичный международный стандарт ISO/TC 193.

Была поставлена задача создать серию гармонизированных стандартов, поддерживающих друг друга

в том, что касается определений. Отправной точкой для понимания и применения любого

международного стандарта являются общепринятые и не допускающие двойного толкования термины

и определения, использованные во всех международных стандартах.

Структура данного международного стандарта разрабатывалась со следующими целями:

— Разбиение на основные главы сделано в соответствии с конкретными отраслями газовой

промышленности. Подходящие под такое разбиение определения, встречающиеся в

международных стандартах ISO, выпущенных ISO/TC 193, объединены в этих главах.

Содержание облегчает поиск конкретных терминов.

— Ко многим определениям даются примечания — там, где было сочтено необходимым дать

справочное руководство по данному определению. Примечания не считаются частью

определения.

vi © ISO 2013– Все права сохраняются

R/E

Introduction

ISO/TC 193 Natural Gas was established in May, 1989, with the task of creating new standards and updating

existing standards relevant to natural gas. This includes gas analysis, direct measurement of properties,

quality designation, and traceability.

In these activities, a comprehensive and uniform review of the definitions, symbols, and abbreviations used in

the standards was not previously systematically pursued. The development of standards with terminology

created to suit specific purposes often resulted in the detriment of uniformity and cohesiveness between

standards.

Thus, there is the need for a work of harmonization of the terminology used in the standards pertaining to

natural gas. The intention of this International Standard is to incorporate the reviewed definitions into the

ISO/TC 193 source International Standard.

As the aim is to create a coherent body of standards which support each other with regard to their definitions,

common and unambiguous terms and definitions used throughout all International Standards is the starting

point for the understanding and application of every International Standard.

The presentation of this International Standard has been arranged to facilitate its use as follows:

— Major headings pertain to specific fields of the natural gas industry. All definitions that fall under these

headings, as gleaned from ISO International Standards issued through ISO/TC 193, are listed under that

heading. A review of the contents will serve to facilitate finding specific terms.

— Notes are given under numerous definitions where it was deemed important to give informative

guidance for a given definition. The Notes are not considered a part of the definition.

R/E

МЕЖДУНАРОДНЫЙ СТАНДАРТ ISO 14532:2014( )

Газ природный. Словарь

1 Область применения

Данный международный стандарт устанавливает термины, определения, обозначения и аббревиатуры,

которые используются в области природного газа.

Термины и определения пересмотрены и изучены с целью охватить все аспекты любого конкретного

термина, используя данные из других источников, например, европейских стандартов, подготовленных

комитетом CEN (Европейский комитет по стандартизации), национальных стандартов, и определения

из Словаря по газовой промышленности (IGU Dictionary of the Gas Industry.

Данный документ имеет определенное намерение включить пересмотренные определения в

исходные стандарты ISO/TC 193.

2 Термины и определения

В данном международном стандарте применяются следующие термины и определения.

2.1 Общие положения

2.1.1 Природный газ

2.1.1.1

природный газ

ПГ

natural gas

NG

сложная газообразная смесь углеводородов; включает, главным образом, метан, а также, в

большинстве случаев, этан, пропан и высшие углеводороды в гораздо меньшем количестве, плюс

некоторые негорючие газы,— например, азот и диоксид углерода

Примечание 1 к статье: Природный газ также может содержать компоненты или составляющие, такие как

соединения серы и/или другие химические вещества.

2.1.1.2

неочищенный (пластовый) газ

raw gas

необработанный газ, отбираемый с устья скважин, поступает по газосборной линии к технологическому

оборудованию и очистным сооружениям

Примечание 1 к статье: Неочищенным газом может также называться частично очищенный попутный газ,

отбираемый из главного приемного технологического оборудования.

2.1.1.3

заменитель природного газа

ЗПГ

substitute natural gas

SNG

неископаемый газ, который по своим свойствам может заменить природный газ

R/E

2.1.1.4

коммунально-бытовой газ

синтез-газ

manufactured gas

synthetic gas

газ, подвергшийся переработке, может содержать компоненты, нехарактерные для природного газа

Примечание 1 к статье: Коммунально-бытовые (синтез-) газы могут содержать значительные количества

химических веществ, которые нетипичны для природных газов, или вещества типичные, но в необычных

пропорциях (как в жирных и высокосернистых газах).

Примечание 2 к статье: Коммунально-бытовые газы делятся на следующие две отдельные категории:

a) те, которые предполагается использовать как синтез-газы или заменители природного газа, и которые весьма

схожи с истинными природными газами по составу и свойствам,

b) те, которые, независимо от того, предполагается их использовать для замены или же дополнения природного

газа в эксплуатации, не строго соответствуют природным газам по составу.

Под случай (b) подпадают газы, такие как коммунальный газ, (неразбавленный) коксовый газ и

СНГ(LPG)/воздушные смеси, ни одна из которых по составу не похожа на истинный природный газ (хотя в

последнем случае они могут функционально заменять природный газ).

2.1.1.5

тощий газ

lean gas

природный газ, имеющий относительно низкое энергосодержание, близкое к энергосодержанию

чистого метана или ниже метана

Примечание 1 к статье: Тощий газ обычно содержит большое количество азота и диоксида углерода.

2.1.1.6

богатый газ

rich gas

природный газ, имеющий достаточно высокое энергосодержание, выше энергосодержания чистого

метана

Примечание 1 к статье: Богатый газ обычно содержит большое количество этана или пропана или более высоких

углеводородов.

2.1.1.7

влажный (жирный) газ

wet gas

газ, не соответствующий требованиям, предъявляемым к природному газу, транспортируемому по

трубопроводу, поскольку содержит нежелательные компоненты, такие, как пары воды, капельную влагу

и/или жидкие углеводороды, в таких количествах, которые могут сконденсироваться в трубе

2.1.1.8

(высоко)сернистый нефтяной газ

sour gas

газ, содержащий значительное количество кислых газов, таких как диоксид углерода и

соединения серы

Примечание 1 к статье: Присутствие кислых соединений более вредно во влажных (жирных) газах.

Примечание 2 к статье: Обычно жирные и высокосернистые газы представляют собой необработанный (попутный)

или частично обработанные природные газы, и могут также содержать конденсированные углеводороды, следы

карбонилсульфида и пары технологических жидкостей, таких, как метанол или гликоли.

Примечание 3 к статье: Диоксид углерода в присутствии несвязной воды также может стать одним из важных

факторов, вызывающих коррозию трубопроводов.

2 © ISO 2014 – Все права сохраняются

R/E

2.1.1.9

сухой природный газ

dry natural gas

природный газ, который содержит мольную долю воды, составляющую не более 0,005% [(50 частей на

миллион (молярных))] в паровой фазе

Примечание 1 к статье: Содержание водяного пара в природном газе может выражаться в терминах концентрации

воды (мг/м ).

[17]

Примечание 2 к статье: Корреляция между содержанием воды и точкой росы по воде приведена в ISO 18453.

2.1.1.10

насыщенный газ

saturated gas

природный газ, который в установленных условиях температуры и давления находится в точке росы по

воде

2.1.1.11

компримированный (сжатый) природный газ

КПГ

compressed natural gas

CNG

природный газ, который после очищения подвергают сжатию (компрессии) для удобства хранения и

транспортирования

Примечание 1 к статье: КПГ используют, главным образом, в качестиве автомобильного топлива, обычно сжатый

до 20 000 kПa он остается в газообразном состоянии .

2.1.1.12

сжиженный природный газ

СПГ

liquefied natural gas

LNG

природный газ, который после очищения подвергают сжижению для удобства хранения и

транспортирования

Примечание 1 к статье: Жидкий природный газ заново испаряют и вводят в трубопроводы для передачи и

распределения в качестве природного газа.

2.1.1.13

качество газа

gas quality

показатели природного газа, определяемые его составом и физическими свойствами

2.1.1.14

биогаз

biogas

обобщенный термин, используемый для ссылки на газы, получаемые в процессе биологического

разложения (брожения) органического вещества в анаэробных условиях без дальнейшей очистки или

повышения качества

Примечание 1 к статье: Этот процесс может происходить в местах скопления растительных (органических)

остатков (на свалках), где образуется газ из органических остатков (свалочный газ).

2.1.1.15

биометан

biomethane

богатый метаном газ, полученный из биогаза или при газификации биомассы за счет улучшения

свойств, аналог природного газа

R/E

2.1.1.16

биомасса

biomass

масса, определенная с научной и технической точки зрения, как материал биологического

происхождения, за исключением материалов, залегающих в геологических образованиях и/или

превратившихся в ископаемые остатки

Примечание 1 к статье: Биомасса является органическим материалом, животного или растительного

происхождения, включая, но этим не ограничиваясь, специальные энергетические и сельскохозяйственные

культуры и деревья, остатки пищевых, кормовых, волокнистых прядильных культур, водные растения, водоросли,

остатки лесоматериалов и древесины, сельскохозяйственные отходы, отходов обработки и другие неископаемые

органические вещества.

Примечание 2 к статье: См. также термины «травяная биомасса», «фруктовая биомасса» и «древесная биомасса».

2.1.2 Сеть трубопроводов

2.1.2.1

система трубопроводов

pipeline grid

система взаимосвязанных трубопроводов, как национальных, так и международных, служащих для

передачи и распределения природного газа

2.1.2.2

местная распределительная система

МРС

local distribution system

LDS

газовые магистрали и службы, обеспечивающие подачу природного газа непосредственно

потребителю

2.1.2.3

пункт приема-сдачи

custody transfer point

место между двумя трубопроводными системами, в котором должно учитываться количество энергии

природного газа

Примечание 1 к статье: В таком месте может также происходить смена режима давления.

2.1.2.4

переключающая станция

transfer station

cистема трубопроводов, измерительно-регулирующих (контроль давления) и вспомогательных

устройств в пункте приема-сдачи, предназначенных для учета количества передаваемых газов и

адаптирования к возможным других режимам давления в сетях

2.2 Методы измерения

2.2.1 Общие определения

2.2.1.1

абсолютное измерение

absolute measurement

измерение показателя с использованием фундаментальных метрологических величин

Примечание 1 к статье: Например, фундаментальными метрологическими величинами являются длина, масса и

время.

4 © ISO 2014 – Все права сохраняются

R/E

Примечание 2 к статье: Например, определение массы газа с использованием аттестованных масс.

2.2.1.2

прямое измерение

direct measurement

измерение показателя по параметрам, которые, в принципе, определяют этот показатель

Примечание 1 к статье: Например, определение теплоты сгорания газа термометрическим измерением энергии,

выделенной в виде тепла при сжигании известного количества газа.

2.2.1.3

косвенное измерение

indirect measurement

определение показателя по параметрам, которые, в принципе, не определяют этого показателя, но

определенным образом с ним связаны

Примечание 1 к статье: Например, определение теплоты сгорания по замерам отношения воздух/газ,

необходимого для достижения стехиометрического сгорания и связанного с теплотой сгорания линейно

2.2.1.4

значение нижней границы диапазона

lower range value

самое низкое значение измеряемой величины (параметра), на измерение которого настроены

измерительная система или датчик

2.2.1.5

значение верхней границы диапазона

upper range value

самое высокое значение измеряемой величины (параметра) на измерение которого настроены

измерительная система или датчик

2.2.1.6

интервал

span

разность между значениями верхней и нижней границ диапазона

2.2.1.7

относительное измерение

relative measurement

измерение показателя путем сравнения со значением этого показателя, измеренного на принятом

стандартном образце

Примечание 1 к статье: Например, определение плотности газа по отношению массы газа, содержащегося в

данном объеме, к массе воздуха, содержащегося в том же объеме при той же температуре и давлении,

умноженному на плотность воздуха при этих температуре и давлении.

2.2.2 Конкретные методы

2.2.2.1

метод газовой хроматографии

gas chromatographic method

метод анализа газа, который использует разделение компонентов газовой смеси с помощью газовой хроматографии

Примечание 1 к статье: Образец проходит в потоке газа-носителя через колонку, которая по-разному удерживает

представляющие интерес компоненты. Разные компоненты проходят колонку с разной скоростью и определяются

по мере элюирования из колонки в разные моменты времени.

R/E

2.2.2.2

потенциометрический метод

potentiometric method

метод анализа газа, в котором известное количество газа сначала пропускают через раствор,

селективно абсорбирующий определенный газовый компонент или группу компонентов. Затем

аналит(ы) в растворе определяют потенциометрическим титрованием

Примечание 1 к статье: Результатом является кривая титрования, показывающая конечные точки напряжения для

искомых компонентов по отношению к необходимым количествам растворов для титрования. По этим данным

может быть вычислена концентрация различных компонентов.

2.2.2.3

потенциометрическое титрование

potentiometric titration

метод, в котором количество титранта, потребляемого в реакции компонента газа с титрантом,

пропорционально концентрации этого компонента, а конечная точка реакции определяется

изменением потенциала внутри ячейки

Примечание 1 к статье: Добавление титранта (раствора для титрования) объемными порциями определяет

измеряемую разность потенциалов. Конечные точки титрования могут быть точнее определены при добавлении

объемов титранта дискретно и уменьшении объемов добавляемых порций вблизи конечных точек.

2.2.2.4

нефелометрическое титрование

turbidimetric titration

метод определения содержания сульфат-ионов путем добавления раствора соли бария к

абсорбирующему раствору с последующим измерением помутнения, вызванного образованием

нерастворимого сульфата бария

Примечание 1 к статье: Этот метод применим в случаях, когда общее содержание серы в растворе меньше 0,1 мг.

Примечание 2 к статье: Для определения точки перегиба при титровании применяется фотометр с индикатором-

гальванометром. По этим данным затем можно рассчитать общее содержание серы в мг/м .

2.2.2.5

метод сжигания

combustion method

метод, по которому образец полностью сжигается и проводится измерение конкретных продуктов

горения для определения общей концентрации элемента (например, серы) в образце

Примечание 1 к статье: Метод Викбольда (Wickbold):Метод сжигания по Викбольду использует сжигание и полное

термическое разложение соединений при высокой температуре водородно-кислородного пламени. Эта операция

[2]

[ ]

осуществляется при помощи специального прибора (см. ISO 4260 ).

Примечание 2 к статье: Метод Лингенера (Lingener): В методе сжигания по Лингенеру используется воздух,

[8]

[ ]

операция осуществляется при помощи специального прибора (см. ISO 6326-5 ).

2.2.2.6

абсорбция

absorption

извлечение одного или нескольких компонентов из смеси газов при пропускании через жидкость

Примечание 1 к статье: Процесс ассимиляции или экстракции вызывает (или сопровождается) физическое либо

химическое изменение в материале сорбента.

Примечание 2 к статье: Компоненты газа удерживаются в результате капиллярных или осмотических эффектов,

химической реакции или растворения.

ПРИМЕР Удаление воды из природного газа с использованием гликоля.

6 © ISO 2014 – Все права сохраняются

R/E

2.2.2.7

адсорбция

adsorption

удерживание физическими или химическими силами, молекул газов, растворенных веществ или

жидкостей поверхностями твердых тел или жидкостей, с которыми они находятся в контакте

Примечание 1 к статье: Например, удерживание метана углеродом.

2.2.2.8

десорбция

desorption

удаление сорбированного вещества с помощью процесса, обратного адсорбции или абсорбции

2.3 Отбор проб

2.3.1 Методы пробоотбора

2.3.1.1

прямой пробоотбор

direct sampling

отбор проб в ситуациях, когда есть непосредственное соединение между природным газом,

проба которой берется, и аналитическим устройством

2.3.1.2

опосредованный пробоотбор

indirect sampling

отбор в ситуациях, когда нет непосредственного соединения между природным газом, проба которой

берется, и аналитическим устройством

2.3.1.3

поточный анализатор, устанавливаемый в трубе

in-line instrument

прибор, активный элемент которого установлен внутри трубопровода и производит измерения в

условиях трубопровода

2.3.1.4

поточный анализатор, устанавливаемый на трубе

on-line instrument

прибор, получающий пробу газа напрямую из трубопровода, но при этом установленный снаружи

трубопровода

2.3.1.5

лабораторный анализатор