IEC 60191-1:2007

(Main)Mechanical standardization of semiconductor devices - Part 1: General rules for the preparation of outline drawings of discrete devices

Mechanical standardization of semiconductor devices - Part 1: General rules for the preparation of outline drawings of discrete devices

IEC 60191-1:2007 gives guidelines on the preparation of outline drawings of discrete devices. For preparation of outline drawings of surface mounted discrete devices, IEC 60191-6 should be referred to as well. The main changes from the previous edition are as follows:

- requirement added for SI-dimensions for new drawings to be published;

- former rules concerning inch-dimensions are given in an informative annex;

- former rules for coding are given in an informative annex; incorporation of the supplements;

- updating of references and

- restructuring and renumbering.

Normalisation mécanique des dispositifs à semiconducteurs - Partie 1: Règles générales pour la préparation des dessins d'encombrement des dispositifs discrets

La CEI 60191-1:2007 donne des lignes directrices pour la préparation des dessins d'encombrement des dispositifs discrets. Il convient également de se référer à la CEI 60191-6 pour la préparation des dessins d'encombrement des dispositifs discrets pour montage en surface. Les principales modifications par rapport à l'édition précédente sont les suivantes:

- exigence ajoutée relative aux dimensions SI pour de nouveaux dessins à publier;

- les anciennes règles concernant les dimensions en pouces sont indiquées dans une annexe informative; - les anciennes règles relatives à la codification sont indiquées dans une annexe informative;

- incorporation des suppléments;

- mise à jour des références et

- restructuration et nouvelle numérotation.

General Information

- Status

- Published

- Publication Date

- 23-Apr-2007

- Technical Committee

- SC 47D - Semiconductor devices packaging

- Drafting Committee

- WG 2 - TC 47/SC 47D/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 23-Jan-2018

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 60191-1:2007

IEC 60191-1:2007 defines general rules for preparing outline drawings of discrete semiconductor devices. Its primary aim is to ensure mechanical interchangeability by specifying how case outlines, terminal positions, mounting features and datum references should be presented on drawings. The 2007 edition introduced a requirement that new drawings use SI dimensions, moved former inch-dimension and coding rules into informative annexes, updated references and reorganized the document.

Key topics and technical requirements

- Drawing scope and layout

- Show all dimensions needed for mechanical interchangeability (case, terminals, locating tab, seating plane).

- Use third-angle projection with appropriate side and end views and detail views where needed.

- Dimensions and tolerances

- Preferential use of SI (metric) dimensions for new drawings.

- Rules for tolerancing and rounding, and procedures for inch–millimetre inter-conversion are included.

- Datums and locating features

- Definition and use of datum references, seating plane/base, mechanical index (locating tab, key) and visual index for orientation.

- Terminal and base drawings

- Separate concepts for case outline drawings, base drawings (terminal dimensions and positions) and device outline drawings (complete device).

- Numbering and positional rules for terminals; controlled zones for lead diameters and lengths.

- Additional elements

- Guidance on gauge drawings, numbering conventions, coding rules (informative annex), and examples of package drawings (informative annexes).

Practical applications and who uses it

IEC 60191-1:2007 is used by:

- Semiconductor manufacturers to produce standardized outline drawings ensuring parts fit existing equipment.

- Mechanical and PCB designers to allocate space, mounting holes and keep-out areas in enclosures and boards.

- Test-fixture and assembly engineers for designing jigs, gauges and handling fixtures.

- Procurement and quality teams to verify mechanical interchangeability between suppliers.

- Regulatory and standards teams to harmonize mechanical documentation internationally.

Benefits include improved cross-supplier compatibility, reduced redesign risk, and clearer mechanical specifications for product development and manufacturing.

Related standards

- IEC 60191 series (Part 2: Dimensions; Part 3: IC outline rules; Part 4: Coding; Part 6: Surface‑mounted device outlines)

- Normative reference in the document: ISO 370 (noted in the standard; withdrawn status should be checked)

For surface-mounted discrete devices, refer also to IEC 60191-6. Always verify you have the latest edition and applicable corrigenda before use.

Buy Documents

IEC 60191-1:2007 - Mechanical standardization of semiconductor devices - Part 1: General rules for the preparation of outline drawings of discrete devices Released:4/24/2007 Isbn:2831891205

IEC 60191-1:2007 - Mechanical standardization of semiconductor devices - Part 1: General rules for the preparation of outline drawings of discrete devices Released:4/24/2007 Isbn:9782832202319

Frequently Asked Questions

IEC 60191-1:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mechanical standardization of semiconductor devices - Part 1: General rules for the preparation of outline drawings of discrete devices". This standard covers: IEC 60191-1:2007 gives guidelines on the preparation of outline drawings of discrete devices. For preparation of outline drawings of surface mounted discrete devices, IEC 60191-6 should be referred to as well. The main changes from the previous edition are as follows: - requirement added for SI-dimensions for new drawings to be published; - former rules concerning inch-dimensions are given in an informative annex; - former rules for coding are given in an informative annex; incorporation of the supplements; - updating of references and - restructuring and renumbering.

IEC 60191-1:2007 gives guidelines on the preparation of outline drawings of discrete devices. For preparation of outline drawings of surface mounted discrete devices, IEC 60191-6 should be referred to as well. The main changes from the previous edition are as follows: - requirement added for SI-dimensions for new drawings to be published; - former rules concerning inch-dimensions are given in an informative annex; - former rules for coding are given in an informative annex; incorporation of the supplements; - updating of references and - restructuring and renumbering.

IEC 60191-1:2007 is classified under the following ICS (International Classification for Standards) categories: 31.080.01 - Semiconductor devices in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60191-1:2007 has the following relationships with other standards: It is inter standard links to IEC 60191-1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60191-1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60191-1

Second edition

2007-04

Mechanical standardization of semiconductor

devices –

Part 1:

General rules for the preparation of outline

drawings of discrete devices

Reference number

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60191-1

Second edition

2007-04

Mechanical standardization of semiconductor

devices –

Part 1:

General rules for the preparation of outline

drawings of discrete devices

PRICE CODE

Commission Electrotechnique Internationale W

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 60191-1 © IEC:2007(E)

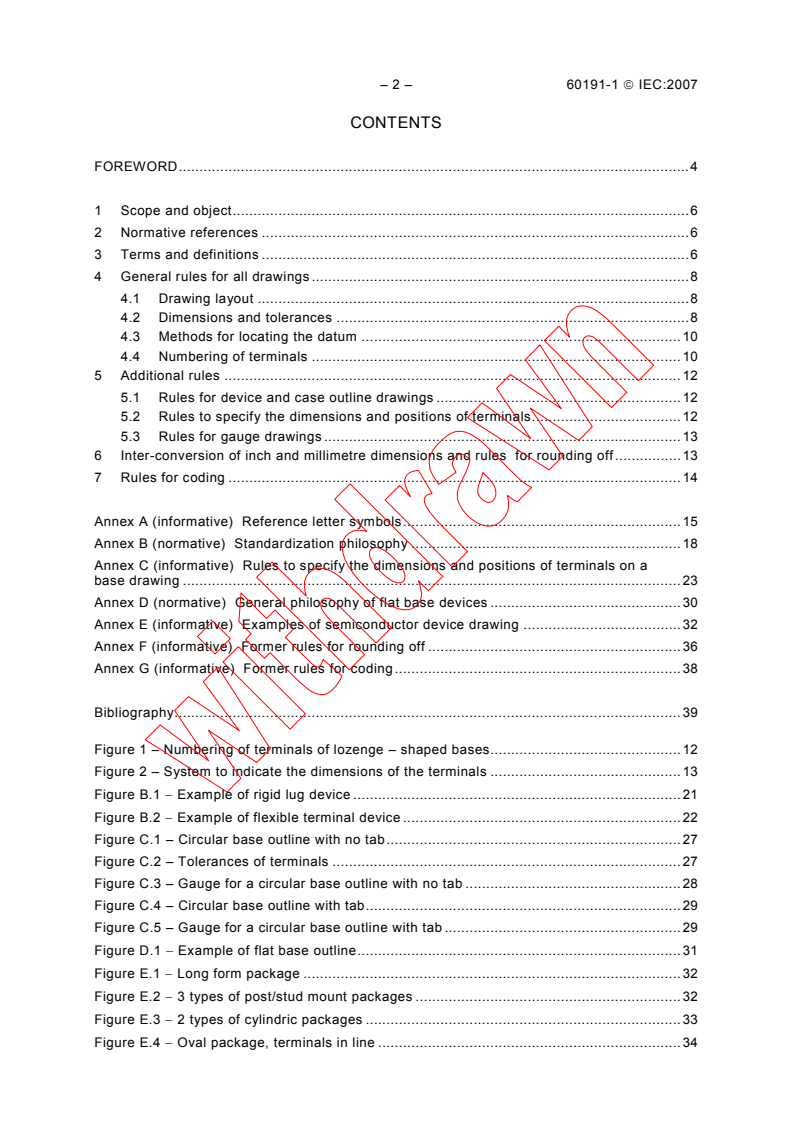

CONTENTS

FOREWORD.4

1 Scope and object.6

2 Normative references .6

3 Terms and definitions .6

4 General rules for all drawings .8

4.1 Drawing layout .8

4.2 Dimensions and tolerances .8

4.3 Methods for locating the datum .10

4.4 Numbering of terminals .10

5 Additional rules .12

5.1 Rules for device and case outline drawings .12

5.2 Rules to specify the dimensions and positions of terminals.12

5.3 Rules for gauge drawings.13

6 Inter-conversion of inch and millimetre dimensions and rules for rounding off.13

7 Rules for coding .14

Annex A (informative) Reference letter symbols.15

Annex B (normative) Standardization philosophy .18

Annex C (informative) Rules to specify the dimensions and positions of terminals on a

base drawing .23

Annex D (normative) General philosophy of flat base devices .30

Annex E (informative) Examples of semiconductor device drawing .32

Annex F (informative) Former rules for rounding off .36

Annex G (informative) Former rules for coding.38

Bibliography.39

Figure 1 – Numbering of terminals of lozenge – shaped bases.11

Figure 2 – System to indicate the dimensions of the terminals .13

Figure B.1 − Example of rigid lug device .21

Figure B.2 − Example of flexible terminal device .22

Figure C.1 – Circular base outline with no tab.27

Figure C.2 – Tolerances of terminals .27

Figure C.3 – Gauge for a circular base outline with no tab .28

Figure C.4 – Circular base outline with tab.29

Figure C.5 – Gauge for a circular base outline with tab .29

Figure D.1 − Example of flat base outline.31

Figure E.1 − Long form package .32

Figure E.2 − 3 types of post/stud mount packages .32

Figure E.3 − 2 types of cylindric packages .33

Figure E.4 − Oval package, terminals in line .34

60191-1 © IEC:2007(E) – 3 –

Figure E.5 − Cylindric package with different terminations .34

Figure E.6 − Flange mount package.34

Figure E.7 − Disk button package with 3 terminations .35

Figure E.8 − Special shape for bolt-fixture .35

Table A.1 – Dimensions of reference letter symbols.15

– 4 – 60191-1 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL STANDARDIZATION OF SEMICONDUCTOR DEVICES –

Part 1: General rules for the preparation of outline drawings

of discrete devices

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60191-1 has been prepared by subcommittee 47D: Mechanical

standardization for semiconductor devices, of IEC technical committee 47: Semiconductor

devices.

This second edition cancels and replaces the first edition published in 1966 together with

supplements 60191-1A:1969, 60191-1B:1970 and 60191-1C:1974 and constitutes a technical

revision. The main changes from the previous edition are as follows:

– requirement added for SI-dimensions for new drawings to be published;

– former rules concerning inch-dimensions are given in an informative annex;

– former rules for coding are given in an informative annex;

– incorporation of the supplements;

– updating of references;

– restructuring and renumbering.

60191-1 © IEC:2007(E) – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

47D/678/FDIS 47D/682/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The IEC 60191 series, published under the general title Mechanical standardization of

semiconductor devices, comprises the following parts:

Part 1: General rules for the preparation of outline drawings of discrete devices

Part 2: Dimensions

Part 3: General rules for the preparation of outline drawings of integrated circuits

Part 4: Coding system and classification into forms of package outlines for semiconductor

device packages

Part 5: Recommendations applying to integrated circuit packages using tape automated

bonding (TAB)

Part 6: General rules for the preparation of outline drawings of surface mounted

semiconductor device packages

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – 60191-1 © IEC:2007(E)

MECHANICAL STANDARDIZATION OF SEMICONDUCTOR DEVICES –

Part 1: General rules for the preparation of outline drawings

of discrete devices

1 Scope and object

This part of IEC 60191 gives guidelines on the preparation of outline drawings of discrete

devices.

NOTE For preparation of outline drawings of surface mounted discrete devices, IEC 60191-6 should be referred to

as well.

The primary object of these drawings is to indicate the space which should be allowed for

devices in an equipment, together with other dimensional characteristics required to ensure

mechanical interchangeability.

It should be noted that complete interchangeability involves other considerations such as the

electrical and thermal characteristics of the semiconductor devices concerned.

The international standardization represented by these drawings therefore encourages the

manufacturers of devices to comply with the tolerances shown on the drawings in order to

extend their range of customers internationally. It also gives equipment designers an

assurance of mechanical interchangeability between the devices obtained from suppliers in

different countries, provided they allow the space in their equipment that is indicated by the

drawings and take note of the more precise information on bases, studs, etc.

NOTE Additional details on the standardization philosophy used in this standard are given in Annex B.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60191-2:1966, Mechanical standardization of semiconductor devices – Part 2:

Dimensions (including all supplements and amendments)

IEC 60191-4, Mechanical standardization of semiconductor devices – Part 4: Coding system

and classification into forms of package outlines for semiconductor device packages

ISO 370, Toleranced dimensions – Conversion from inches to millimetres and vice versa

(withdrawn 2000-05)

3 Terms and definitions

For the purposes of this document, the following definitions apply.

3.1

device outline drawing

drawing which includes all dimensional characteristics required for the mechanical

interchangeability of the complete device. It includes the case or body, all terminals and the

locating tab if present

60191-1 © IEC:2007(E) – 7 –

3.2

terminal

that part of the semiconductor device primarily used in making an electrical, mechanical or

thermal connection. Examples of terminals are flexible leads, rigid leads, pins, studs, etc.

3.3

case outline drawing

drawing which includes all dimensional characteristics required for the mechanical

interchangeability of the case or body. It does not include the dimensions of the terminals or

the locating tab if present, but their positions are shown by dotted lines

3.4

base drawing

drawing which includes all dimensional characteristics required for the mechanical

interchangeability of the terminals and mechanical index

NOTE 1 Examples of these characteristics are: lead length, lead diameters with controlled zones, lead spacing,

pitch circle diameter, thickness, width and length of a tab, etc

NOTE 2 The diameter or major axis of the case outline should not be given on the base drawing.

NOTE 3 Many semiconductor devices have identical cases, but differ in the number or the length of terminals. It is

also possible to have the same type of base associated with cases which are not identical.

Consequently, there are advantages in having:

a) a single drawing including only the dimensional characteristics of the case outline and separate drawings for

the various bases which can be associated with this case outline,

or

b) a single drawing including only the dimensional characteristics of the base and separate drawings for the

various case outlines which can be associated with this base.

3.5

mechanical index

locating feature, or that portion of the device specifically designed to provide orientation.

NOTE Examples of a mechanical index are: key, keyway, locating tab, etc.

3.6

visual index

any single terminal (or omission of) readily distinguished by the eye from others or any

distinctive boss, stippled pattern or colour mark adjacent to a terminal

3.7

datum

a theoretically exact geometric reference (such as axes, planes, straight lines etc.) to which

toleranced features are related. Datums may be based on one or more datum features of a

part

[ISO 5459:1981, definition 3.1]

3.8

seating plane or seating base

reference plane from which, in general, outline and base dimensions are given

3.9

seated height or mounted height

distance from the seating plane to the top of any exposed tip or rigid terminal present,

otherwise to the top of the outline. Flexible terminals should not be included as part of the

seated height, but the mounted height should include a minimum allowance necessary for an

axially mounted flexible lead to be bent at right angles

– 8 – 60191-1 © IEC:2007(E)

3.10

controlled cylindrical zone

zone which defines a portion of the body of minimum length over which the diameter is

controlled to closer tolerances than is allowed over the full length of the body

4 General rules for all drawings

NOTE General rules for the preparation of outline drawings of surface mounted semiconductor device packages

are given in IEC 60191-6.

4.1 Drawing layout

General rules for the drawing layout are as follows.

a) A drawing should show all dimensions required to ensure mechanical interchangeability.

b) The drawing using third angle projection, should include:

– a suitable side-view;

– suitable end-views, where appropriate;

– such additional views and details as are required to show any special configuration or

features.

c) The following information should be put in the cartouche, at the bottom of the page:

– the projection method where there is more than one view, indicated as follows:

– date of publication of the drawing;

– IEC code number;

– country of origin and code of that country indicated by sign Δ;

NOTE This is no longer in practice.

– other interested countries and codes of those countries.

d) When a drawing is re-issued because of modifications, the changes made should be

indicated by arrows in the margin. The date of publication of the revised issue and of the

superseded issue should be stated.

e) While drawings need not to be drawn to scale, they should be roughly in proportion and,

where necessary for clarity, enlarged detail drawing(s) should be used.

4.2 Dimensions and tolerances

Application of dimensions and tolerances are as follows.

a) Dimensions of bases, outlines, etc. quoted shall apply to the finished product. They

should, therefore, not quote manufacturing tolerances, but give customers acceptance

limits.

60191-1 © IEC:2007(E) – 9 –

b) The following types of dimension may be used on the drawings as appropriate:

i) Toleranced dimensions

A toleranced dimension can be expressed:

– preferably by both minimum and maximum limits

(example: L = 5,77 mm, L = 5,82 mm); or

min max

– by a nominal value and maximum and minimum limits. Such a nominal value

need not necessarily be the average of two limits

+0,4

(example: L =6mm ).

−0,2

ii) Untoleranced dimensions

– Untoleranced limiting dimensions

i.e.: minimum only or maximum only

(example: L = 5,85 mm) .

max

– Untoleranced nominal dimensions

These dimensions may be used:

– either for general information as an actual nominal figure;

– or to specify true geometrical position (by means of linear or angular

dimensions). Such dimensions shall be indicated by an asterisk (*) after

the numerical value, the asterisk in this sense meaning "true geometrical

position"

(example: L = 5,85 mm).

nom

c) Single minimum, single maximum or single nominal (where not given for general

information) dimensions should be stated in decimals to such a number of places as is

considered adequate to express the degree of accuracy appropriate for that dimension;

e.g. if measurement to the nearest 0,001 mm is considered appropriate, the dimension

should be expressed to the third decimal place (for example 0,500 mm), but if the

measurement to the nearest 0,01 mm is sufficient, the dimension should be expressed to

the second decimal place (for example 0,50 mm) and so on. Similar consideration should

be given to the number of decimal places necessary when an original dimension is

expressed in millimetres.

d) Limiting values or nominal value and limits of a toleranced dimension should be stated

with the same number of decimal places (e.g. 0,016 mm min. – 0,017 mm nom. –

0,019 mm max.).

e) The use of fractional mm dimensions is permitted to describe nominal hexagon sizes.

f) Numerical dimensions should not be shown directly on the figure(s). They should be

shown in tabular form under the figure(s) and correspond to the reference letter symbols

on the figure(s). The letter symbols on the figure(s) should be upright. Upper case letters

should be used for device outline and case outline dimensions and lower case letters for

base dimensions. If confusion could arise, upper case letters should preferably be used

throughout.

g) In the case of a diameter, the symbol “Ø” should appear in front of the reference letter

concerned both on the figure(s) and in the table. In cases where the cross-section is

uncontrolled (not necessarily round), the “Ø” symbol should not be used.

h) The table shall give dimensions in millimetres. The basic dimensions and system

(millimetres or inches) will be indicated immediately above the table.

NOTE Outline drawings published in IEC 60191-2 before this document came into effect may give

dimensions in inches.

i) The dimensions and limits which should normally be given and their corresponding

reference letter symbols are contained in Annex A. Some examples of drawings prepared

in accordance with these rules are given in Annex E.

Where a particular reference letter is to be used for more than one dimension on the same

drawing, use should be made of a suffix to identify the dimensions.

– 10 – 60191-1 © IEC:2007(E)

Annex A cannot be expected to include all dimensions likely to be necessary for

mechanical standardization, more particularly in the future. A distinction has been made

between primary and secondary reference letter symbols, primary reference letter symbols

being those which are used most frequently, secondary reference letter symbols being

those which are used less frequently and which can, if necessary, be associated with

dimensions other than those given in the table.

j) Where it is self-evident that several angles are equal, it is not necessary to show more

than one angle on the figure(s).

k) Notes will be numbered and placed under the table of dimensions, which will have a

“notes”' column on the right-hand side. The note reference will be placed opposite the

dimension to which the note refers in the table or, when this dimension does not appear in

the table, on the figure(s). The numerical sequence of the notes should follow the

alphabetical sequence of the dimensional reference letters to which the notes refer. Notes

referring to the figure(s) should follow notes referring to dimensions given in the table.

4.3 Methods for locating the datum

These methods are listed below in order of preference. When more than one of these

methods is possible for a given device, the method appearing earliest in the list should be

used. When none of the following methods is possible, the method best suited to the device

should be used.

The datum is

a) the radial line through the centre of the mechanical or visual index;

b) the radial line midway between the two terminals which obviously comprise a gap in an

otherwise equally spaced circular terminal array;

c) the radial line 180° from the locating radius of the most isolated terminal;

d) the radial line 180° from the mid-point of, in order of preference:

– the two most widely spaced terminals;

– the two most closely spaced terminals;

e) the radial line through the centre of the index terminal. In order of preference, the index

terminal is defined as that having:

– the smallest cross-sectional area at the point of emergence from the case;

– the greatest axial length, when one terminal is noticeably longer than the others;

– the smallest axial length, when one terminal is noticeably shorter than the others.

4.4 Numbering of terminals

4.4.1 General

Where possible, device terminals should be identified by numbers according to the system

outlined in 4.4.2 to 4.4.7. In all instances terminals are considered as being viewed from their

free ends.

4.4.2 Single-ended devices with terminals in a linear array

4.4.2.1 Symmetrical linear array

The terminal nearest the reference mark should be numbered as No.1, the other terminals

should be numbered progressively from terminal No.1.

4.4.2.2 Asymmetrical linear array

The terminals should be numbered progressively from the end having the most terminals.

60191-1 IEC:2007(E) – 11 –

4.4.3 Single-ended devices with terminals in a circular array

• The terminal, the centre of which is past the datum, should be numbered as No.1, the

other terminals should be numbered progressively and in a clockwise sequence from No.1.

• Where a terminal is situated in the centre of the base, this should be known as the centre

terminal and shall not be given a number.

• Where omission of one terminal in an otherwise equally spaced array identifies the datum,

the position of the omitted terminal should not be numbered; but, in a fixed modular

circular array, any location of omitted terminal which does not define a datum should be

numbered.

4.4.4 Double-ended devices

Terminals on both end views should be numbered without duplication of numbers.

4.4.5 Devices with terminals disposed in a square or rectangular periphery

Visual identification of the top of the device should be provided. The means of identification of

terminal position number one should also be provided. These identifications may be

combined.

The terminal positions should be numbered progressively in an anti-clockwise direction

around the periphery of the device as viewed from the top. The number one terminal position

shall be the first position anti-clockwise from the means of identification.

Each terminal shall be identified by the number of its position. Terminals may not necessarily be

present in all the numbered positions but those present shall have the number of the position.

4.4.6 Particular case of lozenge – shaped bases

Given two orthogonal axes, X'X and Y'Y, the device is oriented so that:

a) the greatest diagonal of the base coincides with the Y'Y axis, whereas the smallest

diagonal coincides with the X'X axis;

b) the greatest number of terminals is in the upper half (Figure1A, 1B, 1C) or in the right-

hand half (Figure 1D).

The numeration is clockwise, starting from the quadrant in the upper left-hand side.

If the terminals are disposed in a cross on the axis (Figure 1E), it is necessary to mark on the

body with a visual index the terminal which shall be considered as the first in the clockwise

numeration.

IEC 575/07

Figure 1 – Numbering of terminals of lozenge – shaped bases

– 12 – 60191-1 © IEC:2007(E)

4.4.7 Other devices

For devices having terminals, mounting studs or holes, in more than one plane, the following

rules should apply.

The numbering should start at the end:

– opposite to the end containing a threaded stud or hole;

– opposite to the end with the smallest number of terminals;

– opposite to the end identified by a hand, dot or other applied visual identification;

– opposite to the end with the larger ferrule, flange, insert, etc.

5 Additional rules

5.1 Rules for device and case outline drawings

Rules for device and case outline drawings are as follows.

a) The device outline drawings which appear in chapter I of IEC 60191-2 should include all

dimensional characteristics required for interchangeability in accordance with general

rules.

b) Where the requirements for mechanical interchangeability will permit, the minimum and

maximum dimensions should be chosen so that the creation of unnecessary drawings of

variants is avoided.

c) The case outline drawings which appear in Chapter III of IEC 60191-2 should include all

dimensional characteristics required for interchangeability in accordance with general

rules, omitting the terminal dimensioning which will be given on the associated base

drawings appearing in Chapter II of IEC 60191-2.

On the case outline drawings, the terminals should be shown only by dotted lines.

5.2 Rules to specify the dimensions and positions of terminals

5.2.1 General rules

General rules for specifying the dimensions and positions of terminals are as follows.

a) The terminals should be numbered in accordance with 4.4.

b) The following system should be used to locate the terminals on the bases.

The true geometrical position of the terminals (or of the holes in gauge

...

IEC 60191-1 ®

Edition 2.0 2007-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mechanical standardization of semiconductor devices –

Part 1: General rules for the preparation of outline drawings of discrete devices

Normalisation mécanique des dispositifs à semiconducteurs –

Partie 1: Régles générales pour la préparation des dessins d’encombrement des

dispositifs discrets

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60191-1 ®

Edition 2.0 2007-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mechanical standardization of semiconductor devices –

Part 1: General rules for the preparation of outline drawings of discrete devices

Normalisation mécanique des dispositifs à semiconducteurs –

Partie 1: Régles générales pour la préparation des dessins d’encombrement des

dispositifs discrets

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX W

ICS 31.080.01 ISBN 978-2-83220-231-9

– 2 – 60191-1 IEC:2007

CONTENTS

FOREWORD . 4

Scope and object . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General rules for all drawings . 8

4.1 Drawing layout . 8

4.2 Dimensions and tolerances . 8

4.3 Methods for locating the datum . 10

4.4 Numbering of terminals . 10

5 Additional rules . 12

5.1 Rules for device and case outline drawings . 12

5.2 Rules to specify the dimensions and positions of terminals . 12

5.3 Rules for gauge drawings . 13

6 Inter-conversion of inch and millimetre dimensions and rules for rounding off . 13

7 Rules for coding . 14

Annex A (informative) Reference letter symbols . 15

Annex B (normative) Standardization philosophy . 18

Annex C (informative) Rules to specify the dimensions and positions of terminals on a

base drawing . 23

Annex D (normative) General philosophy of flat base devices . 30

Annex E (informative) Examples of semiconductor device drawing . 32

Annex F (informative) Former rules for rounding off . 36

Annex G (informative) Former rules for coding . 38

Bibliography . 39

Figure 1 – Numbering of terminals of lozenge – shaped bases . 12

Figure 2 – System to indicate the dimensions of the terminals . 13

Figure B.1 − Example of rigid lug device . 21

Figure B.2 − Example of flexible terminal device . 22

Figure C.1 – Circular base outline with no tab . 27

Figure C.2 – Tolerances of terminals . 27

Figure C.3 – Gauge for a circular base outline with no tab . 28

Figure C.4 – Circular base outline with tab . 29

Figure C.5 – Gauge for a circular base outline with tab . 29

Figure D.1 − Example of flat base outline . 31

Figure E.1 − Long form package . 32

Figure E.2 − 3 types of post/stud mount packages . 32

Figure E.3 − 2 types of cylindric packages . 33

Figure E.4 − Oval package, terminals in line . 34

60191-1 IEC:2007 – 3 –

Figure E.5 − Cylindric package with different terminations . 34

Figure E.6 − Flange mount package . 34

Figure E.7 − Disk button package with 3 terminations . 35

Figure E.8 − Special shape for bolt-fixture . 35

Table A.1 – Dimensions of reference letter symbols . 15

– 4 – 60191-1 IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL STANDARDIZATION OF SEMICONDUCTOR DEVICES –

Part 1: General rules for the preparation of outline drawings

of discrete devices

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60191-1 has been prepared by subcommittee 47D: Mechanical

standardization for semiconductor devices, of IEC technical committee 47: Semiconductor

devices.

This second edition cancels and replaces the first edition published in 1966 together with

supplements 60191-1A:1969, 60191-1B:1970 and 60191-1C:1974 and constitutes a technical

revision. The main changes from the previous edition are as follows:

– requirement added for SI-dimensions for new drawings to be published;

– former rules concerning inch-dimensions are given in an informative annex;

– former rules for coding are given in an informative annex;

– incorporation of the supplements;

– updating of references;

– restructuring and renumbering.

60191-1 IEC:2007 – 5 –

This bilingual version (2012-07) corresponds to the monolingual English version, published in

2007-04.

The text of this standard is based on the following documents:

FDIS Report on voting

47D/678/FDIS 47D/682/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The IEC 60191 series, published under the general title Mechanical standardization of

semiconductor devices, comprises the following parts:

Part 1: General rules for the preparation of outline drawings of discrete devices

Part 2: Dimensions

Part 3: General rules for the preparation of outline drawings of integrated circuits

Part 4: Coding system and classification into forms of package outlines for semiconductor

device packages

Part 5: Recommendations applying to integrated circuit packages using tape automated

bonding (TAB)

Part 6: General rules for the preparation of outline drawings of surface mounted

semiconductor device packages

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 60191-1 IEC:2007

MECHANICAL STANDARDIZATION OF SEMICONDUCTOR DEVICES –

Part 1: General rules for the preparation of outline drawings

of discrete devices

1 Scope and object

This part of IEC 60191 gives guidelines on the preparation of outline drawings of discrete

devices.

NOTE For preparation of outline drawings of surface mounted discrete devices, IEC 60191-6 should be referred to

as well.

The primary object of these drawings is to indicate the space which should be allowed for

devices in an equipment, together with other dimensional characteristics required to ensure

mechanical interchangeability.

It should be noted that complete interchangeability involves other considerations such as the

electrical and thermal characteristics of the semiconductor devices concerned.

The international standardization represented by these drawings therefore encourages the

manufacturers of devices to comply with the tolerances shown on the drawings in order to

extend their range of customers internationally. It also gives equipment designers an

assurance of mechanical interchangeability between the devices obtained from suppliers in

different countries, provided they allow the space in their equipment that is indicated by the

drawings and take note of the more precise information on bases, studs, etc.

NOTE Additional details on the standardization philosophy used in this standard are given in Annex B.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60191-2:1966, Mechanical standardization of semiconductor devices – Part 2:

Dimensions (including all supplements and amendments)

IEC 60191-4, Mechanical standardization of semiconductor devices – Part 4: Coding system

and classification into forms of package outlines for semiconductor device packages

ISO 370, Toleranced dimensions – Conversion from inches to millimetres and vice versa

(withdrawn 2000-05)

3 Terms and definitions

For the purposes of this document, the following definitions apply.

3.1

device outline drawing

drawing which includes all dimensional characteristics required for the mechanical

interchangeability of the complete device. It includes the case or body, all terminals and the

locating tab if present

60191-1 IEC:2007 – 7 –

3.2

terminal

that part of the semiconductor device primarily used in making an electrical, mechanical or

thermal connection. Examples of terminals are flexible leads, rigid leads, pins, studs, etc.

3.3

case outline drawing

drawing which includes all dimensional characteristics required for the mechanical

interchangeability of the case or body. It does not include the dimensions of the terminals or

the locating tab if present, but their positions are shown by dotted lines

3.4

base drawing

drawing which includes all dimensional characteristics required for the mechanical

interchangeability of the terminals and mechanical index

NOTE 1 Examples of these characteristics are: lead length, lead diameters with controlled zones, lead spacing,

pitch circle diameter, thickness, width and length of a tab, etc

NOTE 2 The diameter or major axis of the case outline should not be given on the base drawing.

NOTE 3 Many semiconductor devices have identical cases, but differ in the number or the length of terminals. It is

also possible to have the same type of base associated with cases which are not identical.

Consequently, there are advantages in having:

a) a single drawing including only the dimensional characteristics of the case outline and separate drawings for

the various bases which can be associated with this case outline,

or

b) a single drawing including only the dimensional characteristics of the base and separate drawings for the

various case outlines which can be associated with this base.

3.5

mechanical index

locating feature, or that portion of the device specifically designed to provide orientation.

NOTE Examples of a mechanical index are: key, keyway, locating tab, etc.

3.6

visual index

any single terminal (or omission of) readily distinguished by the eye from others or any

distinctive boss, stippled pattern or colour mark adjacent to a terminal

3.7

datum

a theoretically exact geometric reference (such as axes, planes, straight lines etc.) to which

toleranced features are related. Datums may be based on one or more datum features of a

part

[ISO 5459:1981, definition 3.1]

3.8

seating plane or seating base

reference plane from which, in general, outline and base dimensions are given

3.9

seated height or mounted height

distance from the seating plane to the top of any exposed tip or rigid terminal present,

otherwise to the top of the outline. Flexible terminals should not be included as part of the

seated height, but the mounted height should include a minimum allowance necessary for an

axially mounted flexible lead to be bent at right angles

– 8 – 60191-1 IEC:2007

3.10

controlled cylindrical zone

zone which defines a portion of the body of minimum length over which the diameter is

controlled to closer tolerances than is allowed over the full length of the body

4 General rules for all drawings

NOTE General rules for the preparation of outline drawings of surface mounted semiconductor device packages

are given in IEC 60191-6.

4.1 Drawing layout

General rules for the drawing layout are as follows.

a) A drawing should show all dimensions required to ensure mechanical interchangeability.

b) The drawing using third angle projection, should include:

– a suitable side-view;

– suitable end-views, where appropriate;

– such additional views and details as are required to show any special configuration or

features.

c) The following information should be put in the cartouche, at the bottom of the page:

– the projection method where there is more than one view, indicated as follows:

– date of publication of the drawing;

– IEC code number;

– country of origin and code of that country indicated by sign ∆;

NOTE This is no longer in practice.

– other interested countries and codes of those countries.

d) When a drawing is re-issued because of modifications, the changes made should be

indicated by arrows in the margin. The date of publication of the revised issue and of the

superseded issue should be stated.

e) While drawings need not to be drawn to scale, they should be roughly in proportion and,

where necessary for clarity, enlarged detail drawing(s) should be used.

4.2 Dimensions and tolerances

Application of dimensions and tolerances are as follows.

a) Dimensions of bases, outlines, etc. quoted shall apply to the finished product. They

should, therefore, not quote manufacturing tolerances, but give customers acceptance

limits.

60191-1 IEC:2007 – 9 –

b) The following types of dimension may be used on the drawings as appropriate:

i) Toleranced dimensions

A toleranced dimension can be expressed:

– preferably by both minimum and maximum limits

(example: L = 5,77 mm, L = 5,82 mm); or

min max

– by a nominal value and maximum and minimum limits. Such a nominal value

need not necessarily be the average of two limits

+0,4

(example: L = 6 mm ).

−0,2

ii) Untoleranced dimensions

– Untoleranced limiting dimensions

i.e.: minimum only or maximum only

(example: L = 5,85 mm) .

max

– Untoleranced nominal dimensions

These dimensions may be used:

– either for general information as an actual nominal figure;

– or to specify true geometrical position (by means of linear or angular

dimensions). Such dimensions shall be indicated by an asterisk (*) after the

numerical value, the asterisk in this sense meaning "true geometrical

position"

(example: L = 5,85 mm).

nom

c) Single minimum, single maximum or single nominal (where not given for general

information) dimensions should be stated in decimals to such a number of places as is

considered adequate to express the degree of accuracy appropriate for that dimension;

e.g. if measurement to the nearest 0,001 mm is considered appropriate, the dimension

should be expressed to the third decimal place (for example 0,500 mm), but if the

measurement to the nearest 0,01 mm is sufficient, the dimension should be expressed to

the second decimal place (for example 0,50 mm) and so on. Similar consideration should

be given to the number of decimal places necessary when an original dimension is

expressed in millimetres.

d) Limiting values or nominal value and limits of a toleranced dimension should be stated

with the same number of decimal places (e.g. 0,016 mm min. – 0,017 mm nom. –

0,019 mm max.).

e) The use of fractional mm dimensions is permitted to describe nominal hexagon sizes.

f) Numerical dimensions should not be shown directly on the figure(s). They should be

shown in tabular form under the figure(s) and correspond to the reference letter symbols

on the figure(s). The letter symbols on the figure(s) should be upright. Upper case letters

should be used for device outline and case outline dimensions and lower case letters for

base dimensions. If confusion could arise, upper case letters should preferably be used

throughout.

g) In the case of a diameter, the symbol “Ø” should appear in front of the reference letter

concerned both on the figure(s) and in the table. In cases where the cross-section is

uncontrolled (not necessarily round), the “Ø” symbol should not be used.

h) The table shall give dimensions in millimetres. The basic dimensions and system

(millimetres or inches) will be indicated immediately above the table.

NOTE Outline drawings published in IEC 60191-2 before this document came into effect may give

dimensions in inches.

i) The dimensions and limits which should normally be given and their corresponding

reference letter symbols are contained in Annex A. Some examples of drawings prepared

in accordance with these rules are given in Annex E.

Where a particular reference letter is to be used for more than one dimension on the same

drawing, use should be made of a suffix to identify the dimensions.

– 10 – 60191-1 IEC:2007

Annex A cannot be expected to include all dimensions likely to be necessary for

mechanical standardization, more particularly in the future. A distinction has been made

between primary and secondary reference letter symbols, primary reference letter symbols

being those which are used most frequently, secondary reference letter symbols being

those which are used less frequently and which can, if necessary, be associated with

dimensions other than those given in the table.

j) Where it is self-evident that several angles are equal, it is not necessary to show more

than one angle on the figure(s).

k) Notes will be numbered and placed under the table of dimensions, which will have a

“notes”' column on the right-hand side. The note reference will be placed opposite the

dimension to which the note refers in the table or, when this dimension does not appear in

the table, on the figure(s). The numerical sequence of the notes should follow the

alphabetical sequence of the dimensional reference letters to which the notes refer. Notes

referring to the figure(s) should follow notes referring to dimensions given in the table.

4.3 Methods for locating the datum

These methods are listed below in order of preference. When more than one of these

methods is possible for a given device, the method appearing earliest in the list should be

used. When none of the following methods is possible, the method best suited to the device

should be used.

The datum is

a) the radial line through the centre of the mechanical or visual index;

b) the radial line midway between the two terminals which obviously comprise a gap in an

otherwise equally spaced circular terminal array;

c) the radial line 180° from the locating radius of the most isolated terminal;

d) the radial line 180° from the mid-point of, in order of preference:

– the two most widely spaced terminals;

– the two most closely spaced terminals;

e) the radial line through the centre of the index terminal. In order of preference, the index

terminal is defined as that having:

– the smallest cross-sectional area at the point of emergence from the case;

– the greatest axial length, when one terminal is noticeably longer than the others;

– the smallest axial length, when one terminal is noticeably shorter than the others.

4.4 Numbering of terminals

4.4.1 General

Where possible, device terminals should be identified by numbers according to the system

outlined in 4.4.2 to 4.4.7. In all instances terminals are considered as being viewed from their

free ends.

4.4.2 Single-ended devices with terminals in a linear array

4.4.2.1 Symmetrical linear array

The terminal nearest the reference mark should be numbered as No.1, the other terminals

should be numbered progressively from terminal No.1.

4.4.2.2 Asymmetrical linear array

The terminals should be numbered progressively from the end having the most terminals.

60191-1 IEC:2007 – 11 –

4.4.3 Single-ended devices with terminals in a circular array

• The terminal, the centre of which is past the datum, should be numbered as No.1, the

other terminals should be numbered progressively and in a clockwise sequence from No.1.

• Where a terminal is situated in the centre of the base, this should be known as the centre

terminal and shall not be given a number.

• Where omission of one terminal in an otherwise equally spaced array identifies the datum,

the position of the omitted terminal should not be numbered; but, in a fixed modular

circular array, any location of omitted terminal which does not define a datum should be

numbered.

4.4.4 Double-ended devices

Terminals on both end views should be numbered without duplication of numbers.

4.4.5 Devices with terminals disposed in a square or rectangular periphery

Visual identification of the top of the device should be provided. The means of identification of

terminal position number one should also be provided. These identifications may be

combined.

The terminal positions should be numbered progressively in an anti-clockwise direction

around the periphery of the device as viewed from the top. The number one terminal position

shall be the first position anti-clockwise from the means of identification.

Each terminal shall be identified by the number of its position. Terminals may not necessarily

be present in all the numbered positions but those present shall have the number of the

position.

4.4.6 Particular case of lozenge – shaped bases

Given two orthogonal axes, X'X and Y'Y, the device is oriented so that:

a) the greatest diagonal of the base coincides with the Y'Y axis, whereas the smallest

diagonal coincides with the X'X axis;

b) the greatest number of terminals is in the upper half (Figure1A, 1B, 1C) or in the right-

hand half (Figure 1D).

The numeration is clockwise, starting from the quadrant in the upper left-hand side.

If the terminals are disposed in a cross on the axis (Figure 1E), it is necessary to mark on the

body with a visual index the terminal which shall be considered as the first in the clockwise

numeration.

– 12 – 60191-1 IEC:2007

IEC 575/07

Figure 1 – Numbering of terminals of lozenge – shaped bases

4.4.7 Other devices

For devices having terminals, mounting studs or holes, in more than one plane, the following

rules should apply.

The numbering should start at the end:

– opposite to the end containing a threaded stud or hole;

– opposite to the end with the smallest number of terminals;

– opposite to the end identified by a hand, dot or other applied visual identification;

– opposite to the end with the larger ferrule, flange, insert, etc.

5 Additional rules

5.1 Rules for device and case outline drawings

Rules for device and case outline drawings are as follows.

a) The device outline drawings which appear in chapter I of IEC 60191-2 should include all

dimensional characteristics required for interchangeability in accordance with general

rules.

b) Where the requirements for mechanical interchangeability will permit, the minimum and

maximum dimensions should be chosen so that the creation of unnecessary drawings of

variants is avoided.

c) The case outline drawings which appear in Chapter III of IEC 60191-2 should include all

dimensional characteristics required for interchangeability in accordance with general

rules, omitting the terminal dimensioning which will be given on the associated base

drawings appearing in Chapter II of IEC 60191-2.

On the case outline drawings, the terminals should be shown only by dotted lines.

5.2 Rules to specify the dimensions and positions of terminals

5.2.1 General rules

General rules for specifying the dimensions and positions of terminals are as follows.

60191-1 IEC:2007 – 13 –

a) The terminals should be numbered in accordance with 4.4.

b) The following system should be used to locate the terminals on the bases.

The true geometrical position of the terminals (or of the holes in gauges) is defined by

angular spacing on a pitch circle (polar co-ordinates) or by rectangular co-ordinates in

relation to certain fixed references. Such dimensions are not toleranced.

c) The positional tolerance is indicated by stating that the cross-section of each terminal at

its point of origin or at a specified distance from the seating plane lies in a circle (of stated

diameter) centred at the true geometrical point defining the terminal axis.

d) The following system should be used either in total or in part to indicate the dimensions of

the terminals.

IEC 576/07

Ø b applies over the length l

1 1

Ø b applies over the length l – l

2 2 1

Ø b applies over the length l – l or where appropriate l – l

3 3 2 2

Figure 2 – System to indicate the dimensions of the terminals

e) The base drawings which appear in Chapter II of IEC 60191-2 should include the

dimensional characteristics required for interchangeability of the base and in certain

instances for compatibility between the base and a socket.

5.2.2 Rules to specify the dimensions and the positions of the terminals on a base

drawing

See Annex C.

5.3 Rules for gauge drawings

Where possible, the same reference letter symbols should be used as on the associated case

outline or base drawing.

6 Inter-conversion of inch and millimetre dimensions and rules

for rounding off

Conversion of toleranced dimensions from inches into millimetres or vice-versa should be

made according to ISO 370.

Tables I and II of ISO 370 may be extended as necessary.

– 14 – 60191-1 IEC:2007

Warning When converting inch dimensions to millimetre dimensions and vice-versa,

attention is drawn to the fact that the first column of Tables I and II are headed

"equal to at least".

ISO 370 has been withdrawn in May 2000. The rules which were applied before the year 2000

are given now in the informative Annex F at the end of this document.

7 Rules for coding

The classification of forms of package outline for semiconductor devices is specified in

IEC 60191-4.

NOTE Drawings in IEC 60191-2, published before IEC 60191-4 came into effect, are classified according to the

coding system in the informative Annex G.

60191-1 IEC:2007 – 15 –

Annex A

(informative)

Reference letter symbols

NOTE These symbols were used in the past. Nowadays use of dimensions A, D and E is preferred.

Where appropriate to the particular drawing being prepared, the dimensions listed in the

following table should be given with the associated reference letter symbols.

Table A.1 – Dimensions of reference letter symbols

Reference Description of the dimension Type of limits Notes

letter symbol

A Length from seating plane to top of case. min. - max. P

a

a Pitch circle diameter of terminals. - nom. - P

B, b Diameter of a terminal, or of the larger terminal min. - max. 1, 2, 3, P

if the cross-section is circular. If the cross-

section is not circular, width or major axis of

the cross-section of a terminal.

B , b Other diameter of terminal as shown in the - - max. P

1 1

diagram in Subclause 5.2.1, d)

B , b Other diameter of terminal as shown in the min. - max. P

2 2

diagram in Subclause 5.2.1, d)

B , b Other diameter of terminal as shown in the min. - max. P

3 3

diagram in Subclause 5.2.1, d)

C, c Diameter of smaller terminal, if the cross- min. - max. 1, 2, 3, 4, S

section is circular. If the cross-section is not

circular, thickness or minor axis of the cross-

section of a terminal.

D Diameter or major axis of case. min. - max. 1, P

D Smallest diameter of case. min. - max. 1, P

D , D , etc. Other diameters of case. min. - max. 1, P

2 3

a

d Distance from an axial reference line to a - nom. - S

terminal centre.

E Minor axis of case. min. - max. 1, S

E Or across flats dimension of a hexagon. min. nom. max. 1, 2, S

a

e Distance between two terminal centres - nom. - S

(distance between the centres of the nearest

terminal when there are more than two

terminals).

e Or clearance between two terminals. min. - - S

a

e , e , etc. Other distances between terminal centres. - nom. - S

1 2

e , e , etc. Or clearances between terminals. min. - - S

1 2

F Thickness or length of flange zone of the case min. - max. 2, S

including any fillet if present.

G Overall length excluding terminals and slugs. min. - max. 1, S

G Overall length excluding terminals but including - - max. S

slugs.

H Overall length including terminals. min. - - S

h Height of a mechanical index. - - max. S

– 16 – 60191-1 IEC:2007

Table A.1 (continued)

Reference Description of the dimension Type of limits Notes

letter symbol

J Seated height or mounted height. - - max. P

j Width or diameter of a mechanical index. min. - max. S

K Length of top zone of the case. - - max. S

k Length of a mechanical index. min. - max. S

L, l Length of a terminal. min. - max. 2,5, 6, P

L , l Other length of terminal as shown in the - - max. 5, P

1 1

diagram in Subclause 5.2.1, d)

L , l Other length of terminal as shown in the min. - - 5, P

2 2

diagram in Subclause 5.2.1, d)

L , l Other length of the terminal as shown in the min. - max. 2, 5, P

3 3

diagram in Subclause 5.2.1, d)

M, m Diameter or width of a terminal stud or slug. min. - max. 1, P

N, n Overall length of a stud threaded entirely or min. - max. P

partially or not at all.

N , n Distance to end of full thread (unthreaded min. - max. 1, P

1 1

portion) of a stud.

O Distance between seated plane and centre of min - max. 2, S

hole in the lug of a terminal.

P Length of controlled zone of the case. min. - - S

p Diameter of a mounting hole. min. - max. S

Q Other dimensions S

q Distance between the centres of two mounting min. - max. S

holes.

R, r Curve radii min. - max. 1, 2, P

R , r Curve radii of the ends of the base seat - - max. P

1 2

S Distance from a reference line to the centre min. - max. 1, S

line of a terminal

a

s Distance from the reference line through the - nom. - S

centres of two terminals to the centre of the

mounting hole which is the farthest from this

reference line.

T, t Diameter of the hole ( or smallest dimension of min. - max. 2, P

a non-circular hole) in a terminal lug or slug .

V, v Depth of a tapped hole. min. - max. S

W, w Diameter of the threaded portion of a stud with Thread reference 7, P

full thread form, or diameter of a tapped hole

(x x)

(y – y)

P

Section reference continuous

x – y Section reference, not continuous P

Z, z Other dimensions S

Small angle - nom. - P

α

β, γ Larger angles - nom. - P

60191-1 IEC:2007 – 17 –

Table A.1 (continued)

P primary reference letter symbol (see Subclause 4.2, i)

S secondary reference letter symbol (see Subclause 4.2, i)

NOTE 1 Minimum dimension may be omitted where appropriate.

NOTE 2 Maximum dimension may be omitted where appropriate.

NOTE 3 To distinguish in the same drawing between major or minor axes of cross-section of different terminals

having different dimensions, the signs (‘) prime, (“) second, etc. may be used with reference letters B, b and C,

c.

NOTE 4 Reference letter symbols C c ; C c ; C c may also be used in the same manner as reference

1, 1 2, 2 3, 3

letter symbols B or b.

NOTE 5 Measured from the seating plane.

NOTE 6 For terminals of different overall lengths, the letter symbols L l L l , L l L , l etc. may be

z, z, y, y x, x, w w,

used.

NOTE 7 Metric and/or inch thread reference. See ISO 261and ISO 263.

a

True geometrical position.

– 18 – 60191-1 IEC:2007

Annex B

(normative)

Standardization philosophy

B.1 General considerations

An attempt has been made here to standardize the dimensions and tolerances in the IEC

drawings to conform as closely as possible with those of the country of origin.

The IEC drawings are based on proposals from National Committees and it was assumed that

the country of origin has given full consideration to the principles of good engineering practice

and mechanical interchangeability when preparing its national proposals.

Any alterations subsequently introduced and receiving the general agreement of IEC still have

to conform to the principles of mechanical interchangeability and good engineering practice.

It is permissible, of course, for any country when preparing its national standards, to introduce

other dimensions or additional details if it is felt these are needed.

If an equipment designer allows for the dimensions and tolerances indicated by the IEC

drawing, he will be able to take advantage of the availability of supplies from more than one

country.

Where an equipment designer is unable to do this, for instance because of stringent space

considerations, it follows that he may be limiting his possible suppliers.

When a device is likely to be used in an equipment where there are stringent packing density

requirements (generally the case for low-power devices), the space required for the body of

such a device is closely defined.