IEC 60092-350:2001

(Main)Electrical installations in ships - Part 350: Shipboard power cables - General construction and test requirements

Electrical installations in ships - Part 350: Shipboard power cables - General construction and test requirements

This part of IEC 60092 specifies the general constructional requirements and general test recommendations for shipboard cables with copper conductors intended for power systems at voltages up to and including 8,7/15 kV.

General Information

- Status

- Published

- Publication Date

- 10-Jun-2001

- Technical Committee

- SC 18A - Electric cables for ships and mobile and fixed offshore units

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 07-Feb-2008

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60092-350:2001 - "Electrical installations in ships - Part 350: Shipboard power cables - General construction and test requirements" is an international standard that defines the general constructional requirements and test recommendations for shipboard power cables with copper conductors for marine power systems up to and including 8.7/15 kV. It is part of the IEC 60092 series covering electrical installations in ships and offshore units.

Key topics and technical requirements

The standard addresses the essential elements of shipboard power cable design, manufacture and testing, including:

- Conductors

- Requirements for copper conductor material, class and form (ref. IEC 60228).

- Insulation

- Acceptable insulating materials and application/thickness principles (see normative reference IEC 60092-351).

- Cabling and internal construction

- Core cabling, inner coverings, fillers and binders to ensure mechanical integrity.

- Protective coverings and armour

- Types of protective layers: non‑metallic sheaths, metal braid/wire/tape armour, bedding and removal instructions.

- Dimensional and mechanical requirements

- Definitions of dimensional limits, outer diameter calculation and armour dimensions (annexes include calculation methods and rounding rules).

- Testing framework

- Routine tests (electrical resistance, high-voltage test, insulation resistance).

- Special tests (thickness measurement, watertightness, hot-set, low temperature behaviour, coatings and galvanizing).

- Type tests, both electrical and non‑electrical (long-duration high-voltage, ageing, flame retardance, fire integrity).

- Normative references and annexes

- Cross-references to IEC 60092-351 (insulating materials), IEC 60092-359 (sheathing materials), IEC 60228, IEC 60331, IEC 60811 series and several normative annex procedures.

Applications and who uses this standard

IEC 60092-350 is used by professionals involved in marine and offshore electrical systems:

- Shipbuilders and naval architects specifying shipboard power cable construction.

- Cable manufacturers designing and certifying marine power cables.

- Marine electrical engineers selecting cables for propulsion, distribution and auxiliary systems.

- Classification societies and regulatory authorities assessing compliance for vessel certification.

- Procurement and inspection teams performing factory acceptance tests and on‑board verification.

Practical applications include cable selection for newbuilds and retrofits, production quality control, type approval testing, and ensuring compatibility with shipboard insulation and sheathing materials.

Related standards

- IEC 60092 series (electrical installations in ships)

- IEC 60092-351 (insulating materials)

- IEC 60092-359 (sheathing materials)

- IEC 60228 (conductors)

- IEC 60331 / IEC 60332 / IEC 60811 (fire and material test methods)

Keywords: IEC 60092-350, shipboard power cables, marine cable construction, ship electrical installations, copper conductors, 8.7/15 kV, cable testing, marine cable standards.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 60092-350:2001 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical installations in ships - Part 350: Shipboard power cables - General construction and test requirements". This standard covers: This part of IEC 60092 specifies the general constructional requirements and general test recommendations for shipboard cables with copper conductors intended for power systems at voltages up to and including 8,7/15 kV.

This part of IEC 60092 specifies the general constructional requirements and general test recommendations for shipboard cables with copper conductors intended for power systems at voltages up to and including 8,7/15 kV.

IEC 60092-350:2001 is classified under the following ICS (International Classification for Standards) categories: 29.035.01 - Insulating materials in general; 29.060.20 - Cables; 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60092-350:2001 has the following relationships with other standards: It is inter standard links to IEC 60092-350:1988/AMD2:1999, IEC 60092-350:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60092-350:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60092-350

Second edition

2001-06

Electrical installations in ships –

Part 350:

Shipboard power cables –

General construction and test requirements

Installations électriques à bord des navires –

Partie 350:

Câbles d'énergie pour utilisation à bord des navires –

Construction générale et prescriptions d'essai

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

60092-350

Second edition

2001-06

Electrical installations in ships –

Part 350:

Shipboard power cables –

General construction and test requirements

Installations électriques à bord des navires –

Partie 350:

Câbles d'énergie pour utilisation à bord des navires –

Construction générale et prescriptions d'essai

IEC 2001 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

X

International Electrotechnical Commission

For price, see current catalogue

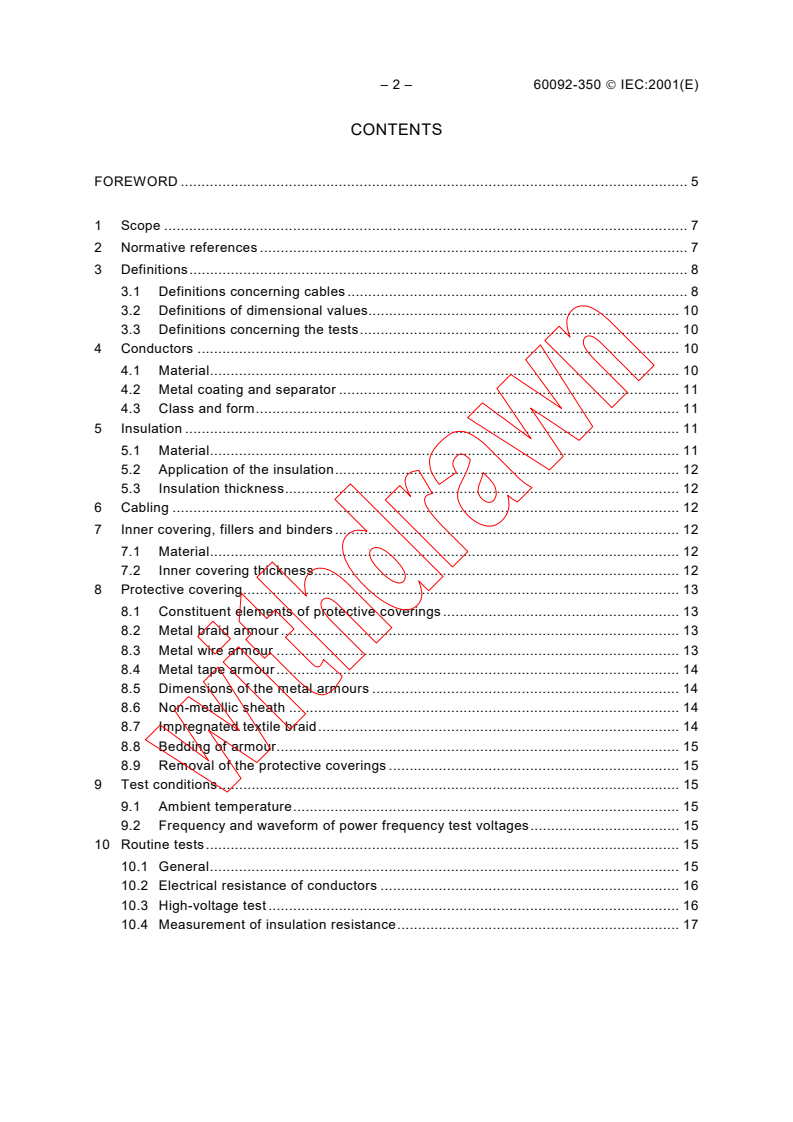

– 2 – 60092-350 IEC:2001(E)

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Definitions. 8

3.1 Definitions concerning cables . 8

3.2 Definitions of dimensional values. 10

3.3 Definitions concerning the tests. 10

4 Conductors . 10

4.1 Material. 10

4.2 Metal coating and separator . 11

4.3 Class and form. 11

5 Insulation . 11

5.1 Material. 11

5.2 Application of the insulation. 12

5.3 Insulation thickness. 12

6 Cabling . 12

7 Inner covering, fillers and binders . 12

7.1 Material. 12

7.2 Inner covering thickness. 12

8 Protective covering. 13

8.1 Constituent elements of protective coverings . 13

8.2 Metal braid armour . 13

8.3 Metal wire armour . 13

8.4 Metal tape armour . 14

8.5 Dimensions of the metal armours . 14

8.6 Non-metallic sheath . 14

8.7 Impregnated textile braid. 14

8.8 Bedding of armour. 15

8.9 Removal of the protective coverings . 15

9 Test conditions. 15

9.1 Ambient temperature. 15

9.2 Frequency and waveform of power frequency test voltages. 15

10 Routine tests. 15

10.1 General. 15

10.2 Electrical resistance of conductors . 16

10.3 High-voltage test . 16

10.4 Measurement of insulation resistance. 17

60092-350 © IEC:2001(E) – 3 –

11 Special tests . 18

11.1 General. 18

11.2 Frequency of special tests. 18

11.3 Conductor examination. 18

11.4 Measurement of thickness of insulation . 19

11.5 Measurements of thickness of non-metallic sheaths (excluding inner

coverings) . 19

11.6 Dimensions of armourings. 20

11.7 Measurement of external diameter . 20

11.8 Hot-set test for insulation and for sheaths . 20

11.9 Test for the behaviour at low temperature of PVC insulation and PVC, SHF 1

and SHF 2 sheaths. 20

11.10 Watertightness test . 20

11.11 Test of the metal coating of copper wires. 21

11.12 Galvanizing test. 21

12 Type tests, electrical . 21

12.1 General. 21

12.2 Insulation resistance measurement . 21

12.3 Increase in a.c. capacitance after immersion in water . 22

12.4 High-voltage test for 4 h . 23

13 Type tests, non-electrical . 23

13.1 Measurement of thickness of insulation . 23

13.2 Measurement of thickness of non-metallic sheaths (excluding inner coverings). 24

13.3 Tests for determining the mechanical properties of insulation before and after

ageing. 24

13.4 Tests for determining the mechanical properties of sheaths before and after

ageing. 24

13.5 Additional ageing test on pieces of completed cables (compatibility test). 25

13.6 Loss of mass test on PVC insulation and sheaths . 25

13.7 Test for the behaviour at high temperature of PVC insulation and PVC and

SHF 1 sheaths (pressure test). 26

13.8 Test for the behaviour at low temperature of PVC insulation and PVC, SHF 1

and SHF 2 sheaths. 26

13.9 Test for resistance to cracking of PVC insulation and PVC and SHF 1 sheaths

(heat shock test) . 26

13.10 Ozone resistance test for insulation and for sheaths . 26

13.11 Hot-set test for insulations and for sheaths . 26

13.12 Oil immersion test for elastomeric sheaths. 27

13.13 Flame retardance test. 27

13.14 Test for fire-proof or fire-resisting cables . 27

13.15 Determination of hardness for HEPR and HF HEPR insulations. 27

13.16 Determination of elastic modulus for HEPR and HF HEPR insulation. 27

13.17 Determination of degree of acidity of gases evolved during the combustion

of insulating materials by measuring pH and conductivity . 27

13.18 Determination of the amount of halogen acid gas for sheathing materials. 27

– 4 – 60092-350 IEC:2001(E)

Annex A (normative) The fictitious calculation method for determination of dimensions

of protective coverings. 30

Annex B (normative) Rounding of numbers . 35

Annex C (Informative) Calculation of the lower and upper limits for the average outer

dimensions of cables with circular copper conductors . 36

Annex D (normative) Procedure for checking the efficacy of the spark testing method . 40

Annex E (normative) Test of the metal coating of copper wires. 42

Annex F (normative) Galvanizing test for steel wires . 43

Bibliography . 44

60092-350 © IEC:2001(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 350: Shipboard power cables –

General construction and test requirements

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60092-350 has been prepared by subcommittee 18A: Cables and

cable installations, of IEC technical committee 18: Electrical installations of ships and of mobile

and fixed offshore units.

This second edition cancels and replaces the first edition published in 1988, Amendment 1

(1994) and Amendment 2 (1999), and constitutes a technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

18A/206/FDIS 18A/213/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B, D, E and F form an integral part of this standard.

Annex C is for information only.

– 6 – 60092-350 IEC:2001(E)

This standard forms a part of IEC 60092 Electrical installations in ships.

The committee has decided that the contents of this publication will remain unchanged until

2004. At this date, the publication will be:

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60092-350 © IEC:2001(E) – 7 –

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 350: Shipboard power cables –

General construction and test requirements

1 Scope

This part of IEC 60092 specifies the general constructional requirements and general test

recommendations for shipboard cables with copper conductors intended for power systems at

voltages up to and including 8,7/15 kV.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60092. For dated references, subsequent amendments

to, or revisions of, any of these publications do not apply. However, parties to agreements

based on this part of IEC 60092 are encouraged to investigate the possibility of applying the

most recent editions of the normative documents indicated below. For undated references, the

latest edition of the normative document referred to applies. Members of IEC and ISO maintain

registers of currently valid International Standards.

IEC 60092-351, Electrical installations in ships – Part 351: Insulating materials for shipboard

and mobile and fixed offshore units power, telecommunication and control data cables

IEC 60092-359, Electrical installations in ships – Part 359: Sheathing materials for shipboard

power and telecommunication cables

IEC 60228, Conductors of insulated cables

IEC 60331 (all parts), Tests for electric cables under fire conditions – Circuit integrity

IEC 60332-3, Tests on electric cables under fire conditions – Part 3: Tests on bunched wires or

cables

IEC 60811-1-1, Common test methods for insulating and sheathing materials of electric cables –

Part 1: Methods for general application – Section 1: Measurement of thickness and overall

dimensions – Tests for determining the mechanical properties

IEC 60811-1-2, Common test methods for insulating and sheathing materials of electric cables –

Part 1: Methods for general application – Section Two: Thermal ageing methods

IEC 60811-1-4, Common test methods for insulating and sheathing materials of electric cables –

Part 1: Methods for general application – Section Four: Tests at low temperature

IEC 60811-2-1, Insulating and sheathing materials of electric and optical cables – Common test

methods – Part 2-1: Methods specific to elastomeric compounds – Ozone resistance, hot set and

mineral oil immersion tests

IEC 60811-3-1, Common test methods for insulating and sheathing materials of electric cables –

Part 3: Methods specific to PVC compounds – Section One: Pressure test at high temperature –

Tests for resistance to cracking

– 8 – 60092-350 IEC:2001(E)

IEC 60811-3-2, Common test methods for insulating and sheathing materials of electric cables –

Part 3: Methods specific to PVC compounds – Section Two: Loss of mass test – Thermal

stability test

IEC 60754-1, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the amount of halogen acid gas

IEC 60754-2, Test on gases evolved during combustion of electric cables – Part 2: Determination

of degree of acidity of gases evolved during the combustion of materials taken from electric

cables by measuring pH and conductivity

3 Definitions

For the purpose of this standard, the following definitions apply.

3.1 Definitions concerning cables

3.1.1

insulated cable

assembly consisting of

– one or more cores;

– individual covering(s) (if any);

– assembly protection (if any);

– protective covering(s) (if any).

Additional uninsulated conductor(s) may be included in the cable

3.1.2

radial field cable

cable in which each core is covered with an individual screen

3.1.3

screen

conducting layer(s) having the function of control of the electric field within the insulation. It

may also provide smooth surfaces at the boundaries of the insulation and assist in the

elimination of spaces at these boundaries

3.1.4

conductor

part of the cable which has the specific function of carrying current

3.1.5

stranded conductor

conductor consisting of a number of individual wires, all or the major part of which should have

a helical form

NOTE The stranded conductor may be circular or shaped.

3.1.6

core

assembly comprising a conductor and its own insulation

3.1.7

core screen

electric screen of non-metallic and/or metallic materials covering the insulation

60092-350 © IEC:2001(E) – 9 –

3.1.8

shield

surrounding earthed metallic layer to confine the electric field within the cable and/or to protect

the cable from external electric influence

3.1.9

flexible cable

cable which is required to be capable of being flexed while in service, and of which the

structure and materials are such as to fulfil this requirement

3.1.10

cord

flexible cable with a limited number of conductors of small cross-sectional area

3.1.11

length of lay

axial length of one complete turn of the helix formed by one of the cable components

3.1.12

separator

thin layer, used as a barrier to prevent mutually detrimental effects between different

components of a cable, for example between conductor and insulation or between insulation

and sheath

3.1.13

filler

material used to fill the interstices between the cores of a multiconductor cable

3.1.14

inner covering

non-metallic covering which surrounds the assembly of the cores (and fillers, if any) of a

multicore cable and over which the protective covering is applied

3.1.15

sheath

uniform and continuous tubular covering consisting of non-metallic material, generally extruded

3.1.16

oversheath

non-metallic sheath applied over a metallic covering, constituting the outermost sheath of the

cable

3.1.17

armour

covering consisting of metal tape(s) or wires, generally used to protect the cable from external

mechanical effects

3.1.18

braid

covering made of plaited metallic or non-metallic material

– 10 – 60092-350 IEC:2001(E)

3.2 Definitions of dimensional values

3.2.1

nominal value

value by which a quantity is designated and which is often used in tables. Usually, nominal

values give rise to values to be checked by measurements, taking into account specified

tolerances

3.2.2

approximate value

value which is neither guaranteed nor checked; it is used, for example, for the calculation of

other dimensional values

3.2.3

median value

when several results have been obtained and ordered in increasing (or decreasing)

succession, the median value is the middle value if the number of available values is odd, and

the mean of the two middle values if the number is even

3.2.4

fictitious value

value calculated according to the "fictitious method" described in annex A

3.3 Definitions concerning the tests

3.3.1

routine tests

routine tests are tests made on all finished cable lengths to demonstrate the integrity of the

cable

NOTE By agreement between purchaser, manufacturer and, when involved, approval organization (making

reference, for example, to results of quality control procedures), the number of lengths of finished cable on which

these tests should be carried out may be reduced.

3.3.2

special tests

tests made by the manufacturer on samples of completed cable or components taken from a

completed cable, at a specified frequency, so as to verify that the finished product meets the

design specifications

3.3.3

type tests

tests required to be made by a manufacturer before supplying on a general commercial basis a

type of cable covered by this standard, in order to demonstrate satisfactory performance

characteristics to meet the intended application. These tests are of such a nature that, after

they have been made, they need not be repeated unless changes are made in the cable

materials or design which might change the performance characteristics

4 Conductors

4.1 Material

The conductors shall consist of plain or metal-coated annealed copper.

60092-350 © IEC:2001(E) – 11 –

4.2 Metal coating and separator

The component copper wires shall be metal-coated when used for conductors having a

thermosetting insulation, unless a separator between the conductor and the insulation is

provided. For conductors having thermoplastic insulation, the metal coating may be omitted.

The same applies to thermosetting insulation provided suitable type tests demonstrate that no

harmful effects occur.

The metal coating shall be considered as satisfactory if, on visual inspection, the wire surface

appears smooth, uniform and bright, and the insulation does not adhere to the conductor.

If a chemical test is required it shall be carried out with the methods and requirements

specified in annex E.

4.3 Class and form

The conductors considered in this standard are intended only for fixed installations and shall

comply with class 2 or class 5 of IEC 60228.

NOTE 1 In these applications the class 5 conductors are used only to facilitate easier installation and termination

under certain circumstances. Cables with such class 5 conductors should not be regarded as flexible cables.

NOTE 2 When using cables with class 5 conductors, users should carefully check the applicable current rating,

which may be lower than for cables with the same cross-sectional area of class 2 conductors.

Stranded circular non-compacted or compacted and sector-shaped conductors are permitted

for class 2.

The nominal cross-sectional area of the conductors shall have one of the values specified in

table II or table III of IEC 60228, with the following limitations:

– for all types of conductors, the nominal cross-sectional area shall not exceed, in general,

630 mm .

NOTE 3 For any cable requiring larger conductors, these should comply with the requirement for class 2 or class 5

of IEC 60228.

Circular non-compacted class 2 and flexible class 5 conductors should be not less than 1 mm

nominal cross-sectional area.

Circular compacted class 2 conductors should be not less than 10 mm nominal cross-

sectional area. (Cross-sectional areas less than 10 mm are under consideration.)

NOTE 4 Sector-shaped conductors should be not less than 25 mm nominal cross-sectional area.

NOTE 5 Conductors for cables suitable for portable use in ships are under consideration.

– All conductors shall have a regular shape, and shall be free from sharp projections and

other defects liable to damage the insulation.

Compliance with these requirements is checked by the appropriate test requirements specified

in clauses 8 to 12 of this standard.

5 Insulation

5.1 Material

The insulation shall consist of one of the insulating compounds considered in IEC 60092-351.

– 12 – 60092-350 IEC:2001(E)

5.2 Application of the insulation

The insulation shall be extruded closely to the conductor or to the separator, if any.

It shall be possible to remove the insulation without damaging the conductor or the metal

coating, if any.

5.3 Insulation thickness

The insulation thicknesses are specified for each type of cable in the relevant standard.

The average thickness of the insulation shall be not less than the value specified for each type

of insulation and conductor cross-section.

The thickness at any point may be less than the specified value provided that the difference

does not exceed 0,1 mm + 10 % of the specified value.

6 Cabling

The cores of a multicore cable shall be laid up. The use of fillers is permitted in the assembly

of multicore cables.

7 Inner covering, fillers and binders

7.1 Material

The inner covering, if any, may be extruded or lapped, as specified in the relevant standard of

the cable.

The inner covering, fillers and binders, if any, shall be of non-hygroscopic suitable material,

capable of withstanding the temperature arising when the conductors are operating at their

maximum rated temperature, and compatible with the insulating material.

An open helix of suitable tape is permitted as a binder before application of an extruded inner

covering. The thickness of the binder tape shall be optional.

When rubberlike or plastic inner coverings or fillers are specified, they should consist of rubber

(including regenerated and/or non-vulcanized rubber) or plastic compounds, and shall be

resistant to moisture. When a non-metallic sheath is applied directly over the inner covering or

the fillers, it may (at manufacturer's option) substitute partially or totally for the inner covering

or fillers.

When a "watertight cable" is specified, the spaces among cores and sheath and the interstices

in the conductor strands shall be filled so as to obtain a continuous sealing all along the cable,

which shall comply with the watertightness test specified in 11.10.

7.2 Inner covering thickness

The approximate thickness of the extruded or lapped inner coverings, if any, is specified in the

relevant standard for the cable.

60092-350 © IEC:2001(E) – 13 –

8 Protective covering

8.1 Constituent elements of protective coverings

The protective covering of any cable consists of one or more "constituent elements" which shall

be specified by the relevant standard for the cable. The following types of "constituent

elements" are considered in this standard:

a) Metallic elements:

1) metal braid armour;

2) metal wire armour;

3) metal tape armour.

b) Non-metallic elements:

1) thermosetting or thermoplastic sheath;

2) impregnated fibrous braid;

3) bedding for metal armour;

4) paint for metal armour.

8.2 Metal braid armour

The standard type of braid armour shall be made of zinc-coated (galvanized) steel wires

complying with the galvanizing test specified in 11.12 and annex F, or copper, tinned copper or

copper-alloy wires. On special request, the braid may be formed of aluminium-alloy wires with

protection against corrosion.

The "coverage density" of the braid shall be such that the weight of the braid is at least 90 % of

the weight of a tube of the same metal, having an internal diameter equal to the calculated

internal diameter under the braid and a thickness equal to the nominal diameter of the wires

forming the braid.

The diameter under the braid is calculated with the fictitious method given in annexes A and B.

(For test method, see item b) of 11.6.)

NOTE An alternative method for evaluating the "coverage density" is given by the following formula giving the

"filling factor", F, per unit:

NPd

F =

sin α

where

α is the slope angle between the cable axis and the braid wires;

d is the diameter of braid wire

N is the number of wires per carrier

P is the number of picks per millimetre.

The corresponding "coverage density", expressed as a percentage, is given by the formula:

π

G = ⋅ F ⋅ 100

G F

To obtain the minimum value of (90 %) the minimum value of should be: 0,573.

8.3 Metal wire armour

The standard type of metal wire armour shall consist of zinc-coated mild steel wires having an

elongation at break of at least 12 % and complying with the galvanized test specified in 11.12

and annex F.

– 14 – 60092-350 IEC:2001(E)

On special request, wires may be of a non-magnetic material instead of steel.

Also on special request, and where the diameter under armour is greater than 15 mm, a flat

wire armour may be used.

The wires should be applied over the bedding so as to form a uniform and substantially

uninterrupted cylindrical layer and so as to ensure sufficient flexibility for the finished cable.

8.4 Metal tape armour

The standard type of metal tape armour shall be made of annealed steel tapes which, on

special request, may be galvanized. Tapes of non-magnetic metals (for instance copper- or

aluminium-alloys) may be used, on special request, in place of steel tapes.

NOTE The risk of corrosion shall be considered when using aluminium alloys.

The armour shall, in general, be formed of two tapes wound over the bedding in the same

direction so that the gap in the first layer is not more than one-half of the tape width, and the

second layer covers this gap with an overlap.

Particular types of metal tape armour (for instance consisting of one tape) may be permitted,

provided their mechanical characteristics are specified.

For cables whose diameter under the bedding is less than 10 mm, the use of a metal type

armour is not recommended.

8.5 Dimensions of the metal armours

For the purposes of this standard, when wire diameters, tape thicknesses and other similar

armouring dimensions are specified, they shall be understood as nominal values, complying

with 11.6.

8.6 Non-metallic sheath

8.6.1 Material

The sheath shall consist of one of the sheathing compounds considered in IEC 60092-359. The

quality of the sheathing material shall be suitable for the operating temperature of the cable.

8.6.2 Thickness of sheath

The thicknesses of the sheaths are specified in the relevant standard for each type of cable.

The average value of the sheath thickness shall be not less than the specified value.

The thickness at any point may be less than the specified value but shall not fall below 85 % of

the specified nominal thickness by more than 0,1 mm for sheaths applied on a smooth

cylindrical surface, or below 80 % of the specified nominal thickness by more than 0,2 mm for

sheaths applied on an irregular cylindrical surface.

8.7 Impregnated textile braid

The textile braid, if permitted, shall be of cotton, hemp, glass, or synthetic or other equivalent

textile fibre.

It shall be effectively impregnated with a compound which is resistant to moisture and free from

deleterious action upon the various materials constituting the cable.

60092-350 © IEC:2001(E) – 15 –

8.8 Bedding of armour

When tapes are used as a bedding, they shall be wound in such a manner that each tape

covers the gap (if any) between the adjacent edges. Woven tapes (for instance cotton or glass

tapes) should be saturated or coated with a moisture-resistant compound.

Synthetic tapes (for instance PVC tapes) do not need coating.

When fibrous rovings are used (for instance jute or glass rovings), they shall be wound in close

spirals and be saturated and filled with a moisture-resistant compound.

When a fibrous braid is used as a bedding, it shall comply with 8.7.

When a non-metallic sheath is used as a bedding, it shall comply with 8.6.

The relevant thickness shall be considered as an approximate value.

8.9 Removal of the protective coverings

It shall be possible to remove easily:

– the outer sheath from the metallic covering

and

– the metallic covering from the inner covering or the inner sheath.

9 Test conditions

9.1 Ambient temperature

Unless otherwise specified in the details for a particular test, voltage tests shall be made at an

ambient temperature of (20 ± 15) °C and other tests at an ambient temperature of (20 ± 5) °C.

9.2 Frequency and waveform of power frequency test voltages

The frequency of the alternating test voltages shall be in the range 49 Hz to 61 Hz. The wave-

form shall be substantially sinusoidal. The values quoted are r.m.s. values.

10 Routine tests

10.1 General

The routine tests required by this standard are:

a) measurement of the electrical resistance of conductors (see 10.2);

b) high-voltage test (see 10.3);

c) insulation resistance test (see 10.4).

The routine tests shall normally be carried out in all finished cable lengths, but the number of

lengths may be reduced by agreement between the purchaser, the manufacturer and, when

involved, the approval organization (making reference, for instance, to the results of quality

control procedures).

– 16 – 60092-350 IEC:2001(E)

The routine test may be carried out, at the manufacturer's option, either on delivery lengths or

on manufacturing lengths before they are cut into delivery lengths.

10.2 Electrical resistance of conductors

a) For multicore cables, measurements shall be made on all conductors of each cable length

selected for the routine test.

b) The completed cable length, or a sample therefrom, shall be in the test room, which shall

be maintained at a reasonably constant temperature for at least 12 h before the test. If it is

doubtful whether the conductor temperature is the same as the room temperature, the

resistance shall be measured after the cable has been in the test room for 24 h.

Alternatively, the resistance shall be measured on a sample of conductor conditioned for at

least 1 h in a temperature-controlled bath.

The measured value of resistance shall be corrected to a temperature of 20 °C and 1 km

length in accordance with the formulae and factors given in clause 6 of IEC 60228.

c) The d.c. resistance of each conductor at 20 °C shall not exceed the appropriate maximum

value specified in table II for class 2 and table III for class 5 of IEC 60228.

10.3 High-voltage test

a) The high-voltage test shall be made at ambient temperature using, at the manufacturer's

option, alternating voltage at power frequency, direct voltage or, for spark testing, high-

frequency or other forms of voltage.

b) Single-core cables without metallic covering shall be immersed in water at room

temperature for 1 h and the test voltage then applied for 5 min between the conductor and

the water.

Alternatively for single-core cycles without sheath, at manufacturer's option, a spark test

shall be carried out on the cable. The spark test equipment shall detect a puncture in the

insulation having a diameter equal to or greater than half of the specified insulation

thickness. The recovery time of the spark shall be not greater than 1 s. The magnitude and

the presence of the voltage shall be such that with the electrode system employed and at

the speed employed for the passage of the cable through the spark tester, the test

requirements are effectively met. The reference method to be used to establish the efficacy

of the spark testing equipment is given in annex D.

c) For multicore cables and single-core cycles with metallic covering, the test voltage shall be

applied for 5 min in succession between each insulated conductor and all the other ones

connected to earth and to the metallic covering, if any. The conductors may be suitably

connected for successive applications of the test voltage to limit the total testing time,

provided that the sequence of connections ensures that the voltage is applied for at least

5 min without interruption between each conductor and the other conductors and between

each conductor and the metallic covering, if any.

d) Unless otherwise stated in the relevant standard for the cable, the values of the test voltage

for the standard rated voltages are given in the following table 1:

60092-350 © IEC:2001(E) – 17 –

Table 1 – Test voltage

Rated voltage of cable Test voltage for 5 min

U /U Alternating current (a.c.) Direct current (d.c.)

o

kV kV kV

Up to and including 0,15 / 0,25 1,5 3,6

Up to and including 0,6 / 1,0 3,5 8,4

Up to and including 1,8 / 3 6,5 15,6

Up to and including 3,6 / 6 11 26,4

Up to and including 6 / 10 15 36

Up to and including 8,7 / 15 22 52,8

e) The test voltage shall be increased gradually to the specified value and no breakdown of

the insulation shall occur.

10.4 Measurement of insulation resistance

a) The insulation resistance shall be measured at ambient temperature using a d.c. voltage of

80 V to 500 V, after the high-voltage test has been carried out.

b) The measurement shall in general be effected 1 min after application of the voltage. In

certain cases, however, in order to reach a substantial steady-state condition, the time of

application may be prolonged up to a maximum of 5 min.

c) The connection procedure in carrying out the test on different types of cables shall be as

follows:

– for single-core cables with metallic covering, the insulation resistance measurement

shall be performed between the conductor and the metallic covering;

– for single-core cables without metallic covering, the insulation resistance measurement

shall be performed between the conductor and the water in which the cable shall be

immersed at least 1 h before the test;

– for cables having two to five conductors, with or without metallic covering, the insulation

resistance measurement shall be performed in turn between each conductor and all

other conductors connected together and to the metallic covering, if any;

– for cables having more than five conductors, the insulation resistance measurement test

shall be performed: first, between all conductors of uneven number in all layers and all

conductors of even number in all layers; second, between all conductors of even layers

and all conductors of uneven layers; third, if necessary, between the first and the last

conductor of each layer having an uneven number of conductors.

d) The measurement values of the insulation resistance shall be corrected to the reference

temperature of 20 °C by using an appropriate temperature correction factor based on

experimental results obtained on the insulation material concerned.

e) The insulation resistance constant K shall be calculated using the formula:

i

−9

"R × 10

K = MΩ⋅km

i

D

log

d

where

R is the measured insulation resistance, in ohms, corrected to 20 °C;

" is the length of the cable, in metres;

D is the outer diameter of the insulation, in millimetres;

d is the inner diameter of the insulation, in millimetres.

– 18 – 60092-350 IEC:2001(E)

The calculated value of K shall be not less than the value specified for the relevant insulating

i

material in table 2 of IEC 60092-351.

NOTE For the core of shaped conductors, the ratio D/d is the ratio of the perimeter over the insulation to the

perimeter over the conductors.

11 Special tests

11.1 General

The special tests required by this standard are:

a) conductor examination (see 11.3);

b) check of dimensions (see 11.4 and 11.7);

c) Hot-set test for insulation and for sheaths: see tables 2 and 3 for applicability of

compounds in the test method (see 11.8);

d) test at low temperature for PVC (see 11.9);

e) watertightness test (see 11.10);

f) test of the metal coating of copper wires (see 11.11);

g) galvanizing test (see 11.12).

11.2 Frequency of special tests

a) Conductor examination and check of dimensions

Conductor examination, measurement of the thickness of insulation and sheath and

measurement of the overall diameter, if required by the purchaser, shall be made on one

length from each manufacturing series of the same type and size of cable, but shall be

limited to not more than 10 % of the number of lengths in any one contract.

b) Electrical and physical tests

By agreement between the purchaser and manufacturer, the test specified shall be made

on samples taken from ca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...