IEC 60793-2-10:2011

(Main)Optical fibres - Part 2-10: Product specifications - Sectional specification for category A1 multimode fibres

Optical fibres - Part 2-10: Product specifications - Sectional specification for category A1 multimode fibres

IEC 60793-2-10:2011 is applicable to optical fibre types A1a, A1b, and A1d. These fibres are used or can be incorporated in information transmission equipment and optical fibre cables. Other applications include, but are not restricted to, the following:

- short reach,

- high bit-rate systems in telephony,

- distribution and local networks carrying data,

- voice and/or video services;

- on-premises intra-building and inter-building fibre installations including Data Centres, LANs, Storage Area Networks, PBXs, video, various multiplexing uses, outside telephone cable plant use, and miscellaneous related uses. The major changes with respect to the previous edition are:

- addition of type A1a.3 fibre;

- reduction of core diameter tolerance from 3,0 to 2,5 mum for A1a fibres.

Fibres optiques - Partie 2-10: Spécifications de produits - Spécification intermédiaire pour les fibres multimodales de catégorie A1

La CEI 60793-2-10:2011 est applicable aux fibres optiques de type A1a, A1b et A1d. Ces fibres sont utilisées ou peuvent être intégrées dans des équipements destinés à la transmission de l'information et dans des câbles à fibres optiques. D'autres applications comprennent, mais sans s'y limiter, ce qui suit:

- les systèmes téléphoniques de courtes distances à haut débit,

- les réseaux de distribution et les réseaux locaux qui transportent des données,

- la voix et/ou des services vidéo;

- et les connexions par fibres intra ou inter bâtiment des locaux utilisateurs englobant les LAN des centres de traitement de données, les réseaux dédiés sauvegarde, les PABX, la vidéo, les différentes utilisations de multiplexage, l'utilisation d'une installation de câble du réseau téléphonique externe et les différentes utilisations associées. Les modifications principales par rapport à l'édition précédente sont:

- ajout des fibres de type A1a3;

- réduction de la tolérance sur le diamètre du coeur de 3,0 à 2,5 mum pour les fibres A1a.

General Information

- Status

- Published

- Publication Date

- 13-Mar-2011

- Technical Committee

- SC 86A - Fibres and cables

- Drafting Committee

- WG 1 - TC 86/SC 86A/WG 1

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 19-Nov-2015

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60793-2-10:2011 is an international standard published by the International Electrotechnical Commission (IEC) that defines product specifications for category A1 multimode optical fibres. This fourth edition focuses on types A1a, A1b, and A1d multimode fibres. It provides detailed sectional specifications covering dimensional, mechanical, transmission, and environmental requirements essential for ensuring fibre performance and interoperability. The standard targets fibres commonly used in information transmission equipment and optical fibre cables.

This standard plays a critical role in establishing benchmarks for optical fibre manufacturing to meet rising demands for reliable high-speed data transmission, particularly in telecommunications, enterprise networking, and data center applications.

Key Topics

Fibre Types and Characteristics

- A1a fibres: 50/125 μm graded-index fibres, including subcategories A1a.1 (standard), A1a.2, and A1a.3 (laser-optimised bandwidth grades for 850 nm operation).

- A1b fibres: 62.5/125 μm graded-index fibres, widely used in legacy multimode applications.

- A1d fibres: 100/140 μm graded-index fibres suited for applications requiring larger core sizes.

Dimensional and Mechanical Specifications

- Core diameter tolerance is refined to ±2.5 μm for A1a fibres, enhancing fibre consistency and performance.

- Mechanical specifications include tensile strength, stripping force, and resistance to environmental stresses, which are crucial for fibre durability in various installation environments.

Transmission Requirements

- Defines bandwidth and attenuation properties essential for supporting high bit-rate systems, including voice, video, and data services.

- Addresses fibre differential mode delay (DMD) and effective modal bandwidth (EMB) for optimized signal integrity.

Environmental Tests

- Specifies mechanical and transmission environmental requirements to ensure fibres maintain performance through temperature variations, humidity, and mechanical handling.

Applications Supported

- Short reach, high bit-rate telephony systems.

- Intra-building and inter-building installations such as Data Centres, LANs, Storage Area Networks, PBXs.

- Transmission of voice, video, and multiplexed data services over optical networks.

Applications

IEC 60793-2-10:2011 fibres are widely implemented in:

- Enterprise Networks and Data Centres - Enables high-speed data transmission within and between buildings, supporting critical applications like Storage Area Networks (SANs) and local area networking.

- Telecommunications - Supports short reach high bit-rate telephony systems and cable plant uses, ensuring reliable voice and data delivery.

- Video Distribution - Facilitates video signals transmission for PBX systems and multimedia applications.

- Multiplexing Systems - Supports advanced multiplexing technologies requiring robust multimode fibre performance.

This standard ensures fibres can reliably handle 1 Gbit/s up to 100 Gbit/s Ethernet speeds, accommodating evolving network bandwidth demands.

Related Standards

IEC 60793-2-10 is part of the larger IEC 60793 series, which collectively defines comprehensive specifications for optical fibres. Related standards include:

- IEC 60793-1 - Generic specification for optical fibres (“Vocabulary and general properties”) which provides fundamental definitions applicable to IEC 60793-2-10.

- IEC 60793-2-50 - Specifications for single-mode fibres supporting long-reach and high-performance networks.

- ISO/IEC 11801 - Information technology standard that references fibres for generic cabling in building infrastructure, aligning with IEC 60793-2-10 fibre types.

Manufacturers and network designers often reference IEC 60793-2-10 to harmonize multimode fibre attributes with global interoperability requirements and leverage IEC’s ongoing revisions to stay updated with technological advances.

Conclusion

IEC 60793-2-10:2011 provides essential specifications for category A1 multimode optical fibres, establishing manufacturing and performance criteria that enable reliable, high-speed data transmission across diverse communication infrastructures. Its focus on graded-index multimode fibres with improved dimensional tolerance and environmental robustness helps support modern telecommunication networks, data centres, and enterprise LANs.

Adhering to IEC 60793-2-10 ensures optical fibres meet global quality and performance standards, facilitating advances in telephony, video, and high-capacity data services while promoting international interoperability in fibre optic technologies.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60793-2-10:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical fibres - Part 2-10: Product specifications - Sectional specification for category A1 multimode fibres". This standard covers: IEC 60793-2-10:2011 is applicable to optical fibre types A1a, A1b, and A1d. These fibres are used or can be incorporated in information transmission equipment and optical fibre cables. Other applications include, but are not restricted to, the following: - short reach, - high bit-rate systems in telephony, - distribution and local networks carrying data, - voice and/or video services; - on-premises intra-building and inter-building fibre installations including Data Centres, LANs, Storage Area Networks, PBXs, video, various multiplexing uses, outside telephone cable plant use, and miscellaneous related uses. The major changes with respect to the previous edition are: - addition of type A1a.3 fibre; - reduction of core diameter tolerance from 3,0 to 2,5 mum for A1a fibres.

IEC 60793-2-10:2011 is applicable to optical fibre types A1a, A1b, and A1d. These fibres are used or can be incorporated in information transmission equipment and optical fibre cables. Other applications include, but are not restricted to, the following: - short reach, - high bit-rate systems in telephony, - distribution and local networks carrying data, - voice and/or video services; - on-premises intra-building and inter-building fibre installations including Data Centres, LANs, Storage Area Networks, PBXs, video, various multiplexing uses, outside telephone cable plant use, and miscellaneous related uses. The major changes with respect to the previous edition are: - addition of type A1a.3 fibre; - reduction of core diameter tolerance from 3,0 to 2,5 mum for A1a fibres.

IEC 60793-2-10:2011 is classified under the following ICS (International Classification for Standards) categories: 29.140.30 - Fluorescent lamps. Discharge lamps; 33.180.10 - Fibres and cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60793-2-10:2011 has the following relationships with other standards: It is inter standard links to IEC 60793-2-10:2015, IEC 60793-2-10:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60793-2-10:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60793-2-10 ®

Edition 4.0 2011-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibres –

Part 2-10: Product specifications – Sectional specification for category A1

multimode fibres

Fibres optiques –

Partie 2-10: Spécifications de produits – Spécification intermédiaire pour les

fibres multimodales de catégorie A1

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60793-2-10 ®

Edition 4.0 2011-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibres –

Part 2-10: Product specifications – Sectional specification for category A1

multimode fibres

Fibres optiques –

Partie 2-10: Spécifications de produits – Spécification intermédiaire pour les

fibres multimodales de catégorie A1

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX W

ICS 33.180.10 ISBN 978-2-88912-406-0

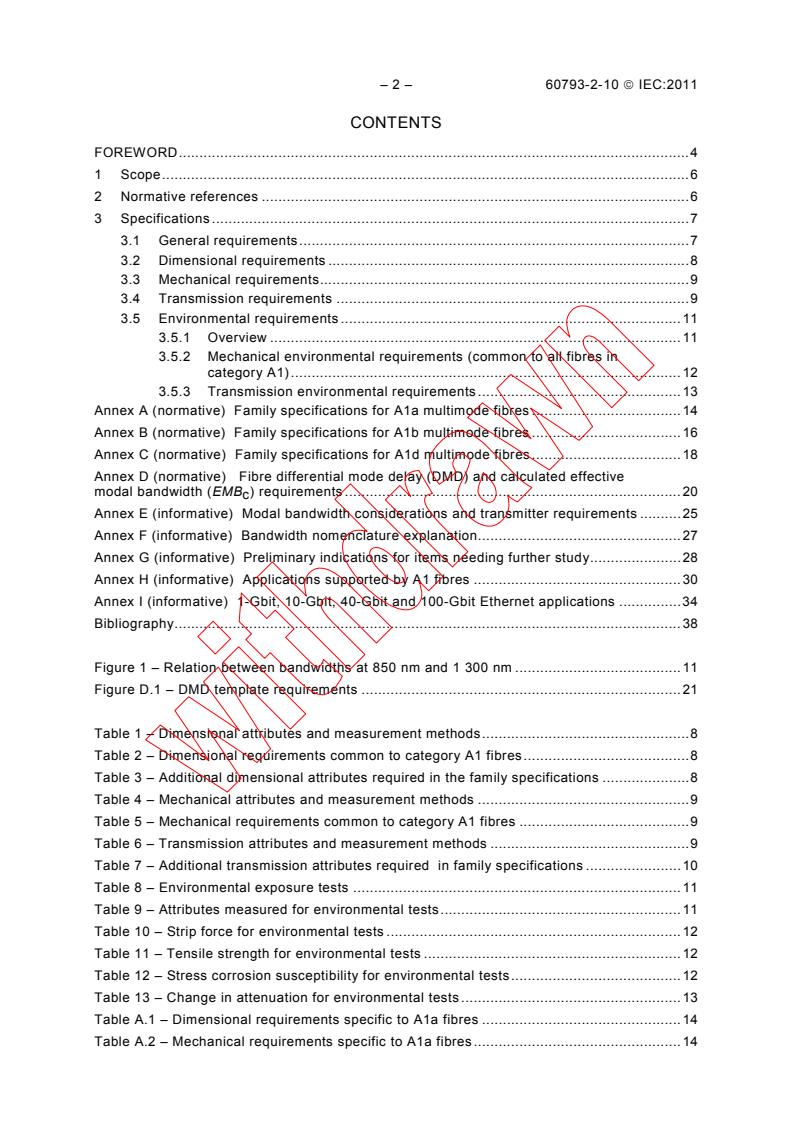

– 2 – 60793-2-10 IEC:2011

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Specifications . 7

3.1 General requirements . 7

3.2 Dimensional requirements . 8

3.3 Mechanical requirements . 9

3.4 Transmission requirements . 9

3.5 Environmental requirements . 11

3.5.1 Overview . 11

3.5.2 Mechanical environmental requirements (common to all fibres in

category A1) . 12

3.5.3 Transmission environmental requirements . 13

Annex A (normative) Family specifications for A1a multimode fibres . 14

Annex B (normative) Family specifications for A1b multimode fibres . 16

Annex C (normative) Family specifications for A1d multimode fibres . 18

Annex D (normative) Fibre differential mode delay (DMD) and calculated effective

modal bandwidth (EMB ) requirements . 20

c

Annex E (informative) Modal bandwidth considerations and transmitter requirements . 25

Annex F (informative) Bandwidth nomenclature explanation. 27

Annex G (informative) Preliminary indications for items needing further study . 28

Annex H (informative) Applications supported by A1 fibres . 30

Annex I (informative) 1-Gbit, 10-Gbit, 40-Gbit and 100-Gbit Ethernet applications . 34

Bibliography . 38

Figure 1 – Relation between bandwidths at 850 nm and 1 300 nm . 11

Figure D.1 – DMD template requirements . 21

Table 1 – Dimensional attributes and measurement methods . 8

Table 2 – Dimensional requirements common to category A1 fibres . 8

Table 3 – Additional dimensional attributes required in the family specifications . 8

Table 4 – Mechanical attributes and measurement methods . 9

Table 5 – Mechanical requirements common to category A1 fibres . 9

Table 6 – Transmission attributes and measurement methods . 9

Table 7 – Additional transmission attributes required in family specifications . 10

Table 8 – Environmental exposure tests . 11

Table 9 – Attributes measured for environmental tests . 11

Table 10 – Strip force for environmental tests . 12

Table 11 – Tensile strength for environmental tests . 12

Table 12 – Stress corrosion susceptibility for environmental tests . 12

Table 13 – Change in attenuation for environmental tests . 13

Table A.1 – Dimensional requirements specific to A1a fibres . 14

Table A.2 – Mechanical requirements specific to A1a fibres . 14

60793-2-10 IEC:2011 – 3 –

Table A.3 – Transmission requirements specific to A1a fibres . 15

Table B.1 – Dimensional requirements specific to A1b fibres . 16

Table B.2 – Mechanical requirements specific to A1b fibres . 16

Table B.3 – Transmission requirements specific to A1b fibres . 17

Table C.1 – Dimensional requirements specific to A1d fibres . 18

Table C.2 – Mechanical requirements specific to A1d fibres . 18

Table C.3 – Transmission requirements specific to A1d fibres . 19

Table D.1 – DMD templates for A1a.2 fibres . 20

Table D.2 – DMD interval masks for A1a.2 fibres . 22

Table D.3 – DMD Weightings . 23

Table D.4 – DMD templates for A1a.3 fibres . 24

Table D.5 – DMD interval masks for A1a.3 fibres . 24

Table F.1 – Bandwidth nomenclature explanation . 27

Table H.1 – Some internationally standardised applications supported by A1a and/or

A1b fibres . 30

Table H.2 – Typically used commercial bandwidth specifications for A1a and A1b

graded-index multimode fibres. . 31

Table H.3 – Cross reference of fibre types and bandwidth cells for this standard and

ISO/IEC 11801 . 32

Table I.1 – Summary of 1 Gbit/s , 10 Gbit/s , 40 Gbit/s and 100 Gbit/s Ethernet

requirements and capabilities for A1b fibres . 35

Table I.2 – Summary of 1 Gbit/s , 10 Gbit/s , 40 Gbit/s and 100 Gbit/s Ethernet

requirements and capabilities for A1a.1 fibres . 36

Table I.3 – Summary of 1 Gbit/s , 10 Gbit/s , 40 Gbit/s and 100 Gbit/s Ethernet

requirements and capabilities for A1a.2 and A1a.3 fibres . 37

– 4 – 60793-2-10 IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRES –

Part 2-10: Product specifications –

Sectional specification for category A1 multimode fibres

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60793-2-10 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This fourth edition cancels and replaces the third edition published in 2007. This edition

constitutes a technical revision.

The major changes with respect to the previous edition are listed below:

• addition of type A1a.3 fibre;

• reduction of core diameter tolerance from 3,0 to 2,5 μm for A1a fibres.

60793-2-10 IEC:2011 – 5 –

The text of this standard is based on the following documents:

CDV Report on voting

86A/1295/CDV 86A/1328/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60793 series, published under the general title Optical fibres can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 60793-2-10 IEC:2011

OPTICAL FIBRES –

Part 2-10: Product specifications –

Sectional specification for category A1 multimode fibres

1 Scope

This part of IEC 60793 is applicable to optical fibre types A1a, A1b, and A1d. These fibres are

used or can be incorporated in information transmission equipment and optical fibre cables.

Type A1a fibre is a 50/125 μm graded index fibre. Type A1a.1 applies to 50/125 μm fibre,

while A1a.2 and A1a.3 apply to two bandwidth grades of 850 nm laser-optimised 50/125 μm

fibre. Type A1b applies to 62,5/125 μm graded index fibre and A1d applies to 100/140 μm

graded index fibre.

Other applications include, but are not restricted to, the following: short reach, high bit-rate

systems in telephony, distribution and local networks carrying data, voice and/or video

services; on-premises intra-building and inter-building fibre installations including Data

Centres, LANs, Storage Area Networks, PBXs, video, various multiplexing uses, outside

telephone cable plant use, and miscellaneous related uses.

Three types of requirements apply to these fibres:

– general requirements, as defined in IEC 60793-2;

– specific requirements common to the category A1 multimode fibres covered in this

standard and which are given in Clause 3;

– particular requirements applicable to individual fibre types or specific applications, which

are defined in the normative family specification annexes.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60793-1-1, Optical fibres – Part 1-1: Measurement methods and test procedures – General

and guidance

IEC 60793-1-20, Optical fibres – Part 1-20: Measurement methods and test procedures – Fibre

geometry

IEC 60793-1-21, Optical fibres – Part 1-21: Measurement methods and test procedures –

Coating geometry

IEC 60793-1-22, Optical fibres – Part 1-22: Measurement methods and test procedures –

Length measurement

IEC 60793-1-30, Optical fibres – Part 1-30: Measurement methods and test procedures – Fibre

proof test

IEC 60793-1-31, Optical fibres – Part 1-31: Measurement methods and test procedures –

Tensile strength

60793-2-10 IEC:2011 – 7 –

IEC 60793-1-32, Optical fibres – Part 1-32: Measurement methods and test procedures –

Coating strippability

IEC 60793-1-33, Optical fibres – Part 1-33: Measurement methods and test procedures – Stress

corrosion susceptibility

IEC 60793-1-34, Optical fibres – Part 1-34: Measurement methods and test procedures – Fibre

curl

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

IEC 60793-1-41, Optical fibres – Part 1-41: Measurement methods and test procedures –

Bandwidth

IEC 60793-1-42, Optical fibres – Part 1-42: Measurement methods and test procedures –

Chromatic dispersion

IEC 60793-1-43, Optical fibres – Part 1-43: Measurement methods and test procedures –

Numerical aperture

IEC 60793-1-46, Optical fibres – Part 1-46: Measurement methods and test procedures –

Monitoring of changes in optical transmittance

IEC 60793-1-47, Optical fibres – Part 1-47: Measurement methods and test procedures –

Macrobending loss

IEC 60793-1-49, Optical fibres – Part 1-49: Measurement methods and test procedures –

Differential mode delay

IEC 60793-1-50, Optical fibres – Part 1-50: Measurement methods and test procedures – Damp

heat (steady state)

IEC 60793-1-51, Optical fibres – Part 1-51: Measurement methods and test procedures – Dry

heat

IEC 60793-1-52, Optical fibres – Part 1-52: Measurement methods and test procedures –

Change of temperature

IEC 60793-1-53, Optical fibres – Part 1-53: Measurement methods and test procedures – Water

immersion

IEC 60793-2:2007, Optical fibres − Part 2: Product specifications - General

IEC 60794-1-1, Optical fibre cables – Part 1-1: Generic specification - General

IEC/TR 62048:2002, Optical fibres – Reliability – Power law theory

ISO/IEC 11801:2002, Information technology – Generic cabling for customer premises

3 Specifications

3.1 General requirements

The fibre shall consist of a glass core with a graded index profile and a glass cladding in

accordance with 5.1 in IEC 60793-2.

The term “glass” usually refers to material consisting of non-metallic oxides.

– 8 – 60793-2-10 IEC:2011

3.2 Dimensional requirements

Dimensional attributes and measurement methods are given in Table 1.

Requirements common to all fibres in category A1 are indicated in Table 2.

Table 3 lists additional attributes that shall be specified by each family specification.

Table 1 – Dimensional attributes and measurement methods

Attributes Measurement

methods

Cladding diameter IEC 60793-1-20

Core diameter IEC 60793-1-20

Cladding non-circularity IEC 60793-1-20

Core non-circularity IEC 60793-1-20

Core-cladding concentricity error IEC 60793-1-20

Primary coating diameter IEC 60793-1-21

Primary coating non-circularity IEC 60793-1-21

Primary coating-cladding concentricity error IEC 60793-1-21

Fibre length IEC 60793-1-22

Table 2 – Dimensional requirements common to category A1 fibres

Attributes Unit Limits

Core non-circularity %

≤6

a

Primary coating diameter – uncoloured

μm 245 ± 10

a

Primary coating diameter – coloured

μm 250 ± 15

Primary coating-cladding concentricity error

μm ≤12,5

b

Fibre length km

a

The above limits on primary coating diameter are most commonly used in

telecommunications cables. There are other applications, which use other primary

coating diameters, several of which are listed below.

Alternative nominal primary coating diameters and tolerance (μm):

400 ± 40

500 ± 50

700 ± 100

900 ± 100

b

Length requirements vary and should be agreed between the supplier and the

customer.

Table 3 – Additional dimensional attributes required

in the family specifications

Attributes

Cladding diameter

Cladding non-circularity

Core diameter

Core-cladding concentricity error

60793-2-10 IEC:2011 – 9 –

3.3 Mechanical requirements

Mechanical attributes and measurement methods are given in Table 4.

Requirements common to all fibres in category A1 are in Table 5.

Table 4 – Mechanical attributes and measurement methods

Attributes Test methods

Proof test IEC 60793-1-30

Tensile strength IEC 60793-1-31

Primary coating strippability IEC 60793-1-32

Stress corrosion susceptibility IEC 60793-1-33

Fibre curl IEC 60793-1-34

Table 5 – Mechanical requirements common to category A1 fibres

Attributes Unit Limits

a

Proof stress level GPa ≥ 0,69

b

Strip force (average) N 1,0 ≤ F ≤ 5,0

ave.strip

b

Strip force (peak) N 1,0 ≤ F ≤ 8,9

peak.strip

Tensile strength (median) for 0,5 m

GPa

≥ 3,8

specimen length

Stress corrosion susceptibility constant n

d ≥ 18

a

The proof stress of 0,69 GPa equals about 1 % strain or about 8,8 N force, for A1a

and A1b fibres. For the relation between these different units, see 7.4 of IEC/

TR 62048.

b

Either average strip force or peak strip force, which are defined in the test

procedure, may be specified by agreement between the supplier and the customer.

3.4 Transmission requirements

Transmission attributes and measurement methods are given in Table 6.

Table 7 lists additional attributes that shall be specified by each family specification.

Table 6 – Transmission attributes and measurement methods

Attributes Measurement

methods

a

Attenuation coefficient IEC 60793-1-40

a

Modal bandwidth IEC 60793-1-41

Numerical aperture IEC 60793-1-43

b

Chromatic dispersion IEC 60793-1-42

Change of optical transmission IEC 60793-1-46

Macrobending loss IEC 60793-1-47

Differential mode delay IEC 60793-1-49

a

When measuring attenuation and modal bandwidth, the appropriate launching

conditions should be applied. These may differ from those prescribed in the test

methods to which reference is made.

b

Specification compliance of chromatic dispersion can be assured by compliance to

the numerical aperture specification.

– 10 – 60793-2-10 IEC:2011

Table 7 – Additional transmission attributes required

in family specifications

Attributes

Attenuation coefficient

Modal bandwidth

Chromatic dispersion

Numerical aperture

Macrobending loss

For attenuation coefficient and modal bandwidth, the family specification contains ranges of

specifiable values instead of fixed limits. The actual values of the maximum attenuation

coefficient and minimum modal bandwidth, at both 850 nm and 1 300 nm (or just at one of

these wavelengths) are to be agreed between the supplier and the customer. For commercial

purposes, the modal bandwidth is linearly normalized to 1 km.

For guidance purposes on bandwidth, Table H.1 shows a number of internationally

standardised applications supported by A1 fibres, and Table H.2 gives a (limited) number of

frequently used commercial bandwidth specifications for A1a and A1b fibres.

The indicated maximum attenuation values apply to uncabled optical fibres; for the maximum

cabled attenuation values, reference is made to IEC 60794-1-1, which can be used in

conjunction with this standard.

Remarks on the specification of modal bandwidth:

Care should be taken in writing dual wavelength bandwidth specifications. For category A1

fibres, the bandwidth at 850 nm may be related to the bandwidth at 1 300 nm in a way shown

in Figure 1, depending on the refractive index parameter, g, (see 5.1 of IEC 60793-2). The

shaded region under the curve of Figure 1 can be defined as the dual window area. In this

area, regions X, Y, and Z are examples of where a fibre manufacturer may choose to optimise

the process. That is, centre the production at 850 nm, 1 300 nm, or between these two

wavelengths.

Due to this optimisation of the manufacturing process, there will be combinations of bandwidth

that are not possible. For example, it is practically impossible to produce a fibre with the

maximum of both indicated bandwidth ranges (e.g. 800 MHz•km /1 000 MHz•km for A1b

multimode fibres).

60793-2-10 IEC:2011 – 11 –

IEC 074/02

Figure 1 – Relation between bandwidths at 850 nm and 1 300 nm

3.5 Environmental requirements

3.5.1 Overview

Environmental exposure tests and measurement methods are documented in two forms:

– Relevant environmental attributes and test procedures are given in Table 8.

– Measurements of a particular mechanical or transmission attribute that may change on the

application of the environment are listed in Table 9.

Table 8 – Environmental exposure tests

Environmental exposure Test

Damp heat IEC 60793-1-50

Dry heat IEC 60793-1-51

Change of temperature IEC 60793-1-52

Water immersion IEC 60793-1-53

Table 9 – Attributes measured for environmental tests

Attribute Measurement method

Change in optical transmission IEC 60793-1-46

Attenuation IEC 60793-1-40

Strip force IEC 60793-1-32

Tensile strength IEC 60793-1-31

Stress corrosion susceptibility IEC 60793-1-33

– 12 – 60793-2-10 IEC:2011

These tests are normally conducted periodically as type-tests for a fibre and coating design.

Unless otherwise indicated, the recovery period allowed between the completion of the

environmental exposure and performing the attribute measurements shall be as stated in the

particular environmental test method.

3.5.2 Mechanical environmental requirements (common to all fibres in category A1)

3.5.2.1 Overview

These tests are, in practice, the most severe requirements amongst the environments defined

in Table 8.

Tables 10, 11, and 12 give the prescriptions for strip force, tensile strength and stress

corrosion susceptibility respectively.

3.5.2.2 Strip force

The following attributes shall be verified following removal of the fibre from the particular

environment.

Table 10 – Strip force for environmental tests

Environment Average strip force Peak strip force

N N

Damp heat

1,0 ≤ F ≤ 5,0 1,0 ≤ F ≤ 8,9

avg.strip peak.strip

Water immersion

1,0 ≤ F ≤ 5,0 1,0 ≤ F ≤ 8,9

avg.strip peak.strip

3.5.2.3 Tensile strength

The following attribute shall be verified following removal of the fibre from the environment.

Table 11 – Tensile strength for environmental tests

Environment Median tensile strength 15th percentile tensile strength

Specimen length: 0,5 m Specimen length: 0,5 m

GPa GPa

Damp heat ≥ 3,03 ≥ 2,76

NOTE These requirements do not apply to hermetically coated fibre.

3.5.2.4 Stress corrosion susceptibility

The following attribute shall be verified following removal of the fibre from the environment.

Table 12 – Stress corrosion susceptibility for environmental tests

Environment Stress corrosion susceptibility constant, nd

Damp heat

≥ 18

NOTE This requirement does not apply to hermetically coated fibre.

60793-2-10 IEC:2011 – 13 –

3.5.3 Transmission environmental requirements

Change in attenuation from the initial value shall be less than the values in Table 13.

Attenuation shall be measured periodically during the entire exposure to each environment

and after removal.

Table 13 – Change in attenuation for environmental tests

Environment Wavelength Attenuation increase

nm dB/km

Damp heat 850 ≤ 0,20

1 300 ≤ 0,20

Dry heat 850 ≤ 0,20

1 300

≤ 0,20

Change of temperature 850

≤ 0,20

1 300

≤ 0,20

Water immersion 850

≤ 0,20

1 300

≤ 0,20

– 14 – 60793-2-10 IEC:2011

Annex A

(normative)

Family specifications for A1a multimode fibres

A.1 General

The following clauses and tables contain particular requirements applicable to A1a fibres.

Common requirements, repeated here for ease of reference from the sectional specification,

are noted by an entry in the “Reference” column. Relevant notes from the sectional specification

SS

“ ”

are not repeated but indicated with a superscript .

Type A1a fibre is a 50/125 μm graded index fibre. Three types of A1a fibre are specified.

Type A1a.1 (defined in the first edition of this standard as type A1a) applies to 50/125 μm

fibre, while types A1a.2 and A1a.3 apply to two bandwidth grades of 850 nm laser-optimised

50/125 μm fibre. The dimensional, mechanical and environmental requirements are common

to all. The differences in the transmission requirements are specified in Table A.3.

A.2 Dimensional requirements

Table A.1 contains dimensional requirements specific to A1a fibres.

Table A.1 – Dimensional requirements specific to A1a fibres

Attribute Unit Limit Reference

Cladding diameter

μm 125 ± 2

Cladding non-circularity %

≤2

Core diameter

μm 50 ± 2,5

Core-cladding concentricity error

μm ≤3

Core non-circularity % 3.2

≤6

Primary coating diameter – uncoloured 3.2

μm 245 ± 10

Primary coating diameter – coloured 3.2

μm 250 ± 15

Primary coating-cladding concentricity error μm ≤12,5 3.2

Length km [see 3.2] 3.2

A.3 Mechanical requirements

Table A.2 contains the mechanical requirements specific to A1a fibres.

Table A.2 – Mechanical requirements specific to A1a fibres

Attribute Unit Limit Reference

SS

Proof stress level GPa ≥0,69 3.3

SS

Strip force (average) N 1,0 ≤ F ≤ 5,0 3.3

ave.strip

SS

Strip force (peak) N 1,0 ≤ F ≤ 8,9 3.3

peak.strip

60793-2-10 IEC:2011 – 15 –

A.4 Transmission requirements

Table A.3 contains transmission requirements specific to A1a fibres.

Table A.3 – Transmission requirements specific to A1a fibres

Attribute Unit Limit Reference

Fibre subtype A1a.1 A1a.2 A1a.3

a

Maximum attenuation coefficient at 850 nm dB/km 2,4 – 3,5 2,5

a

Maximum attenuation coefficient at 1300 nm dB/km 0,7 – 1,5 0,8

a

Minimum modal bandwidth-length product 200 – 800 1 500 3 500

MHz•km

for overfilled launch at 850 nm

a

Minimum modal bandwidth-length product MHz•km 200 – 1 200 500

for overfilled launch at 1 300 nm

Differential mode delay at 850 nm ps/m Not specified Meet Meet Annexes

Clause Clause D, E, F,

D.1 D.3 G

or or

Clause Clause

D.2 D.4

Numerical aperture Unit less 0,20 ± 0,015

Maximum macrobending loss dB 0,5

100 turns on mandrel diameter of 75 mm

b

at wavelengths 850 nm and 1 300 nm

c

nm

Zero dispersion wavelength, λ 1 295 ≤ λ ≤ 1 340

0 0

Zero dispersion slope, S ps/nm ∙km

c

- from 1 295 nm ≤ λ ≤ 1 310 nm ≤ 0,105

c

- from 1 310 nm ≤ λ ≤ 1 340 nm ≤ 0,000375 (1590 - λ )

0 0

a

These values represent a range that may be specified.

b

According to the wavelength-independent behaviour of macrobending loss for A1a fibre under the steady-state

launch conditions used in this test, testing at only one of these wavelengths may be sufficient to ensure

compliance to this specification.

c 2

The worst case chromatic dispersion coefficient at 850 nm (e.g. S = 0,09375 ps/nm ∙km at λ = 1 340 nm or

0 0

S = 0,10125 ps/nm ∙km at λ = 1 320 nm) is -104 ps/nm∙km.

0 0

A.5 Environmental requirements

The requirements of 3.5 shall be met.

– 16 – 60793-2-10 IEC:2011

Annex B

(normative)

Family specifications for A1b multimode fibres

B.1 General

The following clauses and tables contain particular requirements applicable to A1b fibres.

Common requirements, repeated here for ease of reference from the sectional specification,

are noted by an entry in the “Reference” column. Relevant notes from the sectional

SS

” ”

specification are not repeated but indicated with a superscript .

Type A1b fibre is a 62,5/125 μm graded index fibre.

B.2 Dimensional requirements

Table B.1 contains dimensional requirements specific to A1b fibres.

Table B.1 – Dimensional requirements specific to A1b fibres

Attributes Unit Limits Reference

Cladding diameter

μm 125 ± 2

Cladding non-circularity %

≤ 2

Core diameter

μm 62,5 ± 3

Core-cladding concentricity error

μm ≤3

Core non-circularity % 3.2

≤6

Primary coating diameter – uncoloured μm 245 ± 10 3.2

Primary coating diameter – coloured μm 250 ± 15 3.2

Primary coating-cladding concentricity error μm ≤12,5 3.2

Length Km [see 3.2] 3.2

B.3 Mechanical requirements

Table B.2 contains the mechanical requirements specific to A1b fibres.

Table B.2 – Mechanical requirements specific to A1b fibres

Attributes Unit Limits Reference

SS

Proof stress level GPa 3.3

≥ 0,69

SS

Strip force (average) N 3.3

1,0 ≤ F ≤ 5,0

ave.strip

SS

Strip force (peak) N 3.3

1,0 ≤ F ≤ 8,9

peak.strip

60793-2-10 IEC:2011 – 17 –

B.4 Transmission requirements

Table B.3 contains transmission requirements specific to A1b fibres.

Table B.3 – Transmission requirements specific to A1b fibres

Attributes Unit Limits Reference

a

Maximum attenuation coefficient at 850 nm dB/km 2,8 − 3,5

a

Maximum attenuation coefficient at 1 300 nm dB/km 0,7 − 1,5

a

Minimum modal bandwidth at 850 nm MHz•km 100 − 800

a

Minimum modal bandwidth at 1 300 nm

MHz•km 200 − 1 000

Numerical aperture Unit less

0,275 ± 0,015

Maximum macrobending loss dB 0,5

100 turns on mandrel diameter of 75 mm

b

at wavelengths 850 nm and 1300 nm

c

nm

Zero dispersion wavelength, λ 1 320 ≤ λ ≤ 1 365

0 0

Zero dispersion slope S ps/nm ∙km

c

− from 1 320 nm ≤ λ ≤ 1 348 nm ≤ 0,11

c

− from 1 348 nm ≤ λ ≤ 1 365 nm ≤ 0,001 (1 458 – λ )

0 0

a

The limit column forms a range of values that may be specified.

b

According to the wavelength-independent behaviour of macrobending loss for A1b fibre under the steady-state

launch conditions used in this test, testing at only one of these wavelengths may be sufficient to ensure

compliance to this specification.

c 2

The worst case chromatic dispersion coefficient at 850 nm (S = 0,11 ps/nm ∙km at λ = 1 348 nm) is

0 0

-125 ps/nm∙km.

B.5 Environmental requirements

The requirements of 3.5 shall be met.

– 18 – 60793-2-10 IEC:2011

Annex C

(normative)

Family specifications for A1d multimode fibres

C.1 General

The following clauses and tables contain particular requirements for A1d fibres. Common

requirements, repeated here for ease of reference from the sectional specification, are noted

by an entry in the “Reference” column. Relevant notes from the sectional specification are not

SS

“ ”

repeated but indicated with a superscript .

Type A1d fibre is a 100/140 μm graded index fibre.

C.2 Dimensional requirements

Table C.1 contains dimensional requirements specific to A1d fibres.

Table C.1 – Dimensional requirements specific to A1d fibres

Attributes Unit Limits Reference

Cladding diameter

μm 140 ± 4

Cladding non-circularity %

≤ 4

Core diameter

μm 100 ± 5

Core-cladding concentricity error

μm ≤ 6

Core non-circularity % 3.2

≤ 6

Primary coating diameter – uncoloured 3.2

μm 245 ± 10

Primary coating diameter – coloured μm 250 ± 15 3.2

Primary coating-cladding concentricity error μm ≤ 12,5 3.2

Length km [see 3.2] 3.2

C.3 Mechanical requirements

Table C.2 contains the mechanical requirements specific to A1d fibres.

Table C.2 – Mechanical requirements specific to A1d fibres

Attributes Unit Limits Reference

SS

Proof stress level GPa ≥ 0,69 3.3

SS

Strip force (average) N 1,0 ≤ F ≤ 5,0 3.3

ave.strip

SS

Strip force (peak) N 1,0 ≤ F ≤ 8,9 3.3

peak.strip

60793-2-10 IEC:2011 – 19 –

C.4 Transmission requirements

Table C.3 contains transmission requirements specific to A1d fibres.

Table C.3 – Transmission requirements specific to A1d fibres

Attributes Unit Limits Reference

a

Maximum attenuation coefficient at 850 nm dB/km 3,5 − 7,0

a

Maximum attenuation coefficient at 1 300 nm dB/km 1,5 − 4,5

a

Minimum modal bandwidth at 850 nm MHz•km 10 − 200

a

Minimum modal bandwidth at 1 300 nm

MHz•km 100 − 300

Numerical aperture Unit less

0,26 ± 0,03 or

0,29 ± 0,03

Maximum macrobending loss dB For further study

b

nm

Zero dispersion wavelength, λ 1 330 ≤ λ ≤ 1 385

0 0

Zero dispersion slope S ps/nm ∙km

b

− from 1 330 nm ≤ λ ≤ 1 365 nm ≤ 0,105

b

− from 1 365 nm ≤ λ ≤ 1 385 nm ≤ 0,0005 (1 575 – λ )

0 0

a

The limit column forms a range of values that may be specified.

b 2

The worst case chromatic dispersion coefficient at 850 nm (S = 0,105 ps/nm ∙km at λ = 1 365 nm) is

0 0

-126 ps/nm∙km.

C.5 Environmental requirements

The requirements of 3.4 shall be met.

– 20 – 60793-2-10 IEC:2011

Annex D

(normative)

Fibre differential mode delay (DMD) and

calculated effective modal bandwidth (EMB ) requirements

c

D.1 A1a.2 fibre DMD requirements

D.1.1 General

A1a.2 fibres selected using the DMD Mask method shall meet the requirements of D.1.1 and

D.1.2. The radial limits, R and R , were established for transmitters meeting the

INNER OUTER

requirements of Clause E.2.

Refer to Annex E for information regarding effective modal bandwidth (EMB).

D.1.2 DMD templates

A1a.2 fibres shall meet at least one of the six templates given in Table D.1, each of which

includes an inner and outer mask requirement, when measured per IEC 60793-1-49.

Table D.1 – DMD templates for A1a.2 fibres

Template Inner mask DMD (ps/m) for Outer mask DMD (ps/m) for

number

R = 5 μm to R = 18 μm R = 0 μm to R = 23 μm

INNER OUTER INNER OUTER

≤0,23 ≤0,70

≤0,24 ≤0,60

≤0,25 ≤0,50

≤0,26 ≤0,40

≤0,27 ≤0,35

≤0,33 ≤0,33

The DMD requirements in D.1.2 are illustrated in Figure D.1. In this figure, the allowable DMD

(as measured by IEC 60793-1-49) is plotted versus the radial offset position of the single-

mode probe. There is a trade-off between the tightness of the inner mask and the outer mask

to ensure a sufficient amount of the baud energy from a transmitter (meeting the launch

specifications) arrives within the required time period (defined by the baud rate of the

transmission system).

60793-2-10 IEC:2011 – 21 –

Outer mask Inner mask Outer mask Outer mask Inner mask Outer mask

Inner mask floats

Inner mask floats

inside outer mask

inside outer mask

0,70 ps/m 0,70 ps/m 0,40 ps/m 0,26 ps/m 0,40 ps/m

0,23 ps/m

0 5 10 15 20 0 5 10 15 20

18 23 18 23

Radial offset (µm) Radial offset (µm)

Outer mask Inner mask Outer mask Outer mask Inner mask Outer mask

Inner mask floats

inside outer mask

0,24 ps/m

0,60 ps/m

0,60 ps/m

0,35 ps/m 0,35 ps/m

0,27 ps/m

Inner mask floats

inside outer mask

18 18 23

0 5 10 15 20 23 0 5 10 15 20

Radial offset (µm) Radial offset (µm])

Outer mask Inner mask Outer mask Outer mask Inner mask Outer mask

Inner mask floats

inside outer mask

0,33 ps/m

0,50 ps/m 0,25 ps/m 0,50 ps/m

0 5 10 15 18 20 23 0 5 10 15 18 20 23

Radial offset (µm) Radial offset (µm)

IEC 532/11

Figure D.1 – DMD template requirements

The “floating” characteristic of the inner mask is also illustrated in Figure D.1. In this figure,

the inner mask (5 μm to18 μm) may be positioned vertically (temporally) anywhere within the

outer mask (0 μm to 23 μm). The DMD is more tightly constrained in the inner mask to allow

for looser tolerances on the outer mask providing for improved ability to manufacture fibre

conforming with this requirement. In the case of the 0,33 ps/m mask, the requirement is the

same over the whole range from 0 μm to 23 μm creating a “flat” mask.

IEC 60793-1-49 can be used to ensure a minimum effective modal bandwidth-length product,

when using sources meeting appropriate restrictions. When the launch condition requirements

on the transmitters are coupled to the DMD requirements

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...