IEC 61439-6:2012

(Main)Low-voltage switchgear and controlgear assemblies - Part 6: Busbar trunking systems (busways)

Low-voltage switchgear and controlgear assemblies - Part 6: Busbar trunking systems (busways)

IEC 61439-6:2012 lays down the definitions and states the service conditions, construction requirements, technical characteristics and verification requirements for low voltage BTS (see 3.101) as follows:

- BTS for which the rated voltage does not exceed 1 000 V in case of a.c. or 1 500 V in case of d.c.;

- BTS intended for use in connection with the generation, transmission, distribution and conversion of electric energy, and for the control of electric energy consuming equipment;

- BTS designed for use under special service conditions, for example in ships, in rail vehicles, and for domestic applications (operated by unskilled persons), provided that the relevant specific requirements are complied with;

- BTS designed for electrical equipment of machines. Supplementary requirements for BTS forming part of a machine are covered by the IEC 60204 series. This first edition of IEC 61439-6 cancels and replaces the third edition of IEC 60439-2 (2000) and its Amendment 1 (2005), and constitutes a technical revision. This edition of IEC 61439-6 includes the following significant technical changes with respect to the latest edition of IEC 60439-2:

- alignment on the second edition of IEC 61439-1 (2011) regarding the structure and technical content, as applicable;

- introduction of new verifications, accordingly;

- correction of inconsistencies in resistance, reactance and impedance measurements and calculations;

- numerous editorial improvements.

This publication is to be read in conjunction with IEC 61439-1:2011.

Ensembles d'appareillage à basse tension - Partie 6: Systèmes de canalisation préfabriquée

La CEI 61439-6:2012 formule les définitions et indique les conditions d'emploi, les exigences de construction, les caractéristiques techniques et les exigences de vérification pour les SCP à basse tension (voir 3.101), comme suit:

- SCP dont la tension assignée ne dépasse pas 1 000 V en courant alternatif ou 1 500 V en courant continu;

- SCP destinés à être utilisés avec des équipements conçus pour la production, le transport, la distribution et la conversion de l'énergie électrique et la commande des matériels consommant de l'énergie électrique;

- SCP conçus pour être utilisés dans des conditions spéciales d'emploi, par exemple, à bord de navires et de véhicules ferroviaires, et pour des applications domestiques (utilisation par des personnes non qualifiées), sous réserve que les autres exigences spécifiques correspondantes soient respectées;

- SCP conçus pour l'équipement électrique des machines. Les exigences supplémentaires relatives aux SCP faisant partie intégrante d'une machine sont couvertes par la série CEI 60204. Cette première édition de la CEI 61439-6 annule et remplace la troisième édition de la CEI 60439-2 (2000) et son Amendement 1 (2005), dont elle constitue une révision technique. Cette édition de la CEI 61439-6 inclut les modifications techniques majeures suivantes par rapport à la dernière édition de la CEI 60439-2:

- alignement sur la deuxième édition de CEI 61439-1 (2011) concernant la structure et le contenu technique, selon le cas;

- introduction de nouvelles vérifications, en conséquence;

- correction des incohérences en termes de mesures et de calculs des valeurs de résistance, de réactance et d'impédance;

- nombreuses améliorations rédactionnelles.

Cette publication doit être lue conjointement avec la CEI 61439-1:2011.

General Information

- Status

- Published

- Publication Date

- 22-May-2012

- Technical Committee

- SC 121B - Low-voltage switchgear and controlgear assemblies

- Drafting Committee

- MT 3 - TC 121/SC 121B/MT 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-May-2012

- Completion Date

- 15-Jun-2012

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 61439-6:2012 Overview

IEC 61439-6:2012 is an international standard published by the International Electrotechnical Commission (IEC) that specifies requirements for low-voltage busbar trunking systems (BTS), also known as busways. This standard provides comprehensive guidelines on the definitions, service conditions, construction, technical characteristics, and verification procedures for BTS used in low-voltage electrical installations with rated voltages up to 1,000 V AC or 1,500 V DC. It serves as a critical reference for manufacturers, designers, and users involved in the generation, transmission, distribution, and control of electrical energy.

As a part of the IEC 61439 series on low-voltage switchgear and controlgear assemblies, Part 6 aligns with the general rules outlined in IEC 61439-1:2011 and replaces the older IEC 60439-2 standard, introducing enhanced verifications and technical corrections.

Key Topics

Scope and Application

Covers busbar trunking systems for industrial, commercial, and specialized contexts including ships, rail vehicles, and domestic applications. Also addresses BTS integrated within machines following supplementary requirements in IEC 60204.Service Conditions

Specifies standard and special service conditions under which BTS must operate reliably, taking into account environmental and operational factors.Construction and Design Requirements

Defines robust mechanical and electrical construction standards ensuring durability and safety, such as spacing and insulation of busbars, and inclusion of components like tap-off units, joints, expansion units, and adapters.Technical Characteristics

Addresses rated voltage limits, current carrying capacity, resistance, reactance, impedance measurements, and magnetic field considerations to maintain optimal electrical performance.Verification Processes

Details mandatory type and routine tests for BTS verifying compliance through mechanical load tests, electrical testing, fire resistance, thermal cycling, and fault-loop impedance evaluation.Safety and Reliability

Emphasizes adherence to safety standards, including fire resistance according to IEC 60332-3-10 and ISO 834-1, and magnetic field exposure limits as per IEC 61786.

Applications

IEC 61439-6:2012 is applicable in various settings requiring efficient and safe low-voltage power distribution solutions:

Industrial Facilities

For power distribution in factories and manufacturing plants where high current and complex electrical loads demand durable BTS.Commercial Buildings

Enables flexible electrical distribution in shopping centers, office buildings, and hospitals, supporting scalable installations.Transportation Systems

Specialized BTS meeting maritime and rail industry requirements promote safety and performance under harsh operating conditions.Machine Electrical Equipment

Integration within machine assemblies to facilitate controlled electrical supply under IEC 60204 standards.Domestic Installations

Adapted BTS solutions for household electrical distribution, designed for operation by unskilled users while complying with specific safety provisions.

Related Standards

IEC 61439-1:2011 - General rules for low-voltage switchgear and controlgear assemblies; foundational document for Part 6.

IEC 60204 Series - Safety of machinery and electrical equipment; supplementary requirements for BTS within machines.

IEC 60332-3-10:2000 - Fire test methods applicable to cables and BTS components.

IEC 60092-302 - Electrical installations on ships; covers specific additional requirements for maritime BTS applications.

IEC 60570, IEC 61084, IEC 61534 - Standards addressing supply track systems, cable trunking, and power track systems-distinct from BTS covered in IEC 61439-6.

Practical Value

Implementing IEC 61439-6 ensures BTS products comply with internationally recognized criteria, enhancing system safety, reliability, and interoperability. Manufacturers benefit from clear guidance to produce standardized, tested assemblies, while end-users gain confidence in the system's performance for a wide range of electrical distribution needs. Following this standard supports sustainable design practices, reduces risk of electrical hazards, and facilitates regulatory compliance worldwide.

Keywords: IEC 61439-6, busbar trunking systems, busways, low-voltage switchgear, electrical distribution, BTS, low-voltage assemblies, electrical safety standards, IEC standards, switchgear verification, fire resistance, electrical engineering.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61439-6:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Low-voltage switchgear and controlgear assemblies - Part 6: Busbar trunking systems (busways)". This standard covers: IEC 61439-6:2012 lays down the definitions and states the service conditions, construction requirements, technical characteristics and verification requirements for low voltage BTS (see 3.101) as follows: - BTS for which the rated voltage does not exceed 1 000 V in case of a.c. or 1 500 V in case of d.c.; - BTS intended for use in connection with the generation, transmission, distribution and conversion of electric energy, and for the control of electric energy consuming equipment; - BTS designed for use under special service conditions, for example in ships, in rail vehicles, and for domestic applications (operated by unskilled persons), provided that the relevant specific requirements are complied with; - BTS designed for electrical equipment of machines. Supplementary requirements for BTS forming part of a machine are covered by the IEC 60204 series. This first edition of IEC 61439-6 cancels and replaces the third edition of IEC 60439-2 (2000) and its Amendment 1 (2005), and constitutes a technical revision. This edition of IEC 61439-6 includes the following significant technical changes with respect to the latest edition of IEC 60439-2: - alignment on the second edition of IEC 61439-1 (2011) regarding the structure and technical content, as applicable; - introduction of new verifications, accordingly; - correction of inconsistencies in resistance, reactance and impedance measurements and calculations; - numerous editorial improvements. This publication is to be read in conjunction with IEC 61439-1:2011.

IEC 61439-6:2012 lays down the definitions and states the service conditions, construction requirements, technical characteristics and verification requirements for low voltage BTS (see 3.101) as follows: - BTS for which the rated voltage does not exceed 1 000 V in case of a.c. or 1 500 V in case of d.c.; - BTS intended for use in connection with the generation, transmission, distribution and conversion of electric energy, and for the control of electric energy consuming equipment; - BTS designed for use under special service conditions, for example in ships, in rail vehicles, and for domestic applications (operated by unskilled persons), provided that the relevant specific requirements are complied with; - BTS designed for electrical equipment of machines. Supplementary requirements for BTS forming part of a machine are covered by the IEC 60204 series. This first edition of IEC 61439-6 cancels and replaces the third edition of IEC 60439-2 (2000) and its Amendment 1 (2005), and constitutes a technical revision. This edition of IEC 61439-6 includes the following significant technical changes with respect to the latest edition of IEC 60439-2: - alignment on the second edition of IEC 61439-1 (2011) regarding the structure and technical content, as applicable; - introduction of new verifications, accordingly; - correction of inconsistencies in resistance, reactance and impedance measurements and calculations; - numerous editorial improvements. This publication is to be read in conjunction with IEC 61439-1:2011.

IEC 61439-6:2012 is classified under the following ICS (International Classification for Standards) categories: 29.130.20 - Low voltage switchgear and controlgear; 33.200 - Telecontrol. Telemetering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61439-6:2012 has the following relationships with other standards: It is inter standard links to IEC 60439-2:2000/AMD1:2005, IEC 60439-2:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61439-6:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61439-6 ®

Edition 1.0 2012-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Low-voltage switchgear and controlgear assemblies –

Part 6: Busbar trunking systems (busways)

Ensembles d'appareillage à basse tension –

Partie 6: Systèmes de canalisation préfabriquée

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 61439-6 ®

Edition 1.0 2012-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Low-voltage switchgear and controlgear assemblies –

Part 6: Busbar trunking systems (busways)

Ensembles d'appareillage à basse tension –

Partie 6: Systèmes de canalisation préfabriquée

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX X

ICS 29.130.20 ISBN 978-2-83220-084-1

– 2 – 61439-6 © IEC:2012

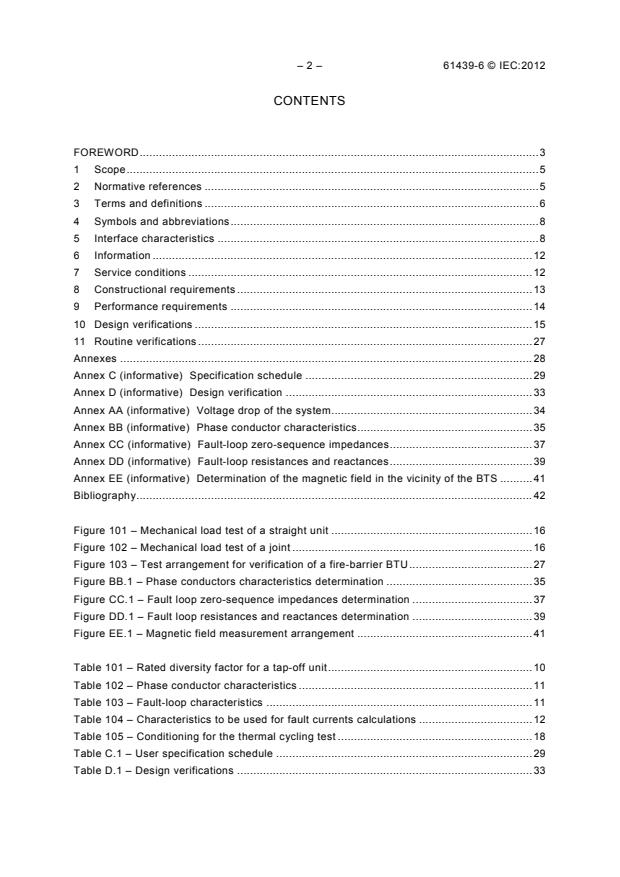

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviations . 8

5 Interface characteristics . 8

6 Information . 12

7 Service conditions . 12

8 Constructional requirements . 13

9 Performance requirements . 14

10 Design verifications . 15

11 Routine verifications . 27

Annexes . 28

Annex C (informative) Specification schedule . 29

Annex D (informative) Design verification . 33

Annex AA (informative) Voltage drop of the system. 34

Annex BB (informative) Phase conductor characteristics . 35

Annex CC (informative) Fault-loop zero-sequence impedances . 37

Annex DD (informative) Fault-loop resistances and reactances . 39

Annex EE (informative) Determination of the magnetic field in the vicinity of the BTS . 41

Bibliography . 42

Figure 101 – Mechanical load test of a straight unit . 16

Figure 102 – Mechanical load test of a joint . 16

Figure 103 – Test arrangement for verification of a fire-barrier BTU . 27

Figure BB.1 – Phase conductors characteristics determination . 35

Figure CC.1 – Fault loop zero-sequence impedances determination . 37

Figure DD.1 – Fault loop resistances and reactances determination . 39

Figure EE.1 – Magnetic field measurement arrangement . 41

Table 101 – Rated diversity factor for a tap-off unit . 10

Table 102 – Phase conductor characteristics . 11

Table 103 – Fault-loop characteristics . 11

Table 104 – Characteristics to be used for fault currents calculations . 12

Table 105 – Conditioning for the thermal cycling test . 18

Table C.1 – User specification schedule . 29

Table D.1 – Design verifications . 33

61439-6 © IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 6: Busbar trunking systems (busways)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61439-6 has been prepared by subcommittee 17D: Low-voltage

switchgear and controlgear assemblies, of IEC technical committee 17: Switchgear and

controlgear.

This first edition of IEC 61439-6 cancels and replaces the third edition of IEC 60439-2 (2000)

and its Amendment 1 (2005), and constitutes a technical revision.

This edition of IEC 61439-6 includes the following significant technical changes with respect

to the latest edition of IEC 60439-2:

• alignment on the second edition of IEC 61439-1 (2011) regarding the structure and

technical content, as applicable;

• introduction of new verifications, accordingly;

• correction of inconsistencies in resistance, reactance and impedance measurements and

calculations;

• numerous editorial improvements.

– 4 – 61439-6 © IEC:2012

The text of this standard is based on the following documents:

FDIS Report on voting

17D/452/FDIS 17D/454/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This standard is to be read in conjunction with the second edition of IEC 61439-1. The

provisions of the general rules dealt with in IEC 61439-1 (hereinafter referred to as Part 1) are

only applicable to this standard insofar as they are specifically cited. When this standard

states “addition”, “modification” or “replacement”, the relevant text in Part 1 is to be adapted

accordingly.

Subclauses that are numbered with a 101 (102, 103 etc.) suffix are additional to the same

subclause in Part 1.

Tables and figures in this Part 6 that are new are numbered starting with 101.

New annexes in this Part 6 are lettered AA, BB, etc.

The “in some countries” notes regarding differing national practices are contained in the

following subclauses:

5.4

A list of all parts of the IEC 61439 series, under the general title Low-voltage switchgear and

controlgear assemblies can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61439-6 © IEC:2012 – 5 –

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 6: Busbar trunking systems (busways)

1 Scope

NOTE 1 Throughout this part, the abbreviation BTS is used for a busbar trunking system. Where reference to

Part 1 is made, the term ASSEMBLY therefore reads as “BTS”.

This part of IEC 61439 lays down the definitions and states the service conditions,

construction requirements, technical characteristics and verification requirements for low

voltage BTS (see 3.101) as follows:

• BTS for which the rated voltage does not exceed 1 000 V in case of a.c. or 1 500 V in

case of d.c.;

• BTS intended for use in connection with the generation, transmission, distribution and

conversion of electric energy, and for the control of electric energy consuming equipment;

• BTS designed for use under special service conditions, for example in ships, in rail

vehicles, and for domestic applications (operated by unskilled persons), provided that the

relevant specific requirements are complied with;

NOTE 2 Supplementary requirements for BTS in ships are covered by IEC 60092-302.

• BTS designed for electrical equipment of machines. Supplementary requirements for BTS

forming part of a machine are covered by the IEC 60204 series.

This standard applies to all BTS whether they are designed, manufactured and verified on a

one-off basis or fully standardized and manufactured in quantity.

The manufacture and/or assembly may be carried out by a manufacturer other than the

original manufacturer (see 3.10.1 and 3.10.2 of Part 1).

This standard does not apply to individual devices and self-contained components, such as

motor starters, fuse switches, electronic equipment, etc. which will comply with the relevant

product standard.

This standard does not apply to the specific types of ASSEMBLIES covered by other parts of the

IEC 61439 series, to supply track systems in accordance with IEC 60570, to cable trunking

and ducting systems in accordance with the IEC 61084 series, nor to power track systems in

accordance with the IEC 61534 series.

2 Normative references

This clause of Part 1 is applicable except as follows.

Addition:

IEC 60332-3-10:2000, Tests on electric and optical fibre cables under fire conditions –

Part 3-10: Test for vertical flame spread of vertically-mounted bunched wires or cables –

Apparatus

IEC 60439-2:2000, Low-voltage switchgear and controlgear assemblies – Part 2: Particular

requirements for busbar trunking systems (busways)

– 6 – 61439-6 © IEC:2012

IEC 61439-1:2011, Low-voltage switchgear and controlgear assemblies – Part 1: General

rules

IEC 61786:1998, Measurement of low-frequency magnetic and electric fields with regard to

exposure of human beings – Special requirements for instruments and guidance for

measurements

ISO 834-1:1999, Fire-resistance tests – Elements of building construction – Part 1: General

requirements

3 Terms and definitions

This clause of Part 1 is applicable except as follows.

Additional definitions:

3.101

busbar trunking system

BTS

busway

enclosed ASSEMBLY used to distribute and control electrical energy for all types of loads,

intended for industrial, commercial and similar applications, in the form of a conductor system

comprising busbars which are spaced and supported by insulating material in a duct, trough

or similar enclosure

[SOURCE: IEC 60050-441:1984, 441-12-07 modified]

Note 1 to entry: See 3.1.1 of Part 1 for the definition of ASSEMBLY.

Note 2 to entry: The BTS may consist of a full range of mechanical and electrical components such as:

– busbar trunking units with or without tap-off facilities;

– phase transposition, expansion, flexible, feeder and adapter units;

– tap-off units;

– additional conductors for communication and/or control.

Note 3 to entry: The term "busbar'' does not presuppose the geometrical shape, size and dimensions of the

conductor.

3.102

busbar trunking unit

BTU

unit of a BTS complete with busbars, their supports and insulation, external enclosure and

any fixing and connecting means to other units, with or without tap-off facilities

Note 1 to entry: BTUs may have different geometrical shapes such as straight length, elbow, tee or cross.

3.103

busbar trunking run

BT run

number of BTUs connected together to form the BTS, excluding the tap-off units

3.104

busbar trunking unit with tap-off facilities

BTU with tap-off facilities

BTU designed to enable tap-off units to be installed at one or more points as predetermined

by the original manufacturer

61439-6 © IEC:2012 – 7 –

3.105

busbar trunking unit with trolley-type tap-off facilities

BTU with trolley-type tap-off facilities

BTU designed to permit the use of roller- or brush-type tap-off units

3.106

busbar trunking adapter unit

adapter BTU

BTU intended to connect two units of the same system but of different type or of different

rated current

3.107

busbar trunking thermal expansion unit

thermal expansion BTU

BTU intended to permit a certain movement in the axial direction of the BT run due to thermal

expansion of the system

Note 1 to entry: This term does not presuppose which elements permit movement, e.g. the conductors within the

enclosure or both conductors and enclosure

3.108

busbar trunking phase transposition unit

phase transposition BTU

BTU intended to change the relative positions of the phase conductors in order to balance the

inductive reactances or to transpose the phases (such as L1-L2-L3-N to N-L3-L2-L1)

3.109

flexible busbar trunking unit

flexible BTU

BTU having conductors and enclosures designed to allow a specified change of direction

during installation

3.110

busbar trunking feeder unit

feeder BTU

BTU serving as an incoming unit

Note 1 to entry: See 3.1.9 of Part 1 for the definition of incoming unit.

3.111

tap-off unit

outgoing unit, either fixed or removable, for tapping-off power from the BTU

Note 1 to entry: See 3.1.10, 3.2.1 and 3.2.2 of Part 1 for the definition of outgoing unit, fixed part and removable

part.

Note 2 to entry: A plug-in tap-off unit is a removable tap-off unit (see 8.5.2) which can be connected or

disconnected by manual operation

3.112

busbar trunking unit for building movements

BTU for building movements

BTU intended to allow for building movements due to thermal expansion, contraction and/or

flexing of the building

3.113

busbar trunking fire barrier unit

fire barrier BTU

BTU or a part of, intended to prevent the propagation of fire through building divisions for a

specified time under fire conditions

– 8 – 61439-6 © IEC:2012

4 Symbols and abbreviations

This clause of Part 1 is applicable except as follows.

Addition:

Symbol / Term Subclause

Abbreviation

k temperature factor of the BTS 5.3.1

1A

k

temperature factor of a circuit 5.3.2

1c

k mounting factor of a circuit 5.3.2

2c

R, X, Z phase conductor and fault-loop characteristics 5.101

5 Interface characteristics

This clause of Part 1 is applicable except as follows.

5.1 General

Replacement:

The characteristics of the BTS shall ensure compatibility with the ratings of the circuits to

which it is connected and the installation conditions and shall be declared by the BTS

manufacturer using the criteria identified in 5.2 to 5.6 and 5.101 to 5.102.

The specification schedule according to informative Annex C is intended to help the user and

the BTS manufacturer to meet this objective, whether the user:

• select catalogue products the characteristics of which meet their needs, and the

requirements of this standard,

• and/or make a specific agreement with the manufacturer.

NOTE Annex C also relates to the topics dealt with in Clauses 6 and 7.

In some cases information provided by the BTS manufacturer may take the place of an

agreement.

5.2.4 Rated impulse withstand voltage (U ) (of the ASSEMBLY)

imp

Replacement of the NOTE:

NOTE Unless otherwise specified, the rated impulse withstand voltage is selected according to overvoltage

category IV (origin of installation level) or III (distribution circuit level) as given in Table G.1 of Part 1.

5.3.1 Rated current of the ASSEMBLY (I )

nA

Addition:

NOTE 4 Where the BTS is not equipped with a single incoming unit at one end of the BT run, (e.g. incoming unit

not installed at one end of the BTS, or more than one incoming unit), the rated currents will be subject to

agreement between the user and the manufacturer.

The rated current shall apply for a specified mounting orientation (see 5.3.2). However the

influence of the mounting orientation may be ignored for short (e.g. less than 3 m long)

vertical sections in a horizontal BTS.

61439-6 © IEC:2012 – 9 –

The BTS manufacturer may state the rated currents of the BTS for different ambient

temperatures for example by means of the following formula:

I’ = k I

nA 1A nA

where k is a temperature factor, equal to 1 at an ambient air temperature of 35 °C.

1A

In case of significant harmonic currents, special agreement shall be made for a reduction

factor, if necessary.

5.3.2 Rated current of a circuit (I )

nc

Addition:

The rated current (I ) of each circuit (i.e. incoming unit, BTU, tap-off unit, outgoing circuit)

nc

shall be equal to or higher than its assumed loading. For tap-off units provided with more than

one main outgoing circuit, see also 5.4.

The rated current shall apply for specified mounting conditions. Mounting conditions may

include orientation and position, as follows:

a) orientation

Orientation may be horizontal or vertical.

Unless otherwise specified, the reference orientation is horizontal.

b) position

Position may be for example edgewise or flatwise for a BT run, and/or below or on top of

the BTU for a tap-off unit.

The BTS manufacturer may state different rated currents for different ambient temperatures

and/or mounting conditions, where applicable, for example by means of the following formula:

I’ = k k I

nc 1c 2c nc

where

k is a temperature factor, equal to 1 at an ambient air temperature of 35 °C;

1c

k is a mounting factor, equal to 1 in the reference mounting conditions.

2c

In case of significant harmonic currents, special agreement shall be made for a reduction

factor, if necessary.

5.4 Rated diversity factor (RDF)

Replacement:

For the whole BTS, unless otherwise specified, the RDF (see 3.8.11 of Part 1) shall be equal

to 1, i.e. all tap-off units can be continuously and simultaneously loaded with their full rated

current, within the limit of the rated current of the BT run(s) and feeder BTU(s)

NOTE 1 This is because thermal influence between tap-off units is considered negligible.

For tap-off units provided with more than one main outgoing circuit, these circuits shall be

able to be continuously and simultaneously loaded at their rated current multiplied by the

RDF, within the limit of the rated current of the tap-off unit. Unless otherwise specified, the

RDF of such tap-off units shall be equal to the values given in Table 101.

– 10 – 61439-6 © IEC:2012

Table 101 – Rated diversity factor for a tap-off unit

Number of main outgoing circuits Rated diversity factor

2 and 3 0,9

4 and 5 0,8

6 to 9 inclusive 0,7

10 (and above) 0,6

The RDF is applicable with the BTS operating at rated current (I )

nA

NOTE 2 The RDF recognizes that multiple functional units are in practice not fully loaded simultaneously or are

intermittently loaded.

NOTE 3 The assumed loading of the outgoing circuits can be a steady continuous current or the thermal

equivalent of a varying current.

NOTE 4 In Norway, the overload protection of conductors is not solely based on the use of diversity factors of the

downstream circuits.

5.6 Other characteristics

Modification of item e):

e) stationary BTS ;

Modification of item j):

j) enclosed BTS;

Addition:

aa) ability to withstand mechanical loads, either normal or heavy (see 8.1.101);

bb) resistance to flame propagation, if applicable (see 9.101);

cc) fire resistance in building penetration, if applicable (see 9.102).

Additional subclauses:

5.101 Phase conductor and fault-loop characteristics

NOTE 1 For BTS rated below 100 A, the reactances are deemed negligible.

R and X according to Table 102 are intended to be used to calculate voltage drops (see

informative Annex AA).

61439-6 © IEC:2012 – 11 –

Table 102 – Phase conductor characteristics

Mean phase conductor characteristics

at rated current I , and rated frequency f

nc n

Ω per-metre length

Resistance,

R

- at an ambient air temperature of 35 °C

R

- at a conductor temperature of 20 °C

Reactance (independent from temperature) X

Positive-sequence and negative-sequence impedances

- at an ambient air temperature of 35 °C Z = Z = Z

(1) (2)

- at a conductor temperature of 20 °C Z = Z = Z

20 (1)20 (2)20

All phase conductor characteristics may be determined according to Annex BB.

R and X according to Table 102, and fault-loop resistances and reactances according to

Table 103, i.e. the total resistances and reactances of the phase conductor(s) and return

path, are intended to be used to calculate fault currents according to the method of

impedances (see Table 104).

Z and Z according to Table 102, and fault-loop zero-sequence impedances according to

Table 103, i.e. the total zero-sequence impedances of the phase conductor(s) and return

path, are intended to be used to calculate fault currents according to the method of

symmetrical components (see Table 104).

NOTE 2 Fault currents reach their lowest value for the highest impedance values; this is deemed to happen when

the BTUs are operating at I at the maximum normal ambient air temperature i.e. 35 °C, resulting in a conductor

nc

temperature of (35 + ∆θ) °C, where ∆θ is the mean stabilized temperature rise measured according to 10.10.

Conversely fault currents reach their highest value for the lowest impedance values; this is deemed to happen

when the BTUs are not operating, resulting in a conductor temperature of 20 °C, and the circuit is closed while a

short-circuit is present.

Table 103 – Fault-loop characteristics

Mean fault-loop characteristics

Phase-to- Phase-to- Phase-to-

at rated frequency f Phase-to-PE

n

phase neutral PEN

Ω per-metre length

Zero-sequence impedances

- at an ambient air temperature of 35 °C Z Z Z

(0)bphN (0)bphPEN (0)bphPE

- at a conductor temperature of 20 °C Z Z Z

(0)b20phN (0)b20phPEN (0)b20phPE

Resistances

- at an ambient air temperature of 35 °C R R R R

bphph bphN bphPEN bphPE

- at a conductor temperature of 20 °C R R R R

b20phph b20phN b20phPEN b20phPE

Reactances (independent from temperature) X X X X

bphph bphN bphPEN bphPE

Fault-loop zero-sequence impedances may be determined according to Annex CC.

Fault-loop resistances and impedances may be determined according to Annex DD.

– 12 – 61439-6 © IEC:2012

Table 104 – Characteristics to be used for fault currents calculations

Method

Fault currents Method of impedances

of symmetrical components

Maximum short-circuit current

- 3-phase R , X Z

20 20

- phase-to-phase R , X Z

b20phph bphph 20

- phase-to-neutral R , X Z and Z

b20phN bphN 20 (0)20phN

Minimum short-circuit current

- phase-to-phase R , X Z

bphph bphph

R , X Z and Z

- phase-to-neutral

bphN bphN (0)phN

Earth fault current (phase-to-PE(N)) R , X Z and Z

bphPE(N) bphPE(N) (0)phPE(N)

NOTE 3 The method of symmetrical components is based on respectively summing the modulus of the fault-loop

positive-, negative- and zero-sequence impedances (see IEC 60909-0). Similarly the method of impedance is

based on respectively summing the modulus of the fault-loop resistances and reactances.

5.102 Electromagnetic field

The strength of the power frequency magnetic field in the vicinity of the BT run may be stated

by the BTS manufacturer.

NOTE The magnetic field is a fast-decreasing function of the distance.

A method for measurement and calculation of the modulus of the magnetic field around the

BTS is given in Annex EE.

6 Information

This clause of Part 1 is applicable except as follows.

6.1 ASSEMBLY designation marking

Addition after the first paragraph:

One nameplate shall be located near one end of each BTU and one on each tap-off unit.

Replacement:

d) IEC 61439-6.

7 Service conditions

This clause of Part 1 is applicable except as follows.

7.2 Special service conditions

Addition:

aa) exposure to special mechanical loads, such as lighting apparatus, additional cables,

ladder supports, etc.;

bb) applications with high repetitive overcurrent, for example resistance welding;

cc) installation near highly sensitive IT equipment, such as high-speed data networks,

radiology apparatus, workstation monitors, etc.;

61439-6 © IEC:2012 – 13 –

dd) applications requiring defined performance under fire conditions, e.g. circuit integrity for a

definite time.

8 Constructional requirements

This clause of Part 1 is applicable except as follows.

8.1.5 Mechanical strength

Addition after the last paragraph:

BTS with trolley-type tap-off facilities shall be able to carry out successfully 10 000 cycles of

to-and-fro movements along the conductors of the BT run, with the sliding contacts carrying

their rated current at rated voltage. In the case of a.c., the power factor of the load shall be

between 0,75 and 0,8.

Compliance to this requirement is checked by the test of 10.13.

Additional subclauses:

8.1.101 Ability to withstand mechanical loads

BTS intended for horizontal installation shall be able to withstand in use normal or heavy

mechanical loads as specified according to 5.6 aa).

Normal mechanical loads include the weight of the feeder unit, if not supported by its own

separate fixings, and tap-off units, in addition to the weight of the BTUs.

Heavy mechanical loads include additional loads such as the weight of a person.

NOTE This statement does not imply that a BTS is a walkway.

The necessary mechanical properties may be obtained by the choice of material, its

thickness, its shape, and/or by the number of and position of fixing points as indicated by the

original manufacturer.

Compliance to this requirement is checked by test according to 10.2.101.

8.1.102 Ability of plug-in tap-off units to withstand thermal variations

Plug-in tap-off units in which the contact force is developed by the deflection of a spring

member shall be able to withstand the mechanical constraints due to temperature variations

when subjected to intermittent duty.

NOTE For the purpose of this requirement, a disc spring is not considered to be a spring member.

Compliance is checked by test according to 10.2.102.

8.2.1 Protection against mechanical impact

Replacement:

Where a degree of protection against mechanical impact according to IEC 62262 IK code is

declared by the original manufacturer, the BTS shall be so designed that it is capable of

withstanding the test according to IEC 62262 IK code (see 10.2.6).

– 14 – 61439-6 © IEC:2012

8.3.2 Clearances

Addition after the first paragraph:

Clearances of supplementary insulation shall be not less than those specified for basic

insulation. Clearances of reinforced insulation shall be dimensioned to the rated impulse

voltage one step higher than those specified for basic insulation (see Table 1 of Part 1).

8.3.3 Creepage distances

Addition after the third paragraph:

Creepage distances of supplementary insulation shall be not less than those specified for

basic insulation. Creepage distances of reinforced insulation shall be twice those specified for

basic insulation (see Table 2 of Part 1).

8.4.3.2.3 Requirements for protective conductors providing protection against the

consequences of faults in external circuits supplied through the BTS

Addition after the last paragraph:

In BTS with trolley tap-off facilities, constructional precautions shall be taken to ensure good

and permanent conductivity between the exposed conductive parts of tap-off units and the

stationary exposed conductive parts, in particular when the enclosure of the fixed units is part

of the protective circuit of the installation.

8.5.2 Removable parts

Replacement of the third paragraph:

A removable part may be fitted with a device, which ensures that it can only be removed and

inserted after its main circuit has been switched off from the load.

Addition:

NOTE A tap-off unit is or is not a removable part as defined in this subclause and in 3.2.2 of Part 1, according to

the manufacturer’s designation.

8.5.5 Accessibility

This subclause of Part 1 is not applicable.

Additional subclause:

8.6.101 Correct connection between BTS units

BTUs shall be so designed as to ensure correct connection between the conductors of

adjacent units forming a BTS (power circuits, auxiliary and communication circuits, PE…).

This requirement may be achieved by proper identification of each connection.

BTUs and tap-off units shall be so designed as to ensure correct connection between their

conductors (power circuits, auxiliary and communication circuits, PE…). This requirement

shall be achieved by insertion interlocks (see 3.2.5 of Part 1).

9 Performance requirements

This clause of Part 1 is applicable except as follows.

61439-6 © IEC:2012 – 15 –

9.2 Temperature rise limits

d

Replacement of footnote in Table 6:

d

Unless otherwise specified, in the case of covers and enclosures, which are accessible but need not be

touched during normal operation, a 25 K increase on these temperature-rise limits for metal surfaces and a

15 K increase on these temperature-rise limits for insulating material surfaces are permissible.

Additional subclauses:

9.101 Resistance to flame propagation

A non-flame-propagating BTS either shall not ignite or, if ignited, shall not continue to burn

when the source of ignition is removed.

Compliance is checked by the flame-propagation tests according to 10.101.

9.102 Fire resistance in building penetration

A fire barrier BTU, if any, shall be designed to prevent the propagation of fire, for a specified

time, under fire conditions, where the BTS passes through horizontal or vertical building

divisions (for example, wall or floor).

Where applicable, the following times are preferred: 60 min, 90 min, 120 min, 180 min or

240 min.

This may be achieved by means of additional parts.

Compliance is checked by the fire-resistance test according to 10.102.

10 Design verifications

This clause of Part 1 is applicable except as follows.

10.1 General

Replacement of the second paragraph:

Where tests on the BTS have been conducted in accordance with IEC 60439-2, and the test

results fulfil the requirements of this Part 6 of IEC 61439, the verification of these

requirements need not be repeated.

Addition at the end of b) Performance:

10.101 Resistance to flame propagation;

10.102 Fire resistance in building penetration.

10.2.6 Mechanical impact

Replacement:

The BTS shall be tested according to IEC 62262.

After the test, the BTS shall continue to provide the IP code and dielectric strength; it shall be

possible to remove and reinstall removable covers and tap-off units and to open and close

doors, as applicable.

Additional subclauses:

– 16 – 61439-6 © IEC:2012

10.2.101 Ability to withstand mechanical loads

10.2.101.1 Test procedure for a straight busbar trunking unit

The first test shall be made on one straight BTU supported as in normal use at two positions

spaced at the maximum distance D specified by the original manufacturer. The location and

form of the supports shall be specified by the original manufacturer. See Figure 101.

M

D D

2 2

D

IEC 834/12

Figure 101 – Mechanical load test of a straight unit

A mass M shall be placed without dynamic loading on a square rigid piece with sides equal to

the width of the BTU, at the midpoint between the supports on top of the enclosure.

The mass M shall be equal to:

m + m for normal loads

• L

• m + m + 90 kg for heavy loads

L

where

• m is the mass of the BTU between the supports

• m is the mass of the feeder and tap-off units specified by the original manufacturer to be

L

connected to the length D.

The duration of the test shall be at least 5 min.

10.2.101.2 Test procedure for a joint

A second test shall be made on two BTUs joined together and supported as in normal use at

the minimum number of positions at the distances D and D . The distance D is that specified

in 10.2.101.1; the distance D is the maximum distance between supports adjacent to a joint

as specified by the original manufacturer. The joint shall be placed midway between the

supports. See Figure 102.

M

D D

1 1

2 2

D

D D

IEC 835/12

Figure 102 – Mechanical load test of a joint

A mass M shall be placed without dynamic loading on top of the enclosure at the joint on a

square rigid piece with sides equal to the width of the BTU.

61439-6 © IEC:2012 – 17 –

The mass M shall be equal to:

m + m for normal loads

• 1 L1

• m + m + 90 kg for heavy loads

1 L1

where

• m is the mass of those parts of the BTUs, including the joint, between the supports

located at distance D

is the maximum mass of the feeder and tap-off units specified by the original

• m

L1

manufacturer to be connected to the length D .

The duration of the test shall be at least 5 min.

10.2.101.3 Resistance of the enclosure to crushing

A straight BTU shall be subjected to a crushing force, successively at four or more points,

including one point between adjacent insulators, if any.

The BTU shall be supported horizontally on a flat surface and the force shall be applied

through a rigid plate equal to the width of the BTU and 120 mm long.

The crushing force shall at least be equal to 4 times the weight of 1 m length, for BTS stated

for normal mechanical loads; a mass of 90 kg shall be added for BTS stated for heavy

mechanical loads.

The duration of the test shall be at least 5 min per point.

10.2.101.4 Results to be obtained

During and after the tests according to 10.2.101.1 to 10.2.101.3, there shall be neither break,

nor permanent deformation of the enclosure which would compromise the degree of

protection, reduce the clearances and creepage distances to values lower than those

specified in 8.3, or impair the correct insertion of incoming and outgoing units.

The protective circuit shall remain functional and the test samples shall withstand the

dielectric test according to 10.9.2 of Part 1.

10.2.102 Thermal cycling test

10.2.102.1 General

Plug-in tap-off units shall be submitted to a thermal cycling test.

10.2.102.2 Test sample

If the same design of the plug assembly is used for a range of tap-off units of different rated

currents or of different protective devices, a test on one combination of a BTU and a tap-off

unit is considered to be representative of the range. The design of the plug assembly includes

the physical characteristics and the material and surface finish (e.g. plating), if applicable.

A tap-off unit incorporating fuses shall be fitted with the maximum size of fuses specified by

the original manufacturer. A tap-off unit incorporating a circuit-breaker shall be fitted with a

circuit-breaker of the maximum rating specified by the original manufacturer.

The tap-off unit shall be arranged and loaded as in 10.10.2.3.6.

– 18 – 61439-6 © IEC:2012

Prior to test, the sample is conditioned by a number of cycles of insertion and removal of the

tap-off unit in the intended manner, without load current, as given in Table 105.

Table 105 – Conditioning for the thermal cycling test

Rated current Number of cycles

A of insertion and removal

I ≤ 63 25

nc

63 < I ≤ 200 10

nc

200 < I

nc

10.2.102.3 Test procedure

The current is applied until the temperatures have stabilised. The temperatures as specified

for the temperature-rise test are recorded. Both currents are switched off and the sample is

allowed to return to room temperature.

The sample is then subjected to 84 cycles consisting of

a) 3 h ON at rated current and 3 h OFF, or

b) 2 h ON at rated current and 2 h OFF,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...