IEC 61029-2-4:1993/AMD1:2001

(Amendment)Amendment 1 - Safety of transportable motor-operated electric tools - Part 2-4: Particular requirements for bench grinders

Amendment 1 - Safety of transportable motor-operated electric tools - Part 2-4: Particular requirements for bench grinders

General Information

- Status

- Published

- Publication Date

- 17-May-2001

- Technical Committee

- TC 116 - Safety of motor-operated electric tools

- Drafting Committee

- WG 9 - TC 116/WG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 18-May-2001

- Completion Date

- 30-Jun-2001

Overview

IEC 61029-2-4:1993/AMD1:2001 is an essential international standard amendment focusing on the safety of transportable motor-operated electric tools, specifically addressing particular requirements for bench grinders and combined bench grinders. Published by the International Electrotechnical Commission (IEC), this amendment provides updated safety guidelines and technical specifications that manufacturers and users must adhere to for ensuring operational safety and reliability of bench grinders with wheel and brush diameters up to 200 mm and peripheral speeds not exceeding 50 m/s.

This document serves to enhance the safety frameworks for transportable bench grinders-tools widely used for grinding, polishing, and deburring metal or similar materials in various industrial and workshop environments.

Key Topics

Scope and Definitions

- Covers transportable bench grinders and combined bench grinders with specific wheel and brush dimensions and speeds.

- Defines critical terms such as machine spindle, nozzle for dust collection, and combined bench grinder to clarify scope and applicability.

Markings and User Information

- Requirements for clear markings on combined bench grinders, including maximum brush diameter and safety warnings (e.g., prohibiting grinding wheel use on the brush side).

- Comprehensive user handbook guidance to cover safe operation, wheel/brush maintenance, assembly, and transport.

Safety and Mechanical Hazards

- Mandatory guarding systems for grinders, designed to cover the wheels adequately and resist accidental breakage.

- Installation of spark arrestors to limit sparks and ejected particles improving dust management.

- Work rests with downward-only tilt functionality to enhance safe grinding operations.

- Detailed flange dimension specifications for both grinding wheels and brushes to ensure mechanical integrity and prevent accidents.

Protective Equipment

- Clear guidelines for transparent screen installation and dimensions, enabling operators to see the grinding or brush surface while being shielded from particle projections.

- Protection of the free extremity of rotating shafts, particularly on the brush side, to avoid accidental contact in combined bench grinders.

Stability and Fixation

- Requirements for provisions allowing each bench grinder to be securely fixed to a support for stable and safe operation.

Start Prevention and Control

- Safety measures that prevent accidental starting of the tool, verified by a sphere test to ensure start buttons cannot be activated unintentionally.

Applications

IEC 61029-2-4:1993/AMD1:2001 is highly relevant for:

- Manufacturers and designers of bench grinders and combined bench grinders, providing clear safety construction criteria and testing methods.

- Workshop safety managers who enforce and audit compliance to electrical tool safety practices, helping prevent workplace injuries and equipment damage.

- Regulatory bodies and certification agencies that assess and certify motor-operated electric tools for market access and safety.

- Maintenance personnel and operators who benefit from comprehensive user guidelines for safe operation, reducing risks associated with inappropriate tool use.

The standard is applicable across industrial sectors including metalworking, fabrication, automotive, and maintenance, promoting uniform safety levels internationally.

Related Standards

- IEC 61029-1 - General requirements for the safety of transportable motor-operated electric tools.

- IEC 60745 series - Safety standards for hand-held motor-operated electric tools covering broader categories beyond bench grinders.

- ISO/IEC 17025 - Testing and calibration laboratories accreditation to ensure compliance verification of safety standards.

Adhering to IEC 61029-2-4 and related standards ensures holistic safety coverage for motor-operated tools, enhances harmonization in tool manufacturing, reduces accident rates, and supports regulatory compliance worldwide.

Keywords: IEC 61029-2-4, bench grinder safety standard, transportable motor-operated electric tools, combined bench grinders, safety requirements, grinding wheel, spark arrestor, transparent screen, dust collection, IEC amendment 2001, tool guarding, mechanical hazard prevention, electrical tool safety.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 61029-2-4:1993/AMD1:2001 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Amendment 1 - Safety of transportable motor-operated electric tools - Part 2-4: Particular requirements for bench grinders". This standard covers: Amendment 1 - Safety of transportable motor-operated electric tools - Part 2-4: Particular requirements for bench grinders

Amendment 1 - Safety of transportable motor-operated electric tools - Part 2-4: Particular requirements for bench grinders

IEC 61029-2-4:1993/AMD1:2001 is classified under the following ICS (International Classification for Standards) categories: 25.080.50 - Grinding and polishing machines; 25.140.20 - Electric tools. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61029-2-4:1993/AMD1:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

61029-2-4

AMENDMENT 1

2001-05

Amendment 1

Safety of transportable motor-operated electric

tools –

Part 2-4:

Particular requirements for bench grinders

Amendement 1

Sécurité des machines-outils électriques semi-fixes –

Partie 2-4:

Règles particulières pour les tourets à meuler

IEC 2001 Copyright - all rights reserved

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

J

International Electrotechnical Commission

For price, see current catalogue

– 2 – 61029-2-4 Amend. 1 IEC:2001(E)

FOREWORD

This amendment has been prepared by subcommittee 61F: Safety of hand-held motor-

operated electric tools, of IEC technical committee 61: Safety of household and similar

electrical appliances.

The text of this amendment is based on the following documents:

FDIS Report on voting

61F/371/FDIS 61F/386/RVD

Full information on the voting for the approval of this amendment can be found in the report

on voting indicated in the above table.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until 2006. At this date, the publication will be

reconfirmed;

withdrawn;

replaced by a revised edition, or

amended.

___________

Page 7

1 Scope

1.1 Modification:

Replace the first paragraph by the following:

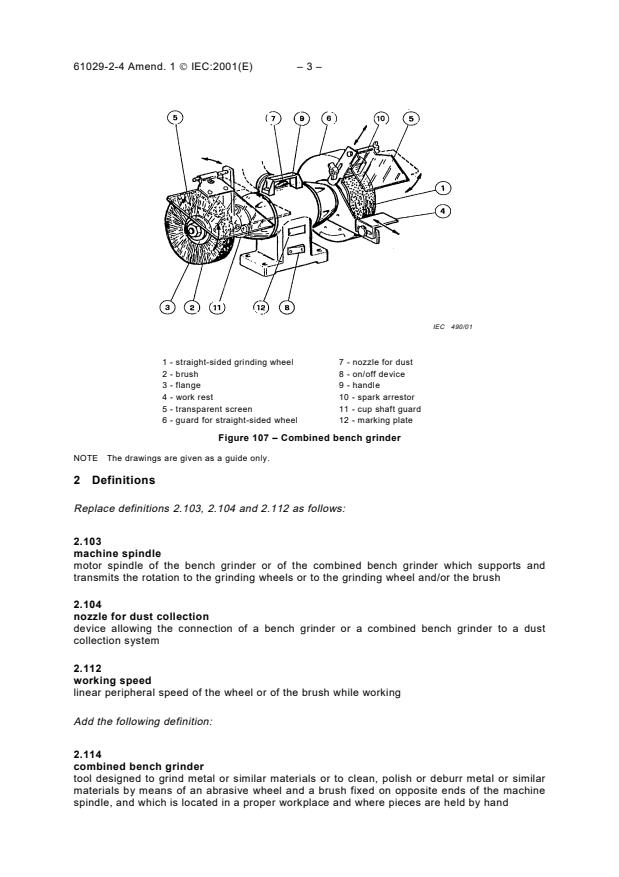

This International Standard applies to transportable bench grinders (figure 101) and combined

bench grinders (figure 107) with a wheel diameter and brush diameter not exceeding 200 mm

and a peripheral speed not exceeding 50 m/s, as defined in 2.101 and 2.114.

Add figure 107 as follows:

61029-2-4 Amend. 1 IEC:2001(E) – 3 –

IEC 490/01

1 - straight-sided grinding wheel 7 - nozzle for dust

2 - brush 8 - on/off device

3 - flange 9 - handle

4 - work rest 10 - spark arrestor

5 - transparent screen 11 - cup shaft guard

6 - guard for straight-sided wheel 12 - marking plate

Figure 107 – Combined bench grinder

NOTE The drawings are given as a guide only.

2 Definitions

Replace definitions 2.103, 2.104 and 2.112 as follows:

2.103

machine spindle

motor spindle of the bench grinder or of the combined bench grinder which supports and

transmits the rotation to the grinding wheels or to the grinding wheel and/or the brush

2.104

nozzle for dust collection

device allowing the connection of a bench grinder or a combined bench grinder to a dust

collection system

2.112

working speed

linear peripheral speed of the wheel or of the brush while working

Add the following definition:

2.114

combined bench grinder

tool designed to grind metal or similar materials or to clean, polish or deburr metal or similar

materials by means of an abrasive wheel and a brush fixed on opposite ends of the machine

spindle, and which is located in a proper workplace and where pieces are held by hand

– 4 – 61029-2-4 Amend. 1 IEC:2001(E)

Page 11

7 Marking

7.1 Addition:

Add the following items:

– for combined bench grinders, the maximum diameter D of the brush to be used;

– for combined bench grinders/brushes, a warning near to the brush holder spindle never to

use a grinding wheel on the brush side of the machine.

7.13 Addition:

Replace the first paragraph as follows:

The handbook or information sheet shall include all the necessary information for safe

working with the bench grinder or combined bench grinder, such as method of operation,

wheel and brush changing, maintenance, assembly, transportation, etc.

Replace the second dash as follows:

– do not use damaged or misshapen wheels or brushes;

Replace the sixth dash as follows:

– for bench grinders and combined bench grinders equipped with straight-sided flanges, the

recommended values of the thickness T and the diameter of the hole;

Add, before the note, the following additional dash:

– for combined bench grinders, to always keep the brush assembled on the spindle in order

to limit the risk of contact with the rotating spindle.

Page 15

18 Stability and mechanical hazards

Addition:

18.1

Replace the first paragraph as follows:

Bench grinders and combined bench grinders shall be equipped with an adequate guarding

system, which cannot be removed without the aid of a tool.

18.1.101 Guard

Change the heading of this subclause as follows:

18.1.101 Guard for wheel

Replace the first paragraph as follows:

Bench grinders and combined bench grinders shall be equipped with guards which leave

uncovered only a portion of the wheel as indicated in figure 102. Guards shall be designed to

have mechanical resistance to accidental breaking of the wheels.

61029-2-4 Amend. 1 IEC:2001(E) – 5 –

Page 23

18.1.101.3 Spark arrestor

Replace the first paragraph as follows:

Bench grinders and combined bench grinders equipped with straight-sided wheels shall have

a spark arrestor to limit the ejection of sparks and pieces of wheel from the wheel guard. Its

aim is also to improve the collection of dust.

18.1.101.4 Work rest

Replace the first paragraph as follows:

Bench grinders and combined bench grinders shall be equipped with work rests. This require-

ment does not apply to the brush side of the combined bench grinder.

Repla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...