IEC 60034-18-1:2010

(Main)Rotating electrical machines - Part 18-1: Functional evaluation of insulation systems - General guidelines

Rotating electrical machines - Part 18-1: Functional evaluation of insulation systems - General guidelines

IEC 60034-18-1:2010 deals with the general guidelines for functional evaluation of electrical insulation systems, used or proposed to be used in rotating electrical machines within the scope of IEC 60034-1, in order to qualify them. The main changes of this new edition with respect to the previous one are as follows:

- provides general guidelines for functional evaluation of different types of windings as before but beyond that for electrical evaluation of windings which are electrically stressed by converter-supply;

- is now focused on general guidelines with all technical details of procedures and qualification principles moved to the subsequent parts;

- details additional general aspects of functional evaluation, particularly the statistical procedure for comparison between reference and candidate insulation systems and the evaluation of minor component or manufacturing changes;

- contains a new acceptance test for verifying the expected production quality level of the insulation systems;

- restricts the classification of insulation systems as a result of the functional evaluation to thermal classification.

Machines électriques tournantes - Partie 18-1: Evaluation fonctionnelle des systèmes d'isolation - Principes directeurs généraux

La CEI 60034-18-1:2010 traite des principes directeurs généraux d'évaluation fonctionnelle des systèmes d'isolation électrique, utilisés ou que l'on se propose d'utiliser dans les machines électriques tournantes entrant dans le domaine d'application de la CEI 60034-1, en vue de leur qualification. Cette nouvelle édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- comme auparavant, fournit des recommandations générales pour l'évaluation fonctionnelle de différents types d'enroulements mais aussi au-delà, pour l'évaluation fonctionnelle des enroulements qui subissent une contrainte électrique du fait d'une alimentation par convertisseur;

- met l'accent sur des recommandations générales, tous les détails techniques des procédures et des principes de qualification étant déplacés vers les parties concernées;

- détaille des aspects généraux supplémentaires de l'évaluation fonctionnelle, particulièrement la procédure statistique pour dresser la comparaison entre les systèmes d'isolation candidat et de référence, ainsi que l'évaluation des changements mineurs de composants et de procédé de fabrication;

- contient un nouvel essai d'acceptation pour la vérification du niveau de qualité de production visé pour le système d'isolation;

- comme résultat de l'évaluation fonctionnelle, restreint la classification du système d'isolation à la classification thermique.

General Information

- Status

- Published

- Publication Date

- 09-Mar-2010

- Technical Committee

- TC 2 - Rotating machinery

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Dec-2022

- Completion Date

- 31-Jul-2019

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60034-18-1:2010 is an international standard published by the International Electrotechnical Commission (IEC) that provides general guidelines for the functional evaluation of electrical insulation systems used in rotating electrical machines. These machines fall within the scope of IEC 60034-1, the standard for rating and performance of rotating electrical machines. This edition of IEC 60034-18-1 emphasizes a systematic approach to qualifying insulation systems based on functional evaluation, particularly focusing on thermal classification.

This standard updates the previous edition by incorporating guidelines for the evaluation of windings electrically stressed by converter supply and introduces a statistical method for comparing candidate insulation systems with reference systems. It also adds acceptance testing protocols to ensure production quality. The classification of insulation systems after evaluation is now strictly restricted to thermal categories.

Key Topics

- Functional Evaluation of Insulation Systems: IEC 60034-18-1 offers a framework for assessing the performance of insulation systems under operational stresses such as thermal, electrical, mechanical, and environmental factors.

- General Guidelines: This part serves as an overarching guide with detailed procedures and qualification principles provided in the subsequent parts of the IEC 60034-18 series.

- Thermal Classification: The standard focuses on thermal endurance as the primary classification measure for insulation systems after functional testing.

- Statistical Procedures: Introduces statistical approaches to compare candidate insulation systems with reference ones and to evaluate minor component modifications or manufacturing changes.

- Acceptance Testing: Specifies new acceptance tests designed to verify the expected quality levels in production runs of insulation systems.

- Converter-Supplied Windings: Provides guidelines not only for traditional winding types but also for those subjected to electrical stresses caused by converter supply.

- Multifactor Stress Testing: Addresses testing methodologies under combined stresses (thermal, electrical, mechanical, environmental) ensuring comprehensive insulation system evaluation.

Applications

IEC 60034-18-1 is essential for manufacturers, engineers, and quality assurance professionals involved in the design, testing, and certification of insulation systems in:

- Rotating Electrical Machines: Such as motors and generators used in industrial, commercial, and utility applications.

- Electrical Equipment Design: For specifying insulation systems that meet rigorous thermal endurance and functional reliability requirements.

- Quality Control: Performing acceptance tests to ensure insulation systems meet production and operational standards.

- Converter-Driven Machinery: Evaluation of windings exposed to converter-induced electrical stresses, which is increasingly common in variable-speed drives and modern motor control technologies.

- Research and Development: Supporting the development of new insulation materials and designs by providing a standardized testing framework for qualification.

Related Standards

IEC 60034-18-1 is part of a broader series addressing insulation system evaluation and works in conjunction with several related documents:

- IEC 60034-1: Covers rating and performance of rotating electrical machines.

- IEC 60034-18-21 to IEC 60034-18-34: Provide detailed test procedures for different winding types and combined stress evaluations, including thermal, electrical, mechanical, and multifactor testing.

- IEC 60505: Offers principles and procedures for estimating aging of electrical insulation from various stress factors.

- IEC 60216 Series: Defines methods for determining thermal endurance properties of insulating materials.

- IEC 60085: Establishes thermal classification and temperature limits for insulation systems in electrical equipment.

- IEC 62539: Specifies statistical analysis methods for breakdown times and voltages of insulation materials.

By aligning with these complementary standards, IEC 60034-18-1 ensures an integrated and harmonized approach to the functional evaluation and qualification of insulation systems in rotating machinery.

Keywords: IEC 60034-18-1, rotating electrical machines, insulation system evaluation, thermal classification, electrical insulation testing, converter supply stress, functional evaluation guidelines, acceptance testing, insulation system qualification, IEC standards for rotating machines, electrical insulation thermal endurance.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60034-18-1:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Rotating electrical machines - Part 18-1: Functional evaluation of insulation systems - General guidelines". This standard covers: IEC 60034-18-1:2010 deals with the general guidelines for functional evaluation of electrical insulation systems, used or proposed to be used in rotating electrical machines within the scope of IEC 60034-1, in order to qualify them. The main changes of this new edition with respect to the previous one are as follows: - provides general guidelines for functional evaluation of different types of windings as before but beyond that for electrical evaluation of windings which are electrically stressed by converter-supply; - is now focused on general guidelines with all technical details of procedures and qualification principles moved to the subsequent parts; - details additional general aspects of functional evaluation, particularly the statistical procedure for comparison between reference and candidate insulation systems and the evaluation of minor component or manufacturing changes; - contains a new acceptance test for verifying the expected production quality level of the insulation systems; - restricts the classification of insulation systems as a result of the functional evaluation to thermal classification.

IEC 60034-18-1:2010 deals with the general guidelines for functional evaluation of electrical insulation systems, used or proposed to be used in rotating electrical machines within the scope of IEC 60034-1, in order to qualify them. The main changes of this new edition with respect to the previous one are as follows: - provides general guidelines for functional evaluation of different types of windings as before but beyond that for electrical evaluation of windings which are electrically stressed by converter-supply; - is now focused on general guidelines with all technical details of procedures and qualification principles moved to the subsequent parts; - details additional general aspects of functional evaluation, particularly the statistical procedure for comparison between reference and candidate insulation systems and the evaluation of minor component or manufacturing changes; - contains a new acceptance test for verifying the expected production quality level of the insulation systems; - restricts the classification of insulation systems as a result of the functional evaluation to thermal classification.

IEC 60034-18-1:2010 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing; 29.160.01 - Rotating machinery in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60034-18-1:2010 has the following relationships with other standards: It is inter standard links to IEC 60034-18-1:1992/AMD1:1996, IEC 60034-18-1:2022, IEC 60034-18-1:1992. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60034-18-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60034-18-1 ®

Edition 2.0 2010-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Rotating electrical machines –

Part 18-1: Functional evaluation of insulation systems – General guidelines

Machines électriques tournantes –

Partie 18-1: Evaluation fonctionnelle des systèmes d’isolation – Principes

directeurs généraux

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60034-18-1 ®

Edition 2.0 2010-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Rotating electrical machines –

Part 18-1: Functional evaluation of insulation systems – General guidelines

Machines électriques tournantes –

Partie 18-1: Evaluation fonctionnelle des systèmes d’isolation – Principes

directeurs généraux

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

Q

CODE PRIX

ICS 29.160 ISBN 978-2-88910-019-4

– 2 – 60034-18-1 © IEC:2010

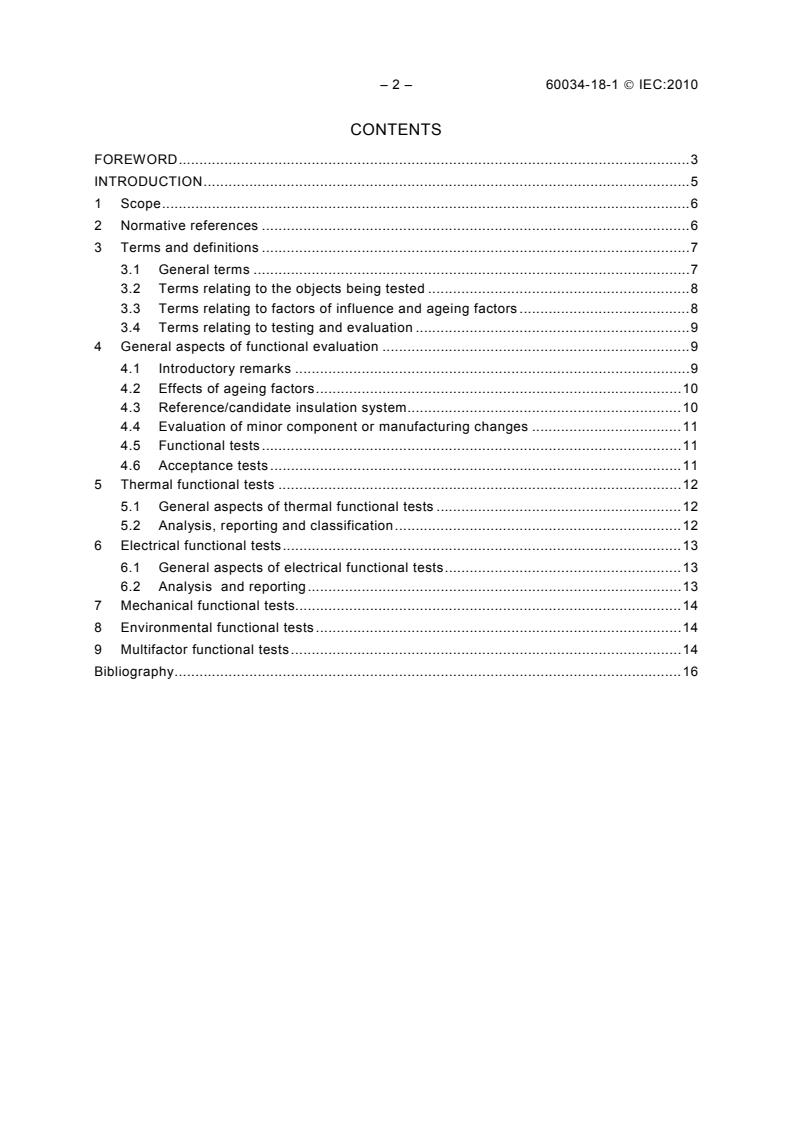

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

3.1 General terms .7

3.2 Terms relating to the objects being tested .8

3.3 Terms relating to factors of influence and ageing factors .8

3.4 Terms relating to testing and evaluation .9

4 General aspects of functional evaluation .9

4.1 Introductory remarks .9

4.2 Effects of ageing factors.10

4.3 Reference/candidate insulation system.10

4.4 Evaluation of minor component or manufacturing changes .11

4.5 Functional tests.11

4.6 Acceptance tests.11

5 Thermal functional tests .12

5.1 General aspects of thermal functional tests .12

5.2 Analysis, reporting and classification.12

6 Electrical functional tests.13

6.1 General aspects of electrical functional tests.13

6.2 Analysis and reporting.13

7 Mechanical functional tests.14

8 Environmental functional tests.14

9 Multifactor functional tests.14

Bibliography.16

60034-18-1 © IEC:2010 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ROTATING ELECTRICAL MACHINES –

Part 18-1: Functional evaluation of insulation systems –

General guidelines

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote interna-

tional co-operation on all questions concerning standardization in the electrical and electronic fields. To this

end and in addition to other activities, IEC publishes International Standards, Technical Specifications, Techni-

cal Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”).

Their preparation is entrusted to technical committees; any IEC National Committee interested in the subject

dealt with may participate in this preparatory work. International, governmental and non-governmental organiza-

tions liaising with the IEC also participate in this preparation. IEC collaborates closely with the International Or-

ganization for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all inter-

ested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any misinter-

pretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence be-

tween any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and ex-

penses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publica-

tions.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of pat-

ent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60034-18-1 has been prepared by IEC technical committee 2:

Rotating machinery.

This second edition cancels and replaces the first edition, published in 1992, and its amend-

ment 1 published in 1996, and constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– provides general guidelines for functional evaluation of different types of windings as be-

fore but beyond that for electrical evaluation of windings which are electrically stressed by

converter-supply;

– is now focused on general guidelines with all technical details of procedures and qualifica-

tion principles moved to the subsequent parts;

– 4 – 60034-18-1 © IEC:2010

– details additional general aspects of functional evaluation, particularly the statistical pro-

cedure for comparison between reference and candidate insulation systems and the

evaluation of minor component or manufacturing changes;

– contains a new acceptance test for verifying the expected production quality level of the

insulation systems;

– restricts the classification of insulation systems as a result of the functional evaluation to

thermal classification. Other kinds of classifications (classes) of insulation systems no

longer exist.

The text of this standard is based on the following documents:

FDIS Report on voting

2/1583/FDIS 2/1592/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

NOTE A list of cross-references of all IEC TC 2 publications can be found in the IEC TC 2 dashboard on the IEC

website.

The committee has decided that the contents of this amendment and the base publication will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the publica-

tion will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60034-18-1 © IEC:2010 – 5 –

INTRODUCTION

IEC 60034-18 comprises several parts, dealing with different types of functional evaluation

and special kinds of test procedures for insulation systems of rotating electrial machines.

IEC 60034-18-1 provides general guidelines for such procedures and qualification principles,

whereas the subsequent parts IEC 60034-18-21, IEC 60034-18-22, IEC 60034-18-31,

IEC 60034-18-32, IEC 60034-18-33, IEC 60034-18-34, IEC 60034-18-41 and IEC 60034-18-

42 give detailed procedures for the various types of windings. Beyond that, part IEC 60034-

18-41 and IEC 60034-18-42 contain special test procedures for electrical evaluation of

windings electrically stressed by converter-supply.

The following standards provide the basis and background for the development of the

previous standards:

IEC 60505 establishes the basis for estimating the ageing of electrical insulation systems

under conditions of either electrical, thermal, mechanical, environmental stresses or

combinations of these (multifactor stresses). It specifies the general principles and

procedures that should be followed defining functional test and evaluation procedures.

The IEC 60216 series deals with the determination of thermal endurance properties of single

insulating materials. On the assumption, that the Arrhenius equations describe the rate of

thermal ageing, test procedures and analyzing instructions for getting characteristic

parameters like the “Temperature index” (TI), the “Halving interval” (HIC) and the “Relative

thermal endurance index” (RTE) are given. For all these parameters selected properties and

accepted end-point-criteria are specified. Consequently, a material may be assigned with

more than one temperature index, derived from the measurement of different properties and

the use of different end-point criteria.

IEC 60085 deals with thermal evaluation of insulation systems used in electrical equipment. In

particular, thermal classes of insulation systems are defined and designations are given,

such as 130 (B), 155 (F) and 180 (H) for use in rotating machines belonging to IEC 60034-1.

In the past, materials for insulation systems were often selected solely on the basis of thermal

endurance of individual materials performed according to the IEC 60216 series. However,

IEC 60085 recognizes that such selection may be used only for screening materials prior to

further functional evaluation of a new insulation system which is not service-proven. Evalua-

tion is performed on the basis of a comparison with a service-proven reference insulation sys-

tem. Service experience is the preferred basis for assessing the thermal endurance of an in-

sulation system.

IEC 62539 defines statistical methods to analyse times to breakdown and breakdown voltage

data obtained from electrical testing of solid insulation materials, for the purposes of

characterization of the system and comparison with other insulation systems. The methods of

analysis are described for the Weibull-distribution but other distributions are also presented.

– 6 – 60034-18-1 © IEC:2010

ROTATING ELECTRICAL MACHINES –

Part 18-1: Functional evaluation of insulation systems –

General guidelines

1 Scope

This part of IEC 60034 deals with the general guidelines for functional evaluation of electrical

insulation systems, used or proposed to be used in rotating electrical machines within the

scope of IEC 60034-1, in order to qualify them.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60034-1, Rotating electrical machines – Part 1: Rating and performance

IEC 60034-18-21, Rotating electrical machines – Part 18-21: Functional evaluation of insula-

tion systems – Test procedures for wire-wound windings – Thermal evaluation and classifica-

tion

IEC 60034-18-22, Rotating electrical machines – Part 18-22: Functional evaluation of insula-

tion systems – Test procedures for wire-wound windings – Classification of changes and insu-

lation component substitutions

IEC 60034-18-31, Rotating electrical machines – Part 18-31: Functional evaluation of insula-

tion systems – Test procedures for form-wound windings – Thermal evaluation and classifica-

tion of insulation systems used in machines up to and including 50 MVA and 15 kV

IEC 60034-18-32, Rotating electrical machines – Part 18-32: Functional evaluation of insula-

tion systems – Test procedures for form-wound windings – Evaluation of electrical endurance

of insulation systems used in machines up to and including 50 MVA and 15 kV

IEC 60034-18-33, Rotating electrical machines – Part 18-33: Functional evaluation of insula-

tion systems – Test procedures for form-wound windings – Multifactor functional evaluation –

Endurance under combined thermal and electrical stresses of insulation systems used in ma-

chines up to and including 50 MVA and 15 kV

IEC 60034-18-34, Rotating electrical machines – Part 18-34: Functional evaluation of insula-

tion systems – Test procedures for form-wound windings – Evaluation of thermomechanical

endurance of insulation systems

IEC 60034-18-41, Rotating electrical machines – Part 18-41: Qualification and type tests for

Type I electrical insulation systems used in rotating electrical machines fed from voltage con-

verters

IEC/TS 60034-18-42, Rotating electrical machines – Part 18-42: Qualification and acceptance

tests for partial discharge resistant electrical insulation systems (Type II) used in rotating

electrical machines fed from voltage converters

IEC 60085, Thermal evaluation and designation of electrical insulation

60034-18-1 © IEC:2010 – 7 –

IEC 60216 (all parts), Electrical insulating materials – Properties of thermal endurance

IEC 60493-1, Guide for the statistical analysis of ageing test data – Part 1: Methods based on

mean values of normally distributed test results

IEC 60505:2004, Evaluation and qualification of electrical insulation systems

IEC 62539, Guide for the statistical analysis of electrical insulation breakdown data

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 General terms

3.1.1

class temperature

temperature for which the insulation system is suitable, as defined by the thermal class in

and as used in IEC 60505

IEC 60085

3.1.2

insulation system

insulating structure containing one or more electrical insulating materials applied over con-

ducting parts employed in rotating electrical machines

[IEC 60505:2004, 3.1.1, modified]

NOTE 1 There may be several insulation components within the windings, each being designed for different

stresses in service, i.e. turn insulation, slot insulation and end-winding insulation. Different criteria may be applied

to the various components within the overall system.

NOTE 2 There may be more than one insulation system in a particular type of machine. These insulation systems

may have different thermal classes (e.g. stator and rotor windings).

3.1.3

candidate insulation system

insulation system being tested to determine its capability with respect to ageing factors

[IEC 60050-411, Amendment 1:2007, 411-39-26, modified]

3.1.4

reference insulation system

insulation system whose performance has been established by satisfactory service

experience

[IEC 60050-411, Amendment 1:2007, 411-39-27]

3.1.5

coil

one or more turns of insulated conductors connected in series and surrounded by common

insulation, arranged to link or produce magnetic flux

[IEC 60050-411:1996, 411-38-03, modified]

3.1.6

bar

either of two parts which, after placed in their slots and when connected together, will form

the complete form-wound coil (see 3.1.8) and which comprise a coil side and an appropriate

end winding

– 8 – 60034-18-1 © IEC:2010

[IEC 60050-411:1996, 411-38-05, modified]

NOTE Large a.c. machines commonly use bars, and usually, though not always, they form single-turn coils in a

two-layer winding.

3.1.7

wire-wound winding

winding which is wound with one or several insulated conductors and in which the individual

conductors occupy random positions in the coil side

NOTE It is usually random-wound with round conductors.

[IEC 60050-411:1996, 411-38-13, modified]

3.1.8

form-wound winding

winding consisting of coils or bars which are preformed to shape, insulated and substantially

completed before they are inserted into their final places

NOTE Coils or bars are usually wound with rectangular conductors.

[IEC 60050-411:1996, 411-38-11, modified]

3.2 Terms relating to the objects being tested

3.2.1

test object

unit being tested

NOTE 1 It may be an actual machine or part thereof or a special test model (see 3.2.3 and 3.2.4) which can be

subjected to functional tests.

NOTE 2 A test object may contain more than one test specimen (see 3.2.2).

3.2.2

test specimen

individual component within a test object which can be used to generate one piece of test

data (e.g. time to failure)

NOTE A test specimen may contain more than one insulation component (e.g. turn insulation and conductor to

earth insulation), any one of which can provide that piece of data.

3.2.3

formette

special test model used for the evaluation of the insulation systems for form-wound windings

[IEC 60050-411, Amendment 1:2007, 411-53-64]

3.2.4

motorette

special test model used for the evaluation of the insulation systems for wire-wound (random-

wound) windings

[IEC 60050-411, Amendment 1:2007, 411-53-65]

3.3 Terms relating to factors of influence and ageing factors

3.3.1

factor of influence

stress imposed by conditions of operation, environment or test that may affect ageing or life of

an insulation system

60034-18-1 © IEC:2010 – 9 –

3.3.2

ageing factor

factor of influence that causes ageing

NOTE In the winding of an electrical machine, different factors of influence or ageing factors can be dominant in

different parts (e.g. turn insulation and end-winding insulation). Therefore, different criteria may be used to assess

those parts of the insulation. It can also be appropriate to apply different procedures of functional evaluation to

these parts.

3.4 Terms relating to testing and evaluation

3.4.1

diagnostic factor

variable or fixed stress applied to an insulation component of a test specimen in order to es-

tablish its condition after ageing without significantly adding to the ageing

[IEC 60505:2004, 3.3.7, modified]

3.4.2

functional test

comparative test in which the candidate and the reference insulation systems are exposed to

ageing and diagnostic factors in order to qualify the candidate system

3.4.3

endurance test

test in which the insulation system of a test object is exposed to one or more ageing factors

related to service conditions and where changes in specific properties are evaluated by

diagnostic tests

3.4.4

diagnostic test

test in which the insulation system of a test object is exposed to one or more diagnostic

factors in order to discern its condition through measurements or proof tests and to determine

when the end-point criterion has been reached

3.4.5

end-point criterion

selected value of a characteristic of a test object indicating the end of its test life or arbitrarily

chosen for the purpose of the comparison of insulation systems

3.4.6

end-point

end of a test as defined by the end-point criterion

3.4.7

classification

set of actions leading to determination of the thermal class of an insulation system

4 General aspects of functional evaluation

4.1 Introductory remarks

All functional tests given in the IEC 60034-18 series are comparative. The performance of a

candidate system is compared with that of a reference system when both are subjected to

equivalent test conditions with respect to test objects, methods of ageing and diagnostic tests.

At the end of every functional test, the functional evaluation shall be made. This means it is

necessary to compare the diagnostic data obtained from the candidate and the reference

system, usually to compare the mean times to failure.

– 10 – 60034-18-1 © IEC:2010

If the data from the candidate system is no worse than from the reference system, the

candidate system is considered to be qualified. This is true if the 90 % confidence interval of

that percentile of the used probability distribution which represents the mean value falls above

or within that obtained from the reference system (see IEC 60493-1 and IEC 62539).

The large differences found in rotating electrical machine windings, in terms of size, voltage

and operating conditions, necessitate the use of different procedures for functional evaluation

to evaluate various types of windings. These procedures can also be of different complexity,

the simplest being based on a single ageing factor (e.g. thermal or electrical).

The procedures for functional evaluation will permit comparisons and allow qualification of

candidate insulation systems. However, they cannot completely determine the merits of any

particular insulation system. Such information can be obtained in general only from extended

service experience.

4.2 Effects of ageing factors

All ageing factors, i.e. thermal, electrical, environmental and mechanical, affect the life of all

types of machines but the significance of each factor varies with the type of machine and the

expected duty. In some cases, one of these ageing factors is considered to be dominant.

In other cases, several ageing factors may be acting significantly. These different conditions

have to be considered in choosing the appropriate functional test according to this standard.

Insulation of small or medium low-voltage line-fed machines is degraded primarily by

temperature and environment, with electrical and mechanical stresses being of less

importance.

Medium to large machines, using form-wound windings, are also affected by temperature and

environment but, in addition, the electrical and mechanical stresses can be important ageing

factors.

Very large machines, which generally utilize form-wound (with bars) windings and which can

operate in a special environment such as hydrogen, are normally most affected by mechanical

stresses or electrical stresses, or both. Temperature and environment can be less significant

ageing factors.

The winding insulation of small, medium, large and very large converter fed machines may be

substantially electrically stressed (see IEC 60034-18-41 and IEC 60034-8-42).

4.3 Reference/candidate insulation system

An insulation system qualifies to be used as a reference insulation system if its performance

has been established by satisfactory service experience. This means:

– it has shown successful operation over suitably long periods of time at operating

conditions characteristic of the rating (or class) and in typical applications of that insul-

ation system;

– its service experience is based on a sufficient number of machines.

A reference insulation system shall be tested together with the candidate system using the

same test procedure and the same test equipment, preferably in the same laboratory.

If it is necessary to verify results in another laboratory it can be found that the test-life values

differ if the conditions in the original test are not duplicated precisely. However, a comparison

of results between qualified laboratories should show the same relative performance between

candidate and reference systems.

60034-18-1 © IEC:2010 – 11 –

4.4 Evaluation of minor component or manufacturing changes

Any substitution of components (insulating materials) or any relevant change in manufacturing

process changes a reference system into a candidate system with the need for a new

functional evaluation, unless the new component can be considered to be chemically and

physically identical (generically identical) and the intended changes in the manufacturing

process are not expected to have any influence on the electrical insulation system properties.

In respect of the dominant ageing factor, or combinations of ageing factors, it may be that the

change proposed is only minor. Such a minor change is the substitution of a component or a

change in the manufacturing process which is expected to have no significant effect on the

performance of the insulation system and may be the justification to use, instead of a full

functional evaluation, merely a reduced functional evaluation or special endurance tests (see

IEC 60034-18-22 together with IEC 60034-18-21, IEC 60034-18-31, IEC 60034-18-32 and

IEC 60034-18-33).

It is the machine manufacturer's responsibility to determine the need for verification and to

justify the use of a reduced functional evaluation or how special endurance tests should be

undertaken. Full or reduced functional evaluation or special endurance tests may be neces-

sary.

In the documentation on insulation system, the manufacturer should include this verification of

a minor change when it is used in the system.

4.5 Functional tests

As defined in 3.4.2, functional tests are used to qualify the insulation systems. They are per-

formed by endurance test cycles, each cycle consisting of an ageing sub-cycle and a diagnos-

tic sub-cycle. In the ageing sub-cycle, test specimens are exposed to the specified ageing

factor, intensified appropriately to accelerate ageing. In the diagnostic sub-cycle, test speci-

mens are subjected to appropriate diagnostic tests to determine the end of test life or to

measure relevant properties of the insulation system at that time. In some cases, the ageing

factor itself can act as the diagnostic factor and produce the end-point.

Not all diagnostic tests need be applied in all cases. Special considerations may render

inapplicable certain diagnostic tests.

The outcome of these tests is comparative and does not allow an estimate to be made, e.g.

by extrapolation or calculation, of a definite lifetime in service because additional factors of

influence can intervene.

4.6 Acceptance tests

Acceptance tests may be performed to verify that the insulation materials used and the manu-

facturing procedure employed are of the expected production quality level. In so far, the

acceptance tests in themselves do not qualify an insulation system.

The decision as to whether acceptance tests are undertaken or not, shall be agreed between

the manufacturer and purchaser.

In cases where there is no chance to make the acceptance tests with test objects produced

together with those winding elements to be sold according to the contract, the acceptance test

may be a type test.

– 12 – 60034-18-1 © IEC:2010

5 Thermal functional tests

5.1 General aspects of thermal functional tests

The purpose of the thermal functional tests in this standard is to provide data which may be

used to establish the thermal class of a new insulation system before it is service-proven.

These guidelines are used in conjunction with IEC 60034-18-21, IEC 60034-18-22 and

IEC 60034-18-31 for the specific type of winding being considered and where the thermal

ageing factor shall be considered dominant in comparison to the other ageing factors.

The concepts implemented in this standard are based on IEC 60085, IEC 60493-1, IEC 60505

and IEC 62539.

The thermal ageing processes in the insulation system of rotating electrical machines can be

complex in nature. Since the insulation systems of rotating machines are complicated in vary-

ing degrees, simple systems referred to in IEC 60085 do not exist in rotating machines.

If the intended thermal class of the candidate system differs from the known thermal class of

the reference system, different ageing temperatures, sub-cycle lengths and (when technically

justified) different diagnostic values shall be used in an appropriate manner.

Diagnostic tests (such as mechanical, moisture and voltage tests) shall be applied after each

thermal ageing sub-cycle to check the condition of the insulation system.

It should be recognized that greater mechanical stress and higher concentration of the prod-

ucts of decomposition can occur during ageing tests above the service temperature. Also, it

is recognized that failures from abnormally high mechanical or voltage stresses are generally

of a different character to those failures which are produced in long service.

5.2 Analysis, reporting and classification

The end of insulation test life is assumed to have occurred at the mid-point-time of the ageing

sub-cycle between the last two consecutive diagnostic sub-cycles.

The total number of hours of thermal ageing to the end of test shall be recorded for each

specimen and for each temperature.

A thermal endurance graph is drawn using the results of ageing, according to the guidelines

given in IEC 60493-1 and IEC 62539 for both the candidate system and reference systems.

Having chosen a distribution to represent the test results of ageing, it is necessary to check

that the distribution is adequate for this purpose.

If, in special cases of application, the requirements for the expected life time of the candidate

insulation system essentially differ from that of the reference insulation system within the

same thermal class, then the classification can be made, taking account of this fact (see

IEC 60034-18-21 and IEC 60034-18-31). This shall be stated in the report together with an

appropriate justification.

If the thermal endurance graphs of the reference and candidate systems have clearly dissimi-

lar slopes, it is evident that their ageing processes are significantly different and it is thus

doubtful whether a valid classification can be made from the comparison.

When reporting, it is useful to record all relevant details of the test, including those in the

following list:

– references to IEC test standards;

– description of the insulation systems tested (the reference and candidate systems);

60034-18-1 © IEC:2010 – 13 –

– ageing temperatures and ageing sub-cycle lengths for each insulation system;

– diagnostic tests used with applied test or stress levels for each insulation system;

– construction of the test specimens and test objects;

– number of specimens at each temperature for each insulation system;

– method of applying the ageing temperatures and the way in which the temperatures have

been measured (including oven type, etc.);

– rate of oven air replacement;

– individual times to failure and failure modes;

– mean log times to failure and the log standard deviation, or the lower confidence limits for

each ageing temperature and for each insulation system;

– thermal endurance graph with log mean points and regression line;

– thermal class of the reference system;

– thermal class of the candidate system as determined by the test.

6 Electrical functional tests

6.1 General aspects of electrical functional tests

Insulation systems are subjected to electrical ageing by applying a voltage between parts

operating at different electric potentials and where the electrical ageing factor is to be

considered dominant in comparison to the other ageing factors. Qualification procedures for

these conditions are given in detail in IEC 60034-18-32, IEC 60034-18-41 and IEC 60034-18-

42.

The ageing process can be accelerated by raising the electrical stress and/or increasing the

frequency of the test voltage. End of life is manifested either as breakdown during exposure

to electrical ageing or as failure in a diagnostic test.

If it is necessary to adapt the design of single components of the insulation systems to make

the electrical functional test practicable (e.g. the stress grading system), then for these

components special endurance or acceptance tests are recommended.

By conducting tests at different voltages, a relationship of test life versus electrical stress can

be plotted. Note that increased frequency has often been used to accelerate electrical ageing,

with the assumption that the test acceleration is proportional to frequency. However, this as-

sumption does not always hold. A discussion on this issue is given in IEC 60034-18-42.

Test life normally exhibits a widespread variation for any particular voltage stress level.

Therefore, it is essential that a statistically significant number of failure times be obtained at

each electrical ageing stress.

In certain cases, special endurance or acceptance tests, e.g. non-destructive PD

measurements, can be used for electrical qualification, see IEC 60034-18-41.

Specimens should be at room temperature or at the thermal class temperature. Care should

be taken that dielectric losses at high stress or at increased frequency do not raise insulation

temperature enough to affect the results.

6.2 Analysis and reporting

An electrical endurance graph is drawn using the results of ageing, according to the

guidelines given in IEC 62539 for both the candidate system and reference systems. Having

chosen a distribution to represent the test results of ageing, it is necessary to check that the

distribution is adequate for this purpose. According to present experience it would normally be

the Weibull distribution.

– 14 – 60034-18-1 © IEC:2010

When reporting, it is useful to record all relevant details of the test, including those in the

following list:

– maximum intended rated voltage of the system;

– test temperature;

– description of the insulation systems tested (the reference and the candidate systems);

– ageing voltages, frequencies and ageing sub-cycle lengths if appropriate;

– diagnostic tests including the values of the diagnostic factors used;

– construction of the test object;

– number of test specimens at each voltage (fixed voltage test);

– individual times to failure and failure modes;

– method of statistical treatment used for the test data (preferably the Weibull-distribution)

to determine the mean time to failure (63 % value in the case of Weibull) and the confi-

dence limits, see IEC 62539;

– electrical endurance graph with mean or median points for each electrical ageing stress

and regression line.

7 Mechanical functional tests

It is recognized that mechanical stress in some applications acts as an ageing factor, either

alone or in combination with other ageing factors. Mechanical ageing can be a consequence

of vibrational stresses, stresses caused by electrodynamic forces or thermomechanical

stresses due to very large number of considerable load changes during normal operation,

see IEC 60034-18-34.

Sufficient technical information is not available at the present time to permit standard me-

chanical ageing test procedures with dominant mechanical ageing factors to be presented.

NOTE An approach of an empirical life model and test procedures are discussed in IEC 60505.

8 Environmental functional tests

It is recognized that environmental factors in some applications act as ageing factors.

Environmental ageing factors include chemically/physically active or electrically conductive

substances in industrial atmospheres, exceptionally high moisture content of the ambient air,

fungus or microbe-contaminated environments, or mechanically abrasive materials (e.g. sand)

in the cooling air.

Such chemical/physical environmental ageing factors can e.g. also be the effect of refriger-

ants in hermetic motors or the ionizing radiation in nuclear power plants. For insulation sys-

tems of these special applications, extensive endurance test procedures beyond the

IEC 60034-18 series exist.

Sufficient technical information is not available at the present time to permit standard

environmental ageing test procedures with dominant environmental ageing factors to be

presented.

9 Multifactor functional tests

It is recognized that more than one factor of influence, e.g. thermal and electrical, can affect

the performance of insulation systems, particularly when these factors act simultaneously, see

IEC 60034-18-33.

60034-18-1 © IEC:2010 – 15 –

Such multifactor ageing can occur in mechanically or thermomechanically high-stressed low

and high voltage machines.

In general, for multifactor functional tests, the following principles which are derived from

IEC 60505 shall be considered:

a) Simultaneously acting factors of influence in service should preferably be simulated in

simultaneous ageing tests, while sequentially acting factors of influence should preferably

be simulated with sequential ageing cycles, to ensure that possible direct or indirect

interactions between the different ageing factors during the funtional test act as in service.

b) When one of the ageing factors is known to be more important than the others, then the

multifactor tests may be performed by accelerating the effects of that factor only and

keeping other factors at service levels.

c) In other cases, all the important ageing factors should be accelerated. It is recommended

that the acceleration factor (relative rate of ageing) be similar for each ageing factor and

that the levels of the ageing factors be established on the basis of single-factor ageing

tests until experience is obtained.

d) It is recommended that the reference operating conditions be established. This is the set

of the service conditions for which the machine and its insulation system have been

designed.

The levels of the factors of influence in the set of reference operating conditions serve as

the basis for estimating the acceleration factors during the ageing sub-cycle a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...