IEC TR 62998-2:2020

(Main)Safety of machinery - Part 2: Examples of application

Safety of machinery - Part 2: Examples of application

IEC TR 62998-2:2020 establishes guidance for the application of IEC TS 62998-1:2019.

It provides examples of:

– application for which SRS/SRSS are relevant,

– use of SRS/SRSS information from an application point of view,

– fusion of SRS into SRSS for given applications, and

– appropriate information for use for given applications.

General Information

- Status

- Published

- Publication Date

- 13-Apr-2020

- Technical Committee

- TC 44 - Safety of machinery - Electrotechnical aspects

- Drafting Committee

- WG 14 - TC 44/WG 14

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-Apr-2020

- Completion Date

- 18-Mar-2020

Overview - IEC TR 62998-2:2020 (Safety of machinery - Part 2: Examples of application)

IEC TR 62998-2:2020 is a Technical Report from the IEC that provides practical guidance for applying IEC TS 62998-1:2019. It focuses on the real-world use of safety-related sensors (SRS) and safety-related sensor systems (SRSS) for the protection of people around machinery. Rather than defining new normative requirements, this report supplies worked examples, application scenarios and recommended information for use to help manufacturers, integrators and safety engineers implement compliant and effective sensor-based safety solutions.

Key topics and technical requirements highlighted

- Application examples demonstrating where SRS/SRSS are relevant (e.g., mobile robots and container‑handling equipment).

- Fusion of SRS into SRSS: guidance on combining multiple sensors to improve coverage and create coherent safety-related zones.

- SRS/SRSS performance considerations: performance class determination, SRS limits of use, and how fusion affects SRSS performance.

- Safety-related functions and zones: defining sensing zones, safety-related zones and mapping between sensor outputs and required safety functions.

- Environmental and dependability factors: guidance on environmental limits, influence of weather/lighting (e.g., MOR), and robustness requirements.

- Verification, validation and information for use: test/validation approaches, confidence data, and the operational/maintenance information that must be provided to users.

- Referenced normative material: meant to be used in conjunction with IEC TS 62998-1:2019 and takes into account robot classifications such as ISO 13482:2014.

Practical applications and who uses this standard

This TR is practical for:

- Sensor manufacturers designing safety LiDAR, TOF, camera or other SRS products and documenting limits of use.

- System integrators and OEMs integrating multiple sensors into an SRSS for mobile robots (mail transport, cleaning robots) or heavy equipment (container‑handling equipment in ports).

- Safety engineers and compliance teams assessing performance classes, conducting verification/validation and preparing safety documentation.

- Facility operators and service teams who need the “information for use” (installation, limitations, maintenance) to keep safety systems effective.

Benefits include clearer guidance for sensor fusion, improved risk reduction through better-defined sensing/safety zones, and practical templates for verification and user information.

Related standards

- IEC TS 62998-1:2019 - Primary normative specification for safety-related sensors used for protection of persons (use this TR alongside TS 62998-1).

- ISO 13482:2014 - Robot classification referenced for mobile robot intended use.

Keywords: IEC TR 62998-2:2020, safety of machinery, safety-related sensors, SRSS fusion, mobile robot safety, container-handling equipment safety, IEC TS 62998-1:2019.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

IEC TR 62998-2:2020 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Safety of machinery - Part 2: Examples of application". This standard covers: IEC TR 62998-2:2020 establishes guidance for the application of IEC TS 62998-1:2019. It provides examples of: – application for which SRS/SRSS are relevant, – use of SRS/SRSS information from an application point of view, – fusion of SRS into SRSS for given applications, and – appropriate information for use for given applications.

IEC TR 62998-2:2020 establishes guidance for the application of IEC TS 62998-1:2019. It provides examples of: – application for which SRS/SRSS are relevant, – use of SRS/SRSS information from an application point of view, – fusion of SRS into SRSS for given applications, and – appropriate information for use for given applications.

IEC TR 62998-2:2020 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 21.020 - Characteristics and design of machines, apparatus, equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62998-2:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62998-2 ®

Edition 1.0 2020-04

TECHNICAL

REPORT

colour

inside

Safety of machinery –

Part 2: Examples of application

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and once 67 000 electrotechnical terminology entries in English and

a month by email. French extracted from the Terms and Definitions clause of IEC

publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or need CISPR.

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 62998-2 ®

Edition 1.0 2020-04

TECHNICAL

REPORT

colour

inside

Safety of machinery –

Part 2: Examples of application

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 13.110; 21.020 ISBN 978-2-8322-7975-5

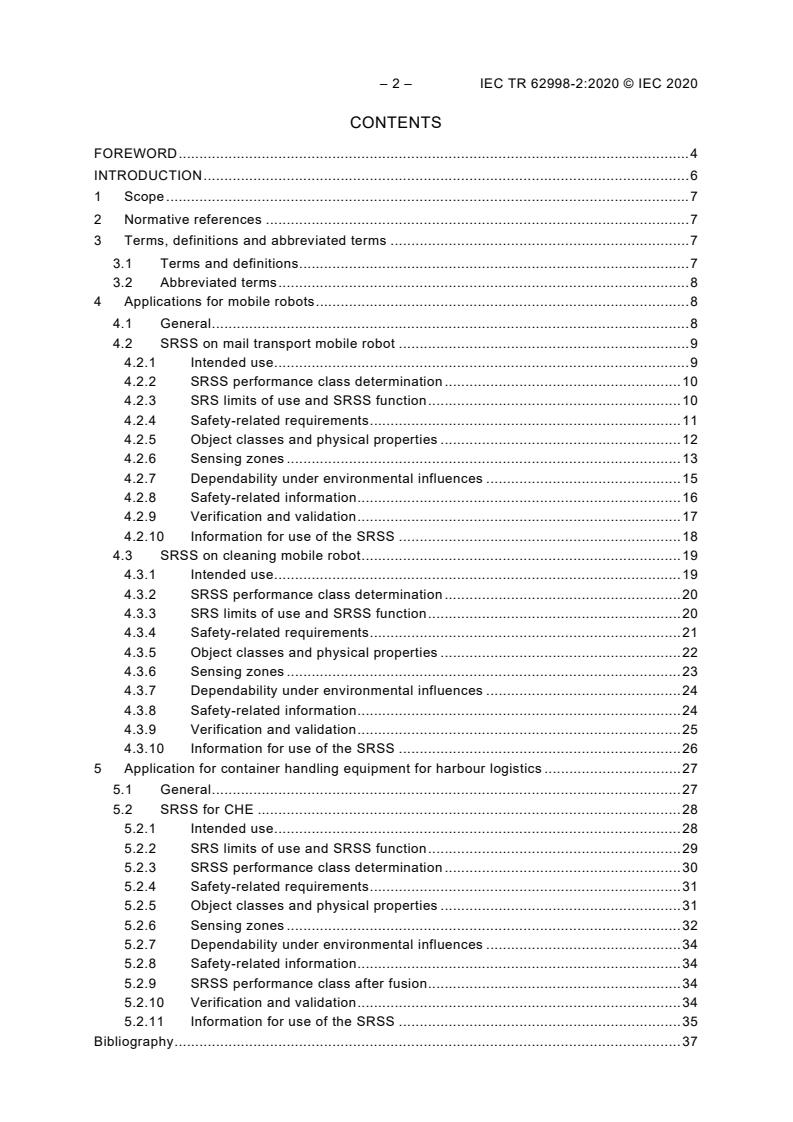

– 2 – IEC TR 62998-2:2020 © IEC 2020

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviated terms . 7

3.1 Terms and definitions . 7

3.2 Abbreviated terms . 8

4 Applications for mobile robots . 8

4.1 General . 8

4.2 SRSS on mail transport mobile robot . 9

4.2.1 Intended use . 9

4.2.2 SRSS performance class determination . 10

4.2.3 SRS limits of use and SRSS function . 10

4.2.4 Safety-related requirements . 11

4.2.5 Object classes and physical properties . 12

4.2.6 Sensing zones . 13

4.2.7 Dependability under environmental influences . 15

4.2.8 Safety-related information . 16

4.2.9 Verification and validation . 17

4.2.10 Information for use of the SRSS . 18

4.3 SRSS on cleaning mobile robot . 19

4.3.1 Intended use . 19

4.3.2 SRSS performance class determination . 20

4.3.3 SRS limits of use and SRSS function . 20

4.3.4 Safety-related requirements . 21

4.3.5 Object classes and physical properties . 22

4.3.6 Sensing zones . 23

4.3.7 Dependability under environmental influences . 24

4.3.8 Safety-related information . 24

4.3.9 Verification and validation . 25

4.3.10 Information for use of the SRSS . 26

5 Application for container handling equipment for harbour logistics . 27

5.1 General . 27

5.2 SRSS for CHE . 28

5.2.1 Intended use . 28

5.2.2 SRS limits of use and SRSS function . 29

5.2.3 SRSS performance class determination . 30

5.2.4 Safety-related requirements . 31

5.2.5 Object classes and physical properties . 31

5.2.6 Sensing zones . 32

5.2.7 Dependability under environmental influences . 34

5.2.8 Safety-related information . 34

5.2.9 SRSS performance class after fusion . 34

5.2.10 Verification and validation . 34

5.2.11 Information for use of the SRSS . 35

Bibliography . 37

Figure 1 – Outdoor scene . 8

Figure 2 – Mobile robot with 2 distinctive safety-related zones . 10

Figure 3 – Combination of three SRSs into an SRSS and SRSS functions . 11

Figure 4 – Mounting positions and sensing zones of the SRS and safety-related zones

of SRSS . 14

Figure 5 – Mounting positions and sensing zones of the SRS and safety-related zones

of SRSS . 14

Figure 6 – Examples of measurement data for evaluation of coverage interval . 17

Figure 7 – Test setup . 18

Figure 8 – CHE application . 28

Figure 9 – Operation areas of CHE . 29

Figure 10 – SRSS structure and safety-related functions . 30

Figure 11 – Safety-related zones of SRSS . 32

Figure 12 – Mounting positions and sensing zones of the SRS, and safety-related

zones of the SRSS . 33

Table 1 – Safety-related requirements . 12

Table 2 – Example of confidence information for SRS . 17

Table 3 – Information for use of the SRSS . 19

Table 4 – Safety-related requirements . 22

Table 5 – Information for use of the SRSS . 27

Table 6 – Safety-related requirements . 31

Table 7 – Environmental limits of SRSS . 34

Table 8 – Information for use of the SRSS . 36

– 4 – IEC TR 62998-2:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY OF MACHINERY –

Part 2: Examples of application

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 62998-2, which is a Technical Report, has been prepared by IEC technical committee

TC 44: Safety of machinery – Electrotechnical aspects.

The text of this Technical Report is based on the following documents:

Enquiry draft Report on voting

44/849/DTR 44/865A/RVDTR

Full information on the voting for the approval of this technical report can be found in the report

on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This document is to be used in conjunction with IEC TS 62998-1:2019.

A list of all parts in the IEC 62998 series, published under the general title Safety of machinery,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

reconfirmed,

withdrawn,

replaced by a revised edition, or

amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC TR 62998-2:2020 © IEC 2020

INTRODUCTION

Safety-related sensors are applied to machinery presenting a risk of personal injury. They

provide protection by causing the machine to revert to a safe condition before a person can be

placed in a hazardous situation.

IEC TS 62998-1:2019 is intended for use by safety-related sensor manufacturers and

integrators of safety-related sensors for the design of safety-related sensor systems used for

the protection of persons.

This document gives guidance for manufacturers and integrators on the application of IEC TS

62998-1:2019.

SAFETY OF MACHINERY –

Part 2: Examples of application

1 Scope

This document establishes guidance for the application of IEC TS 62998-1:2019.

It provides examples of:

– application for which SRS/SRSS are relevant,

– use of SRS/SRSS information from an application point of view,

– fusion of SRS into SRSS for given applications, and

– appropriate information for use for given applications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC TS 62998-1:2019, Safety of machinery – Safety-related sensors used for protection of

persons

3 Terms, definitions and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Terms and definitions

3.1.1

mobile robot

robot able to travel under its own control

[SOURCE: ISO 8373:2012, 2.13, modified – The note has been omitted.]

3.1.2

robot

actuated mechanism programmable in two or more axes with a degree of autonomy, moving

within its environment, to perform intended tasks

[SOURCE: ISO 8373:2012, 2.6, modified – Notes 1 and 2 have been omitted.]

– 8 – IEC TR 62998-2:2020 © IEC 2020

3.2 Abbreviated terms

CHE container-handling equipment

ALARP as low as reasonably practical

LiDAR light detection and ranging

MOR meteorological optical range

TOF time of flight

SLAM Simultaneous Localization and Mapping

SRS safety-related sensor

SRSS safety-related sensor system

SCS safety-related control system

4 Applications for mobile robots

4.1 General

This example covers the integration and installation phase using fusion of three SRSs into an

SRSS in accordance with Clause 6 of IEC TS 62998-1:2019 to improve sensing zones and

safety-related zones in accordance with requirements for the intended use. The intended uses

are 2 different mobile robot types, in accordance with ISO 13482:2014, that operate

autonomously in a public area with limited access. The reader should be aware that the

following descriptions are not based on comprehensive analysis and are only examples for

mobile robotics.

NOTE ISO 13482:2014 covers mobile robots operating in an autonomous manner. For simplification, the term

"mobile robot" will be used from now on.

Two different mobile robots operate on a certain university campus with buildings to achieve:

transport of in-house mail items among office buildings of the university, and

cleaning of pavements of the university.

Figure 1 shows the typical outdoor pavement of a university campus. Person(s) being present

or approaching the safety related zone(s) of an SRSS should be detected and the safety-related

control system should initiate appropriate reaction of the mobile robot.

Figure 1 – Outdoor scene

4.2 SRSS on mail transport mobile robot

4.2.1 Intended use

The intended use should be determined (see 6.2.1 of IEC TS 62998-1:2019) by the integrator.

It is defined by the following selected example items:

1) The mobile robot is a Type 1.1 robot specified in ISO 13482:2014 with a weight of 30 kg

and size of length: 500mm × width: 500mm × height: 600mm.

2) The mobile robot automatically navigates the pavement connecting the university office

buildings. The path of the robot is predetermined according to the map created by SLAM

technology [1] and physical constraints. The map includes position information for objects

that are fixed along the pavement, such as guardrails, building walls, trees, etc. By referring

to the map, the robot determines its own restricted space (ISO 13482:2014, 3.18.2) while

moving.

3) The mobile robot moves during daytime on non-carriageways where:

a) light vehicles such as bicycles are not allowed to enter;

b) wheelchairs can enter;

c) pavements are smooth paved with slopes of up to 5 degrees in some areas, as shown

in Figure 1;

d) standing or walking people on the pavements are adults and/or children. Children under

and including 3 years are assumed to be controlled and children from 4 years up to

including 10 years are assumed to be accompanied by adults. An adult might not

accompany children over 10 years up to 14. For the purpose of this example, the speed

of a person towards the mobile robot is assumed to be between 0 mm/s and 800 mm/s

if the person enters into the safeguarded zone.

NOTE The speed in this example deviates from ISO 13855:2010 under the assumption of different human

behaviour in this application. For other applications, faster or slower speeds might be more appropriate. On

the campus, people are informed by organizational measures and warning signals that running is not

allowed in the areas where mobile robots are present. Other examples of properties are given in 4.2.4.

4) The mobile robot:

a) is intended to make a protective stop when a standing or walking person comes into the

protective stop zone (see Figure 2);

b) is intended to reduce the speed when a standing or walking person moves into the

safeguarded zone (see Figure 2);

c) is driven with a speed up to 700 mm/s reduced by the safety related speed control

function down to 300 mm/s;

d) can reduce speed within 0,5 s from 700 mm/s to 300 mm/s, and another 0,2 s to reduce

to zero speed;

e) is intended to be used in the daytime.

5) The outdoor environmental conditions during operation:

a) can be up to 10 mm/h precipitation;

b) can have light interference representing daytime.

___________

Numbers in square brackets refer to the Bibliography.

– 10 – IEC TR 62998-2:2020 © IEC 2020

The mobile robot has two distinctive zones, in accordance with ISO 13482:2014. The protective stop zone, where

the mobile robot performs a protective stop, and the safeguarded zone, where a safety-related speed control function

is performed when a safety-related object is detected. In accordance with IEC TS 62998-1:2019, the protective stop

zone and safeguarded zone would be safety-related zone(s).

Figure 2 – Mobile robot with 2 distinctive safety-related zones

4.2.2 SRSS performance class determination

In the chosen approach, using ISO 13482:2014 the required performance level of the safety

functions of a Type 1.1 mobile robot is PL b, in accordance with ISO 13849-1:2015. The safety

functions include the protective stop function, the safety-related speed control function, the

hazardous collision avoidance function, and the travel surface detection function in accordance

with ISO 13482:2014, which will be initiated by the SRSS.

The required performance class of the SRSS corresponding to PL b is the sensor performance

class B specified in IEC TS 62998-1:2019.

4.2.3 SRS limits of use and SRSS function

The SRSS consists of three SRSs defined by the manufacturer as follows (see Figure 3).

1. SRS1: a 2D LiDAR suitable to be used up to PL b, in accordance with ISO 13849-1:2015,

which allows the detection of persons and other safety-related objects and the measurement

of their positions and velocities with high accuracy. The systematic capabilities are

assessed in accordance with IEC TS 62998-1:2019. The sensing zone is up to a radius of

7 000 mm, and a viewing angle of 270°. The detection capability is given for safety-related

objects with the properties: minimum size 40 mm × 40mm; minimum object reflectivity 5 %;

maximum object speed 1 600 mm/s. The response time is 0,05 s. Use in indoor and outdoor

environmental conditions is possible within defined limits.

2. SRS2: a TOF camera suitable to be used up to PL b, in accordance with ISO 13849-1:2015,

which allows detecting parts of 3D volumes of persons, road surface, and other safety-

related objects using 3D imaging technology. The systematic capabilities are assessed in

accordance with IEC TS 62998-1:2019. SRS2 is capable of measuring the position and

velocity of objects within the 3D sensor coordinate system. The sensing zone is up to

4 000 mm and vertical and horizontal field of views angle of 60° and 70°, respectively. The

detection capability is given for safety-related objects with properties: minimum size

40 mm × 40 mm × 40 mm; minimum object reflectivity 5 %; maximum object speed

1 600 mm/s. The response time is 0,05 s. It is possible to distinguish a paved road surface

and other objects three-dimensionally. Use in indoor and outdoor environmental conditions

is possible within defined limits.

3. SRS3: the same specification as SRS1.

Figure 3 – Combination of three SRSs into an SRSS and SRSS functions

The target applications require four SRSS functions (see Figure 3):

• Safety-related function 1: to detect persons and hazardous objects in the protective stop

zone for initiating the protective stop function specified in ISO 13482:2014, 6.2.2.3.

• Safety-related function 2: to detect persons and hazardous objects and to provide their

positions and velocities as safety-related information for the safety-related speed control

function and/or the hazardous collision avoidance function specified in ISO 13482:2014,

6.4 and 6.5.2.1.

• Safety-related function 3: to detect the geometry of the travel surface of the robot as

specified in ISO 13482:2014, 6.5.3. When a travelable surface is observed in the

travelling direction of the robot, the robot can move forwards. If the robot moves

backwards, the road surface that it has already travelled is definitely present, so this

function is not required.

• Automation related function: to provide 3D point cloud with timestamp in the robot

coordinate system for SLAM.

4.2.4 Safety-related requirements

The SRSS safety-related requirements should be specified by the integrator (see 6.2.1 of

IEC TS 62998-1:2019) based on the intended use. For example, see the requirements defined

in Table 1.

– 12 – IEC TR 62998-2:2020 © IEC 2020

Table 1 – Safety-related requirements

Term Requirement Details

SRSS performance class B See 4.2.2

Intended to be integrated from SRS

of the same performance class B

Demand rate of SRSS safety 10/h

related function(s)

SRSS response time 0,1 s

SRSS detection capability e.g. Person related properties: See 4.2.5

Sizes representing a 4-year-old

person in an upright position.

Minimum reflection value 5 %

Speed 800 mm/s

e.g. Hazardous object properties:

Sizes representing wheelchair

Minimum reflection value 5 %

Speed 800mm/s

SRSS sensing zones e.g. Safety related zones See 4.2.6

2-dimensional; 360° with S = 656

mm and S = 1 255 mm;

3-dimensional; vertical and

horizontal field of view 60°; with S

= 656 mm and S = 1 255 mm;

4.2.5 Object classes and physical properties

The SRSS detection capability should be specified by the integrator in accordance with 6.2.3

of IEC TS 62998-1:2019. The following specific examples are considered.

Object classes to be analysed are:

1) objects used to perform the person detection function;

a) supervised children up to and including 3 years;

b) accompanied children between 4 years and including 10 years;

c) unaccompanied children between 11 years and including 13 years;

d) adult persons from 14 years.

2) objects used to perform the hazardous object function;

a) wheelchairs.

3) objects used to perform the automation related function

a) landmarks used for navigation.

Furthermore, only the properties of an accompanied standing or walking child will be analysed

for the safety-related function 1 and safety related function 2.

For safety related function 2, the limit that SRS2 detects is the forearm of a 4-year-old child.

The simplified shape is estimated as cylinder with a diameter of 40 mm or more and a length of

200 mm.

NOTE 1 The 5th percentile value of the hand width and the hand length of a Japanese 4-year-old child is 49 mm

and 107 mm respectively. There is no arm length data for the child [2].

For safety-related function 1, the lower limbs of a 4 year-old-child are used to identify the

minimum size. The simplified shape is estimated as cylinder with a diameter of 50 mm in

mounting height of SRS1 and SRS3.

NOTE 2 The 5th percentile value of circumference is estimated based on Data for Japanese Children measured for

calf and ankle [3].

For the safety-related function 3, performed by SRS2 of the SRSS, the travelling surface to be

detected is a continuous flat surface or smooth curved surface with a slope of 5° or less in front

of the robot.

NOTE 3 SRS1 may detect the road surface as a hazardous object at the entrance to the slope. Other measures

might be put in place to prevent a permanent stop of the mobile robot.

The minimum diffuse reflectivity used as representation for a person, a hazardous object, and

a travel surface is assumed to be 5 % or more at the wavelength used by each SRS.

NOTE 4 The 5 % minimum reflectivity value is taken for a safety function of PL b following the ALARP principle.

Many standard LiDAR sensors state 10 % as minimum reflectivity value in security and automation applications, or

6% minimum reflection value is required for person detection with sensors used on automated guided vehicles in

accordance with B56.5:2012. In general, additional validation in the application can be required for mobile robots

within information for use as a possibility to test appropriateness of used object properties or stated performance

(e.g. speed of objects or minimum reflection value). The minimum reflectivity value is discussed specifically taking

care of the situation that many people using sensors for person protection in machinery are focused on it. The reader

of this document is asked to consider that detection capability of SRS is often based on a combination of different

properties and not a single one taken for deterministic analysis. For example, a combination of low reflection value

with small object size and maximum assumed speed can be estimated as of very low probability. The practical use

and the combination of properties, under consideration of their probability distribution, is an increasing challenge in

applications of SRSs and SRSS.

The speed of persons moving during daytime towards the mobile robot is assumed to be

800 mm/s.

NOTE 5 Persons moving over the university are informed that mobile robots are in progress and that they are

required to stay at a distance from them.

For the automation-related function of the SRSS, all objects within the SRSS sensing zone

representing reliable, fixed landmarks on the mobile-robot travelling path will be identified within

a procedure during the starting of operation.

4.2.6 Sensing zones

The integrator should specify the SRSS sensing zones in accordance with 6.2.4 of

IEC TS 62998-1:2019.

The mounting position and the sensing zone of each SRS, and the improved safety-related

zones of the SRSS after fusion, are shown in Figure 4 and Figure 5.

SRS1 and SRS3 are mounted horizontally on the left front and the right rear of the robot,

respectively, at a height of 200 mm from the ground level. By mounting SRS1 and SRS3 to the

opposite corners of the robot, it is possible to observe the entire circumference of the robot

without blind spots.

SRS2 is mounted at the centre of the front of the robot at a height of 400 mm to measure in the

direction of robot’s movement. It enables detection of safety-related objects above the detection

plane of SRS1 and carries out the travel surface detection function.

The mounting positions of the SRS are calibrated with a dedicated calibration tool before use.

– 14 – IEC TR 62998-2:2020 © IEC 2020

Exemplary top view.

Figure 4 – Mounting positions and sensing zones of the SRS

and safety-related zones of SRSS

Exemplary side view not corresponding to top view.

Figure 5 – Mounting positions and sensing zones of the SRS

and safety-related zones of SRSS

The safety-related zones of the SRSS correspond to the protective stop zone and safeguarded

zone of the robot. They are defined by distances S and S respectively from the robot's outer

0 1

surface, as shown in Figure 4.

NOTE This is not in accordance with informative Annex C of ISO 13482:2014, which references the centre point of

the robot and not the outer surface. To prevent confusion for the typical, assumed reader of this document, the

calculations are based on concepts of ISO 13855:2010 as referenced in normative Subclause 5.10.8.3 of

ISO 13482:2014. Concepts of ISO 13855:2010 are adapted in accordance with the results of an assumed, exhaustive,

application specific risk assessment. Existing calculations in accordance with ISO 13855:2010 seem to be developed

often under consideration of "high" performance classes like PL d respective SIL 2 and parameters considered out

of context (e.g. speed without consideration of direction of movement, stopped hazardous movement when hazardous

point is reached or bending over of a human body during movement).

S is a minimum distance between the mobile robot and a safety-related object. It is assumed

to be calculated based on concepts of ISO 13855:2010 and application of the specific risk

assessment in accordance with ISO 12100 as follows:

S= K×+T C+M= V +V × T +T+ 300 mm+M (1)

( )

( )

0 r−stop obj SRSS r

Where V is a maximum speed of the robot when initiating a protective stop, V is the

r-stop obj

approaching speed of the object, T and T are the response times of the SRSS and the

SRSS r

robot respectively, and M is the measurement uncertainty determined in accordance with 4.2.8,

which can be half value of the coverage intervals around the measurement distance (for values

see Table 2 of this document).

The distance C is an additional distance in millimetres, based on intrusion towards the danger

zone prior to actuation of the protective equipment in accordance with concepts of

ISO 13855:2010. The value of C is the result of an analysis of potential hazards for the lower

limbs. For upper limbs, there is no significant hazard due to the characteristic of the mobile

robot.

NOTE 2 If it is significant, an additional stopping distance can be considered when S is calculated.

S specifies the safeguarded zone where the robot is moving with maximum speed V

1 r-reduce

when initiating the safety-related speed control function for speed reduction down to V .

r-stop

The formula for the calculation is as follows:

(2)

S V +V×(T+T)++CM

( )

1 r-reduce obj SRSS r

The safety related zones of the SRSS sensing zone are determined as follows:

S = (300 mm/s + 800 mm/s) × (0,1 s + 0,2 s) + 300 mm + 26 mm = 656 mm

S = (700 mm/s + 800 mm/s) × (0,1 s + 0,5 s) + 300 mm + 55 mm = 1 255 mm

The automation related zone of the SRSS is the union of the sensing zones of the SRS.

4.2.7 Dependability under environmental influences

The SRSS integrator should specify the limits of all relevant environmental influences (see 6.2.5

of IEC TS 62998-1:2019).

In the following, the integrator verified that no failure to danger occurs and normal operation is

achieved within the specified limits for the environmental influences of precipitation and direct

sunlight in 4.2.1.

NOTE Further information is given in Annex F of IEC TS 62998-1:2019 for environmental influences and the use of

environmental classes in accordance with IEC 60721 series.

=

– 16 – IEC TR 62998-2:2020 © IEC 2020

4.2.8 Safety-related information

The SRSS integrator should specify logic functions performed in a processing unit of the SRSS

and should specify the safety-related information provided by the SRSS (see 6.2.6 of

IEC TS 62998-1:2019). Examples of safety-related information are given in the following

paragraphs.

The SRSS provides safety-related information as output signals. The safety-related information

(see Figure 3) of the SRSS consists of:

decision information relating to safety-related function 1, binary;

decision information related to safety-related function 3, binary;

measurement information related to safety-related function 2, n-ary;

confidence information for all safety-related function, n-ary.

The automation-related information of the SRSS output functions consists of:

point cloud for SLAM, n-ary;

The confidence information provided within the information for use as stated by the

manufacturer is as follows:

For each SRS the stated performance class is B. The required one for the SRSS is also B.

−6

The stated coverage probability or decision probability is 1 − 10 . The required one is

determined in accordance with Formula (1) in IEC TS 62998-1:2019 as follows:

coverage probability or decision probability > 1 – (upper limit PFH corresponding to

−5

SRS/SRSS performance class B)/(the application-specific demand rate) = 1 – 10 /

−6

10 = 1 – 10 .

The manufacturers provide results of confidence information of each SRS depending on the

detection distance. The value of the coverage interval is determined statistically from the

uncertainty of the SRS.

In addition to the information for use provided by the manufacturer, the integrator is performing

their own measurements in accordance with Figure 6. The tests are carried out using a test

piece with about 5 % reflection value. The experimental results obtained by measuring the

uncertainty of SRS1 and 3 and SRS 2 result in a standard deviation of 76,29 mm (SRS1 and 3)

at 7 m distance and 48,24 mm (SRS2) at 4 m distance.

−6

Because the coverage interval corresponding to the coverage probability 1 – 10 is calculated

as 2 × 4,89σ, assuming that SRS1 and SRS2 use this LiDAR and TOF camera as sensor units

respectively, the coverage interval of SRS1 at a distance of 7 m is 2 × 4,89 × 76,29 = 746,10 mm

(±373,05 mm) and the coverage interval of SRS2 at distance 4 m is 2 × 4,89 × 48,24 =

471,75 mm (±235,88 mm). These values are below the ones provided by the SRS manufacturer

within the information for use. For calculations in 5.2.6, the integrators decide to use the ones

stated in Table 2.

Table 2 – Example of confidence information for SRS

Distance Coverage probability Coverage intervals Coverage intervals

of SRS1/3 of SRS2

[m]

[mm] [mm]

−6

1 m 51,67 62,89

1 − 10

−6

2 m 53,43 110,60

1 − 10

−6

3 m 57,37 232,46

1 − 10

−6

4 m 72,08 471,75

1 − 10

−6

5 m 77,06 -

1 − 10

−6

6 m 106,17 -

1 − 10

−6

7 m 746,10 -

1 − 10

NOTE For calculation of M in Formulas (1) and (2), the half value in accordance with Table 2 is used under the

assumption that a normal distribution can be claimed.

Figure 6 – Examples of measurement data for evaluation of coverage interval

4.2.9 Verification and validation

The SRSS integrator should verify and/or validate the SRSS in accordance with 6.2.3, 6.2.4

and 6.2.7 of IEC TS 62998-1:2019.

A normal operation laboratory test of the safety-related function 1 and 2 as example for

verification of an SRSS is given in the following.

Test setup for normal operation test is as follows:

SRS1, SRS2, and SRS3 are mounted at predefined positions of the robot with the brackets, as

defined by the manufacturer;

the safety-related zones described in 4.2.6 are determined as S = 656 mm and S = 1 255 mm;

0 1

as described in 4.2.5, a black cylinder with diameter 40 mm, height 200 mm and surface

reflectivity 5 % is chosen as the test piece representing safety-related object properties for

children.

– 18 – IEC TR 62998-2:2020 © IEC 2020

Figure 7 illustrates the example of the test setup. The linear slider is placed at a location that

intersects the protective stop zone and/or the safeguarded zone of the SRSS.

Exemplary top view

Figure 7 – Test setup

Test procedures are as follows:

1) Power on the SRSS.

2) Construct the map to register test equipment such as the linear slider.

3) Place the test piece on the linear slider.

4) Start to move the slider and let the test piece enter the safety-related zones at the maximum

relative speed.

5) Record the safety-related information of the SRSS and the motion of the linear slider with

timestamps.

6) Power off the SRSS.

7) Change the relative locations of the linear slider and repeat from at least the test piece

approaches from the front, left, right, rear of the robot covering all field of views of the

different SRS and relevant speeds of the test piece.

8) Analyse the recorded safety related information and the slider motion.

During further verification by the integrator, it was determined that the SRSS can be used within

the limits of use as defined by the manufacturer of each SRS.

4.2.10 Information for use of the SRSS

This subclause describes the documentation of the limits of use in accordance with 6.2.2 of

IEC/TS 62998-1:2019. Table 3 shows examples for the limit of use of an SRSS documented in

the information for use of the SRSS.

Table 3 – Information for use of the SRSS

Clause(s) of IEC Overview of information for Information for use of the SRSS

TS 62998-1:2019 use to be provided

The SRSS performance class is B in accordance with IEC TS

4.3 The supplier should state the

62998-1 to achieve the level of safety performance PL b in

SRS/SRSS performance class

accordance with ISO 13849-1:2015.

and the level of safety

performance (PL, SIL or SIL CL)

and the referenced standard.

Safety-related function 1: to detect persons and hazardous

5.2 The SRSS function should be

objects in the protective stop zone for initiating the protective

defined by the manufacturer in

stop function specified in ISO 13482:2014, 6.2.2.3.

accordance with general

description of Table 2 of IEC TS

Safety-related function 2: to detect persons and hazardous

62998-1:2019.

objects and to provide their positions as safety related

information for the safety-related speed control function

and/or the hazardous collision avoidance function specified

in ISO 13482:2014, 6.4 and 6.5.2.1.

Safety-related function 3: to detect the geometry of the travel

surface of the robot, which is specified in ISO 13482:2014,

6.5.3. When a travelable surface is observed in the travelling

direction of the robot, the robot can move forwards. If the

robot moves backwards, the road surface that has already

travelled is definitely present, so this function is not required.

Automation-related function: to provide a 3D point cloud

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...