IEC 60974-9:2018

(Main)Arc welding equipment - Part 9: Installation and use

Arc welding equipment - Part 9: Installation and use

IEC 60974-9:2018 is applicable to requirements for installation and instructions for use of equipment for arc welding and allied processes designed in accordance with safety requirements of IEC 60974-1, IEC 60974-6 or equivalent. This standard cancels and replaces the first edition published in 2010. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- addition of a new Clause 8;

- addition of interpolation details in Table 1.

Matériel de soudage à l'arc - Partie 9: Installation et utilisation

L'IEC 60974-9:2018 est applicable aux exigences relatives à l’installation et aux instructions d’utilisation du matériel pour le soudage à l’arc et les procédés connexes conçus dans le respect des exigences de sécurité de l’IEC 60974-1, de l’IEC 60974-6 ou équivalent. La présente norme annule et remplace la première édition parue en 2010. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- ajout d’un nouvel Article 8;

- ajout de détails relatifs à l’interpolation au Tableau 1.

General Information

- Status

- Published

- Publication Date

- 26-Apr-2018

- Technical Committee

- TC 26 - Electric welding

- Drafting Committee

- WG 1 - TC 26/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Apr-2018

- Completion Date

- 11-May-2018

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 60974-9:2018 (Arc welding equipment - Installation and use)

IEC 60974-9:2018 provides safety and practical guidance for the installation and use of arc welding equipment and allied processes. It applies to equipment designed to the safety requirements of IEC 60974-1, IEC 60974-6 or equivalent standards. This second edition (2018) cancels the 2010 edition and includes technical revisions such as the addition of a new Clause 8 (battery-powered welding power sources) and interpolation details added to Table 1.

Key topics and technical requirements

The standard focuses on installation, operator information and safe operation. Major technical topics include:

- Installation requirements (Clause 4): selection and routing of supply cables, supply disconnecting devices and emergency stopping.

- Welding circuit: isolation from input supply, summation of no‑load voltages, welding cable selection and connections, earthing of the workpiece, and gas cylinder location.

- Electromagnetic compatibility (EMC) (Clause 5): assessment of the installation area and methods to reduce emissions (cabling, bonding, screening).

- Electromagnetic fields (EMF) (Clause 6): assessment of exposure and mitigation measures for personnel.

- Use, inspection and maintenance (Clause 7): routine and periodic inspections, disconnection procedures, guards, operator information, protective measures and special environments (confined spaces, elevated positions).

- Battery-powered welding power sources (Clause 8): safety recommendations and transportation considerations for portable/battery devices.

- Annexes: informative guidance on hazards (fume control, arc radiation, fire/explosion, noise), voltage drops and cable current ratings (Table 1 / interpolation details).

Practical applications - who uses IEC 60974-9

This standard is used by:

- Welding engineers, installation contractors and maintenance technicians specifying and installing welding systems.

- Health & safety managers, site supervisors and instructors developing safe work procedures and training.

- Equipment manufacturers for user instructions and compliance information.

- Certification bodies, inspectors and auditors verifying safe installation, EMC/EMF mitigation and operator guidance.

Practical benefits include improved electrical safety (earthing, isolation), reduced electromagnetic interference, controlled exposure to EMF and fumes, and clearer operator instructions for safer welding operations.

Related standards

- IEC 60974-1 (safety requirements for welding power sources)

- IEC 60974-6 (occupational practical requirements / requirements for specific equipment)

- Applicable national electrical and occupational safety standards for EMC, EMF and confined space work

For sourcing the full technical text and normative figures/tables (e.g., Table 1 current ratings and voltage drop tables), consult the official IEC publication.

Buy Documents

IEC 60974-9:2018 RLV - Arc welding equipment - Part 9: Installation and use Released:4/27/2018 Isbn:9782832256671

IEC 60974-9:2018 - Arc welding equipment - Part 9: Installation and use Released:4/27/2018 Isbn:9782832256350

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60974-9:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Arc welding equipment - Part 9: Installation and use". This standard covers: IEC 60974-9:2018 is applicable to requirements for installation and instructions for use of equipment for arc welding and allied processes designed in accordance with safety requirements of IEC 60974-1, IEC 60974-6 or equivalent. This standard cancels and replaces the first edition published in 2010. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - addition of a new Clause 8; - addition of interpolation details in Table 1.

IEC 60974-9:2018 is applicable to requirements for installation and instructions for use of equipment for arc welding and allied processes designed in accordance with safety requirements of IEC 60974-1, IEC 60974-6 or equivalent. This standard cancels and replaces the first edition published in 2010. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - addition of a new Clause 8; - addition of interpolation details in Table 1.

IEC 60974-9:2018 is classified under the following ICS (International Classification for Standards) categories: 25.160.30 - Welding equipment; 31.080.01 - Semiconductor devices in general; 31.260 - Optoelectronics. Laser equipment; 33.180.01 - Fibre optic systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60974-9:2018 has the following relationships with other standards: It is inter standard links to IEC 60974-9:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60974-9:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60974-9 ®

Edition 2.0 2018-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Arc welding equipment –

Part 9: Installation and use

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60974-9 ®

Edition 2.0 2018-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Arc welding equipment –

Part 9: Installation and use

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 25.160.30 ISBN 978-2-8322-5667-1

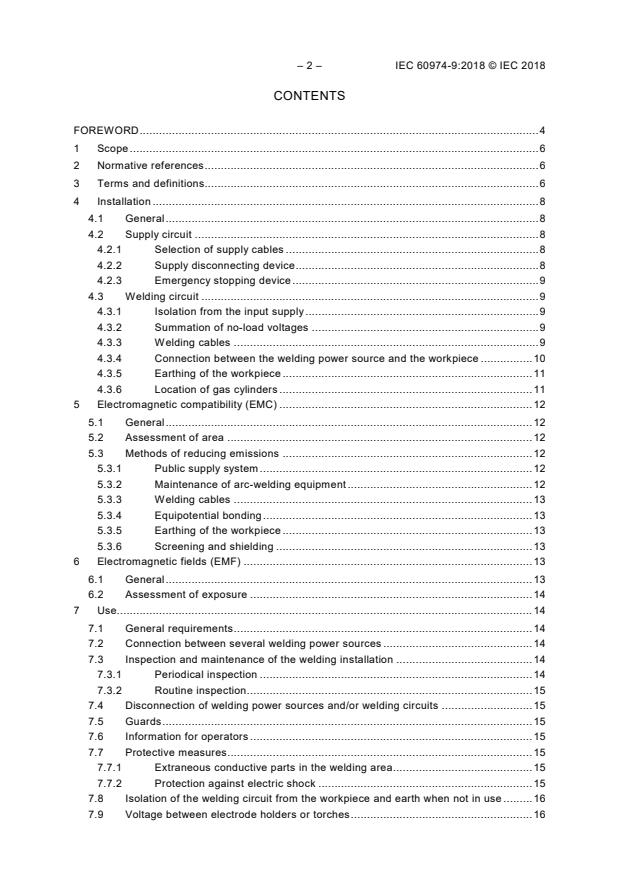

– 2 – IEC 60974-9:2018 RLV © IEC 2018

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions. 6

4 Installation . 8

4.1 General . 8

4.2 Supply circuit . 9

4.2.1 Selection of supply cables . 9

4.2.2 Supply disconnecting device . 9

4.2.3 Emergency stopping device . 9

4.3 Welding circuit . 9

4.3.1 Isolation from the input supply . 9

4.3.2 Summation of no-load voltages . 9

4.3.3 Welding cables . 9

4.3.4 Connection between the welding power source and the workpiece . 10

4.3.5 Earthing of the workpiece . 11

4.3.6 Location of gas cylinders . 12

5 Electromagnetic compatibility (EMC) . 12

5.1 General . 12

5.2 Assessment of area . 12

5.3 Methods of reducing emissions . 12

5.3.1 Public supply system . 12

5.3.2 Maintenance of arc-welding equipment . 12

5.3.3 Welding cables . 13

5.3.4 Equipotential bonding . 13

5.3.5 Earthing of the workpiece . 13

5.3.6 Screening and shielding . 13

6 Electromagnetic fields (EMF) . 13

6.1 General . 13

6.2 Assessment of exposure . 14

7 Use. 14

7.1 General requirements . 14

7.2 Connection between several welding power sources . 14

7.3 Inspection and maintenance of the welding installation . 14

7.3.1 Periodical inspection . 14

7.3.2 Routine inspection . 15

7.4 Disconnection of welding power sources and/or welding circuits . 15

7.5 Guards . 15

7.6 Information for operators . 15

7.7 Protective measures . 15

7.7.1 Extraneous conductive parts in the welding area . 15

7.7.2 Protection against electric shock . 15

7.8 Isolation of the welding circuit from the workpiece and earth when not in use . 16

7.9 Voltage between electrode holders or torches . 16

7.10 Welding in an environment with increased hazard risk of electric shock . 18

7.11 Use of shoulder slings . 18

7.12 Welding at elevated positions . 19

7.13 Welding with suspended welding equipment . 19

8 Battery-powered welding power sources . 19

8.1 Safety recommendations . 19

8.2 Transportation . 19

Annex A (informative) Hazards associated with arc welding . 20

A.1 General . 20

A.2 Equipment condition and maintenance . 20

A.3 Operation . 20

A.4 Training . 20

A.5 Arc radiation. 20

A.5.1 General . 20

A.5.2 Eye and face protection (see also A.9) . 21

A.5.3 Body protection (see also A.9) . 21

A.5.4 Protection of persons in the vicinity of an arc . 21

A.6 EMF . 21

A.6.1 General . 21

A.6.2 Body protection . 21

A.6.3 Protection of persons in the vicinity of the welding operation . 21

A.7 Welding fume . 21

A.8 Noise . 22

A.9 Fire and explosion . 24

A.9.1 General . 24

A.9.2 Fire . 24

A.9.3 Explosion . 24

A.10 General protective clothing . 24

A.11 Confined spaces . 24

Annex B (informative) Voltage drops in the welding circuit . 26

Bibliography . 28

Figure 1 – Example of DC voltage between electrode holders or torches . 17

Figure 2 – Example of AC voltage between electrode holders or torches – Single-phase

supply from the same pair of lines of a three-phase mains supply . 17

Figure 3 – Example of AC voltage between electrode holders or torches – Single-phase

supply from different pairs of lines of a three-phase mains supply . 17

Figure 4 – Example of AC voltage between electrode holders connected between

different lines of output . 18

Figure A.1 – Steps for the control of welding fumes . 23

Figure A.2 – Example steps of operation for work in confined spaces . 25

Figure B.1 – Example of MIG/MAG equipment . 26

Table 1 – Current ratings for copper welding cables . 10

Table B.1 – Voltage drop in copper and aluminium welding cables at normal and

elevated temperatures . 27

– 4 – IEC 60974-9:2018 RLV © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ARC WELDING EQUIPMENT –

Part 9: Installation and use

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60974-9 has been prepared by IEC technical committee 26: Electric

welding.

This standard cancels and replaces the first edition published in 2010. This edition constitutes

a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) addition of a new Clause 8;

b) addition of interpolation details in Table 1.

The text of this International Standard is based on the following documents:

FDIS Report on voting

26/648/FDIS 26/649/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this standard, the following print types are used:

– terms defined in Clause 3: in bold type.

A list of all the parts of the IEC 60974 series can be found, under the general title Arc welding

equipment, on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60974-9:2018 RLV © IEC 2018

ARC WELDING EQUIPMENT –

Part 9: Installation and use

1 Scope

This document is applicable to requirements for installation and instructions for use of

equipment for arc welding and allied processes designed in accordance with safety

requirements of IEC 60974-1, IEC 60974-6 or equivalent.

This document is applicable for the guidance of instructors, operators, welders, managers, and

supervisors in the safe installation and use of equipment for arc welding and allied processes

and the safe performance of welding and cutting operations.

National and local regulations take precedence over this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition cited

applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60245-6, Rubber insulated cables – Rated voltages up to and including 450/750 V – Part 6:

Arc welding electrode cables

IEC/TR 60755, General requirements for residual current operated protective devices

IEC 60974-1:2005, Arc welding equipment – Part 1: Welding power sources

IEC 60974-4, Arc welding equipment – Part 4: In-service Periodic inspection and testing

IEC 60974-6, Arc welding equipment – Part 6: Limited duty manual metal arc welding power

sources

IEC 60974-10, Arc welding equipment – Part 10: Electromagnetic compatibility (EMC)

requirements

IEC 60974-11, Arc welding equipment – Part 11: Electrode holders

IEC 60974-12, Arc welding equipment – Part 12: Coupling devices for welding cables

IEC 60974-13, Arc welding equipment – Part 13: Welding clamp

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

welding circuit

circuit that includes all conductive material through which the welding current is intended to

flow

Note 1 to entry: In arc welding, the arc is a part of the welding circuit.

Note 2 to entry: In certain arc welding processes, the arc may can be established between two electrodes. In such

a case, the workpiece is not necessarily a part of the welding circuit.

[SOURCE: IEC 60974-1:2005, 3.11 IEC 60050-851:2008, 851-14-10]

3.2

extraneous conductive part

conductive part not forming part of the electrical installation and liable to introduce an electric

potential, generally the earth potential

Note 1 to entry: Electrical installation includes the welding circuit.

[SOURCE: IEC 60050-851:2008, 851-14-57]

3.3

workpiece

metal piece or pieces on which welding or allied processes are performed

[SOURCE: IEC 60050-851:2008, 851-11-19]

3.4

protective clothing

protective accessories

protective clothing and accessories (e.g. gloves, hand shields, head masks and filter lenses)

used in order to diminish electric shock risks and the effects of fume and spatter and to protect

the skin and eyes against arc radiation

[SOURCE: IEC 60050-851:2008, 851-11-18]

3.5

environments with increased hazard risk of electric shock

environments where the hazard of electric shock by arc welding is increased in relation to

normal arc welding conditions

Note 1 to entry: Such environments are found for example

a) locations in which freedom of movement is restricted, so that the operator is forced to perform the welding in a

cramped (for example kneeling, sitting, lying) position with physical contact with conductive parts;

b) in locations which are fully or partially limited by conductive elements and in which there is a high risk of

unavoidable or accidental contact by the operator;

c) in wet, damp or hot locations where humidity or perspiration considerably reduces the skin resistance of the

human body and the insulating properties of protective accessories.

Note 2 to entry: Environments with increased hazard risk of electric shock are not meant to include places

where electrically conductive parts in the near vicinity of the operator which can cause increased hazard have been

insulated.

[SOURCE: IEC 60974-1:2005, 3.46 IEC 60050-851:2008, 851-15-09]

– 8 – IEC 60974-9:2018 RLV © IEC 2018

3.6

industrial and professional use

use intended only for experts or instructed persons

[IEC 60974-1:2005, 3.2]

3.6

expert

competent person

skilled person

person who can judge the work assigned and recognize possible hazards on the basis of

professional training, knowledge, experience and knowledge of the relevant equipment

Note 1 to entry: Several years of practice in the relevant technical field may can be taken into consideration in

assessment of professional training.

[SOURCE: IEC 60974-1:2005, 3.3 IEC 60050-851:2008, 851-11-10]

3.7

wire feeder

equipment that delivers filler wire to the arc or weld zone which includes the wire-feed control

and means to apply motion to the filler wire and may also include the filler wire supply

Note 1 to entry: The wire feeder may also include the wire-feed control, the filler wire supply, devices for gas

control, indicators and remote connectors.

[SOURCE: IEC 60974-5:2007, 3.11 IEC 60050-851:2008, 851-14-39]

3.8

auxiliary power output

circuit of a welding power source designed to provide electrical power to auxiliary equipment

4 Installation

4.1 General

Welding equipment used in arc welding installations shall be intended for the purpose and shall

be built in accordance with IEC 60974-1, IEC 60974-4, IEC 60974-6, IEC 60974-10, IEC 60974-

11 and IEC 60974-12 (see Clause 2), as given on the rating plate.

Electromagnetic compatibility (EMC) requirements shall be taken into consideration during

installation, see Clause 5.

The requirements of national and local regulations shall be taken into consideration during

installation, including grounding or protective earth connections, fuses, supply disconnecting

device, type of supply circuit, etc.

Read the manufacturer's instruction manual before installing the equipment. Full use shall be

made of the technical information relevant to the welding equipment.

Specific advice may be obtained from the welding equipment manufacturer, if necessary.

4.2 Supply circuit

4.2.1 Selection of supply cables

Supply cables for welding equipment and their overload protection, if not provided by the

manufacturer, shall be selected in accordance with the information given in the manufacturer's

instruction manual.

NOTE Examples of local regulations are given in the Bibliography, e.g. EN 50525-2-21, Electrical code NFPA 70

(SE, SO, ST, STO or other extra hard usage cable) or CSA C22.1. PVC insulation has been proven not suitable for

the application.

Supply cables shall be placed so that they cannot be damaged in use. If that cannot be

achieved, a sensitive residual current circuit breaker device (RCD), capable of operating at a

leakage current not exceeding 30 mA in accordance with IEC/TR 60755, shall be used to

reduce the risk of electric shock.

4.2.2 Supply disconnecting device

The installer shall ensure that a supply disconnecting device is fitted at the point of supply.

NOTE A plug may can be used as supply disconnecting device in accordance with national or local regulation.

4.2.3 Emergency stopping device

When an emergency stopping device is required by a national regulation (e.g. automatic

welding equipment), it shall conform to the relevant IEC standard.

For welding in an environment with increased hazard risk of electric shock, see 7.10.

4.3 Welding circuit

4.3.1 Isolation from the input supply

The welding circuit and circuits electrically connected to the welding circuit shall be

electrically isolated from the mains supply.

Verification shall be carried out by an expert.

4.3.2 Summation of no-load voltages

If more than one welding power source is in use at the same time, their no-load voltages can

be cumulative and could create an increased hazard of electric shock. Welding power sources

shall be installed so as to minimize this risk. Guidance is given in 7.9.

NOTE In the case of two welding transformers connected to the same lines, the resulting output voltage may can

be the sum of both no-load voltages. This can be avoided by using a suitable input or output connection (see 7.9).

NOTE Where more than one welding power source is installed, individual welding power

sources with their separate controls and connections should be clearly identified to show which

items belong to any one welding circuit.

4.3.3 Welding cables

Welding cables shall comply with IEC 60245-6. Copper conductor welding cables shall be

selected in accordance with the duty cycle and national regulations or, when inexistant, the

current rating given in Table 1. Where long cable runs are involved, it may can be necessary to

choose the cable size on the basis of voltage drop, see Annex B.

– 10 – IEC 60974-9:2018 RLV © IEC 2018

Table 1 – Current ratings for copper welding cables

a

Current ratings for specified duty cycle at an ambient temperature of 25 °C

Nominal cross-

b

sectional area

100 % 85 % 80 % 60 % 35 % 20 % 8 %

mm A A A A A A A

10 100 100 100 101 106 118 158

16 135 136 136 139 150 174 243

25 180 182 183 190 213 254 366

35 225 229 231 243 279 338 497

50 285 293 296 316 371 457 681

70 355 367 373 403 482 602 908

95 430 448 456 498 606 765 1 164

120 500 524 534 587 721 917 1 404

150 580 610 622 689 853 1 090 1 676

185 665 702 717 797 995 1 277 1 971

a

For higher ambient temperatures, a correction factor shall be applied:

0,96 (30 °C); 0,91 (35 °C); 0,87 (40 °C); 0,82 (45 °C). No interpolation is allowed for duty cycle values.

b

For intermediate values of nominal cross-section areas, interpolation is allowed.

NOTE Table originates from EN 50565-1:2014.

4.3.4 Connection between the welding power source and the workpiece

When the welding current does not flow entirely in the welding circuit, stray currents, which

are components of the welding current, occur. These can cause damage and may be

eliminated to electrical systems of buildings and to other sensitive systems in buildings and can

be minimized by the following means:

a) the electrical connection between the welding power source and the workpieces shall be

made as direct as practicable by means of an insulated return cable having an adequate

current-carrying capacity;

b) extraneous conductive parts, such as metal rails, pipes and frames shall not be used as

part of the welding circuit, unless they constitute the workpiece itself;

c) the return welding clamp shall be as near as practicable to the welding arc;

NOTE 1 When the return clamp is removed, it should be electrically isolated from parts connected to earth,

e.g. metallic enclosures with protective earth connection (class I), metal floors, building services.

d) the welding clamp disconnected from the workpiece shall be electrically isolated from

parts connected to earth, e.g. metallic enclosures with protective earth connection (class I),

metal floors, building services;

NOTE 1 The welding clamp can cause an electrical shock when welding current is flowing or when the

electrode circuit is in contact with the electrical ground circuit or work piece.

e) the welding circuit shall not be earthed unless required by national or local regulations

(see 4.3.5);

f) connection of the return cable to the workpiece shall be ensured by the use of devices

having suitable means for cable connection, a fastening system not liable to come loose

accidentally, and good electrical contact. Magnetic devices only present a good electrical

contact if the contact surfaces of the magnetic device and the contact area of the

workpiece are sufficiently large, even, conductive and clean (e.g. free from rust and

primer) and if the contact area of the workpiece is magnetic;

NOTE 2 If workpieces are on a welding bench or a work-handling device, the return cable may can be

connected to the bench or the device.

g) connection devices for non-stationary flexible welding cables in the welding circuit shall:

1) have an adequate covering of insulating material to prevent inadvertent contact with live

parts, when connected, with the exception of the return welding clamp at the workpiece

itself;

2) be suitable for the sizes of cables used and the welding current;

3) be effectively connected to the welding cables and in good electrical contact with them.

h) Welding, control and mains cables shall be protected from spatter and heat to prohibit

unintentional damage to the insulation.

Both the welding cable and the connection device shall be used within their specified current

rating. The connection device shall not be fitted with a cable smaller in diameter than specified

by the manufacturer of the connection device.

When coupling devices or welding clamps are used, they shall comply with IEC 60974-12 or

IEC 60974-13, respectively.

4.3.5 Earthing of the workpiece

The welding circuit should not be earthed, since it can increase the risk of stray welding

currents (see 4.3.3). Earthing of the welding circuit can also increase the area of metal

through which a person in contact with the welding circuit (e.g. the welding electrode) could

receive an electric shock.

NOTE 1 There are workpieces that have an inherent connection to earth, e.g. steel structures, ships, pipelines

etc. When these are welded, the possibility of stray currents is increased.

NOTE 2 In some cases, the workpiece may can be in permanent contact with earth, e.g. with protection class I

equipment which itself has protective conductors connected to earth. Such a workpiece is considered to be

inherently connected to earth.

An assessment of the welding circuit and the welding area shall be made to ensure that a

stray welding current will not flow through any object connected to earth and that is not

intended or capable of carrying the welding current (e.g. protective earth connection).

If electrical hand tools are used that may could come into contact with the workpiece, then

those tools shall be class II equipment (i.e. with double or reinforced insulation without

protective earth connection).

If earthing is required by national or local regulations, the earth connection shall be made by a

separate dedicated cable or conductor with a rating of at least that of the return cable and

connected directly to the workpiece.

Precautions shall be taken to insulate the operator from earth as well as from the workpiece

(see 7.7.2).

NOTE Where external radio frequency noise suppression networks are connected to the

welding circuit, an expert should shall assess whether the welding circuit can still be

regarded as insulated from earth.

NOTE 3 External radio frequency noise suppression networks could consist of a number of different components,

for example, LCR filters (inductance/capacitance/resistance).

– 12 – IEC 60974-9:2018 RLV © IEC 2018

4.3.6 Location of gas cylinders

Care shall be taken to prevent gas cylinders in the vicinity of the workpiece from becoming

part of the welding circuit.

5 Electromagnetic compatibility (EMC)

5.1 General

The user is responsible for installing and using the arc welding equipment in accordance with

the manufacturer’s instructions. If electromagnetic disturbances are detected, then it shall be

the responsibility of the user of the arc welding equipment to resolve the situation with the

technical assistance of the manufacturer.

5.2 Assessment of area

Before installing arc welding equipment, the user shall make an assessment of potential

electromagnetic interferences in the surrounding area. The following shall be taken into

account:

a) other supply cables, control cables, signalling and telephone cables, above, below and

adjacent to the arc welding equipment;

b) radio and television transmitters and receivers;

c) computer and other control equipment;

d) safety-critical equipment, for example, guarding of industrial equipment;

e) the health of the people around, for example, the use of pacemakers and hearing aids

wearable medical devices and implants;

f) equipment used for calibration or measurement;

g) the immunity of other equipment in the environment. The user shall ensure that other

equipment being used in the environment is compatible. This may can require additional

protection measures;

h) the time of day that welding or other activities are to be carried out.

The size of the surrounding area to be considered will depend on the structure of the building

and other activities that are taking place. The surrounding area may can extend beyond the

boundaries of the premises.

5.3 Methods of reducing emissions

5.3.1 Public supply system

The arc-welding equipment shall be connected to the public supply system in accordance with

the manufacturer’s recommendations. If interference occurs, it may can be necessary to take

additional precautions, such as filtering of the supply system. Consideration shall be given to

shielding the supply cable of permanently installed arc-welding equipment, in a metallic conduit

or equivalent. Shielding shall be electrically continuous throughout its length. The shielding

shall be connected to the welding power source so that good electrical contact is maintained

between the conduit and the welding power source enclosure.

5.3.2 Maintenance of arc-welding equipment

The arc-welding equipment shall be routinely maintained in accordance with IEC 60974-4 and

the manufacturer’s instructions. All access and service doors and covers shall be closed and

properly fastened when the arc-welding equipment is in operation. The arc-welding equipment

shall not be modified in any way, except for those changes and adjustments covered in the

manufacturer’s instructions. In particular, the spark gaps of arc striking and stabilising devices

shall be adjusted and maintained in accordance with the manufacturer’s instructions.

5.3.3 Welding cables

The welding cables shall be kept as short as possible and shall be positioned as close as

possible to each other, running at or close to the floor level. The welding cables shall never be

coiled during welding.

5.3.4 Equipotential bonding

Bonding of all metallic objects in the surrounding area should be considered for the purpose of

reducing emissions. However, metallic objects bonded to the workpiece will increase the risk

that the operator could receive an electric shock by touching these metallic objects and the

electrode at the same time. The operator shall be insulated from all such bonded metallic

objects.

5.3.5 Earthing of the workpiece

Where the workpiece is not bonded to earth for electrical safety, a connection bonding the

workpiece to earth may can reduce emissions in some, but not all instances. Care should be

taken to prevent the earthing of the workpiece increasing the risk of injury to users, or damage

to other electrical equipment. Where necessary, the connection of the workpiece to earth

should be made by a direct connection to the workpiece, but in some countries where direct

connection is not permitted, the bonding should be achieved by suitable capacitance, selected

in accordance with national and local regulations.

5.3.6 Screening and shielding

Selective screening and shielding of other cables and equipment in the surrounding area may

can alleviate problems of interference. Screening of the entire welding area may be considered

for special applications.

6 Electromagnetic fields (EMF)

6.1 General

Electric current flowing through any conductor causes localized electric and magnetic fields

(EMF). All welders should use the following procedures in order to minimize the risk associated

with exposure to EMFs from the welding circuit:

– route the welding cables together – secure them with tape when possible;

– place your torso and head body as far away as possible from the welding circuit;

– never coil welding cables around your body;

– do not place your body between welding cables. Keep both welding cables on the same

side of your body;

– connect the return cable to the workpiece as close as possible to the area being welded;

– do not work next to, sit or lean on the welding power source;

– do not weld whilst carrying the welding power source or wire feeder.

EMFs may can also interfere with wearable medical devices and implants, e.g. pacemakers.

Protective measures for persons with wearable medical devices and implants shall be taken.

For example, access restrictions for passers-by or individual risk-evaluations for welders. Risk

assessment and recommendation for users of wearable medical devices and implants shall be

made by a medical expert.

– 14 – IEC 60974-9:2018 RLV © IEC 2018

6.2 Assessment of exposure

When arc-welding equipment is configured an assessment of potential effects of

electromagnetic fields in the surrounding area shall be done. The following shall be taken into

account:

a) the datasheet regarding EMFs and special instructions in the user manual of the arc-

welding equipment;

b) busbars and other conductors carrying high voltages and/or currents;

c) other equipment generating high field strengths;

d) the health of the people around, for example the use of pacemakers and hearing aids.

The size of the surrounding area to be considered will depend on the structure of the building

and other activities that are taking place. The surrounding area can extend beyond the

boundaries of the premises.

7 Use

7.1 General requirements

User shall ensure that arc-welding equipment and accessories conform to the relevant parts of

IEC 60974, see Clause 2, as given on the rating plate. These documents contain necessary

information for health and safety to be included in instructions and manuals.

Before welding equipment is put into service, the user shall read and understand the

instructions provided by the manufacturer, national or local regulation, trade association and

occupational recommendations, national health and safety recommendations.

Consideration shall be given to the environment in which the welding equipment is used as

additional precautions may can need to be taken e.g. increased hazard of electric shock;

confined spaces; flammable area, asphyxiation (further references to specific hazards, see

Annex A).

7.2 Connection between several welding power sources

If welding power sources are to be connected in parallel or in series, this shall be carried out by

an expert and in accordance with the manufacturer's recommendations. The equipment shall

be approved for arc-welding operations only after a check has been carried out to ensure that

the permissible no-load voltage cannot be exceeded.

When one welding power source connected in parallel or series is taken out of service, that

power source shall be disconnected from the mains supply and from the welding circuit, so as

to prevent any hazards that might be caused by feedback voltages.

7.3 Inspection and maintenance of the welding installation

7.3.1 Periodical inspection

On installation, and periodically thereafter, an expert nominated for the task shall check that

the welding equipment has been correctly selected and connected for the work to be carried

out in accordance with IEC 60974-4 and the manufacturer's instructions and that all

connections are clean and tight and the welding equipment is in good condition.

In addition, all protective earthing shall be checked for effectiveness. Any defects found shall

be repaired.

7.3.2 Routine inspection

The operator shall be instructed to check all external connections daily and each time a

reconnection is made. Particular attention shall be paid to the installation of supply and welding

cables, electrode holders and coupling devices. Any defects found shall be reported, and faulty

equipment shall not be used until it has been repaired.

The return welding clamp shall be connected directly to the workpiece as close as practicable

to the point of welding or to the welding bench on which the workpiece is situated or to the

work-handling device.

For plasma cutting the no-load voltages are higher than with welding. This shall be considered

during inspection and maintenance procedures. Particular attention shall be paid to the

watercooling equipment to ensure that any leaks do not affect the insulation.

Before car

...

IEC 60974-9 ®

Edition 2.0 2018-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Arc welding equipment –

Part 9: Installation and use

Matériel de soudage à l’arc –

Partie 9: Installation et utilisation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 60974-9 ®

Edition 2.0 2018-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Arc welding equipment –

Part 9: Installation and use

Matériel de soudage à l’arc –

Partie 9: Installation et utilisation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.160.30 ISBN 978-2-8322-5635-0

– 2 – IEC 60974-9:2018 © IEC 2018

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions. 6

4 Installation . 8

4.1 General . 8

4.2 Supply circuit . 8

4.2.1 Selection of supply cables . 8

4.2.2 Supply disconnecting device . 8

4.2.3 Emergency stopping device . 9

4.3 Welding circuit . 9

4.3.1 Isolation from the input supply . 9

4.3.2 Summation of no-load voltages . 9

4.3.3 Welding cables . 9

4.3.4 Connection between the welding power source and the workpiece . 10

4.3.5 Earthing of the workpiece . 11

4.3.6 Location of gas cylinders . 11

5 Electromagnetic compatibility (EMC) . 12

5.1 General . 12

5.2 Assessment of area . 12

5.3 Methods of reducing emissions . 12

5.3.1 Public supply system . 12

5.3.2 Maintenance of arc-welding equipment . 12

5.3.3 Welding cables . 13

5.3.4 Equipotential bonding . 13

5.3.5 Earthing of the workpiece . 13

5.3.6 Screening and shielding . 13

6 Electromagnetic fields (EMF) . 13

6.1 General . 13

6.2 Assessment of exposure . 14

7 Use. 14

7.1 General requirements . 14

7.2 Connection between several welding power sources . 14

7.3 Inspection and maintenance of the welding installation . 14

7.3.1 Periodical inspection . 14

7.3.2 Routine inspection . 15

7.4 Disconnection of welding power sources and/or welding circuits . 15

7.5 Guards . 15

7.6 Information for operators . 15

7.7 Protective measures . 15

7.7.1 Extraneous conductive parts in the welding area . 15

7.7.2 Protection against electric shock . 15

7.8 Isolation of the welding circuit from the workpiece and earth when not in use . 16

7.9 Voltage between electrode holders or torches . 16

7.10 Welding in an environment with increased risk of electric shock . 18

7.11 Use of shoulder slings . 18

7.12 Welding at elevated positions . 19

7.13 Welding with suspended welding equipment . 19

8 Battery-powered welding power sources . 19

8.1 Safety recommendations . 19

8.2 Transportation . 19

Annex A (informative) Hazards associated with arc welding . 20

A.1 General . 20

A.2 Equipment condition and maintenance . 20

A.3 Operation . 20

A.4 Training . 20

A.5 Arc radiation. 20

A.5.1 General . 20

A.5.2 Eye and face protection (see also A.9) . 21

A.5.3 Body protection (see also A.9) . 21

A.5.4 Protection of persons in the vicinity of an arc . 21

A.6 EMF . 21

A.6.1 General . 21

A.6.2 Body protection . 21

A.6.3 Protection of persons in the vicinity of the welding operation . 21

A.7 Welding fume . 21

A.8 Noise . 22

A.9 Fire and explosion . 24

A.9.1 General . 24

A.9.2 Fire . 24

A.9.3 Explosion . 24

A.10 General protective clothing . 24

A.11 Confined spaces . 24

Annex B (informative) Voltage drops in the welding circuit . 26

Bibliography . 28

Figure 1 – Example of DC voltage between electrode holders or torches . 17

Figure 2 – Example of AC voltage between electrode holders or torches – Single-phase

supply from the same pair of lines of a three-phase mains supply . 17

Figure 3 – Example of AC voltage between electrode holders or torches – Single-phase

supply from different pairs of lines of a three-phase mains supply . 17

Figure 4 – Example of AC voltage between electrode holders connected between

different lines of output . 18

Figure A.1 – Steps for the control of welding fumes . 23

Figure A.2 – Example steps of operation for work in confined spaces . 25

Figure B.1 – Example of MIG/MAG equipment . 26

Table 1 – Current ratings for copper welding cables . 10

Table B.1 – Voltage drop in copper and aluminium welding cables at normal and

elevated temperatures . 27

– 4 – IEC 60974-9:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ARC WELDING EQUIPMENT –

Part 9: Installation and use

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60974-9 has been prepared by IEC technical committee 26: Electric

welding.

This standard cancels and replaces the first edition published in 2010. This edition constitutes

a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) addition of a new Clause 8;

b) addition of interpolation details in Table 1.

The text of this International Standard is based on the following documents:

FDIS Report on voting

26/648/FDIS 26/649/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this standard, the following print types are used:

– terms defined in Clause 3: in bold type.

A list of all the parts of the IEC 60974 series can be found, under the general title Arc welding

equipment, on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60974-9:2018 © IEC 2018

ARC WELDING EQUIPMENT –

Part 9: Installation and use

1 Scope

This document is applicable to requirements for installation and instructions for use of

equipment for arc welding and allied processes designed in accordance with safety

requirements of IEC 60974-1, IEC 60974-6 or equivalent.

This document is applicable for the guidance of instructors, operators, welders, managers, and

supervisors in the safe installation and use of equipment for arc welding and allied processes

and the safe performance of welding and cutting operations.

National and local regulations take precedence over this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition cited

applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60245-6, Rubber insulated cables – Rated voltages up to and including 450/750 V – Part 6:

Arc welding electrode cables

IEC 60755, General requirements for residual current operated protective devices

IEC 60974-1, Arc welding equipment – Part 1: Welding power sources

IEC 60974-4, Arc welding equipment – Part 4: Periodic inspection and testing

IEC 60974-11, Arc welding equipment – Part 11: Electrode holders

IEC 60974-12, Arc welding equipment – Part 12: Coupling devices for welding cables

IEC 60974-13, Arc welding equipment – Part 13: Welding clamp

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

welding circuit

conductive material through which the welding current is intended to flow

Note 1 to entry: In arc welding, the arc is a part of the welding circuit.

Note 2 to entry: In certain arc welding processes, the arc can be established between two electrodes. In such a

case, the workpiece is not necessarily a part of the welding circuit.

[SOURCE: IEC 60050-851:2008, 851-14-10]

3.2

extraneous conductive part

conductive part not forming part of the electrical installation and liable to introduce an electric

potential, generally the earth potential

Note 1 to entry: Electrical installation includes the welding circuit.

[SOURCE: IEC 60050-851:2008, 851-14-57]

3.3

workpiece

metal piece or pieces on which welding or allied processes are performed

[SOURCE: IEC 60050-851:2008, 851-11-19]

3.4

protective clothing

protective accessories

protective clothing and accessories (e.g. gloves, hand shields, head masks and filter lenses)

used in order to diminish electric shock risks and the effects of fume and spatter and to protect

the skin and eyes against arc radiation

[SOURCE: IEC 60050-851:2008, 851-11-18]

3.5

environment with increased risk of electric shock

environment where the hazard of electric shock by arc welding is increased in relation to

normal arc welding conditions

Note 1 to entry: Such environments are found for example

a) locations in which freedom of movement is restricted, so that the operator is forced to perform the welding in a

cramped (for example kneeling, sitting, lying) position with physical contact with conductive parts;

b) in locations which are fully or partially limited by conductive elements and in which there is a high risk of

unavoidable or accidental contact by the operator;

c) in wet, damp or hot locations where humidity or perspiration considerably reduces the skin resistance of the

human body and the insulating properties of protective accessories.

Note 2 to entry: Environments with increased risk of electric shock are not meant to include places where

electrically conductive parts in the near vicinity of the operator which can cause increased hazard have been

insulated.

[SOURCE: IEC 60050-851:2008, 851-15-09]

3.6

expert

competent person

skilled person

person who can judge the work assigned and recognize possible hazards on the basis of

professional training, knowledge, experience and knowledge of the relevant equipment

– 8 – IEC 60974-9:2018 © IEC 2018

Note 1 to entry: Several years of practice in the relevant technical field can be taken into consideration in

assessment of professional training.

[SOURCE: IEC 60050-851:2008, 851-11-10]

3.7

wire feeder

equipment that delivers filler wire to the arc or weld zone which includes means to apply motion

to the filler wire

Note 1 to entry: The wire feeder may also include the wire-feed control, the filler wire supply, devices for gas

control, indicators and remote connectors.

[SOURCE: IEC 60050-851:2008, 851-14-39]

4 Installation

4.1 General

Welding equipment used in arc welding installations shall be intended for the purpose as given

on the rating plate.

Electromagnetic compatibility (EMC) requirements shall be taken into consideration during

installation, see Clause 5.

The requirements of national and local regulations shall be taken into consideration during

installation, including grounding or protective earth connections, fuses, supply disconnecting

device, type of supply circuit, etc.

Read the manufacturer's instruction manual before installing the equipment. Full use shall be

made of the technical information relevant to the welding equipment.

Specific advice may be obtained from the welding equipment manufacturer, if necessary.

4.2 Supply circuit

4.2.1 Selection of supply cables

Supply cables for welding equipment and their overload protection, if not provided by the

manufacturer, shall be selected in accordance with the information given in the manufacturer's

instruction manual.

NOTE Examples of local regulations are given in the Bibliography, e.g. EN 50525-2-21, Electrical code NFPA 70

(SE, SO, ST, STO or other extra hard usage cable) or CSA C22.1. PVC insulation has been proven not suitable for

the application.

Supply cables shall be placed so that they cannot be damaged in use. If that cannot be

achieved, a residual current device (RCD), capable of operating at a leakage current not

exceeding 30 mA in accordance with IEC 60755, shall be used to reduce the risk of electric

shock.

4.2.2 Supply disconnecting device

The installer shall ensure that a supply disconnecting device is fitted at the point of supply.

NOTE A plug can be used as supply disconnecting device in accordance with national or local regulation.

4.2.3 Emergency stopping device

When an emergency stopping device is required by a national regulation (e.g. automatic

welding equipment), it shall conform to the relevant IEC standard.

For welding in an environment with increased risk of electric shock, see 7.10.

4.3 Welding circuit

4.3.1 Isolation from the input supply

The welding circuit and circuits electrically connected to the welding circuit shall be

electrically isolated from the mains supply.

Verification shall be carried out by an expert.

4.3.2 Summation of no-load voltages

If more than one welding power source is in use at the same time, their no-load voltages can

be cumulative and could create an increased hazard of electric shock. Welding power sources

shall be installed so as to minimize this risk. Guidance is given in 7.9.

NOTE In the case of two welding transformers connected to the same lines, the resulting output voltage can be

the sum of both no-load voltages. This can be avoided by using a suitable input or output connection (see 7.9).

Where more than one welding power source is installed, individual welding power sources with

their separate controls and connections should be clearly identified to show which items belong

to any one welding circuit.

4.3.3 Welding cables

Welding cables shall comply with IEC 60245-6. Copper conductor welding cables shall be

selected in accordance with the duty cycle and national regulations or, when inexistant, the

current rating given in Table 1. Where long cable runs are involved, it can be necessary to

choose the cable size on the basis of voltage drop, see Annex B.

– 10 – IEC 60974-9:2018 © IEC 2018

Table 1 – Current ratings for copper welding cables

a

Current ratings for specified duty cycle at an ambient temperature of 25 °C

Nominal cross-

b

sectional area

100 % 85 % 80 % 60 % 35 % 20 % 8 %

mm A A A A A A A

10 100 100 100 101 106 118 158

16 135 136 136 139 150 174 243

25 180 182 183 190 213 254 366

35 225 229 231 243 279 338 497

50 285 293 296 316 371 457 681

70 355 367 373 403 482 602 908

95 430 448 456 498 606 765 1 164

120 500 524 534 587 721 917 1 404

150 580 610 622 689 853 1 090 1 676

185 665 702 717 797 995 1 277 1 971

a

For higher ambient temperatures, a correction factor shall be applied:

0,96 (30 °C); 0,91 (35 °C); 0,87 (40 °C); 0,82 (45 °C). No interpolation is allowed for duty cycle values.

b

For intermediate values of nominal cross-section areas, interpolation is allowed.

NOTE Table originates from EN 50565-1:2014.

4.3.4 Connection between the welding power source and the workpiece

When the welding current does not flow entirely in the welding circuit, stray currents, which

are components of the welding current, occur. These can cause damage to electrical systems

of buildings and to other sensitive systems in buildings and can be minimized by the following

means:

a) the electrical connection between the welding power source and the workpieces shall be

made as direct as practicable by means of an insulated return cable having an adequate

current-carrying capacity;

b) extraneous conductive parts, such as metal rails, pipes and frames shall not be used as

part of the welding circuit, unless they constitute the workpiece itself;

c) the welding clamp shall be as near as practicable to the welding arc;

d) the welding clamp disconnected from the workpiece shall be electrically isolated from parts

connected to earth, e.g. metallic enclosures with protective earth connection (class I), metal

floors, building services;

NOTE 1 The welding clamp can cause an electrical shock when welding current is flowing or when the

electrode circuit is in contact with the electrical ground circuit or work piece.

e) the welding circuit shall not be earthed unless required by national or local regulations

(see 4.3.5);

f) connection of the return cable to the workpiece shall be ensured by the use of devices

having suitable means for cable connection, a fastening system not liable to come loose

accidentally, and good electrical contact. Magnetic devices only present a good electrical

contact if the contact surfaces of the magnetic device and the contact area of the

workpiece are sufficiently large, even, conductive and clean (e.g. free from rust and

primer) and if the contact area of the workpiece is magnetic;

NOTE 2 If workpieces are on a welding bench or a work-handling device, the return cable can be connected

to the bench or the device.

g) connection devices for non-stationary flexible welding cables in the welding circuit shall:

1) have an adequate covering of insulating material to prevent inadvertent contact with live

parts, when connected, with the exception of the welding clamp at the workpiece itself;

2) be suitable for the sizes of cables used and the welding current;

3) be effectively connected to the welding cables and in good electrical contact with them.

h) Welding, control and mains cables shall be protected from spatter and heat to prohibit

unintentional damage to the insulation.

Both the welding cable and the connection device shall be used within their specified current

rating. The connection device shall not be fitted with a cable smaller in diameter than specified

by the manufacturer of the connection device.

When coupling devices or welding clamps are used, they shall comply with IEC 60974-12 or

IEC 60974-13, respectively.

4.3.5 Earthing of the workpiece

The welding circuit should not be earthed, since it can increase the risk of stray welding

currents (see 4.3.3). Earthing of the welding circuit can also increase the area of metal

through which a person in contact with the welding circuit (e.g. the welding electrode) could

receive an electric shock.

NOTE 1 There are workpieces that have an inherent connection to earth, e.g. steel structures, ships, pipelines.

When these are welded, the possibility of stray currents is increased.

NOTE 2 In some cases, the workpiece can be in permanent contact with earth, e.g. with protection class I

equipment which itself has protective conductors connected to earth. Such a workpiece is considered to be

inherently connected to earth.

An assessment of the welding circuit and the welding area shall be made to ensure that a

stray welding current will not flow through any object connected to earth that is not intended or

capable of carrying the welding current (e.g. protective earth connection).

If electrical hand tools are used that could come into contact with the workpiece, then those

tools shall be class II equipment (i.e. with double or reinforced insulation without protective

earth connection).

If earthing is required by national or local regulations, the earth connection shall be made by a

separate dedicated cable or conductor with a rating of at least that of the return cable and

connected directly to the workpiece.

Precautions shall be taken to insulate the operator from earth as well as from the workpiece

(see 7.7.2).

Where external radio frequency noise suppression networks are connected to the welding

circuit, an expert shall assess whether the welding circuit can still be regarded as insulated

from earth.

NOTE 3 External radio frequency noise suppression networks could consist of a number of different components,

for example, LCR filters (inductance/capacitance/resistance).

4.3.6 Location of gas cylinders

Care shall be taken to prevent gas cylinders in the vicinity of the workpiece from becoming

part of the welding circuit.

– 12 – IEC 60974-9:2018 © IEC 2018

5 Electromagnetic compatibility (EMC)

5.1 General

The user is responsible for installing and using the arc welding equipment in accordance with

the manufacturer’s instructions. If electromagnetic disturbances are detected, then it shall be

the responsibility of the user of the arc welding equipment to resolve the situation with the

technical assistance of the manufacturer.

5.2 Assessment of area

Before installing arc welding equipment, the user shall make an assessment of potential

electromagnetic interferences in the surrounding area. The following shall be taken into

account:

a) other supply cables, control cables, signalling and telephone cables, above, below and

adjacent to the arc welding equipment;

b) radio and television transmitters and receivers;

c) computer and other control equipment;

d) safety-critical equipment, for example, guarding of industrial equipment;

e) the health of the people around, for example, the use of wearable medical devices and

implants;

f) equipment used for calibration or measurement;

g) the immunity of other equipment in the environment. The user shall ensure that other

equipment being used in the environment is compatible. This can require additional

protection measures;

h) the time of day that welding or other activities are to be carried out.

The size of the surrounding area to be considered will depend on the structure of the building

and other activities that are taking place. The surrounding area can extend beyond the

boundaries of the premises.

5.3 Methods of reducing emissions

5.3.1 Public supply system

The arc-welding equipment shall be connected to the public supply system in accordance with

the manufacturer’s recommendations. If interference occurs, it can be necessary to take

additional precautions, such as filtering of the supply system. Consideration shall be given to