IEC 62031:2008

(Main)LED modules for general lighting - Safety specifications

LED modules for general lighting - Safety specifications

This International Standard specifies general and safety requirements for light-emitting diode (LED) modules:

- LED modules without integral control gear for operation under constant voltage, constant current or constant power;

- self-ballasted LED modules for use on d.c. supplies up to 250 V or a.c. supplies up to 1 000 V at 50 Hz or 60 Hz.

Modules de DEL pour éclairage général - Spécifications de sécurité

La présente Norme internationale spécifie les exigences générales et les exigences de sécurité relatives aux modules de diodes électroluminescentes (DEL):

- modules de DEL sans appareillage d'alimentation intégré pour fonctionnement sous tension constante, courant constant ou puissance constante;

- modules de DEL à ballast intégré pour utilisation sur des alimentations à courant continu jusqu'à 250 V ou à courant alternatif 50 Hz ou 60 Hz jusqu'à 1 000 V.

General Information

- Status

- Published

- Publication Date

- 18-Sep-2014

- Technical Committee

- SC 34A - Electric light sources

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 08-Mar-2018

- Completion Date

- 14-Feb-2026

Relations

- Amended By

IEC 62031:2008/AMD1:2012 - Amendment 1 - LED modules for general lighting - Safety specifications - Effective Date

- 05-Sep-2023

- Amended By

IEC 62031:2008/AMD2:2014 - Amendment 2 - LED modules for general lighting - Safety specifications - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62031:2008 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the general and safety requirements for LED modules used in general lighting applications. This standard focuses specifically on LED modules without integral control gear, as well as self-ballasted LED modules designed for operation on both direct current (DC) supplies up to 250 V and alternating current (AC) supplies up to 1000 V at 50 Hz or 60 Hz. By providing comprehensive safety specifications, IEC 62031 ensures the reliable and safe use of LED modules in various lighting systems globally.

This standard is essential for manufacturers, designers, and quality assurance teams involved in the production and integration of LED lighting modules to guarantee safety, performance, and compliance with international regulations.

Key Topics

Scope and Applicability

IEC 62031 covers LED modules operating under constant voltage, current, or power without integral control gear, and self-ballasted LED modules for general lighting. It excludes detailed requirements for separate control gear (covered under IEC 61347-2-13 and IEC 62384).General Safety Requirements

The standard presents safety criteria including protection against electric shock, mechanical hazards, moisture resistance, insulation properties, and fault condition management (e.g., overpower situations). These requirements ensure the product's electrical safety during normal operation and potential fault scenarios.Marking and Identification

Mandatory marking for built-in or independent LED modules is defined, emphasizing durability and legibility under real-world conditions. Proper labeling facilitates traceability and compliance verification.Construction and Materials

IEC 62031 covers requirements related to the construction of LED modules, such as creepage distances and clearances, resistance to heat, fire, corrosion, and tracking to maintain long-term safety and reliability.Heat Management

Effective thermal management guidelines are provided to avoid overheating, which can degrade LED performance and pose safety risks. Recommendations include the use of heat-conducting foils and pastes and design considerations for heat dissipation.Photobiological Safety

Special attention is given to the photobiological safety aspects of LED modules, including UV radiation, blue light hazards, and infrared radiation, which are critical for protecting users from potential optical hazards.Testing and Certification

The standard outlines conformity testing during manufacture to ensure compliance with safety specifications. This includes electrical strength tests, moisture resistance, and fault condition testing.

Applications

IEC 62031 is applicable to a wide range of LED modules used in general lighting settings including:

- Indoor and outdoor luminaires for residential, commercial, and industrial environments

- Street lighting and public area illumination

- Architectural and decorative LED lighting solutions

- Automotive and transportation lighting systems where self-ballasted modules are appropriate

Compliance with IEC 62031 improves product safety and performance, facilitating market acceptance and reducing risks related to electrical hazards, overheating, or photobiological effects.

Related Standards

- IEC 61347-2-13 – Safety requirements for control gear for LED modules

- IEC 62384 – Performance requirements for LED control gear

- IEC 60598 – Luminaires safety specifications, often complementing LED module standards

- IEC 62471 – Photobiological safety of lamps and lamp systems, relating to blue light and UV hazards

Manufacturers and testing laboratories often use IEC 62031 together with these standards to ensure comprehensive safety, performance, and compatibility of LED lighting products.

By adhering to IEC 62031:2008, industry stakeholders ensure that LED modules meet internationally recognized safety standards, reducing risks and enhancing consumer confidence in LED lighting technologies.

Buy Documents

IEC 62031:2008 - LED modules for general lighting - Safety specifications Released:1/15/2008 Isbn:2831895030

IEC 62031:2008+AMD1:2012 CSV - LED modules for general lighting - Safety specifications Released:10/30/2012 Isbn:9782832204764

IEC 62031:2008+AMD1:2012+AMD2:2014 CSV - LED modules for general lighting - Safety specifications Released:9/19/2014 Isbn:9782832218648

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62031:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "LED modules for general lighting - Safety specifications". This standard covers: This International Standard specifies general and safety requirements for light-emitting diode (LED) modules: - LED modules without integral control gear for operation under constant voltage, constant current or constant power; - self-ballasted LED modules for use on d.c. supplies up to 250 V or a.c. supplies up to 1 000 V at 50 Hz or 60 Hz.

This International Standard specifies general and safety requirements for light-emitting diode (LED) modules: - LED modules without integral control gear for operation under constant voltage, constant current or constant power; - self-ballasted LED modules for use on d.c. supplies up to 250 V or a.c. supplies up to 1 000 V at 50 Hz or 60 Hz.

IEC 62031:2008 is classified under the following ICS (International Classification for Standards) categories: 29.140.99 - Other standards related to lamps; 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62031:2008 has the following relationships with other standards: It is inter standard links to IEC 62031:2008/AMD1:2012, IEC 62031:2008/AMD2:2014, IEC 62031:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62031:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62031

Edition 1.0 2008-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

LED modules for general lighting – Safety specifications

Modules de DEL pour éclairage général – Spécifications de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62031

Edition 1.0 2008-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

LED modules for general lighting – Safety specifications

Modules de DEL pour éclairage général – Spécifications de sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

P

CODE PRIX

ICS 29.140.99 ; 31.080.99 ISBN 2-8318-9503-0

– 2 – 62031 © IEC:2008

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

4 General requirements .8

5 General test requirements .8

6 Classification.9

7 Marking .9

7.1 Mandatory marking for built-in or independent modules.9

7.2 Location of marking .10

7.3 Durability and legibility of marking .10

8 Terminals .10

9 Provisions for protective earthing .10

10 Protection against accidental contact with live parts .10

11 Moisture resistance and insulation.10

12 Electric strength .10

13 Fault conditions .11

13.1 General .11

13.2 Overpower condition .11

14 Conformity testing during manufacture .11

15 Construction .11

16 Creepage distances and clearances .11

17 Screws, current-carrying parts and connections.11

18 Resistance to heat, fire and tracking.12

19 Resistance to corrosion .12

Annex A (normative) Tests.13

Annex B (informative) Overview of systems composed of LED modules and control

gear .14

Annex C (informative) Conformity testing during manufacture .15

Bibliography.16

Figure B.1 – Overview of systems composed of LED modules and control gear .14

62031 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

LED MODULES FOR GENERAL LIGHTING –

SAFETY SPECIFICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62031 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

The text of this first edition is based on the following documents:

FDIS Report on voting

34A/1237/FDIS 34A/1256/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 62031 © IEC:2008

NOTE In this standard, the following print types are used:

– Requirements proper: in roman type.

– Test specifications: in italic type.

– Explanatory matter: in smaller roman type.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

62031 © IEC:2008 – 5 –

INTRODUCTION

The first edition of a safety standard for LED modules for general lighting applications

acknowledges the need for relevant tests for this new source of electrical light, sometimes

called “solid state lighting”.

The provisions in the standard represent the technical knowledge of experts from the fields of

the semiconductor industry and those of the traditional electrical light sources.

Two types of LED modules are covered: with integral and external control gear.

– 6 – 62031 © IEC:2008

LED MODULES FOR GENERAL LIGHTING –

SAFETY SPECIFICATIONS

1 Scope

This International Standard specifies general and safety requirements for light-emitting diode

(LED) modules:

٭ LED modules without integral control gear for operation under constant voltage, constant

current or constant power;

٭ self-ballasted LED modules for use on d.c. supplies up to 250 V or a.c. supplies up to

1 000 V at 50 Hz or 60 Hz.

NOTE 1 The safety requirements for separate control gear are specified in IEC 61347-2-13. The performance

requirements for separate control gear are specified in IEC 62384.

NOTE 2 Requirements for LED modules with integrated control gear and equipped with a lamp cap (self-ballasted

lamp), intended for mains voltage general lighting service retrofit applications (thereby replacing existing lamps

with identical lamp caps) are specified in IEC 60968 (an amendment to the present edition or a new edition with

extended scope is in preparation).

Requirements for LED modules with integrated control gear and equipped with a lamp cap (self-ballasted lamp),

intended for non-mains voltage general lighting service retrofit applications (thereby replacing existing lamps with

identical lamp caps) are under consideration.

NOTE 3 Where in the requirements of this standard both types of LED modules, with and without integral control

gear, are addressed, the word “modules” is used instead. Where only the expression “LED module(s)” is used, it is

understood to refer to the type without integral control gear.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

)

IEC 60598-1:2003, Luminaires, Part 1: General requirements and tests

Amendment 1 (2006)

IEC 60838-2-2, Miscellaneous lampholders – Part 2-2: Particular requirements – Connectors

for LED modules

IEC 61347-1:2007, Lamp controlgear – Part 1: General and safety requirements

IEC 61347-2-13:2006, Lamp controlgear – Part 2-13: Particular requirements for d.c. or a.c.

supplied electronic controlgear for LED modules

IEC 62471:2006, Photobiological safety of lamps and lamp systems

ISO 4046-4:2002, Paper, board, pulp and related terms – Vocabulary – Part 4: Paper and

board grades and converted products

—————————

)

A consolidated 6.1 (2006) exists, that includes IEC 60598-1 (2003) and its Amendment 1 (2006).

62031 © IEC:2008 – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

For expressions and terms in the field of LEDs and LED modules, refer to IEC TS 62504,

which is currently in development.

3.1

light-emitting diode

LED

solid state device embodying a p-n junction, emitting optical radiation when excited by an

electric current

[IEV 845-04-40]

3.2

LED module

unit supplied as a light source. In addition to one or more LEDs, it may contain further

components, e.g. optical, mechanical, electrical and electronic, but excluding the control gear.

3.3

self-ballasted LED module

LED module, designed for connection to the supply voltage

NOTE If the self-ballasted LED module is equipped with a lamp cap, it is regarded to be a self-ballasted lamp.

3.4

integral LED module

LED module, generally designed to form a non-replaceable part of a luminaire

3.5

integral self-ballasted LED module

self-ballasted LED module, generally designed to form a non-replaceable part of a luminaire

3.6

built-in LED module

LED module, generally designed to form a replaceable part built into a luminaire, a box, an

enclosure or the like and not intended to be mounted outside a luminaire, etc. without special

precautions

3.7

built-in self-ballasted LED module

self-ballasted LED module, generally designed to form a replaceable part built into a

luminaire, a box, an enclosure or the like and not intended to be mounted outside a luminaire,

etc. without special precautions

3.8

independent LED module

LED module, so designed that it can be mounted or placed separately from a luminaire, an

additional box or enclosure or the like. The independent LED module provides all the

necessary protection with regard to safety according to its classification and marking.

NOTE The control gear must not necessarily be integrated in the module.

– 8 – 62031 © IEC:2008

3.9

independent self-ballasted LED module

self-ballasted LED module, so designed that it can be mounted or placed separately from a

luminaire, an additional box or enclosure or the like. The independent LED module provides

all the necessary protection with regard to safety according to its classification and marking.

NOTE The control gear may be integrated in the module.

3.10

rated maximum temperature

t

c

highest permissible temperature which may occur on the outer surface of the LED module (at

the indicated position, if marked) under normal operating conditions and at the rated

voltage/current/power or the maximum of the rated voltage/current/power range

4 General requirements

4.1 Modules shall be so designed and constructed that in normal use (see manufacturer’s

instruction) they operate without danger to the user or surroundings.

4.2 For LED modules, all electrical measurements, unless otherwise specified, shall be

carried out at voltage limits (min/max), current limits (min/max) or power limits (min/max) and

minimum frequency, in a draught-free room at the temperature limits of the allowed range

specified by the manufacturer. Unless the manufacturer indicates the most critical

combination, all combinations (min/max) of voltage/current/power and temperature shall be

tested.

4.3 For self-ballasted LED modules, the electrical measurements shall be carried out at the

tolerance limit values of the marked supply voltage.

4.4 Integral modules not having their own enclosure shall be treated as integral components

of luminaires as defined in IEC 60598-1, Clause 0.5. They shall be tested assembled in the

luminaire, and as far as applicable with the present standard.

4.5 Independent modules shall comply, in addition to this standard, with the requirements of

relevant clauses of IEC 60598-1, where these requirements are not already covered in this

standard.

4.6 If the module is a factory sealed unit, it shall not be opened for any tests. In the case of

doubt based on the inspection of the module and the examination of the circuit diagram, and

in agreement with the manufacturer or responsible vendor, such specially prepared modules

shall be submitted for testing so that a fault condition can be simulated.

5 General test requirements

5.1 Tests according to this standard shall be type tests.

NOTE The requirements and tolerances permitted by this standard are related to testing of a type-test sample

submitted by the manufacturer for that purpose. Compliance of the type-test sample does not ensure compliance of

the whole production of a manufacturer with this safety standard.

Conformity of production is the responsibility of the manufacturer and may need routine tests and quality assurance

in addition to type testing.

62031 © IEC:2008 – 9 –

5.2 Unless otherwise specified, the tests shall be carried out at an ambient temperature of

10 °C to 30 °C.

5.3 Unless otherwise specified, the type test shall be carried out on one sample consisting

of one or more items submitted for the purpose of the type test.

In general, all tests shall be carried out on each type of module or, where a range of similar

modules is involved, for each wattage in the range or on a representative selection from the

range, as agreed with the manufacturer.

5.4 If the light output has detectably changed, the module shall not be used for further tests.

NOTE Usually, a value of 50 % indicates irreversible changes in the module.

5.5 For SELV-operated LED modules, the requirements of IEC 61347-2-13, Annex I, apply

additionally.

General conditions for tests are given in Annex A.

6 Classification

Modules are classified, according to the method of installation, as:

– built-in;

– independent;

– integral.

For integral modules, the NOTE to 1.2.1 in IEC 60598-1 applies.

7 Marking

7.1 Mandatory marking for built-in or independent modules

a) Mark of origin (trade mark, manufacturer’s name or name of the responsible

vendor/supplier).

b) Model number or type reference of the manufacturer.

c) Either the

● rated supply voltage(s), or voltage range, supply frequency or/and

● rated supply current(s) or current range, supply frequency (the supply current may be

given in the manufacturer’s literature) or/and

● rated input power, or power range.

d) Nominal power.

e) Indication of position and purpose of the connections where it is necessary for safety. In

case of connecting wires, a clear indication shall be given in a wiring diagram.

f) Value of t . If this relates to a certain place on the LED module, this place shall be

c

indicated or specified in the manufacturer’s literature.

g) For eye protection, see requirements of IEC 62471.

h) Built-in modules shall be marked in order to separate them from independent modules.

The mark shall be located on the packaging or on the module itself.

NOTE The symbol is under consideration.

– 10 – 62031 © IEC:2008

7.2 Location of marking

Items a), b), c) and f) of 7.1 shall be marked on the module.

Items d), e), g) and h) of 7.1 shall be marked legible on the module or on the module data

sheet.

For integral modules, no marking is required, but the information given in 7.1 a) to g) shall be

provided in the technical literature of the manufacturer.

7.3 Durability and legibility of marking

Marking shall be durable and legible.

For items a), b), c) and f) of 7.1, compliance is checked by inspection and by trying to remove

the marking by rubbing the area lightly by hand for 15 s with a piece of smooth cloth,

dampened with water.

The marking shall be legible after the test.

For items d) to h) of 7.1, compliance is checked by inspection.

8 Terminals

For screw terminals, the requirements of IEC 60598-1, Section 14, shall be used, if

applicable.

For screwless terminals, the requirements of IEC 60598-1, Section 15, shall be used, if

applicable.

For connectors, the requirements of IEC 60838-2-2 shall be used, if applicable.

9 Provisions for protective earthing

The requirements of IEC 61347-1, Clause 9, apply.

10 Protection against accidental contact with live parts

The requirements of IEC 61347-1, Clause 10, apply.

11 Moisture resistance and insulation

The requirements of IEC 61347-1, Clause 11, apply.

12 Electric strength

The requirements of IEC 61347-1, Clause 12, apply.

62031 © IEC:2008 – 11 –

13 Fault conditions

13.1 General

The module shall not impair safety when operated under fault conditions that may occur

during the intended use. The requirements of IEC 61347-1, Clause 14, apply. Additionally, the

following test shall be carried out.

13.2 Overpower condition

The test shall be started at an ambient temperature as specified in Annex A.

The module shall be switched on and the power monitored (at the input side) and increased

until 150 % of the rated voltage, current or power is reached. The test shall be continued until

the module is thermally stabilised. A stable condition is reached, if the temperature does not

change by more than 5 K in 1 h. The temperature shall be measured in the t point. The

c

module shall withstand the overpower condition for at least 15 min, the time period of which

can lie within the stabilisation period if the temperature change is ≤ 5 K.

If the module contains an automatic protective device or circuit which limits the power, it is

subjected to a 15 min operation at this limit. If the device or circuit effectively limits the power

over this period, the module has passed the test, provided the compliance (4.1 and last

paragraph of 13.2) is fulfilled.

After finalising the overpower mode, the module is operated under normal conditions until

thermally being stable.

A module fails safe if no fire, smoke or flammable gas is produced and if the 15 min

overpower condition has been withstood. To check whether molten material might present a

safety hazard, a tissue paper, as specified in 4.187 of ISO 4046-4, spread below the module

shall not ignite.

14 Conformity testing during manufacture

See Annex C.

15 Construction

Wood, cotton, silk, paper and similar fibrous material shall not be used as insulation.

Compliance is checked by inspection.

16 Creepage distances and clearances

The requirements of IEC 60598-1, Section 11, apply.

17 Screws, current-carrying parts and connections

The requirements of IEC 61347-1, Clause 17, apply.

– 12 – 62031 © IEC:2008

18 Resistance to heat, fire and tracking

The requirements of IEC 61347-1, Clause 18, apply.

19 Resistance to corrosion

The requirements of IEC 61347-1, Clause 19, apply.

62031 © IEC:2008 – 13 –

Annex A

(normative)

Tests

Refer to IEC 61347-1, Annex H, Clauses H.1, H.2, H.4, H.7, and to Subclause H.11.2. In

H.1.3, ignore the first paragraph. In all clauses, replace “lamp”, “(lamp) control gear” or

“ballast” by “LED module”.

– 14 – 62031 © IEC:2008

Annex B

(informative)

Overview of systems composed of LED modules and control gear

LED gear LED module

Lampholder

Supply

Gear and LED module: one unit

voltage:

Built-in

Integral “”Self-ballasted LED lamp

Independent

AC

Built-in

(up to

1 000V

Connection

50 Hz Gear without LEDs

LED module

Integral

or system

(IEC 61347-2-13)

60 Hz)

(IEC 62031)

(IEC 62384)

Independent

or

Combinations possible

“Electronic control gear for

LED modules”

DC

(up to

Built-in

250 V)

Gear LEDs

+ Integral

Independent

(IEC 62031)

“Self- ballasted LED module”

IEC 2316/07

Figure B.1 – Overview of systems composed of LED modules and control gear

62031 © IEC:2008 – 15 –

Annex C

(informative)

Conformity testing during manufacture

This test is carried out at 100 % of production. It is combined with

...

IEC 62031 ®

Edition 1.1 2012-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

LED modules for general lighting – Safety specifications

Modules de DEL pour éclairage général – Spécifications de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62031 ®

Edition 1.1 2012-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

LED modules for general lighting – Safety specifications

Modules de DEL pour éclairage général – Spécifications de sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.140.99; 31.080.99 ISBN 978-2-8322-0476-4

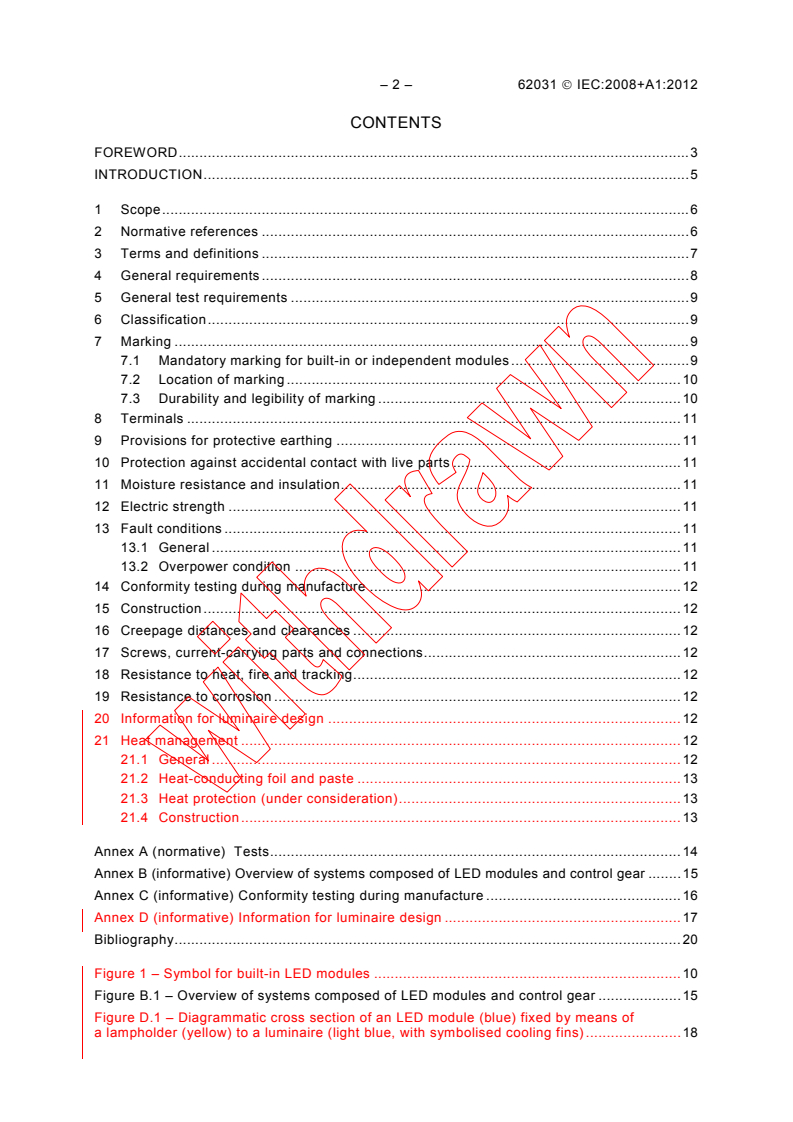

– 2 – 62031 IEC:2008+A1:2012

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 General requirements . 8

5 General test requirements . 9

6 Classification . 9

7 Marking . 9

7.1 Mandatory marking for built-in or independent modules . 9

7.2 Location of marking . 10

7.3 Durability and legibility of marking . 10

8 Terminals . 11

9 Provisions for protective earthing . 11

10 Protection against accidental contact with live parts . 11

11 Moisture resistance and insulation . 11

12 Electric strength . 11

13 Fault conditions . 11

13.1 General . 11

13.2 Overpower condition . 11

14 Conformity testing during manufacture . 12

15 Construction . 12

16 Creepage distances and clearances . 12

17 Screws, current-carrying parts and connections . 12

18 Resistance to heat, fire and tracking . 12

19 Resistance to corrosion . 12

20 Information for luminaire design . 12

21 Heat management . 12

21.1 General . 12

21.2 Heat-conducting foil and paste . 13

21.3 Heat protection (under consideration) . 13

21.4 Construction . 13

Annex A (normative) Tests . 14

Annex B (informative) Overview of systems composed of LED modules and control gear . 15

Annex C (informative) Conformity testing during manufacture . 16

Annex D (informative) Information for luminaire design . 17

Bibliography . 20

Figure 1 – Symbol for built-in LED modules . 10

Figure B.1 – Overview of systems composed of LED modules and control gear . 15

Figure D.1 – Diagrammatic cross section of an LED module (blue) fixed by means of

a lampholder (yellow) to a luminaire (light blue, with symbolised cooling fins) . 18

62031 IEC:2008+A1:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

LED MODULES FOR GENERAL LIGHTING –

SAFETY SPECIFICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 62031 consists of the first edition (2008) [documents

34A/1237/FDIS and 34A/1256/RVD] and its amendment 1 (2012) [documents

34A/1608/FDIS and 34A/1628/RVD]. It bears the edition number 1.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

– 4 – 62031 IEC:2008+A1:2012

International Standard IEC 62031 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

NOTE In this standard, the following print types are used:

– Requirements proper: in roman type.

– Test specifications: in italic type.

– Explanatory matter: in smaller roman type.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

62031 IEC:2008+A1:2012 – 5 –

INTRODUCTION

The first edition of a safety standard for LED modules for general lighting applications

acknowledges the need for relevant tests for this new source of electrical light, sometimes

called “solid state lighting”.

The provisions in the standard represent the technical knowledge of experts from the fields of

the semiconductor industry and those of the traditional electrical light sources.

Two types of LED modules are covered: with integral and external control gear.

– 6 – 62031 IEC:2008+A1:2012

LED MODULES FOR GENERAL LIGHTING –

SAFETY SPECIFICATIONS

1 Scope

This International Standard specifies general and safety requirements for light-emitting diode

(LED) modules:

٭ LED modules without integral control gear for operation under constant voltage, constant

current or constant power;

٭ self-ballasted LED modules for use on d.c. supplies up to 250 V or a.c. supplies up to

1 000 V at 50 Hz or 60 Hz.

NOTE 1 The safety requirements for separate control gear are specified in IEC 61347-2-13. The performance

requirements for separate control gear are specified in IEC 62384.

NOTE 2 Requirements for LED modules with integrated control gear and equipped with a lamp cap (self-ballasted

lamp), intended for mains voltage general lighting service retrofit applications (thereby replacing existing lamps

with identical lamp caps) are specified in IEC 60968 (an amendment to the present edition or a new edition with

extended scope is in preparation).

Requirements for LED modules with integrated control gear and equipped with a lamp cap (self-ballasted lamp),

intended for non-mains voltage general lighting service retrofit applications (thereby replacing existing lamps with

identical lamp caps) are under consideration.

NOTE 3 Where in the requirements of this standard both types of LED modules, with and without integral control

gear, are addressed, the word “modules” is used instead. Where only the expression “LED module(s)” is used, it is

understood to refer to the type without integral control gear.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

)

IEC 60598-1:2003, Luminaires – Part 1: General requirements and tests

Amendment 1 (2006)

IEC 60417, Graphical symbols for use on equipment. Available at http://www.graphical-

symbols.info/equipment

IEC 60838-2-2, Miscellaneous lampholders – Part 2-2: Particular requirements – Connectors

for LED modules

IEC 61347-1:2007, Lamp controlgear – Part 1: General and safety requirements

IEC 61347-2-13:2006, Lamp controlgear – Part 2-13: Particular requirements for d.c. or a.c.

supplied electronic controlgear for LED modules

IEC 62471:2006, Photobiological safety of lamps and lamp systems

ISO 4046-4:2002, Paper, board, pulp and related terms – Vocabulary – Part 4: Paper and

board grades and converted products

—————————

)

A consolidated 6.1 (2006) exists, that includes IEC 60598-1 (2003) and its Amendment 1 (2006).

62031 IEC:2008+A1:2012 – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

For expressions and terms in the field of LEDs and LED modules, refer to IEC TS 62504,

which is currently in development.

3.1

light-emitting diode

LED

solid state device embodying a p-n junction, emitting optical radiation when excited by an

electric current

[IEV 845-04-40]

3.2

LED module

unit supplied as a light source. In addition to one or more LEDs, it may contain further

components, e.g. optical, mechanical, electrical and electronic, but excluding the control gear.

3.3

self-ballasted LED module

LED module, designed for connection to the supply voltage

NOTE If the self-ballasted LED module is equipped with a lamp cap, it is regarded to be a self-ballasted lamp.

3.4

integral LED module

LED module, generally designed to form a non-replaceable part of a luminaire

3.5

integral self-ballasted LED module

self-ballasted LED module, generally designed to form a non-replaceable part of a luminaire

3.6

built-in LED module

LED module, generally designed to form a replaceable part built into a luminaire, a box, an

enclosure or the like and not intended to be mounted outside a luminaire, etc. without special

precautions

3.7

built-in self-ballasted LED module

self-ballasted LED module, generally designed to form a replaceable part built into a

luminaire, a box, an enclosure or the like and not intended to be mounted outside a luminaire,

etc. without special precautions

3.8

independent LED module

LED module, so designed that it can be mounted or placed separately from a luminaire, an

additional box or enclosure or the like. The independent LED module provides all the

necessary protection with regard to safety according to its classification and marking.

NOTE The control gear must not necessarily be integrated in the module.

– 8 – 62031 IEC:2008+A1:2012

3.9

independent self-ballasted LED module

self-ballasted LED module, so designed that it can be mounted or placed separately from a

luminaire, an additional box or enclosure or the like. The independent LED module provides

all the necessary protection with regard to safety according to its classification and marking.

NOTE The control gear may be integrated in the module.

3.10

rated maximum temperature

t

c

highest permissible temperature which may occur on the outer surface of the LED module (at

the indicated position, if marked) under normal operating conditions and at the rated

voltage/current/power or the maximum of the rated voltage/current/power range

3.11

heat transfer temperature

t

d

temperature occurring on a representative part of the LED module (or any heat-conducting foil

or paste applied as for insertion if delivered with the LED module) (at the indicated position if

marked) intended for the passing of heat to the lampholder or to other parts of the luminaire

under normal operating conditions and at the rated voltage/current/power or the maximum of

the rated voltage/current/power range

NOTE A measurement method is under consideration.

3.12

heat output to the luminaire

P

d

power to be transferred to the luminaire by means of heat-conduction in order to keep t

c

NOTE 1 P is below the rated power of an LED module.

d

NOTE 2 For LED modules which do not need heat-conduction to the luminaire for keeping t , P is equal to zero.

c d

NOTE 3 A measurement method is under consideration.

4 General requirements

4.1 Modules shall be so designed and constructed that in normal use (see manufacturer’s

instruction) they operate without danger to the user or surroundings.

4.2 For LED modules, all electrical measurements, unless otherwise specified, shall be

carried out at voltage limits (min/max), current limits (min/max) or power limits (min/max) and

minimum frequency, in a draught-free room at the temperature limits of the allowed range

specified by the manufacturer. Unless the manufacturer indicates the most critical

combination, all combinations (min/max) of voltage/current/power and temperature shall be

tested.

4.3 For self-ballasted LED modules, the electrical measurements shall be carried out at the

tolerance limit values of the marked supply voltage.

4.4 Integral modules not having their own enclosure shall be treated as integral components

of luminaires as defined in IEC 60598-1, Clause 0.5. They shall be tested assembled in the

luminaire, and as far as applicable with the present standard.

4.5 In addition, independent modules shall comply, in addition to this standard, with the

requirements of relevant clauses of IEC 60598-1, where these requirements are not already

covered in this standard including marking requirements of that standard such as IP

classification and mechanical stress.

62031 IEC:2008+A1:2012 – 9 –

4.6 If the module is a factory sealed unit, it shall not be opened for any tests. In the case of

doubt based on the inspection of the module and the examination of the circuit diagram, and

in agreement with the manufacturer or responsible vendor, such specially prepared modules

shall be submitted for testing so that a fault condition can be simulated.

5 General test requirements

5.1 Tests according to this standard shall be type tests.

NOTE The requirements and tolerances permitted by this standard are related to testing of a type-test sample

submitted by the manufacturer for that purpose. Compliance of the type-test sample does not ensure compliance of

the whole production of a manufacturer with this safety standard.

Conformity of production is the responsibility of the manufacturer and may need routine tests and quality assurance

in addition to type testing.

5.2 Unless otherwise specified, the tests shall be carried out at an ambient temperature of

10 °C to 30 °C.

5.3 Unless otherwise specified, the type test shall be carried out on one sample consisting

of one or more items submitted for the purpose of the type test.

In general, all tests shall be carried out on each type of module or, where a range of similar

modules is involved, for each wattage in the range or on a representative selection from the

range, as agreed with the manufacturer.

5.4 If the light output has detectably changed, the module shall not be used for further tests.

NOTE Usually, a value of 50 % indicates irreversible changes in the module.

5.5 For SELV-operated LED modules, the requirements of IEC 61347-2-13, Annex I, apply

additionally.

General conditions for tests are given in Annex A.

6 Classification

Modules are classified, according to the method of installation, as:

– built-in;

– independent;

– integral.

For integral modules, the NOTE to 1.2.1 in IEC 60598-1 applies.

7 Marking

7.1 Mandatory marking for built-in or independent modules

a) Mark of origin (trade mark, manufacturer’s name or name of the responsible

vendor/supplier).

b) Model number or type reference of the manufacturer.

c) Either the

● rated supply voltage(s), or voltage range, supply frequency or/and

● rated supply current(s) or current range, supply frequency (the supply current may be

given in the manufacturer’s literature) or/and

– 10 – 62031 IEC:2008+A1:2012

● rated input power, or power range.

1) If the LED module requires a stable voltage(s), the rated supply voltage or voltage

range, both together with the supply frequency shall be marked. Marking of the rated

supply current(s) is voluntary.

2) If the LED module requires a stable current, the rated supply current(s) or current

range, both together with the supply frequency shall be marked. Marking of the rated

supply voltage(s) is voluntary.

d) Nominal power.

e) Indication of position and purpose of the connections where it is necessary for safety. In

case of connecting wires, a clear indication shall be given in a wiring diagram.

f) Value of t . If this relates to a certain place on the LED module, this place shall be

c

indicated or specified in the manufacturer’s literature.

g) For eye protection, see requirements of IEC 62471.

h) Built-in modules shall be marked with the symbol according to Figure 1 in order to

separate them from independent modules. The mark shall be located on the packaging or

on the LED module itself.

Source: IEC 60417-6053 (2011-05)

Figure 1 – Symbol for built-in LED modules

i) The heat transfer temperature t (if the LED module is provided with a cap enabling the

d

insertion and the withdrawal without the use of tools and reliant on heat-conduction to the

luminaire).

j) The power for heat-conduction P (if the LED module is provided with a cap enabling the

d

insertion and the withdrawal without the use of tools and reliant on heat-conduction to the

luminaire). If P is not known exactly, the rated power of the LED module may be taken

d

instead.

k) Working voltage at which the insulation is designed.

NOTE The symbol is under consideration.

7.2 Location of marking

Items a), b), c) and f) of 7.1 shall be marked on the module.

Items d), e), g) and, h), i) and j) of 7.1 shall be marked legible on the LED module or on the

LED module data sheet. Item k) should be in the manufacturer's literature.

For integral modules, no marking is required, but the information given in 7.1 a) to g) shall be

provided in the technical literature of the manufacturer.

7.3 Durability and legibility of marking

Marking shall be durable and legible.

62031 IEC:2008+A1:2012 – 11 –

For items a), b), c) and f) of 7.1, compliance is checked by inspection and by trying to remove

the marking by rubbing the area lightly by hand for 15 s with a piece of smooth cloth,

dampened with water.

The marking shall be legible after the test.

For items d) to hj) of 7.1, compliance is checked by inspection.

8 Terminals

For screw terminals, the requirements of IEC 60598-1, Section 14, shall be used, if

applicable.

For screwless terminals, the requirements of IEC 60598-1, Section 15, shall be used, if

applicable.

For connectors, the requirements of IEC 60838-2-2 shall be used, if applicable.

9 Provisions for protective earthing

The requirements of IEC 61347-1, Clause 9, apply.

10 Protection against accidental contact with live parts

The requirements of IEC 61347-1, Clause 10, apply.

11 Moisture resistance and insulation

The requirements of IEC 61347-1, Clause 11, apply.

12 Electric strength

The requirements of IEC 61347-1, Clause 12, apply.

13 Fault conditions

13.1 General

The module shall not impair safety when operated under fault conditions that may occur

during the intended use. The requirements of IEC 61347-1, Clause 14, apply. Additionally, the

following test shall be carried out.

13.2 Overpower condition

The test shall be started at an ambient temperature as specified in Annex A.

The LED module shall be switched on and the power monitored (at the input side) and

increased until 150 % of the rated voltage, current or power is reached. The voltage or the

current shall be increased until 150 % of the rated power is reached. The test shall be

continued until the LED module is thermally stabilised. A stable condition is reached, if the

temperature does not change by more than 5 K in 1 h. The temperature shall be measured in

the t point. The LED module shall withstand the overpower condition for at least 15 min, the

c

time period of which can lie within the stabilisation period if the temperature change is ≤ 5K.

– 12 – 62031 IEC:2008+A1:2012

If the module contains an automatic protective device or circuit which limits the power, it is

subjected to a 15 min operation at this limit. If the device or circuit effectively limits the power

over this period, the module has passed the test, provided the compliance (4.1 and last

paragraph of 13.2) is fulfilled.

After finalising the overpower mode, the module is operated under normal conditions until

thermally being stable.

A module fails safe if no fire, smoke or flammable gas is produced and if the 15 min

overpower condition has been withstood. To check whether molten material might present a

safety hazard, a tissue paper, as specified in 4.187 of ISO 4046-4, spread below the module

shall not ignite.

14 Conformity testing during manufacture

See Annex C.

15 Construction

Wood, cotton, silk, paper and similar fibrous material shall not be used as insulation.

Compliance is checked by inspection.

16 Creepage distances and clearances

The requirements of IEC 60598-1, Section 11, apply.

17 Screws, current-carrying parts and connections

The requirements of IEC 61347-1, Clause 17, apply.

18 Resistance to heat, fire and tracking

The requirements of IEC 61347-1, Clause 18, apply.

19 Resistance to corrosion

The requirements of IEC 61347-1, Clause 19, apply.

20 Information for luminaire design

Information is given in Annex D.

21 Heat management

21.1 General

Clause 21 is applicable for exchangeable modules. It is not applicable for non-exchangeable

modules. Exchangeability is safeguarded by means of a cap or base and a lampholder.

Precondition is that a heat conducting thermal interface to the luminaire is needed for keeping

the temperature below the rated maximum temperature t .

c

62031 IEC:2008+A1:2012 – 13 –

21.2 Heat-conducting foil and paste

For the purpose of heat-transfer from the LED module to the luminaire, the use of a heat-

conducting foil can be necessary. Any heat-conducting foil shall be delivered within the LED

module packaging.

Heat-conducting paste shall not be used (under consideration).

21.3 Heat protection (under consideration)

LED modules shall be equipped with a device that cuts the power off or reduces it when t is

c

exceeded.

21.4 Construction

The heat-conduction from the LED module to the luminaire, the electrical connection and the

mechanical holding in the cap/holder system should be separate unless the contrary is proven

safe (under consideration).

– 14 – 62031 IEC:2008+A1:2012

Annex A

(normative)

Tests

Refer to IEC 61347-1, Annex H, Clauses H.1, H.2, H.4, H.7, and to Subclause H.11.2. In

H.1.3, ignore the first paragraph. In all clauses, replace “lamp”, “(lamp) control gear” or

“ballast” by “LED module”.

62031 IEC:2008+A1:2012 – 15 –

Annex B

(informative)

Overview of systems composed of LED modules and control gear

LED module

LED gear

Lampholder

Supply

Gear and LED module: one unit

voltage:

Built-in

Integral “”Self-ballasted LED lamp

Independent

AC

Built-in

(up to

1 000V

Connection

50 Hz

Gear without LEDs

LED module

Integral

system

or

(IEC 61347-2-13)

60 Hz)

(IEC 62031)

(IEC 62384)

Independent

or

“Electronic control gear for Combinations possible

LED modules”

DC

(up to

Built-in

250 V)

Gear LEDs

+ Integral

Independent

(IEC 62031)

“Self- ballasted LED module”

IEC 2316/07

Figure B.1 – Overview of systems composed of LED modules and control gear

– 16 – 62031 IEC:2008+A1:2012

Annex C

(informative)

Conformity testing during manufacture

This test is carried out at 100 % of production. It is combined with the measurement of input

power at rated voltage/current. The luminous flux of no module should be significantly lower

than that of the rest of the production.

NOTE Very low values of the luminous flux indicate internal losses that may be safety relevant, like current

bridges.

For independent and built-in modules, IEC 60598-1, Annex Q, is applicable, but without

polarity check.

62031 IEC:2008+A1:2012 – 17 –

Annex D

(informative)

Information for luminaire design

D.1 General

This annex applies for LED modules that:

have a cap/base enabling the insertion and the withdrawal of the LED module with or

without the use of tools,

do not have a heat management on board and rather rely on heat-conduction to the

luminaire for safe operation.

This annex covers only those provisions that are related to the thermal needs specific for

these LED modules.

NOTE Because of their non-interchangeability, integral LED modules are excluded. Because independent LED

modules are luminaire-like, not needing protection or else from a luminaire neither using a lampholder, they

provide for their own heat management and are excluded. Only built-in LED modules remain within the scope of

this annex.

For safe operation of these LED modules, it is essential to observe the recommendations of

this annex.

D.2 Design freedom

A diagrammatic cross section of an LED module fixed by means of a lampholder to a

luminaire with the locations for temperature measurements (t , t , t , t and t ) and thermal

a c d j l

resistances (R , R and R ) is given with Figure D.1.

th, module th, luminaire th, ambient

– 18 – 62031 IEC:2008+A1:2012

t

j

t

c

R

th, module

R

th, luminaire

t

d

R

th, ambient

t

a

t

l

IEC 2089/12

Key:

t rated maximum ambient temperature of the luminaire as defined in IEC 60598-1

a

t rated maximum temperature

c

t minimum heat transfer temperature

d

t junction temperature (shown for illustration only)

j

t temperature on the surface of the luminaire (shown for illustration only)

l

R thermal resistance between t point and t point

th, module c d

R thermal resistance between t point and t point

th, luminaire d l

R thermal resistance between t and ambient

th, ambient l

Figure D.1 – Diagrammatic cross section of an LED module (blue) fixed by means of a

lampholder (yellow) to a luminaire (light blue, with symbolised cooling fins)

The thermal resistances shown in Figure D.1 can be added to a thermal resistance of the

system:

R + R + R = R (D.1)

th, module th, luminaire th, ambient th, system

Any thermal resistance can be calculated from the temperature difference and the heat flow,

e. g.:

R = (t – t ) / P (D.2)

th, system c a d

R = (t – t ) / P (D.3)

th, module c d d

The design freedom of the luminaire is given by the sum of R + R . It can

th, luminaire th, ambient

be calculated as follows:

R + R = (t – t ) / P (D.4)

th, luminaire th, ambient d a d

62031 IEC:2008+A1:2012 – 19 –

D.3 Testing in the luminaire

The knowledge of t and P as provided by the LED module manufacturer, of the geometry

d d

and the surface properties of the cap and of the t of the luminaire to be designed, will allow

a

for designing a luminaire that will most probably keep the t of the LED module. However,

c

testing in the luminaire if the luminaires does so will still be necessary.

Details of the test procedure are under consideration.

– 20 – 62031 IEC:2008+A1:2012

Bibliography

IEC 60050-845:1987, International Electrotechnical Vocabulary – Chapter 845: Lighting

IEC 60968, Self-ballasted lamps for general lighting services – Safety requirements

IEC 62384, DC or AC supplied electronic control gear for LED modules – Performance

requirements

)

IEC TS 62504:___,Terms and definitions for LEDs and LED modules in general lighting

___________

—————————

)

In preparation.

– 22 – 62031 CEI:2008+A1:2012

SOMMAIRE

AVANT-PROPOS . 23

INTRODUCTION . 25

1 Domaine d’application . 26

2 Références normatives . 26

3 Termes et définitions . 27

4 Exigences générales . 28

5 Exigences générales pour les contrôles . 29

6 Classification . 29

7 Marquage . 29

7.1 Marquage obligatoire des modules à monter et des modules indépendants . 29

7.2 Emplacement du marquage . 30

7.3 Durabilité et lisibilité du marquage . 31

8 Bornes. 31

9 Dispositions en vue de la mise à la terre de protection . 31

10 Protection contre le contact accidentel avec des parties actives . 31

11 Résistance à l’humidité et isolement . 31

12 Rigidité diélectrique . 31

13 Conditions de défaut . 31

13.1 Généralités. 31

13.2 Condition de surpuissance . 32

14 Contrôle de conformité pendant la fabrication . 32

15 Construction . 32

16 Lignes de fuite et distances dans l’air . 32

17 Vis, parties transportant le courant et connexions. 32

18 Résistance à la chaleur, au feu et aux courants de cheminement . 32

19 Résistance à la corrosion . 33

20 Renseignements pour la conception des luminaires . 33

21 Gestion de la chaleur . 33

21.1 Généralités. 33

21.2 Feuille et pâte conductrice de chaleur . 33

21.3 Protection thermique (à l'étude) . 33

21.4 Construction . 33

Annexe A (normative) Essais . 34

Annexe B (informative) Systèmes composés de modules de DEL et d’appareillages . 35

Annexe C (informative) Contrôle de conformité pendant la fabrication . 36

Annexe D (informative) Renseignements pour la conception des luminaires . 37

Bibliographie . 40

Figure 1 – Symbole pour les modules de DEL à monter . 30

Figure B.1 – Vue d’ensemble des systèmes composés de modules de DEL et

d’appareillages . 35

Figure D.1 – Schéma de vue en coupe d’un module de DEL (bleu) fixé au moyen d’une

douille (jaune) à un luminaire (bleu clair, avec ailettes de refroidissement symbolisées) . 38

62031 CEI:2008+A1:2012 – 23 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

MODULES DE DEL POUR ÉCLAIRAGE GÉNÉRAL –

SPÉCIFICATIONS DE SÉCURITÉ

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalis

...

IEC 62031 ®

Edition 1.2 2014-09

CONSOLIDATED

VERSION

VERSION

CONSOLIDÉE

colour

inside

LED modules for general lighting – Safety specifications

Modules de DEL pour éclairage général – Spécifications de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres