IEC PAS 63312:2021

(Main)Technical specification for flame detector system of boiler

Technical specification for flame detector system of boiler

IEC PAS 63312:2021 deals with the general requirements, classification and technical requirements, installation and commissioning requirements, inspection and maintenance requirements, test methods and requirements of radiant energy sensing flame detectors (including IR, UV, visible light, and imaging-based flame detectors).

This PAS is applicable to the type selection, design, installation, commissioning, inspection, maintenance and acceptance of the radiant energy sensing flame detectors, which monitor the flame status of burners

General Information

- Status

- Published

- Publication Date

- 13-Jan-2021

- Technical Committee

- SC 65B - Measurement and control devices

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-Jan-2021

- Completion Date

- 28-Jan-2021

Overview

IEC PAS 63312:2021 is a Publicly Available Specification from the International Electrotechnical Commission (IEC) that defines technical requirements for flame detector systems of boilers. It covers radiant‑energy sensing flame detectors - including IR, UV, visible‑light and imaging‑based detectors - and is intended for the type selection, design, installation, commissioning, inspection, maintenance and acceptance of systems that monitor burner flame status.

Keywords: IEC PAS 63312:2021, flame detector system, boiler, radiant energy sensing, IR UV flame detectors, imaging-based flame detectors.

Key Topics

The PAS organizes practical requirements and test guidance across the lifecycle of flame detector systems. Major technical topics include:

- General requirements: power supply, functional performance, signal output and interchangeability.

- Classification: by detection principle (IR/UV/visible/imaging), structure, installation method and safety level.

- Design and performance: basic functional and performance requirements, reliability and optional cooling‑system requirements for optical probes.

- Installation & commissioning: installation preparations, mounting and alignment, static and dynamic commissioning procedures, and acceptance criteria.

- Inspection & maintenance: routine and regular maintenance tasks, inspections for power, optical fibers, analysis units, cables and cooling systems, and archive requirements.

- Test methods: factory acceptance tests, type tests, test instruments and reference conditions, sampling principles and pass/fail criteria.

- Ancillary topics: marking, packaging, transport and storage recommendations and an informative annex showing typical system compositions (signal probes, transmission, analysis units, power and cooling).

Applications

IEC PAS 63312:2021 is practical for organizations and professionals responsible for boiler safety and combustion control:

- Boiler and burner manufacturers specifying factory‑equipped flame detection.

- Plant engineers and control system integrators designing flame monitoring and interlock systems.

- Maintenance teams and inspection bodies conducting commissioning, periodic tests and acceptance checks.

- Safety and reliability engineers assessing detector selection, redundancy and cooling requirements to reduce nuisance trips and ensure fail‑safe behavior.

- Procurement and QA for defining factory and site acceptance test (FAT/SAT) criteria.

Using this PAS helps improve flame monitoring reliability, ensure consistent installation and commissioning practices, meet regulatory and insurance expectations, and reduce unplanned shutdowns.

Related standards

IEC PAS 63312 was prepared by IEC TC 65B (industrial‑process measurement, control and automation) and complements other IEC and industry standards on measurement, control, combustion safety and electrical installations. Users should review applicable national regulations and sector safety codes when applying the PAS.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC PAS 63312:2021 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Technical specification for flame detector system of boiler". This standard covers: IEC PAS 63312:2021 deals with the general requirements, classification and technical requirements, installation and commissioning requirements, inspection and maintenance requirements, test methods and requirements of radiant energy sensing flame detectors (including IR, UV, visible light, and imaging-based flame detectors). This PAS is applicable to the type selection, design, installation, commissioning, inspection, maintenance and acceptance of the radiant energy sensing flame detectors, which monitor the flame status of burners

IEC PAS 63312:2021 deals with the general requirements, classification and technical requirements, installation and commissioning requirements, inspection and maintenance requirements, test methods and requirements of radiant energy sensing flame detectors (including IR, UV, visible light, and imaging-based flame detectors). This PAS is applicable to the type selection, design, installation, commissioning, inspection, maintenance and acceptance of the radiant energy sensing flame detectors, which monitor the flame status of burners

IEC PAS 63312:2021 is classified under the following ICS (International Classification for Standards) categories: 27.060 - Burners. Boilers. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 63312:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC PAS 63312 ®

Edition 1.0 2021-01

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

colour

inside

Technical specification for flame detector system of boiler

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC PAS 63312 ®

Edition 1.0 2021-01

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

colour

inside

Technical specification for flame detector system of boiler

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.060 ISBN 978-2-8322-9241-9

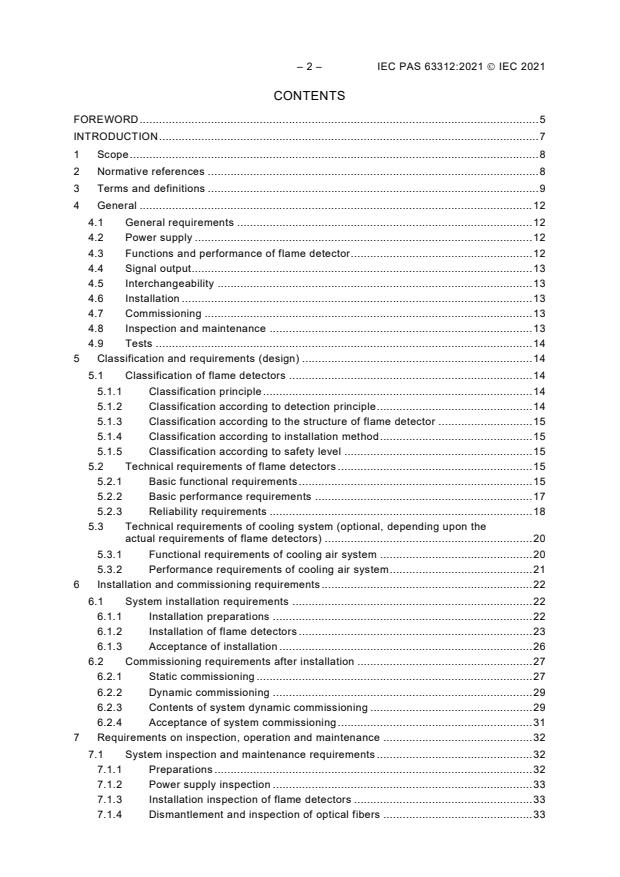

– 2 – IEC PAS 63312:2021 IEC 2021

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 General . 12

4.1 General requirements . 12

4.2 Power supply . 12

4.3 Functions and performance of flame detector . 12

4.4 Signal output. 13

4.5 Interchangeability . 13

4.6 Installation . 13

4.7 Commissioning . 13

4.8 Inspection and maintenance . 13

4.9 Tests . 14

5 Classification and requirements (design) . 14

5.1 Classification of flame detectors . 14

5.1.1 Classification principle . 14

5.1.2 Classification according to detection principle . 14

5.1.3 Classification according to the structure of flame detector . 15

5.1.4 Classification according to installation method . 15

5.1.5 Classification according to safety level . 15

5.2 Technical requirements of flame detectors . 15

5.2.1 Basic functional requirements . 15

5.2.2 Basic performance requirements . 17

5.2.3 Reliability requirements . 18

5.3 Technical requirements of cooling system (optional, depending upon the

actual requirements of flame detectors) . 20

5.3.1 Functional requirements of cooling air system . 20

5.3.2 Performance requirements of cooling air system . 21

6 Installation and commissioning requirements . 22

6.1 System installation requirements . 22

6.1.1 Installation preparations . 22

6.1.2 Installation of flame detectors . 23

6.1.3 Acceptance of installation . 26

6.2 Commissioning requirements after installation . 27

6.2.1 Static commissioning . 27

6.2.2 Dynamic commissioning . 29

6.2.3 Contents of system dynamic commissioning . 29

6.2.4 Acceptance of system commissioning . 31

7 Requirements on inspection, operation and maintenance . 32

7.1 System inspection and maintenance requirements . 32

7.1.1 Preparations . 32

7.1.2 Power supply inspection . 33

7.1.3 Installation inspection of flame detectors . 33

7.1.4 Dismantlement and inspection of optical fibers . 33

7.1.5 Inspection and maintenance of analysis and processing unit . 34

7.1.6 Inspection and maintenance of cables . 35

7.1.7 Inspection and maintenance of cooling air system . 35

7.2 System test requirements . 36

7.2.1 Power system test . 36

7.2.2 Inspection on the analysis and processing unit . 36

7.2.3 Inspection and tests on flame detector probes . 36

7.2.4 Basic functional tests . 37

7.2.5 Parameter adjustment test . 37

7.2.6 Check of parameter settings . 37

7.2.7 Tests on cooling fans . 37

7.3 System operation . 38

7.3.1 Restart . 38

7.3.2 Maintenance during operation . 38

7.3.3 Inspections before boiler shutdown . 39

7.4 System maintenance requirements . 39

7.4.1 Routine maintenance . 39

7.4.2 Regular maintenance . 39

7.5 Archives . 40

8 Test methods and requirements . 41

8.1 Test methods . 41

8.1.1 General . 41

8.1.2 Test reference conditions . 41

8.1.3 Test instruments and equipment . 41

8.1.4 Test items and methods . 42

8.2 Equipment factory acceptance test. 44

8.2.1 Test items . 44

8.2.2 Judgment of eligibility . 44

8.3 Type test . 44

8.3.1 General . 44

8.3.2 Situations requiring type test . 44

8.3.3 Sampling principles . 44

8.3.4 Judgment of eligibility in type test . 45

Annex A (informative) Composition of flame detector system . 46

A.1 General . 46

A.2 Flame detector . 46

A.3 Signal transmission components and cables . 47

A.4 Analysis and engineering tools . 47

A.5 Power system . 47

A.6 Cooling air system (optical, depending on design requirements) . 47

Annex B (informative) Marking, packaging, transportation and storage of flame

detectors . 48

B.1 Marking . 48

B.2 Packaging . 48

B.3 Transportation . 48

B.4 Storage . 48

– 4 – IEC PAS 63312:2021 IEC 2021

Figure A.1 – Schematic diagram of a typical light signal-based flame probe . 46

Figure A.2 – Schematic diagram of an imaging-based flame detector probe . 46

Table 1 – Configuration of monitoring and interlocking instruments of flame detector

cooling air system . 20

Table 2 – Installation acceptance criteria of flame detector system . 26

Table 3 – Commissioning acceptance items of flame detector system . 32

Table 4 – Test instruments and equipment . 41

Table 5 – Requirements on insulation resistance tester . 42

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TECHNICAL SPECIFICATION FOR FLAME DETECTOR SYSTEM OF BOILER

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is an intermediate specification made available to the public and needing a lower level

of consensus than an International Standard to be approved by vote (simple majority).

IEC PAS 63312 has been processed by subcommittee 65B: Measurement and control devices,

of IEC technical committee 65: Industrial-process measurement, control and automation.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document

Draft PAS Report on voting

65B/1175/DPAS 65B/1180/RVDPAS

Following publication of this PAS, which is a pre-standard publication, the technical committee

or subcommittee concerned may transform it into an International Standard.

– 6 – IEC PAS 63312:2021 IEC 2021

This PAS shall remain valid for an initial maximum period of 2 years starting from the

publication date. The validity may be extended for a single period up to a maximum of 2 years,

at the end of which it shall be published as another type of normative document, or shall be

withdrawn.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

The flame detector is the key testing equipment for the boiler furnace safety protection and

burner interlock control. In the whole combustion process of the boiler (especially in the

variable operating condition), it detects the change of the combustion condition, and the

corresponding control measures are taken through the connected terminal devices; so its

reliability is related to the safety of the combustion system and the quality of the terminal

products. Due to the difference in combustion conditions in the furnace, the reliability of the

flame detector itself and the quality of the installation and maintenance, many problems are

exposed during the operation, such as peeping of fire detection signals, missed detection,

instability, false alarm information, fiber overheating loss, etc. All of these will bring safety

hazards to the industrial production.

The purpose of this PAS is to develop comprehensive technical specifications for the

functions and performance of industrial boiler flame detectors, as well as the technical

requirements related to design, manufacture, installation, testing, operation, maintenance,

etc., so as to provide the technical basis for flame detector system users.

– 8 – IEC PAS 63312:2021 IEC 2021

TECHNICAL SPECIFICATION FOR FLAME DETECTOR SYSTEM OF BOILER

1 Scope

This PAS deals with the general requirements, classification and technical requirements,

installation and commissioning requirements, inspection and maintenance requirements, test

methods and requirements of radiant energy sensing flame detectors (including IR, UV, visible

light, and imaging-based flame detectors).

This PAS is applicable to the type selection, design, installation, commissioning, inspection,

maintenance and acceptance of the radiant energy sensing flame detectors, which monitor

the flame status of burners.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60034-30-1, Rotating electrical machines – Part 30-1: Efficiency classes of line operated

AC motors (IE code)

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60079-0, Explosive atmospheres – Part 0: Equipment – General requirements

IEC 60079-1, Explosive atmospheres – Part 1: Equipment protection by flameproof

enclosures "d"

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 61010-1, Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 1: General requirements

IEC 61326-1, Electrical equipment for measurement, control and laboratory use – EMC

requirements – Part 1: General requirements

IEC 61326-2-5, Electrical equipment for measurement, control and laboratory use – EMC

requirements – Part 2-5: Particular requirements – Test configurations, operational conditions

and performance criteria for field devices with field bus interfaces according to IEC 61784-1

NFPA 85, Boiler and Combustion Systems Hazards Code

ANSI/TIA/EIA-232-F, Interface between Data Terminal Equipment and Data Circuit-

Terminating Equipment Employing Serial Binary Data Interchange

ANSI/TIA/EIA-422-B, Electrical Characteristics of Balance Voltage Digital Interface Circuits

ANSI/TIA/EIA-644-A, Electrical Characteristics of Low Voltage Differential Signaling (LVDS)

Interface Circuits

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

flame detector

device in the furnace safety supervisory system that detects the combustion status in real

time according to the flame characteristics of the fuel, and which, when the flame status fails

to meet the preset conditions, considers the target flame abnormal or disappeared and sends

a signal in a certain manner to stop the corresponding fuel supply

3.2

infrared signal

radiant energy signals falling within the infrared spectrum, emitted from the flames of burning

fuel such as coal and oil

3.3

ultraviolet signal

radiant energy signals falling within the ultraviolet spectrum, emitted from the flames of

burning fuel such as natural gas and light oil

3.4

visible light signal

radiant energy signals falling within the visible light spectrum, emitted from the flames of

burning fuel such as lean coal and mixed fuels

3.5

flame on

presence of flame in the furnace, as computed by the flame detector system

3.6

flame off

absence of flame in the furnace, as computed by the flame detector system

3.7

target flame

predefined flame to be detected, rather than the extended background radiation or the

adjacent and opposing flames

3.8

flame intensity

value computed by flame detector according to the received radiant energy intensity of flame,

representing the radiant energy intensity of the flame

– 10 – IEC PAS 63312:2021 IEC 2021

3.9

flicker frequency

pulsation frequency of flame radiant energy, representing the change rate of the target flame's

radiant energy intensity

3.10

AC amplitude

pulsation amplitude of radiant energy from flame, representing the peak-to-peak value of the

radiant energy intensity pulsation of target flame

3.11

flame quality

extent away from the flame-off status, computed from the detected flame intensity and flicker

frequency, representing the degree of flame stability

3.12

flame threshold

minimum value set for the flame detector to determine the presence of flame (i.e. flame-on

threshold) or the maximum value to determine the absence of flame (i.e. flame-off threshold)

3.13

flame relay

on/off control switch that switches on when the flame logic judges that flame is present and

switches off when it judges that flame is absent

3.14

fault relay

on/off control switch that switches on when no fault is detected and switches off when any

fault is detected

3.15

flame detector probe

device installed locally, capable of flame information sensing, photoelectric conversion and

signal amplification

3.16

analysis and processing unit

device that receives the signals transmitted from one or more flame detector probes, and,

after analysing and processing by the corresponding processor, outputs the digital and analog

signals of each flame signal

Note 1 to entry: The relevant parameters of each flame can be set independently.

3.17

one-to-one detection

detection mode in which each target flame has a separate, fixed flame detector

3.18

flame detector peeping

situation that exists when the flame detector cannot distinguish between a target flame and a

non-target flame, and considers a non-target flame as the target flame

3.19

static commissioning

commissioning of flame detector system using simulative light sources before the boiler is

started up

3.20

dynamic commissioning

commissioning of flame detector system after the boiler is started up, during which the flame

detection data throughout the period from the startup to the full load operation of the boiler

under typical operating conditions is analyzed and compared and the parameters setting is

completed to meet the actual operating requirements of the boiler

3.21

light signal-based flame detector

flame detector that detects flames relying on the intensity, pulsation and other signals of the

radiant light emitted by target flame, including infrared, visible light, ultraviolet, dual-spectrum,

and full-spectrum types

3.22

imaging-based flame detector

flame detector that detects the flame by acquiring the real-time video images of the target

flame

3.23

Class A unit overhaul

thorough inspection and repair on the generator unit, intended to maintain, restore or improve

the performance of the unit equipment

Note 1 to entry: Class A is the highest level overhaul among regular unit overhauls.

3.24

Class B overhaul

inspection and repair on the faulty or defective equipment within the unit, which may include

some targeted Class A overhaul items or rotational maintenance items depending on the

evaluation outcome of the unit

3.25

Class C overhaul

targeted inspection, evaluation and repair carried out on the unit according to the wearing and

aging trends of equipment, which may include the replacement of a small number of parts, the

defect elimination, adjustment, preventive tests and other operations on the equipment, as

well as some Class A overhaul items or rotational maintenance items

3.26

troubleshooting

activities performed on faulty equipment for the purpose of restoring it to such a status that it

can execute its intended functions

Note 1 to entry: Troubleshooting includes diagnosis, repair, and replacement.

3.27

mean time between operating failures

MTBF

expectation of the duration of the operating time between failures

[SOURCE: IEC 60050-192:2015, 192-05-13]

– 12 – IEC PAS 63312:2021 IEC 2021

3.28

reliability

ability to perform as required, without failure, for a given time interval, under given conditions

Note 1 to entry: The time interval duration may be expressed in units appropriate to the item concerned,

e.g. calendar time, operating cycles, distance run, etc., and the units should always be clearly stated.

Note 2 to entry: Given conditions include aspects that affect reliability, such as: mode of operation, stress levels,

environmental conditions, and maintenance.

[SOURCE: IEC 60050-192:2015, 192-01-24]

4 General

4.1 General requirements

The flame detector system mainly consists of flame detectors, signal transmission

components and cables, junction boxes, flame detection cabinets, the analysis and

processing unit, engineer tools, power supplies, installation accessories and the cooling

system (if necessary). For the use purpose of each component, see Annex A.

The flame detectors should be marked with QR codes. The outer surfaces and nameplates

shall be smooth, intact, scratch-free, and contamination-free. The film over the surface shall

have no peeling and scratching. The characters in panels and nameplates shall be legible.

There shall be no loose connections or junctions.

4.2 Power supply

The flame detector cabinet shall be provided with duplicate power supplies, which back up

each other. It shall have a built-in power switching module, which balances the two power

supplies via the automatic power distribution circuit.

Any failure of either power supply shall be alarmed, without affecting the normal operation of

the equipment and missending signals. Switching between the two power supplies shall

generate no disturbance and shall not enable the flame detector to send the "flame off" signal.

Each power supply circuit of the flame detector amplifier/flame detector shall be provided with

a separate fuse or other separate protective measures.

The power supply to the fans in the flame detector cabinet shall be independent of the power

supply to the flame detector system, or appropriate isolation measures shall be taken between

them.

4.3 Functions and performance of flame detector

The functions and performance of flame detectors shall meet the requirements of NFPA 85

Boiler and Combustion Systems Hazards Code. Flame detectors shall be able to correctly

identify the flames of fuel (coal, oil and gas) for the corresponding burners. They shall be

continuously adjustable within the full frequency spectrum under monitoring (or the

corresponding frequency spectrum), so that the flames can be detected throughout the whole

range of working conditions.

The flame detectors should allow selection among multiple parameters, so that appropriate

parameter groups can be selected for the specific fuel and combustion condition, and that the

flame parameters can be switched according to the current background conditions.

The flame detectors shall correctly reflect the various flame statuses (such as flame

frequency and intensity). They shall be able to mitigate the interference from the adjacent,

opposite, furnace-reflected non-target flames or the interference from the adjacent main flame

to the minimal level.

The flame detectors shall have the self-test function, which allows them, in a timely manner,

to reflect their own conditions, make self-diagnosis of faults, and give alarms at the specified

interval.

4.4 Signal output

The flame detector of each burner shall provide analog signal (4 mA to 20 mA or 0 to 10 V)

outputs or communication means to indicate the intensity of flame output signal.

The flame detector of each burner shall have at least two passive dry contacts to output flame

status signals (flame on/flame off) and flame detector fault signals.

For digital outputs of flame detector, single relay mode or double relay mode may be used.

a) Single relay mode: The deenergized/energized status of flame relay (contact open/closed)

is used to indicate the flame on/flame off status, and the deenergized/energized status of

fault relay (contact open/closed) is used to indicate the faulty/normal status.

b) Double relay mode: Two relays are used to indicate the flame on and flame off statuses

respectively. When the flame-on relay is closed and the flame-off relay is open, it indicates

the presence of flame. When the flame-on relay is open and the flame-off relay is closed,

it indicates the absence of flame. When both relays are closed/open, it indicates a faulty

status.

4.5 Interchangeability

Parts of the same type shall be interchangeable. The measurements of the same target flame

indicated by different flame detection devices shall be substantially consistent and meet the

overall accuracy and linearity requirements.

4.6 Installation

Flame detectors from different manufacturers may have different probe installation methods

and requirements. They shall be installed in accordance with 6.1 and the manufacturer's

instructions, so that the probe detection point aligns with the sensitive area for flame

detection.

4.7 Commissioning

The commissioning of flame detectors consists of two stages: the static commissioning before

startup of the boiler and the dynamic commissioning after startup of the boiler. The two-stage

commissioning shall be so conducted that the internal parameters of each flame detector are

optimized and the flame status in the boiler is correctly indicated throughout the period from

boiler startup to full load operation.

4.8 Inspection and maintenance

The probe of flame detector is usually exposed to a harsh working environment. So proper

inspection and maintenance is necessary for keeping stable and reliable operation of the

flame detector system. In addition to the inspection and maintenance of the flame detector

system during unit overhauls, the maintenance personnel shall also carry out routine

maintenance and regular maintenance to identify and eliminate problems in a timely manner

and improve the reliability of the flame detector system.

– 14 – IEC PAS 63312:2021 IEC 2021

4.9 Tests

The purpose of tests is to verify the performance of flame detectors and the effectiveness of

their maintenance activities. In order to ensure reliable operation of flame detectors, targeted

tests shall be carried out during manufacture, delivery and maintenance.

5 Classification and requirements (design)

5.1 Classification of flame detectors

5.1.1 Classification principle

Flame detectors can be classified according to the detection principle, device structure,

installation method, and safety level.

5.1.2 Classification according to detection principle

5.1.2.1 Overview

The flames of coal, oil or gas in the furnace of boiler are characterized by the continuous

infrared, visible light and ultraviolet spectrums of radiation and the flame pulsation or flicker

phenomenon. The intensity and spectrum distribution of flames vary with the type of fuel. And

the spectral frequency and intensity of flame radiation constantly change with the combustion

zone. Generally, the flame combustion zones can be divided into the initial combustion zone,

the high temperature zone and the burn-out zone. The flame in the initial combustion zone

features the most intensive flicker frequency. Appropriate flame detectors shall be used

according to the specific characteristics of the target flame. The flame detector converts light

signal to pulsation electrical signal (current or voltage signal) and distinguishes the target

flame from background flame by detecting the frequency ranges, realizing effective detection

of flame signals. According to the detection principle, flame detectors can also be classified

into the light signal-based flame detectors and imaging-based flame detectors.

5.1.2.2 Light signal-based flame detector

Light signal-based flame detectors include the infrared, visible light, ultraviolet, dual-spectrum,

and full-spectrum types. They detect the target flame by analysing and processing the

intensity and spectral characteristics of flame radiation light. Electrical signals are pre-

processed in a printed circuit board in the shell of flame detector probe. After logarithmic

amplification and being converted into current signals by voltage/current conversion, the

signals are transmitted through a shielded cable to the analysis and processing unit (flame

amplifier) in the remote signal processing cabinet for processing. After various processes

including frequency detection, intensity detection, and circuit detection, standard signals

including the quality conditions of flame detector (flame intensity analog signal) and the

presence/absence of flame (digital signals and flame detector fault signals) are output for

display, alarming and boiler trip logic judgment.

5.1.2.3 Imaging-based flame detector

Real-time video images of flames are collected and the target flames are detected by using

the image processing technology. The flame image contains the position, brightness, and

pulsation information of target flame and background flame. By properly determining the

position of detection area, the target flame can be distinguished from most background flames.

Reasonably setting the parameters for judging the target flame could further improve the

identification of background flame. Generally, the imaging-based flame detector collects the

real-time video images of the target flame via the camera in burner's secondary air duct, and

transmits signals to its signal processing unit via a video coaxial cable for processing. After

the video analog-to-digital conversion, the built-in image processing algorithm is used to

identify the target flame, and the signals such as flame intensity, flame status, and faults are

output for display, alarming, and logic judgment.

5.1.3 Classification according to the structure of flame detector

5.1.3.1 Overview

According to detector structure, flame detectors can be classified into the integrated flame

detector and split flame detector.

5.1.3.2 Integrated flame detector

The integrated flame detector is usually composed of a probe assembly and a flame signal

analysis and processing unit, of which all the electronic devices are integrated and installed at

the same local detection position.

5.1.3.3 Split flame detector

The split flame detector is also composed of a probe assembly and a flame signal analysis

and processing unit, which, however, are independent of each other. The probe assembly is

installed at the local detection position, while the flame signal analysis and processing unit is

installed at another place in a favorable environment (such as an electronics room).

5.1.4 Classification according to installation method

5.1.4.1 Internally sighting flame detector

In the "internally sighting" installation mode of flame detector, the optical signals of flame

radiation are transmitted to the flame sensor outside the boiler via the optical fibers or light

guide tubes installed inside the boiler for flame detection.

5.1.4.2 Externally sighting flame detector

In the "externally sighting" installation mode of flame detector, the flame detector is installed

outside the boiler and directly receives the light signals of the target flame in boiler for flame

detection.

5.1.5 Classification according to safety level

5.1.5.1 Explosion-proof flame detector

The explosion-proof flame detectors, capable of explosion resistance, are used in explosive

environments. Generally, the flame detectors for gas-fired boilers or gas-reacting boilers are

exposed to an explosive environment. The common explosive installation environments for

flame detectors mainly include gas-fired boiler, coal-fired boiler cofiring combustible gases,

waste gas-fired boiler, gas synthesis boiler (such as HCL synthesis boiler), and gas-reacting

boiler.

5.1.5.2 Non-explosion-proof flame detector

The non-explosion-proof flame detectors, incapable of explosion resistance, are used in non-

explosive environments. The common non-explosive installation environments for flame

detectors mainly include oil-fired boiler and coal-fired boiler.

5.2 Technical requirements of flame detectors

5.2.1 Basic functional requirements

5.2.1.1 Self-test function

Flame detectors shall be able to reflect their working conditions in real time by conducting

continuous self-test and shall ensure the continuity of their self-test. Under the specified

working conditions and when the flame input signal is valid, if the flame detector detects a

fault, it shall automatically give an alarm signal via the relay or communication devices.

– 16 – IEC PAS 63312:2021 IEC 2021

5.2.1.2 Flame threshold setting function

Under the specified working conditions, the flame-on and flame-off thresholds shall be

adjustable. For the imaging-based flame detectors, both the position of each flame judgment

zone and the flame recognition threshold shall be adjustable.

5.2.1.3 Flame intensity display

Under the specified working conditions and when the flame input signal is valid, the flame

detector shall display the intensity of the flame input signal in real time. For the imaging-

based flame detector, the flame signal intensity at the flame zone corresponding to the real-

time image shall be provided in the control software.

5.2.1.4 Flame-on delay setting

Under the specified working conditions, the period from the time the flame input signal

changes from flame-off to flame-on to the time the flame detector outputs flame-on signal is

referred to as the flame-on delay. The delay shall allow appropriate presetting.

5.2.1.5 Flame-off delay setting

Under the specified working conditions, the period from the time the flame input signal

changes from flame-on to flame-off to the time the flame detector outputs flame-off signal is

referred to as the flame-off delay. The delay may be provided by the boiler manufacturer or

preset by professionals.

5.2.1.6 Analog output signal

The analog output signal of flame detector is used for remote monitoring and shall meet the

following conditions.

a) When the intensity of flame input signal is less than the lower limit of measuring range of

flame detector, the output is DC 4 mA.

b) When the intensity of flame input signal is within the measuring range of flame detector,

the output is DC (4 to 20) mA.

c) When the intensity of flame input signal is greater than the upper limit of measuring range

of flame detector (overflow), the output is DC 20 mA.

5.2.1.7 Remote communication fun

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...