IEC 62899-301-3:2024

(Main)Printed Electronics - Part 301-3: Equipment - Contact printing - Rigid master - Method to measure the shape errors of printing plate rollers

Printed Electronics - Part 301-3: Equipment - Contact printing - Rigid master - Method to measure the shape errors of printing plate rollers

IEC 62899-301-3:2024 defines measurement terms and methods related to the shape errors of printing plate rollers. Measurement terms include radius, total run-out, and three kinds of shape errors of printing plate rollers that are axial deviation, radial deviation, and cross-sectional deviation. The remaining shape error excluding the three errors mentioned above is defined as a residual shape error.

This document applies to printing plate rollers with or without patterns while excluding the pattern area for the measurement.

General Information

- Status

- Published

- Publication Date

- 26-Sep-2024

- Technical Committee

- TC 119 - Printed Electronics

- Drafting Committee

- WG 3 - TC 119/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Sep-2024

- Completion Date

- 18-Oct-2024

Overview

IEC 62899-301-3:2024 - Printed Electronics, Part 301-3: Equipment - Contact printing - Rigid master - Method to measure the shape errors of printing plate rollers - is an International Electrotechnical Commission (IEC) standard that defines measurement terms and methods for quantifying the geometric shape errors of printing plate rollers used in contact printing for printed electronics.

This standard specifies how to measure and report key geometrical parameters such as radius, total run‑out, and three primary shape errors: axial deviation, radial deviation, and cross‑sectional deviation. Any remaining variation beyond these three is defined as the residual shape error. Measurement excludes the pattern area and applies to printing plate rollers with or without patterns.

Key topics and technical requirements

- Defined measurement terms: radius, total run‑out, axial deviation, radial deviation, cross‑sectional deviation, residual shape error.

- Scope limitation: applies to rigid master printing plate rollers; excludes patterned areas for measurement.

- Measurement methods (Clause 4):

- General principles for measuring shape errors.

- Requirements for the measuring instrument and recommended measurement setup.

- Measuring process steps to capture circumferential and axial data points.

- Reporting requirements and example report formats.

- Numerical procedures (Annex B, normative): procedures to extract the least‑squares reference circle, remove axial and radial deviations, compute cross‑sectional deviation, and calculate residual shape errors.

- Supplementary guidance:

- Annex A (informative): relationship between roller shape and printing force variation.

- Annex C (informative): worked examples of reports and graphical outputs.

- Metrology detail: guidance on sample points per circumference and data handling (table and figures provided), but no specific acceptance/tolerance levels are prescribed in this document.

Practical applications and who uses this standard

- Printed electronics manufacturers and production engineers use the standard to assess master quality and control printed feature fidelity (critical when printing features <20 µm).

- Printing plate roller manufacturers and tooling suppliers for quality assurance and product specifications.

- Equipment vendors and metrology labs to design measurement fixtures, select instruments, and produce standardized reports.

- R&D teams working on high‑resolution contact printing methods to separate roller-induced dynamic errors from bearing/motion or loading effects.

- Use cases include reducing printing registration errors, minimizing linewidth variations, and improving mass‑production yield for printed circuits and devices.

Related standards

- Part of the IEC 62899 series - Printed Electronics. Users should consult other parts of IEC 62899 for related measurement, process, and equipment requirements in printed electronics. For implementation details, refer to the normative references listed in the standard.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 62899-301-3:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Printed Electronics - Part 301-3: Equipment - Contact printing - Rigid master - Method to measure the shape errors of printing plate rollers". This standard covers: IEC 62899-301-3:2024 defines measurement terms and methods related to the shape errors of printing plate rollers. Measurement terms include radius, total run-out, and three kinds of shape errors of printing plate rollers that are axial deviation, radial deviation, and cross-sectional deviation. The remaining shape error excluding the three errors mentioned above is defined as a residual shape error. This document applies to printing plate rollers with or without patterns while excluding the pattern area for the measurement.

IEC 62899-301-3:2024 defines measurement terms and methods related to the shape errors of printing plate rollers. Measurement terms include radius, total run-out, and three kinds of shape errors of printing plate rollers that are axial deviation, radial deviation, and cross-sectional deviation. The remaining shape error excluding the three errors mentioned above is defined as a residual shape error. This document applies to printing plate rollers with or without patterns while excluding the pattern area for the measurement.

IEC 62899-301-3:2024 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing; 37.100.01 - Graphic technology in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62899-301-3:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62899-301-3 ®

Edition 1.0 2024-09

INTERNATIONAL

STANDARD

Printed Electronics –

Part 301-3: Equipment – Contact printing – Rigid master – Method to measure

the shape errors of printing plate rollers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62899-301-3 ®

Edition 1.0 2024-09

INTERNATIONAL

STANDARD

Printed Electronics –

Part 301-3: Equipment – Contact printing – Rigid master – Method to measure

the shape errors of printing plate rollers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.080; 37.100.01 ISBN 978-2-8322-9717-9

– 2 – IEC 62899-301-3:2024 © IEC 2024

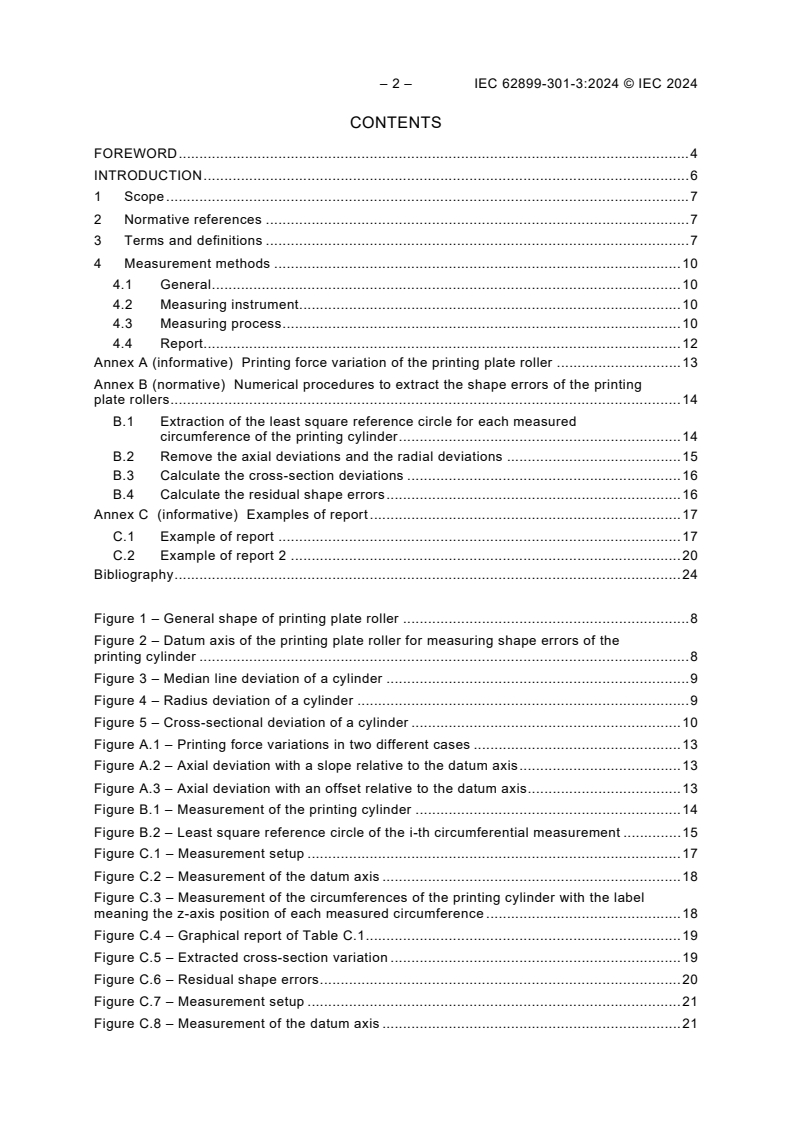

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Measurement methods . 10

4.1 General . 10

4.2 Measuring instrument. 10

4.3 Measuring process . 10

4.4 Report. 12

Annex A (informative) Printing force variation of the printing plate roller . 13

Annex B (normative) Numerical procedures to extract the shape errors of the printing

plate rollers . 14

B.1 Extraction of the least square reference circle for each measured

circumference of the printing cylinder . 14

B.2 Remove the axial deviations and the radial deviations . 15

B.3 Calculate the cross-section deviations . 16

B.4 Calculate the residual shape errors . 16

Annex C (informative) Examples of report . 17

C.1 Example of report . 17

C.2 Example of report 2 . 20

Bibliography . 24

Figure 1 – General shape of printing plate roller . 8

Figure 2 – Datum axis of the printing plate roller for measuring shape errors of the

printing cylinder . 8

Figure 3 – Median line deviation of a cylinder . 9

Figure 4 – Radius deviation of a cylinder . 9

Figure 5 – Cross-sectional deviation of a cylinder . 10

Figure A.1 – Printing force variations in two different cases . 13

Figure A.2 – Axial deviation with a slope relative to the datum axis . 13

Figure A.3 – Axial deviation with an offset relative to the datum axis . 13

Figure B.1 – Measurement of the printing cylinder . 14

Figure B.2 – Least square reference circle of the i-th circumferential measurement . 15

Figure C.1 – Measurement setup . 17

Figure C.2 – Measurement of the datum axis . 18

Figure C.3 – Measurement of the circumferences of the printing cylinder with the label

meaning the z-axis position of each measured circumference . 18

Figure C.4 – Graphical report of Table C.1 . 19

Figure C.5 – Extracted cross-section variation . 19

Figure C.6 – Residual shape errors . 20

Figure C.7 – Measurement setup . 21

Figure C.8 – Measurement of the datum axis . 21

Figure C.9 – Measurement of the circumferences of the printing cylinder with the label

meaning the z-axis position of each measured circumference . 22

Figure C.10 – Graphical report of Table C.2 . 22

Figure C.11 – Extracted cross-section variation . 23

Figure C.12 – Residual shape errors . 23

Table 1 – Guideline for the sample points on each circumferential measurement . 11

Table B.1 – Report form for the axial deviations and radial deviations of the printing

cylinder . 15

Table C.1 – Report for the axial deviations and radial deviations of the printing cylinder

fitted from measured circumferences given in Figure C.3 . 19

Table C.2 – Report for the axial deviations and radial deviations of the printing cylinder

fitted from measured circumferences given in Figure C.9 . 22

– 4 – IEC 62899-301-3:2024 © IEC 2024

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRINTED ELECTRONICS –

Part 301-3: Equipment – Contact printing – Rigid master –

Method to measure the shape errors of printing plate rollers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 62899-302-3 has been prepared by IEC technical committee 119: Printed Electronics. It is

an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

119/505/FDIS 119/511/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 62899 series, published under the general title Printed electronics,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62899-301-3:2024 © IEC 2024

INTRODUCTION

The term "printed electronics" can be easily understood in that this industry involves electronic

devices and products that are manufactured by using state-of-the-art printing techniques,

otherwise known as additive processes. Printing methods have been widely used in textile and

paper type substrates for centuries. In the past, the advent of mass producible printouts had a

significant impact on how knowledge is stored, transferred and reproduced. At this current stage

of technological development, printing on either rigid or flexible substrates is considered to

supplement or replace traditional electronic device manufacturing processes. The difference

between media printing and printed electronics stems from the fact that media print is used to

convey information for humans to process using their eyes while printed electronics requires

machines to process electronic information; the level of resolution and functionality required

makes the difference. Some of the widely used functional materials for printed electronics are,

but not limited to, nano- or micro-size metal particles, semiconductive polymers, and dielectric

materials. Due to the available and required readout resolution, small feature sizes below 20 µm

will necessarily be printed. Layer thickness and registration accuracy of printed products are

closely related to the quality control of electronic devices with ink materials requiring a high

level of quality. Overall, printing tolerance is much smaller in printed electronics.

There are two main categories in the printing process for printed electronics. One is a non-

contact printing process, such as inkjet printing or an electrostatic discharge (ESD) printing

process. The other is a contact printing process, such as gravure printing, gravure offset printing,

reverse offset printing and screen printing. This document provides a proposal for measuring

and assessing the printing master. Therefore, the scope is limited to the printing process using

the printing master.

The quality of the printing master is important because the ink is transferred from the printing

master to the substrate directly in these processes, which means that the quality of the results

of the printed circuit depends on the quality of the printing master. For the mass production of

printed electronic devices, many companies, such as device manufacturers, printing master

manufacturers and printing master manufacturing equipment vendors, are related to

manufacturing and thus they will use a printing master and standardized measurement and

assessment methods.

Printed electronics requires more precise dimensional control than conventional media printing

as mentioned above. It means that the evaluation of printing plate rollers is critical to achieving

the reliable production of high-resolution patterns and the reduction of printing registration

errors. One of the most important performance parameters of the printing plate roller is the

dynamic error in actual printing equipment during actual printing. The dynamic error of the

printing plate roller causes the changes in the printing process condition, such as the printing

pressure and the synchronization error between the roller and the substrate. Such a dynamic

error results in printed linewidth variations and printing registration errors. The dynamic error is

the combined results of the shape errors of the printing plate roller, the motion guiding error of

the bearing assembly, and the unexpected deformation of the roller by the external load

including self-gravity load. To reduce the occurrence of dynamic errors of the printing plate

roller, each contributor to the dynamic error of the printing plate roller will be evaluated. For the

first step to evaluate the dynamic error of the printing plate roller, this document focuses on

measuring the shape errors of the printing plate roller.

PRINTED ELECTRONICS –

Part 301-3: Equipment – Contact printing – Rigid master –

Method to measure the shape errors of printing plate rollers

1 Scope

This part of IEC 62899 defines measurement terms and methods related to the shape errors of

printing plate rollers. Measurement terms include radius, total run-out, and three kinds of shape

errors of printing plate rollers that are axial deviation, radial deviation, and cross-sectional

deviation. The remaining shape error excluding the three errors mentioned above is defined as

a residual shape error.

This document applies to printing plate rollers with or without patterns while excluding the

pattern area for the measurement.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

ISO 1101, Geometrical product specifications (GPS) – Geometrical tolerancing – Tolerances of

form, orientation, location and run-out

ISO 12180-1:2011, Geometrical product specifications (GPS) – Cylindricity – Part 1: Vocabulary

and parameters of cylindrical form

ISO 12180-2, Geometrical product specifications (GPS) – Cylindricity – Part 2: Specification

operators

ISO 12181-2, Geometrical product specifications (GPS) – Roundness – Part 2: Specification

operators

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...