EN 13445-1:2009

(Main)Unfired pressure vessels - Part 1: General

Unfired pressure vessels - Part 1: General

This part of this European Standard defines the terms, definitions, quantities, symbols and units that are used

throughout the EN 13445. It also contains instructions on how to use the standard (Annex A) as well as an index

which covers the whole standard (Annex B). This information is aimed to aid the user of the EN 13445.

This European Standard applies to unfired pressure vessels with a maximum allowable pressure greater than 0,5

bar gauge but may be used for vessels operating at lower pressures, including vacuum.

NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during

operation are covered in EN 764-7.

This European Standard is not applicable to pressure vessels of the following types:

- vessels of riveted construction;

- vessels of lamellar cast iron or any other materials not included in parts 2, 6, or 8 of the standard;

- multilayered, autofrettaged or pre-stressed vessels;

This European standard may be applied to the following vessels, provided that account is taken of additional and/or

alternative requirements resulting from the hazard analysis:

- transportable vessels;

- items specifically designed for nuclear use;

- pressure vessels with a risk of overheating

Other European standards apply to industrial piping (EN 13480) and to water tube and shell boilers (EN 12952 and

12953).

Unbefeuerte Druckbehälter - Teil 1: Allgemeines

Dieser Teil der Europäischen Norm legt die für die gesamte EN 13445 geltenden Begriffe, Größen, Symbole und

Einheiten fest. Er enthält ferner Anleitungen für die Anwendung der Norm (Anhang A) sowie einen Index, der die

gesamte Norm abdeckt (Anhang B). Diese Information soll dem Anwender der EN 13445 als Hilfestellung dienen.

Diese Europäische Norm gilt für unbefeuerte Druckbehälter mit einem maximal zulässigen Druck über 0,5 bar, sie

kann jedoch auch für Behälter angewendet werden, die bei niedrigeren Drücken, einschließlich Vakuum, betrieben

werden.

ANMERKUNG Auswahl, Anwendung und der Einbau von Sicherheitseinrichtungen zum Schutz der Druckbehälter während

des Betriebs sind in EN 764-7 festgelegt.

Diese europäische Norm gilt nicht für Druckbehälter folgender Bauarten:

- Behälter mit Nietverbindungen;

- Behälter aus Gusseisen mit Lamellengraphit oder anderen Werkstoffen, die nicht in den Teilen 2, 6 oder 8

dieser Norm festgelegt sind;

- Mehrlagenbehälter, kaltgereckte (Autofrettage) oder vorgespannte Behälter.

Unter der Voraussetzung, dass zusätzliche und/oder alternative Anforderungen berücksichtigt werden, die aus der

Gefahrenanalyse resultieren, darf diese europäische Norm für folgende Behälterarten angewandt werden:

- transportable Behälter;

- speziell für die Kerntechnik ausgelegte Behälter;

- überhitzungsgefährdete Druckbehälter.

Andere europäische Normen gelten für industrielle Rohrleitungen (EN 13480) sowie für Wasserrohrkessel und

Großwasserraumkessel (EN 12952 und 12953).

Récipients sous pression non soumis à la flamme - Partie 1 : généralités

La présente partie de cette Norme Européenne définit les termes, définitions, grandeurs, symboles et unités utilisés

tout au long de l’EN 13445. Elle contient également des instructions sur le mode d’utilisation de la norme

(Annexe A) ainsi qu’un index qui couvre l’ensemble de la norme (Annexe B). Ces informations sont destinées à

aider l’utilisateur de l’EN 13445.

La présente Norme Européenne s’applique aux récipients sous pression non soumis à la flamme, ayant une

pression maximale admissible supérieure à 0,5 bar, mais elle peut être utilisée pour des récipients soumis à des

pressions inférieures, y compris le vide.

NOTE Le choix, la mise en oeuvre et l’installation des accessoires de sécurité destinés à protéger les récipients sous

pression en service font l’objet de l’EN 764-7.

Cette Norme européenne ne s'applique pas aux récipients sous pression suivants :

- récipients rivetés ;

- récipients en fonte lamellaire ou tout autre matériau non inclus dans les Parties 2, 6 ou 8 de la norme ;

- récipients muti-couches, autofrettés ou pré-contraints ;

Cette Norme européenne peut être appliquée aux récipients suivants, sous réserve de prendre en compte les

exigences additionnelles et/ou alternatives résultant de l'analyse des phénomènes dangereux :

- récipients sous pression transportables ;

- récipients conçus spécifiquement pour les applications nucléaires ;

- récipients sous pression présentant un risque de surchauffe.

D'autres Normes européennes s'appliquent aux tuyauteries industrielles (EN 13480) et aux chaudières à tube

d'eau et à tube de fumée (EN 12952 et 12953).

Neogrevane tlačne posode - 1. del: Splošno

General Information

- Status

- Withdrawn

- Publication Date

- 21-Jul-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 54 - Unfired pressure vessels

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Sep-2014

- Completion Date

- 09-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 25-Jul-2009

- Effective Date

- 25-Jul-2009

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 17-Sep-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13445-1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Unfired pressure vessels - Part 1: General". This standard covers: This part of this European Standard defines the terms, definitions, quantities, symbols and units that are used throughout the EN 13445. It also contains instructions on how to use the standard (Annex A) as well as an index which covers the whole standard (Annex B). This information is aimed to aid the user of the EN 13445. This European Standard applies to unfired pressure vessels with a maximum allowable pressure greater than 0,5 bar gauge but may be used for vessels operating at lower pressures, including vacuum. NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during operation are covered in EN 764-7. This European Standard is not applicable to pressure vessels of the following types: - vessels of riveted construction; - vessels of lamellar cast iron or any other materials not included in parts 2, 6, or 8 of the standard; - multilayered, autofrettaged or pre-stressed vessels; This European standard may be applied to the following vessels, provided that account is taken of additional and/or alternative requirements resulting from the hazard analysis: - transportable vessels; - items specifically designed for nuclear use; - pressure vessels with a risk of overheating Other European standards apply to industrial piping (EN 13480) and to water tube and shell boilers (EN 12952 and 12953).

This part of this European Standard defines the terms, definitions, quantities, symbols and units that are used throughout the EN 13445. It also contains instructions on how to use the standard (Annex A) as well as an index which covers the whole standard (Annex B). This information is aimed to aid the user of the EN 13445. This European Standard applies to unfired pressure vessels with a maximum allowable pressure greater than 0,5 bar gauge but may be used for vessels operating at lower pressures, including vacuum. NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during operation are covered in EN 764-7. This European Standard is not applicable to pressure vessels of the following types: - vessels of riveted construction; - vessels of lamellar cast iron or any other materials not included in parts 2, 6, or 8 of the standard; - multilayered, autofrettaged or pre-stressed vessels; This European standard may be applied to the following vessels, provided that account is taken of additional and/or alternative requirements resulting from the hazard analysis: - transportable vessels; - items specifically designed for nuclear use; - pressure vessels with a risk of overheating Other European standards apply to industrial piping (EN 13480) and to water tube and shell boilers (EN 12952 and 12953).

EN 13445-1:2009 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13445-1:2009 has the following relationships with other standards: It is inter standard links to EN 13445-1:2002/A3:2007, EN 13445-1:2002/A1:2007, EN 13445-1:2002/A2:2006, EN 13445-1:2002, EN 13445-1:2014, EN 13445-8:2009, EN 13445-6:2009, EN 13445-2:2009, EN 764-3:2002, EN 764-2:2002, EN 13445-5:2009, EN 764-1:2004, EN 13445-3:2009, EN 13445-4:2009, CEN/TR 13445-102:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13445-1:2009 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13445-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Unbefeuerte Druckbehälter - Teil 1: AllgemeinesRécipients sous pression non soumis à la flamme - Partie 1 : généralitésUnfired pressure vessels - Part 1: General23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 13445-1:2009SIST EN 13445-1:2009en,fr,de01-november-2009SIST EN 13445-1:2009SLOVENSKI

STANDARDSIST EN 13445-1:2002/A3:2007SIST EN 13445-1:2002/A2:2007SIST EN 13445-1:2002/A1:20091DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13445-1July 2009ICS 23.020.30Supersedes EN 13445-1:2002

English VersionUnfired pressure vessels - Part 1: GeneralRécipients sous pression non soumis à la flamme - Partie 1: généralitésUnbefeuerte Druckbehälter - Teil 1: AllgemeinesThis European Standard was approved by CEN on 30 June 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13445-1:2009: ESIST EN 13445-1:2009

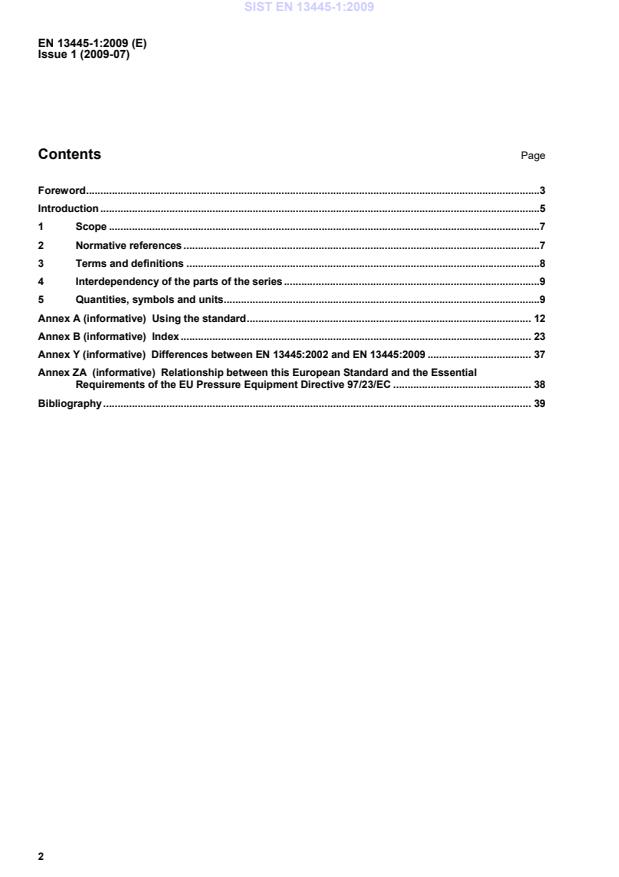

Using the standard.12 Annex B (informative)

Index.23 Annex Y (informative)

Differences between EN 13445:2002 and EN 13445:2009.37 Annex ZA

(informative)

Relationship between this European Standard and the Essential Requirements of the EU Pressure Equipment Directive 97/23/EC.38 Bibliography.39

Issue 1 (2009-07) 3 Foreword This document (EN 13445-1:2009) has been prepared by Technical Committee CEN/TC 54 “Unfired pressure vessels”, the secretariat of which is held by BSI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by December 2009, and conflicting national standards shall be withdrawn at the latest by December 2009. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative annex ZA, which is an integral part of this document. This European Standard concerning “Unfired pressure vessels” comprises the following Parts: ⎯ Part 1: General. ⎯ Part 2: Materials. ⎯ Part 3: Design. ⎯ Part 4: Fabrication. ⎯ Part 5: Inspection and testing. ⎯ Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron. ⎯ CR 13445-7, Unfired pressure vessels — Part 7: Guidance on the use of conformity assessment procedures.

⎯ Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys. ⎯ CEN/TR 13445-9, Unfired pressure vessels — Part 9: Conformance of EN 13445 series to ISO 16528. Although these Parts may be obtained separately, it should be recognised that the Parts are inter-dependant. As such the manufacture of unfired pressure vessels requires the application of all the relevant Parts in order for the requirements of the Standard to be satisfactorily fulfilled. Corrections to the standard interpretations where several options seem possible are conducted through the Migration Help Desk (MHD). The link and information related to the Help Desk can be found at http://www.cen.eu/cenorm/sectors/sectors/mechanicalengineering/pressure/index.asp. A form for submitting questions can be downloaded from the link to the MHD website. After subject experts have agreed an answer, the answer will be communicated to the questioner. Corrected pages will be given specific issue number and issued by CEN according to CEN Rules. Interpretation sheets will be posted on the website of the MHD. SIST EN 13445-1:2009

Issue 1 (2009-07) 5 Introduction EN 13445 specifies the requirements for design, construction, inspection and testing of unfired pressure vessels. It defines terms, definitions and symbols applicable to unfired pressure vessels.

NOTE In EN 13445 the term pressure vessel includes the welded attachments up to and including the nozzle flanges, screwed or welded connections, or the edge to be welded at the first circumferential weld at connecting piping or other elements. The term unfired excludes vessels that are subject to direct generated heat or flame impingement from a fired process. This does not exclude vessels subject to electrical heating or heated process streams.

In Parts 2 to 5 only pressure vessels manufactured from steels and steel castings as detailed in Part 2 of this standard are covered. Parts 6 and 8 specifically deal with vessels of spheroidal graphite cast iron and aluminium, respectively, where special considerations apply. Part 1 This part contains general information on the scope of the standard as well as terms, definitions, quantities, symbols and units which are applied throughout the standard. NOTE It is intended to revise EN 764-2:2002 for consistence, with EN 13445. Part 2 This part deals with the general philosophy on materials, material grouping and low temperature behaviour. It is limited to steel with sufficient ductility and, for components operating in the creep range, sufficient creep ductility.

Part 2 also provides the general requirements for establishing technical delivery conditions and the requirements for marking of material.

Part 3 This part of the standard gives the rules to be used for design and calculation under internal and/or external pressure (as applicable), local loads and actions other than pressure. The rules provided are both design by formulae (DBF), design by analysis (DBA) and design by experiment (DBE). The part also sets the requirements for when fatigue analysis must be performed and the rules to be followed when this is the case. NOTE Collaborative work is in hand to harmoniz flange design across European standards. Part 4 This part is based on existing good practice in previous national European Standards on manufacturing. It covers forming, welding procedures and welding qualification, production testing, and post weld heat treatment and repairs. Rules are also provided for material traceability and tolerances. Part 5 This part covers all those inspection and testing activities associated with the verification of the pressure vessel for compliance with the standard, including design review by the manufacturer and supporting technical documentation, NDT and other inspection activities including document control, material traceability, joint preparation and welding. SIST EN 13445-1:2009

Part 8 This part contains special rules for material, design, fabrication, inspection, and testing of pressure vessels made from aluminium and aluminium alloys. In general the rules in the relevant parts of parts 2–5 apply with additions and exceptions outlined in this part. Part 9 This part details the conformance of the whole EN 13445 series to ISO 16528-1 "Boilers and pressure vessels — Part 1: Performance requirements". This is a CEN Technical Report. The first edition is limited to vessels of steel construction, but will be amended later to include spheroidal graphite cast iron and aluminium. SIST EN 13445-1:2009

Issue 1 (2009-07) 7 1 Scope 1.1

This part of this European Standard defines the terms, definitions, quantities, symbols and units that are used throughout the EN 13445. It also contains instructions on how to use the standard (Annex A) as well as an index which covers the whole standard (Annex B). This information is aimed to aid the user of the EN 13445.

This European Standard applies to unfired pressure vessels with a maximum allowable pressure greater than 0,5 bar gauge but may be used for vessels operating at lower pressures, including vacuum. NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during operation are covered in EN 764-7. 1.2 Exclusions This European Standard is not applicable to pressure equipment of the following types: a) transportable pressure equipment; b) items specifically designed for nuclear use, the failure of which may cause a release of radioactivity; c) pressure equipment intended for the generation of steam or superheated water at temperatures higher than 110 °C; d) vessels of riveted construction; e) vessels of lamellar cast iron or any other materials not included in parts 2, 6, or 8 of the standard; f) multilayered, autofrettaged or pre-stressed vessels; g) pipelines and industrial piping. 2 Normative references This European Standard incorporates, by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments)

EN 764-1:2004, Pressure Equipment — Part 1: Terminology — Pressure, temperature, volume, nominal size. EN 764-2:2002, Pressure Equipment — Part 2: Quantities, symbols and units. EN 764-3:2002, Pressure Equipment — Part 3: Definition of parties involved. EN 13445-2:2009, Unfired pressure vessels — Part 2: Materials. EN 13445-3:2009, Unfired pressure vessels — Part 3: Design. EN 13445-4:2009, Unfired pressure vessels — Part 4: Fabrication. SIST EN 13445-1:2009

NOTE A vessel may be composed of more than one chamber. 3.3 fluid gas, liquid and vapour in their pure phase as well as mixtures thereof

NOTE A fluid may contain a suspension of solids. 3.4 piping pipe or system of pipes, tubing, fittings, expansion joints, hoses or other pressure-bearing components, intended for the transport of fluid, connected together and integrated into a pressure system 3.5 assembly several pieces of pressure equipment assembled by a manufacturer to constitute an integrated and functional whole 3.6 pipelines piping or system of piping designed for the conveyance of any fluid or substance to or from an installation (onshore or offshore) starting from and including the first isolation device located within the installation and including all the annexed equipment designed specifically for pipelines 3.7 maximum allowable pressure (PS) maximum pressure for which the pressure vessel is designed as specified by the manufacturer

3.8 maximum/minimum allowable temperature (TS) maximum/minimum temperature for which the pressure vessel is designed as specified by the manufacturer 3.9 testing group one of the four groups designed to specify the extent of non-destructive testing and destructive testing necessary in association with joint coefficient, material grouping, welding process, maximum thickness, service temperature range SIST EN 13445-1:2009

Issue 1 (2009-07) 9 NOTE The testing group of a vessel is not linked to the hazard category. 3.10 joint coefficient reduction coefficient related to the testing group and which is applied to the nominal design stress 3.11 required thickness thickness excluding corrosion or any other allowances specified in EN 13445 3.12 hazard category category of the pressure vessel taking into account the potential hazards 3.13 testing factor a factor taking into account the amount of NDT testing in castings, applied on the nominal design stress 3.14 material manufacturer individual or organization that produces material in the basic product form used in the manufacture of pressure equipment 3.15 manufacturer individual or organization that is responsible for design, fabrication, testing, inspection, installation of pressure equipment and assemblies where relevant NOTE 1 The manufacturer may subcontract one or more of the above mentioned tasks under its responsibility. NOTE 2 In EU member states the manufacturer is responsible for compliance with the Pressure Equipment Directive 97/23/EC. For those manufacturers outside the EU their authorized representative inside the EU assumes this responsibility.

3.16 weldment weld metal, heat affected zone and adjacent base material(s) 4 Interdependency of the parts of the series Parts 2 to 6 and part 8 of EN 13445, together with Part 1, form a consistent set of specifications which shall be followed for compliance to the standard. NOTE Parts 7 and 9 of this series are published as a CEN Report and a CEN Technical Report respectively. They are not European Standards. 5 Quantities, symbols and units Quantities, symbols and units to be used for pressure equipment shall be in accordance with Tables 5-1 and 5-2 and EN 764-2:2002

NOTE 1 Other symbols used in specific parts of this European Standard are tabulated in the relevant part. SIST EN 13445-1:2009

Therefore when indicating quantities it is recommended that decimal multiple or sub-multiple quantities be chosen such that the resulting values are easy to handle, e.g. between 0,1 and 1 000. The non-SI units, bar for pressure and L for volume should be used on the nameplate. Table 5-1 — Quantities for space and time Quantity Symbol Unit Time t s, min, h Frequency f Hz Dimension any Latin letter a mm Length l mm Thickness e mm Corrosion allowance c mm Diameter d, D mm Radius r, R mm Area A, S mm2 Volume, capacity V mm3 b c Weight W N, kN Density ρ kg/mm3 d Second moment of area Ι mm4 Section modulus Z mm3 Acceleration γ m/s2 Plane angle any Greek letter a rad, ° a Symbols may use any lower-case letter, except for those defined elsewhere in this table. b volume may also be given in m3 or L. c litre "L" is a non-SI unit which may be used with SI units and their multiples. d Density may also be given in kg/m3. SIST EN 13445-1:2009

Issue 1 (2009-07) 11 Table 5-2 — Mechanical quantities

Quantity a Symbol b Unit Force F N Moment M N.mm Pressure p, P

bar c, MPa Temperature T °C Linear expansion coefficient α μm/m°C Normal stress σ MPa Shear stress τ MPa Nominal design stress f MPa Tensile strength

Rm MPa Yield strength Re MPa 1 % proof strength Rp1.0 MPa Proof strength at temperature T Rp/T MPa Upper yield strength

ReH MPa 0,2 % proof strength

Rp0,2 MPa 0,2 % proof strength at temperature T Rp0,2/T MPa Ultimate tensile strength at temperature T Rm/T MPa Modulus of elasticity E MPa Shear modulus G MPa Poisson's ratio υ - Strain ε % Elongation after rupture/fracture A % Impact

energy KV J Hardness

HB,HV - Joint coefficient z - Safety factor S - a Quantities without a temperature index normally refer to room temperature. b Some of these symbols, such as R, f, are not part of ISO 31. c

"bar" is a non-SI unit which may be used with SI units and their multiples. .The unit bar shall be used on nameplates, certificates, drawings, pressure gauges and instrumentation and is always used as a gauge pressure. This is in line with the requirements of the Pressure Equipment Directive 97/23/EC. Note

The use of symbols for temperature may be different from the PED. SIST EN 13445-1:2009

Using the standard A.1 Purpose EN 13445 is a new standard (first issued in 2002) and in many places uses new design, fabrication, inspection, and testing philosophies. This annex is designed to facilitate the introduction to the use of the standard. This annex only gives a general overview of the requirements of the standard. Reference must always be made to the standard text itself, and not all requirements are necessarily mentioned in this annex. A.2 General The standard is harmonized under the Pressure Equipment Directive (97/23/EC). This means that if an unfired pressure vessel meets the requirements of the standard, this pressure vessel can be presumed to conform to those essential safety requirements in Annex I of the Directive which are listed in the Annexes ZA of the individual parts of the standard. In this connection, it should be understood that the standard is indivisible. The design and manufacture of unfired pressure vessels requires the application of all relevant Parts of the standard for the requirements of the standard to be fulfilled. Only in the case that the standard gives no information to specific parts of pressure vessels other standards may be used exceptionally. In such a case, special attention should be paid to ensure that application of such other standard(s) is made consistent with the safety philosophy and the general safety requirements of EN 13445 (i.e. same nominal design stresses, same safety margins, etc.). NOTE Part 7 and Part 9 are not mandatory parts of the standard in this sense. This standard applies to unfired pressure vessels with the limitations and exclusions stated in Clause 1 of EN 13445-1:2009. A.3 Prerequisites Prior to designing and manufacturing a pressure vessel under the standard, the manufacturer must establish a number of prerequisites: ⎯ The conditions under which the vessel will be operating. ⎯ Load cases to be considered are enumerated in 5.3.1 to 5.3.2 of EN 13445-3:2009. ⎯ The category of the vessel (I to IV) as defined in the Directive. Subclause 4.2 of CR 13445-7:2002 and Annex A of CR 13445-7:2002 show how the category of a vessel is to be established. NOTE 1 The category determines the type of inspection document required for the materials of the main pressure-bearing parts, as stated in Annex I, section. 4.3 of the Directive (Inspection Documents are defined in EN 10204:2004). The category may also influence how particular material appraisals (see A.4.2) are to be performed. ⎯ The assessment module (as defined in the directive) to be used. Subclause 4.3 of CR 13445-7:2002 and Annex B of CR 13445-7:2002 describe the different assessment modules and which assessment modules can be used for the different categories. SIST EN 13445-1:2009

Issue 1 (2009-07) 13 NOTE 2 The choice of module may affect the participation of a notified body and/or a recognized third party organization or user inspectorate in the inspection and testing of the vessel as enumerated in Annex C of CR 13445-7:2002. (It should be noted that the use of user inspectorates may not be permitted in all member states). ⎯ The testing group of the vessel according to 6.6.1.1 of EN 13445-5:2009. The available testing groups depend upon the material group, thickness, and welding method. Category 4 is further limited with regards to pressure, temperature, content, number of cycles, design stress, and dimensions.

NOTE 3 The testing group affects not only the testing requirements but also design and manufacturing aspects, e.g., joint coefficient, permitted weld details and required weld production tests.

NOTE 4 Although the same testing group normally applies to the whole vessel, it is (with the exception of Group 4) permissible to have different testing groups apply to different parts (e.g., welds). A.4 Materials A.4.1 General Specific requirements for steels are given in Part 2.

NOTE Specific rules for spheroidal graphite cast iron and aluminium are given in EN13445-6:2009 (see A.8 in this annex) and EN13445-8:2009 (see A.9 in this annex), respectively. In some instances, references may be made from these parts to EN13445-2:2009. A.4.2 Permitted materials Only materials which are qualified for pressure equipment may be used. Qualification of materials can be made in three different ways ⎯ Materials from European harmonized Standards, see 4.3.1 of EN 13445-2:2009; Certain materials supplied in accordance with European material Standards are accepted as qualified for use in pressure-bearing parts. These materials are enumerated in Table E.2-1 of EN 13445-2:2009. ⎯ Materials with a European Approval for Materials (EAM), see 4.3.2 of EN 13445-2:2009; Materials with an EAM, which states that they can be used for products under the PED, are qualified for use in relevant products according to this standard. EAMs are published in the Official Journal, and the European Commission maintains a list of EAMs on their web site NOTE 1 This web site is presently accessible under the address http://ec.europa.eu/enterprise/pressure_equipment/ped/materials/published_en.html.

⎯ Materials with a Particular Material Appraisal (PMA) , see 4.3.3 of EN 13445-2:2009. Materials, which have been subject to a PMA are qualified. This appraisal is carried out by the manufacturer (and in certain cases checked by a Notified Body).

NOTE 2 The European Commission and Member States have in November 2006 agreed on ”Guiding Principles for the contents of Particular Materials Appraisals. The document is published on, http://ec.europa.eu/enterprise/pressure_equipment/ped/materials/index_en.html. SIST EN 13445-1:2009

Whichever way the material has been qualified, all other rules in Part 2 will have to be fulfilled. A.4.3 Prevention of brittle fracture Rules for prevention against brittle fracture are given in Annex B of EN 13445-2:2009. Three different routes are allowed: ⎯ Code of practice based on operating experience and fracture mechanics (B.2.2 of EN 13445-2:2009). ⎯ Code of more flexibility based on fracture mechanics (B.2.3 of EN 13445-2:2009). ⎯ Application of fracture mechanics analysis (B.2.4 of EN 13445-2:2009). The first two methods are limited to certain materials and thickness. The third method requires detailed work in fracture mechanics and the standard only contains guidance on it. It can only be used after agreement between the concerned parties.

A.4.4 Material grouping Materials are grouped in Table A-1 of EN 13445-2:2009 with respect to major chemical elements, specified minimum tensile test data. This grouping is used throughout the standard to decide design, manufacturing, and inspection aspects. A.5 Design A.5.1 General Most of the requirements for design are to be found in Part 3. NOTE Specific design rules for vessels manufactured from spheroidal graphite cast iron and aluminium are given in EN13445-6:2009 (see A.8 in this annex) and EN13445-8:2009 (see A.9 in this annex), respectively. A.5.2 Design for static loads There are four different methods for design, which can be used either separately or in combination with each other ⎯ Design by formulas (DBF) These rules are contained in Clauses 7 to 16 and 20 to 21 of EN 13445-3:2009 and Annexes F, G, GA and J of EN 13445-3:2009. For simple geometries such as cylinders and spheres, formulas can be given where pressure and geometrical dimensions give the required minimum thicknesses directly. For more complicated geometries, a trial-and-error approach must be used in most cases. The designer will have to assume the analysis thickness(es), and use the formulas to compute the stresses and/or the load ratios as applicable. These stresses and/or load ratios are then compared with allowable values. Figure 5-1 of EN 13445-3:2009 shows the relations between different thickness definitions.

Issue 1 (2009-07) 15 In the design formulas of components having a governing weld, the weakening effect of that weld is accounted for by means of a joint coefficient z. The maximum allowed value of this coefficient depends upon the testing group of the weld as specified in 6.6.1.1 of EN 13445-5:2009.

NOTE 1 Governing welds are listed in 5.6 of EN 13445-3:2009. For two types of components, flange connections and heat exchanger tubesheets, a multiple sets of rules are given (in Clause 11 of EN 13445-3:2009, Annex G of EN 13445-3:2009, and Annex GA of EN 13445-3:2009, in Clause 13 of EN 13445-3:2009 and Annex J of EN 13445-3:2009, respectively). The alternative rules of Annexes G, GA and J of EN 13445-3:2009 are based on more advanced methods than their corresponding main clause, and are expected to lead to more appropriate and less conservative designs. Either set can be used at the designer's option within the limitations given for each set. NOTE 2 Annex G is recommended for the design of flange connections where the flanges are subject to strong leak-tightness requirements, significant thermal cycling, and/or significant additional loads (forces or moments). It implies that the bolt stress is controlled by the use of a defined tightening procedure. NOTE 3 Annex GA is a further development of Annex G. It may be used particularly for flange connections in vessels containing gases or vapours, for which it is necessary to fix a maximum allowable leak rate. NOTE 4 Annex J is recommended for the design of heat exchanger tubesheets subject to relatively low cyclic loading. ⎯ Design by analysis using direct assessment of failure modes (DBA - Direct Route) These rules are contained in Annex B of EN 13445-3:2009.

For each failure mode a specific assessment method is provided (e.g. : limit analysis for assessment of gross plastic deformation, shakedown analysis for progressive deformation). ⎯ Design by analysis using stress categorization (DBA – Method based on stress categories) These rules are contained in Annex C of EN 13445-3:2009. Stresses must be computed (in most cases using finite element methods) and divided into different categories. The stresses in each category are then compared to allowable values for the respective category.

⎯ Design by experiment (DBE) These rules are contained in Annex T of EN 13445-3:2009. Design by experiment always includes a burst test and may be supplemented by control of deformation and a fatigue test. It can either be used separately or as a verification of DBF calculations. DBF is the most common and simple way to design vessels. All DBF rules cover pressure. Non-pressure loads can be taken into account, for some cases, through use of Clause 16. Design by analysis is used to assess structural shapes and load configurations not covered by DBF. It may also be used as an alternative to DBF. Between the two possible DBA routes, that in Annex B of EN 13445-3:2009 is expected to be less conservative or more realistic than that in Annex C of EN 13445-3:2009, as being based on more advanced methods. SIST EN 13445-1:2009

Each vessel which is subjected to more than a certain number (given in Equation 5.4-1 of EN 13445-3:2009) of equivalent full pressure cycles must be checked against fatigue. The standard provides two methods, and either method can be used at the designer's option. ⎯ A simplified fatigue analysis (Clause 17 of EN 13445-3:2009) This simplified method uses coefficients for different geometries and different weld details to compute the maximum number of fatigue cycles allowed. It is essentially applicable to vessels predominantly subject to pressure fluctuations, with however some provisions to account (to a certain extent) for other load fluctuations. It will normally give more conservative results than a detailed fatigue analysis ⎯ A detailed fatigue analysis (Clause 18 of EN 13445-3:2009) This method presumes a detailed stress analysis at all critical points (in practice mostly using finite element methods) In both analyses, the intensity of the fatigue loading is measured, at any vessel point, by a "damage factor" from which the "critical areas" of the vessel can be found. In these areas, more NDT is required, as defined in Annex G of EN 13445-5:2009. A.5.5 Nominal design stresses The nominal design stress f to be introduced into the formulas giving the minimum required thickness or to be used to calculate the allowable stresses shall be computed as detailed in Clause 6 of EN 13445-3:2009 (19.5 of EN 13445-3:2009 for operation in the creep range). SIST EN 13445-1:2009

Issue 1 (2009-07) 17 NOTE 1 The concept of nominal design stress is not used within Annex B of EN 13445-3:2009. In this annex, allowable loads are directly derived from the material characteristics.

NOTE 2 For non-austenitic steels there are two alternative sets of design stresses, the normal one in 6.2 of EN 13445-3:2009 and the Alternative Route in 6.3 of EN 13445-3:2009, which permits higher stresses under certain conditions. A.5.6 Weld details Butt welds are preferred for all welded joints, but joggle joints, joints with permanent backing strips, and lap joints are permitted for certain circumferential joints, provided that the restrictions given in 5.7 of EN 13445-3:2009 are observed. Allowable weld designs with material and geometry limitations are listed in Annex A of EN 13445-3:2009. A.5.7 Access openings The standard specifies a minimum number and size of access openings which are detailed in C.2 to C.4 of EN 13445-5:2009. Rules for closing mechanisms and locking devices are given in C.5 of EN 13445-5:2009. A.6 Manufacturing A.6.1 General Most of the requirements for manufacturing are to be found in EN13445-4:2009. NOTE Specific rules for vessels manufactured from spheroidal graphite cast iron and aluminium

are given in EN13445-6:2009 (see A.8 in this annex) and EN13445-8:2009 (see A.9 in this annex), respectively. A.6.2 Tolerances The standard specifies manufacturing tolerances both for vessel parts themselves and for welds: ⎯ Permitted shape tolerances for vessels under internal pressure are specified in 5.4 of EN 13445-4:2009.

Shape tolerances for vessels under external pressure must not exceed those given for internal pressure, but they must also fulfill the requirements of 8.5.1 and 8.6.1 of EN 13445-3:2009 (cylindrical and conical shells) and 8.7.2 of EN 13445-3:2009

(spherical shells). Larger shape deviations may be accepted, but lead to reduced allowable external pressures. The rules for computing these reduced pressures are given in Annex F of EN 13445-3:2009. Annexes D and E of EN 13445-3:2009

give directions for measuring shape deviations in vessels under external pressure. The rules cited above are absolute requirements of the standard. For other measurements, recommended maximum tolerances are given in the informative Annex A of EN 13445-4:2009.

⎯ There are two sets of requirements on alignment at welds, for middle-line alignment (5.2 of EN 13445-4:2009) and for surface alignment (5.3 of EN 13445-4:2009). Both sets must be observed simultaneously. SIST EN 13445-1:2009

Formulas to compute this deformation are given in 9.2 of EN 13445-4:2009. The requirements for heat treatment after hot forming depend on the material group and on the product form.

If heat treatment is performed, the standard (depending on material group and heat treatment condition) requires tests on test coupons.

The samples, the type of coupons and tests are specified in 9.6 of EN 13445-4:2009. A.6.4 Welding The welding rules are to be found in Clauses 6 and 7 of EN 13445-4:2009. The standard specifies three prerequisites for welding: ⎯ the manufacturer shall have a welding procedure specification (WPS), see 7.2 of EN 13445-4:2009; ⎯ the welding procedure shall be qualified (WPAR) , see 7.3 of EN 13445-4:2009; ⎯ the welder or welding operator shall be qualified, see 7.4 of EN 13445-4:2009. The requirements generally refer to other European Standards, with the addition of some extra requirements regarding mechanical testing of welding procedure qualification tests. A.6.5 Production Tests on Welds In many cases, production tests are required on governing welds (longitudinal and circumferential welds where membrane stresses govern the thickness) as defined in Clause 8 of EN 13445-4:2009. The amount of required production tests is specified in 8.2 of EN 13445-4:2009 (for some special welds in 5.7.4 of EN 13445-3:2009) and depends upon material group, testing group, welding method and material thickness and vary widely from no tests at all to one test per 100 m of weld. When a specified number of tests have passed successfully, the standard allows a reduction in the frequency of the production tests. The actual testing and the acceptance criteria are given in 8.3 and 8.4 of EN 13445-4:2009. A.6.6 PWHT (Post Weld Heat Treatment)

In some cases, the welding procedure will require that a PWHT be carried out after welding as defined in Clause 10 of EN 13445-4:2009. Holding times and holding temperatures are specified in the standard and depend upon material group and nominal thickness. For some material groups, PWHT is waived for low thicknesses, except in special cases, e.g., danger of stress corrosion. For materials submitted to PWHT and which are not listed in Table 10.1-1 of EN 13445-4:2009, this treatment shall be performed according to a procedure established in agreement with the material manufacturer, or in conformity with other recognized codes. If the PWHT temperature is too close to the maximum tempering temperature or the holding time exceeds a certain number, the effect of the PWHT on the mechanical properties must be demonstrated either on test coupons heat treated with the vessel or test coupons subjected to a simulated PWHT. SIST EN 13445-1:2009

Issue 1 (2009-07) 19 A.7 Inspection and testing A.7.1 General Most of the requirements for inspection and testing are to be found in EN13445-5:2009. NOTE Specific rules for vessels manufactured from spheroidal graphite cast iron and aluminium are given in EN13445-6:2009 (see A.8 in this annex) and EN13445-8:2009 (see A.9 in this annex), respectively. A.7.2 Technical documentation The elements of the technical documentation for the vessel are specified in detail in Clause 5 of EN 13445-5:2009. It is also specified how the design review of these documents shall be performed. The required amount of dimensional details is given in Annex B of EN 13445-5:2009. NOTE Depending upon the assessment module selected for the vessel, this review is carried out by the manufacturer only or by the manufacturer and the responsible notified body. A.7.3 Non-destructive testing of welds Subclause 6.6.2 of EN 13445-5:2009 specifies the extent of NDT for different types of welds as a function of the testing group. The testing group determines the value of the joint coefficient used for calculation of the components having governing welds. For the performance of NDT, 6.6.3 of EN 13445-5:2009 specifies the method to be used, depending upon the type of welded joint, but for details about NDT methods, techniques, characterization, and acceptance criteria, reference is made to other specified European Standards with some additional requirements. Critical areas of vessels operating in cyclic service have to be subjected to more extended NDT as specified in Annex G of EN 13445-5:2009.

NOTE Critical areas in fatigue are defined in Clauses 17 and 18 of EN 13445-3:2009. A.7.4 Final assessment

Clause 10 of EN 13445-5:2009 specifies how final assessment shall be performed. Detailed rules are given for the performance of the proof test, including the calculation of the test pressure.

NOTE Depending upon the module selected for the assessment of the vessel, this assessment is carried out by the manufacturer only or by the manufacturer and the responsible notified body. A.7.5 Marking and records Clauses 11 and 12 of EN 13445-5:2009 specify the minimum requirements of marking on the vessel and of the records to be kept for the vessel, respectively. A.8 Pressure vessels constructed from spheroidal graphite cast iron A.8.1 General Special requirements for such vessels (which must lie within the limits determined by Clause 1 and 4.2 of EN 13445-6:2009) are to be found in EN13445-6:2009, which contains additions to and exceptions from the general rules in EN13445-2:2009 to EN13445-5:2009. SIST EN 13445-1:2009

DBE by means of burst tests can also be used, either as sole design method or as a complement to the other methods, depending upon the energy content of the vessel. Part 6 contains its own DBE rules in 5.2.2.1.4 to 5.2.2.1.5 of EN 13445-6:2009. Fatigue must be considered for vessels with more than a certain number of full pressure cycles, this number depending upon testing factor and stress concentration factors as shown in Table 4.1-1 of EN 13445-6:2009. The available methods are described in 5.2.2.1.7 of EN 13445-6:2009 (simplified and detailed assessment, with the detailed rules in Annex D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...