EN 1013:2012

(Main)Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods

Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods

This European Standard specifies the requirements for light transmitting single skin profiled plastics sheets for internal and external walls, roofs and ceilings. It is applicable to single skin sheets which are used as a single layer or when assembled to form a multiple layer construction.

It also specifies the test methods and provides for the evaluation of conformity and marking of the sheets.

Lichtdurchlässige, einschalige profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Dächern, Wänden und Decken - Anforderungen und Prüfverfahren

Diese Europäische Norm legt die Anforderungen an lichtdurchlässige, einschalige, profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Wänden, Dächern und Decken fest. Es ist anwendbar auf einschalige Platten, die als eine Lage oder zum Herstellen eines mehrlagigen Aufbaus verwendet werden.

Die Norm legt auch die Prüfverfahren fest und dient der Konformitätsbewertung und Kennzeichnung der Platten.

Plaques d'éclairement profilées, simple paroi, en matière plastique, pour toitures, bardages et plafonds intérieurs et extérieurs - Exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences relatives aux plaques d'éclairement profilées, simple paroi, en matière plastique pour toitures, bardages et plafonds, intérieurs et extérieurs. Elle est applicable aux plaques simple paroi qui sont mise en œuvre sous forme d'une couche unique ou assemblées pour former une construction à plusieurs couches.

Elle spécifie également les méthodes d'essai ainsi que l'évaluation de la conformité et le marquage des plaques.

Prosojne enoslojne profilirane polimerne plošče za notranje in zunanje strehe, stene in stropove - Zahteve in preskusne metode

Ta evropski standard določa zahteve za prosojne enoslojne profilirane polimerne plošče za notranje in zunanje strehe, stene in stropove. Velja za enoslojne plošče, ki se uporabljajo kot posamezen sloj ali so zložene skupaj in tvorijo večslojno tvorbo. Določa tudi preskusne metode ter podaja vrednotenje skladnosti in označevanje plošč.

General Information

- Status

- Withdrawn

- Publication Date

- 11-Dec-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 128 - Roof covering products for discontinuous laying and products for wall cladding

- Drafting Committee

- CEN/TC 128/SC 9 - Prefabricated accessories for roofing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Dec-2014

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 26-Dec-2012

- Effective Date

- 21-Dec-2011

- Effective Date

- 21-Dec-2011

- Effective Date

- 21-Dec-2011

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Smithers Quality Assessments

US management systems and product certification.

Sponsored listings

Frequently Asked Questions

EN 1013:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods". This standard covers: This European Standard specifies the requirements for light transmitting single skin profiled plastics sheets for internal and external walls, roofs and ceilings. It is applicable to single skin sheets which are used as a single layer or when assembled to form a multiple layer construction. It also specifies the test methods and provides for the evaluation of conformity and marking of the sheets.

This European Standard specifies the requirements for light transmitting single skin profiled plastics sheets for internal and external walls, roofs and ceilings. It is applicable to single skin sheets which are used as a single layer or when assembled to form a multiple layer construction. It also specifies the test methods and provides for the evaluation of conformity and marking of the sheets.

EN 1013:2012 is classified under the following ICS (International Classification for Standards) categories: 83.140.10 - Films and sheets; 91.060.01 - Elements of buildings in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1013:2012 has the following relationships with other standards: It is inter standard links to EN 1013-3:1997, EN 1013-2:1998, EN 1013-1:1997, EN 1013-5:2000, EN 1013-4:2000, EN 1013:2012+A1:2014, EN ISO 472:2001, EN ISO 13468-2:2021, EN ISO 178:2019, CEN ISO/TR 3834-6:2007, EN ISO 9001:2008, EN ISO 11925-2:2010, EN ISO 4892-3:2006, EN ISO 13468-1:2019, EN 13501-5:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1013:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/121, M/122. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1013:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

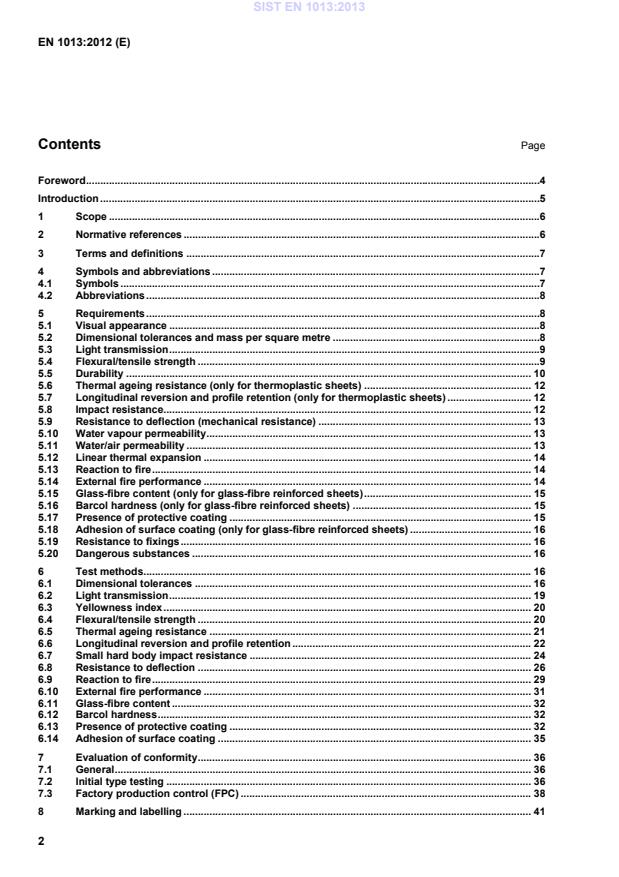

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Lichtdurchlässige, einschalige profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Dächern, Wänden und Decken - Anforderungen und PrüfverfahrenPlaques d'éclairement profilées, simple paroi, en matière plastique, pour toitures, bardages et plafonds intérieurs et extérieurs - Exigences et méthodes d'essaiLight transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods91.060.20StreheRoofs91.060.30Stropi. Tla. StopniceCeilings. Floors. Stairs83.140.10Filmi in folijeFilms and sheets91.060.10Stene. Predelne stene. FasadeWalls. Partitions. FacadesICS:Ta slovenski standard je istoveten z:EN 1013:2012SIST EN 1013:2013en,fr,de01-marec-2013SIST EN 1013:2013SLOVENSKI

STANDARDSIST EN 1013-4:2000SIST EN 1013-5:2000SIST EN 1013-3:1998SIST EN 1013-1:1998SIST EN 1013-2:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1013

December 2012 ICS 83.140.10; 91.060.01 Supersedes EN 1013-1:1997, EN 1013-2:1998, EN 1013-3:1997, EN 1013-4:2000, EN 1013-5:2000English Version

Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods

Plaques d'éclairement profilées, simple paroi, en matière plastique, pour toitures, bardages et plafonds intérieurs et extérieurs - Exigences et méthodes d'essai

Lichtdurchlässige, einschalige profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Dächern, Wänden und Decken - Anforderungen und Prüfverfahren This European Standard was approved by CEN on 20 October 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1013:2012: ESIST EN 1013:2013

Profile terminology . 42A.1 Non-sinusoidal profiles . 42A.2 Sinusoidal profile . 43A.3 Minimum information to be declared . 43Annex B (normative)

Glass content by density of laminate . 44B.1 Determination of density of laminate constituents . 44B.2 Test specimens . 44B.3 Procedure . 44Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 46ZA.1 Scope and relevant characteristics . 46ZA.2 Procedures for the attestation of conformity of light transmitting single skin profiled plastics sheets . 48ZA.3 CE marking and labelling. 53Bibliography . 58 SIST EN 1013:2013

a complete technical review of requirements and test methods, based on the essential characteristics given in Mandates M/121 and M/122;

a technical review of the artificial ageing procedure based on the current test methods, with the possibility to use either the exposition to arc-xenon lamps or to fluorescence UV lamps;

a technical review of the impact resistance of the sheets: in addition to the existing small hard body impact resistance, test methods for assessing the large soft body impact resistance have been added;

introduction of new subclauses for the reaction to fire and external fire performance;

a review of the flexural/tensile strength and the resistance to deflection;

deletion of the hail resistance;

introduction of a new clause dealing with evaluation of conformity; introduction of an informative Annex ZA giving the clauses of this European Standard addressing the provisions of the EU Construction Products Directives. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 1013:2013

EN 508-3 [5] and EN 494 [6]. They do not necessarily have the same span capabilities and alternative fixing specifications are generally required. Reference should be made to national regulations and the manufacturer's literature for requirements concerning design, storage and installation, including all safety aspects, according to the material. SIST EN 1013:2013

ETAG 010, Self supporting translucent roof kits 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 472:2001, EN ISO 1043-1:2011, EN ISO 1043-2:2011 and Annex A and the following apply. 3.1 indirect test (IT) test performed by the manufacturer, different from that specified for that particular characteristic, having verified its correlation with the specified test 3.2 yellowness deviation in chroma from whiteness or water-whiteness in the dominant wavelength range from 570 nm to 580 nm 3.3 yellowness index magnitude in yellowness relative to CIE standard illuminant D 65 3.4 radiant exposure H time integral of irradiance, measured in joules per square metre (J · m-2) [SOURCE: ISO 9370:1997] [7] 4 Symbols and abbreviations 4.1 Symbols An

class for the exposure to artificial accelerated weathering using xenon-arc lamps SIST EN 1013:2013

class for the exposure to artificial accelerated weathering using fluorescent UV lamps H

radiant exposure YI

yellowness index of a test specimen exposed to ageing YI0

yellowness index of a test specimen unexposed to ageing ∆YI

change of the yellowness index after ageing 4.2 Abbreviations FPC factory production control GRA glass-fibre reinforced acrylic (PMMA) GRP glass-fibre reinforced polyester ITT

initial type testing PC

polycarbonate PET

poly(ethylene terephthalate) PMMA poly(methyl methacrylate) PVC-U unplasticised poly(vinyl chloride) PVF

poly(vinyl fluoride) 5 Requirements 5.1 Visual appearance Both sides of the sheets shall be of regular appearance. Visual or tactile examination shall reveal no evidence of any hole, cracking or splitting, and no cluster of bubbles greater than 1 mm in diameter, or inclusions that are likely to affect properties. For GRP sheets, any defects such as resin ribs, glass folds or glass knots shall not exceed 5 mm in diameter. The edges of the sheet shall be straight and clean. Further requirements concerning the visual aspects of the sheets can be agreed upon between the manufacturer and the customer. Where required, the sheet shall be declared as “diffusing” or “non-diffusing” depending on whether the image of an object placed 1 m behind the sheet appears blurred or sharp, respectively. 5.2 Dimensional tolerances and mass per square metre The dimensional tolerances and mass per square metre shall be assessed when subject to regulatory requirement. When measured in accordance with the test methods as specified in 6.1.1 to 6.1.3 and Table 1, the dimensional tolerances and mass per square metre of the sheets shall conform to the requirements given in Table 1. The test methods given in Table 1 are used for initial type testing, and are the reference test methods. Any other indirect test method may be chosen provided that it is sufficiently accurate to ensure that the dimensions SIST EN 1013:2013

6.1.5 The mass per square metre of the material in flat form, prior to profiling, which is the reference value, shall be controlled and declared. The mean value of the mass per square metre shall not vary by more than ± 10 % of the declared nominal mass per square metre. The mass per linear metre of profiled sheet, which can be calculated from the mass per square metre of the material in flat form, may be also declared. Cover width

6.1.6 The measured cover width shall be within ± 0,8 % of the declared nominal cover width. Shape of the sheet profile 6.1.7 When it is intended that the profile of the sheets shall match the shape of a dissimilar material (e.g. metal or fibre cement), the shape of the profile shall match the nominal shape with a maximum tolerance (deviation) at any point of 4 mm. Sheet length 6.1.8 The sheet length shall be within the interval from: 0 mm to + 20 mm of the declared sheet length, for sheet length up to 2,5 m;

0 % to + 0,8 % of the declared sheet length for sheet length greater than 2,5 m. Sheet straightness 6.1.9 The sheet straightness shall be less than or equal to 2,0 mm/m length. Squareness of a sheet 6.1.10 The out of squareness of a sheet shall be less than or equal to 0,5 % of the declared cover width.

5.3 Light transmission The total luminous transmittance shall be determined by testing five samples in accordance with 6.2 and calculating the mean value. The total luminous transmittance based on the mean value shall be declared and the mean value of subsequent measurements shall be within ± 5 % of the declared value. 5.4 Flexural/tensile strength The flexural/tensile strength shall be assessed when subject to regulatory requirement. The flexural strength and flexural modulus or the tensile strength and Young's modulus, as applicable, of the material of the sheets shall be measured in accordance with 6.4. SIST EN 1013:2013

The dimensions of the exposed test pieces shall be sufficient to allow carrying out the light transmission test and the subsequent specific tests. 5.5.3 Variation of the yellowness index after artificial ageing Variation of the yellowness index after artificial ageing shall be assessed when subject to regulatory requirement. The yellowness index shall be measured in accordance with 6.3. The amount of variation in yellowness for each applied class of Table 2 or Table 3, as applicable, shall be declared. The performance at class A3, or B3, as applicable, may be declared but the performance at higher classes of exposure shall only be declared provided that the yellowness index does not change by more than 20 units at any higher class(es) declared. 5.5.4 Variation of the light transmission after artificial ageing Variation of the light transmission after artificial ageing shall be assessed when subject to regulatory requirement. The total luminous transmittance shall be measured in accordance with 6.2. The variation of the total luminous transmittance, û2t, for each applied class of Table 2 or Table 3, as applicable, shall be declared, defined as the percentage reduction of the total luminous transmittance of an unaged sample as follows: 010ttttττττ∆−= (1) where û2t0

is the total luminous transmittance, in percentage, of an unaged sample;

û2t1

is the total luminous transmittance, in percentage, of an aged sample. The performance at class A3 or B3, as applicable, may be declared but the performance at higher classes of exposure shall only be declared provided that the variation of the total luminous transmission is not greater than 20 % at any higher class(es) declared. 5.5.5 Variation of the flexural/tensile strength after ageing The variation of the flexural/tensile strength after ageing shall be assessed when subject to regulatory requirement. SIST EN 1013:2013

The small hard body impact resistance shall be assessed when subject to regulatory requirement. The small hard body impact resistance shall be measured in accordance with 6.7.

5.8.2 Large soft body impact resistance The resistance to large soft body impact depends very heavily on the method of installation and the roof system into which the light transmitting sheet is incorporated, rather than a property of the sheet itself. The large soft body impact resistance of the same product is likely to be different when the same product is used in different roofing systems and/or installed with different methods of installation, and therefore cannot be declared for a particular product. In the absence of an appropriate European test method for sheets, the manufacturer may declare the method of installation for each application, which shall consider the large soft body impact resistance. The manufacturer shall assess the large soft body impact resistance separately in accordance with ETAG 010, EN 14963 or individual national safety requirements for each such application. The test report shall record the test method and the manufacturer's instructions for the installation. NOTE At the date of publication of this document, the following national safety requirements have been identified: DS 1133:1987[8], XP P 38-505:1998[9], XP P 38-506:1999[10], XP P 38-507:2000[11] and ACR[M]001:2005[12]. The user should not assume that the large soft body impact resistance for any one application shall apply to any other application or method of installation. SIST EN 1013:2013

3tE⋅ (2) where E is the flexural modulus as defined in 5.4, in pascals; t

is the nominal thickness of the sheet, in metres. The deflection of a sheet of any given profile can be assumed to be approximately proportional to the material stiffness factor. 5.10 Water vapour permeability The water vapour permeability coefficient shall be assessed when subject to regulatory requirement. The value of the water vapour permeability coefficient of the sheet material according to Table 4 shall be declared when a higher performance is sought for declaration, the water vapour permeability coefficient of the material used for the sheet shall be determined according to EN ISO 12572. Table 4 — Typical values for water vapour permeability coefficient Material Reference value mg/(m·h·Pa) GRA GRP PC PVC-U PMMA 3,8 x 10-5 1,5 x 10-5 3,8 x 10-5 0,8 x 10-5 3,8 x 10-5

5.11 Water/air permeability The water/air permeability shall be assessed when subject to regulatory requirement. All plastics sheets covered by this standard shall be deemed to satisfy the water/air permeability requirement without the need for testing provided that there are no defects in the sheets. The absence of defects shall be evaluated by examination of visual appearance according to 5.1. SIST EN 1013:2013

5.13 Reaction to fire The reaction to fire performance shall be assessed when subject to regulatory requirement. The reaction to fire performance of light transmitting profiled sheets shall be determined in accordance with 6.9 and declared according to EN 13501-1. Test samples shall be the same weight/thickness as the final product. Where there is a range of thicknesses of product, the manufacturer can test at least two thicknesses of sample, and the poorer of the two results can be applied to all products between the two thicknesses tested. Test results shall not be assumed to apply to products thicker than the thickest sample tested, or thinner than the thinnest sample tested. Test results on flat samples shall be applied to all profiles within the product range provided the effect of the profile does not add more than 30 % additional material. Where the effect of the profile adds more than 30 % material, the thickness of the test sample shall be increased to ensure the difference in material mass between the test sample and profiled sheet is less than 30 %. Where the product has no surface protection on the inner surface of the product, or where the surface protection on this surface is a co-extrusion of the same base material, or is less than 75 µm thick, then samples shall be tested either with or without this surface protection. The test results achieved can be applied both to products with or without such surface protection. Where the product has a surface protection which is not co-extruded of a similar material and is more than 75 µm thick, it shall be present on the specimens tested, and the results shall only apply to specimens with such surface protection. 5.14 External fire performance The external fire performance shall be assessed when subject to regulatory requirement. SIST EN 1013:2013

5.17.3 UV protection on PVC-U sheets Where a UV protection layer is provided, the thickness of that layer shall be declared.

When tested in accordance with 6.13.3.2, the thickness of the UV protection layer shall not be less that the declared value. Where UV protection is throughout the thickness of the sheet, the content of the UV protective material shall be declared. When tested in accordance with 6.13.3.3, the content of the UV protective material shall not be less that the declared value. 5.17.4 Durability of coating The tests given in 5.17.2 and 5.17.3 confirm the presence of surface coatings only. The durability of such coatings shall be demonstrated by testing the variations after artificial ageing of the yellowness index and total luminous transmittance (see 5.5.3 and 5.5.4). 5.18 Adhesion of surface coating (only for glass-fibre reinforced sheets) When tested in accordance with 6.14, the adhesion of surface coating shall be considered satisfactory when the coating cannot be pried up (raised up) or peeled on a length more than 3 mm. 5.19 Resistance to fixings The principles of fixing of the sheets shall be declared. The method(s) of installation shall consider resistance to wind loads, snow loads and resistance to large soft body impact which may be assessed separately, e.g. in accordance with the requirements given in EN 14963, EN 1873, ETAG 010, or individual safety national requirements. 5.20 Dangerous substances

Materials used in products shall not release any dangerous substances in excess of the maximum permitted levels specified in a relevant European Standard for the material or permitted in the national regulations of the member state of destination. NOTE See Notes in ZA.1. 6 Test methods 6.1 Dimensional tolerances 6.1.1 General

The measurements shall be carried out either at an ambient temperature of (20 ± 5) °C or, when this is not possible, a correction factor according to 5.12 shall be applied from the test temperature to 20 °C. SIST EN 1013:2013

The first and the last measurements shall be within 25 mm of the sheet edges.

Nine values shall be recorded and their mean value calculated to the nearest 0,01 mm. 6.1.5 Mass per square metre The reference test method is to measure the weight of a full width sample of profiled sheet, approximately 1 m length, to the nearest gram. The ‘extended’ width of the profiled sample shall be measured by: applying a piece of non-stretching tape (e.g. masking tape or glass filament tape) to the top surface of the sample, perpendicular to the corrugations, ensuring it is in direct contact with the sample surface across the whole width; marking the position of the edges of the sample sheet on the tape; removing the tape and apply to a flat surface; measuring the distance between the two marks. The overall width of the sample shall be measured (between the two outer edges) to the nearest mil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...