EN 14025:2013

(Main)Tanks for the transport of dangerous goods - Metallic pressure tanks - Design and construction

Tanks for the transport of dangerous goods - Metallic pressure tanks - Design and construction

This European Standard specifies the minimum requirements for the design and construction of metallic pressure tanks having a maximum working or test pressure exceeding 50 kPa (0,5 bar), for the transport of dangerous goods by road and rail and sea. This European Standard includes requirements for openings, closures and structural equipment; it does not cover requirements of service equipment. For tanks for the transport of cryogenic liquids, EN 13530-1 and EN 13530-2 apply.

NOTE Design and construction of pressure tanks according to the scope of this European Standard are primarily subject to the requirements of RID/ADR, 6.8.2.1, 6.8.3.1 and 6.8.5, as relevant. In addition, the relevant requirements of RID/ADR, columns 12 and 13 of Table A to chapter 3.2, 4.3 and 6.8.2.4 apply. For the structural equipment subsections 6.8.2.2 and 6.8.3.2 apply, as relevant. The definitions of RID/ADR 1.2.1 are referred to. For portable tanks see also Chapter 4.2 and Sections 6.7.2 and 6.7.3 of RID and ADR. In addition, the relevant requirements of RID/ADR, columns 10 and 11 of Table A to Chapter 3.2, 4.2, 6.7.2 and 6.7.3 apply.

The paragraph numbers above relate to the 2013 issue of RID/ADR which are subject to regular revisions. This can lead to temporary non-compliances with EN 14025. It is important to know that requirements of RID/ADR take precedence over any clause of this standard.

If not otherwise specified, provisions which take up the whole width of the page apply to all kind of tanks. Provisions contained in a single column apply only to:

road and rail pressure tanks according to RID/ADR chapter 6.8 (left-hand column); portable tanks according to RID/ADR chapter 6.7 (right-hand column).

Tanks für die Beförderung gefährlicher Güter - Metallische Drucktanks - Auslegung und Bau

Diese Europäische Norm legt die Mindestanforderungen für Auslegung und Bau von metallischen Drucktanks mit einem maximalen Betriebs- oder Prüfdruck von mehr als 50 kPa (0,5 bar) für die Beförderung gefährlicher Güter auf der Straße, mit der Eisenbahn und mit Seeschiffen fest. Diese Europäische Norm enthält Anforderungen an Öffnungen, Verschlüsse und die bauliche Ausrüstung; Anforderungen an die Bedienungsausrüstung werden nicht behandelt. Zu Tanks für die Beförderung von tiefkalten Flüssigkeiten siehe EN 13530-1 und EN 13530 2.

ANMERKUNG 1 Auslegung und Bau von Drucktanks entsprechend des Anwendungsbereichs dieser Europäischen Norm unterliegen im Wesentlichen den zutreffenden Vorschriften in 6.8.2.1, 6.8.3.1 und 6.8.5 der RID/des ADR. Zusätzlich gelten außerdem die zutreffenden Anforderungen nach Kapitel 3.2, Tabelle A, Spalten 12 und 13, 4.3 und 6.8.2.4 der RID/des ADR. Für die bauliche Ausrüstung gelten 6.8.2.2 bzw. 6.8.3.2. Auf die in 1.2.1 der RID/des ADR enthaltenen Begriffs¬bestimmungen wird verwiesen. Zu ortsbeweglichen Tanks siehe auch Kapitel 4.2 sowie 6.7.2 und 6.7.3 der RID und des ADR. Darüber hinaus gelten die maßgebenden Anforderungen in Tabelle A, Spalten 10 und 11, 3.2, 4.2, 6.7.2 und 6.7.3 von RID/ADR. Die oben angegebene Nummerierung der Kapitel bezieht sich die Ausgaben der RID/des ADR von 2013, die regelmäßig überarbeitet werden. Daher kann es vorübergehend zu Nichtübereinstimmungen mit EN 14025 kommen. Es wird darauf hingewiesen, dass die Anforderungen der RID/des ADR Vorrang gegenüber den Anforderungen der vorliegenden Norm haben.

ANMERKUNG 2 Diese Norm gilt auch für verflüssigte Gase einschließlich Flüssiggas (LPG); für eine dezidierte LPG-Norm siehe jedoch EN 12493.

Sofern nicht anders festgelegt, gelten die Festlegungen, die die gesamte Breite der Seite einnehmen, für alle Arten von Tanks. Festlegungen in einzelnen Spalten gelten ausschließlich für:

Drucktanks für die Beförderung gefährlicher Güter auf der Straße oder mit der Eisenbahn nach RID/ADR, Kapitel 6.8 (linke Spalte) ortsbewegliche Tanks nach RID/ADR, Kapitel 6.7 (rechte Spalte)

Citernes destinées au transport de matières dangereuses - Citernes métalliques sous pression - Conception et fabrication

La présente Norme européenne spécifie les prescriptions minimales pour la conception et la construction des citernes métalliques sous pression ayant une pression maximale de service ou une pression d’épreuve supérieure à 50 kPa (0,5 bar) utilisées pour le transport de marchandises dangereuses par route, par chemin de fer et par mer. La présente norme inclut les prescriptions relatives aux ouvertures, fermetures et équipements de structure ; elle ne couvre pas les prescriptions relatives aux équipements de service. Pour les citernes destinées au transport de liquides cryogéniques, les EN 13530-1 et EN 13530-2 s’appliquent.

NOTE 1 La conception et la construction des citernes sous pression conformes au domaine d'application de la présente norme sont principalement soumises aux prescriptions des 6.8.2.1, 6.8.3.1 et 6.8.5 du RID/ADR, selon le cas. En outre, les prescriptions pertinentes en colonnes 12 et 13 du Tableau A du Chapitre 3.2, en 4.3 et en 6.8.2.4 du RID/ADR s’appliquent. Pour les équipements de structure, les paragraphes 6.8.2.2 et 6.8.3.2 s'appliquent, selon le cas. Les définitions du 1.2.1 du RID/ADR s’appliquent. Pour les citernes mobiles, voir également le Chapitre 4.2 et les paragraphes 6.7.2 et 6.7.3 du RID et de l’ADR. De plus, les prescriptions pertinentes en colonnes 10 et 11 du Tableau A du Chapitre 3.2, en 4.2, en 6.7.2 et en 6.7.3 du RID/ADR s’appliquent. Les numéros de paragraphe donnés ci-dessus se rapportent aux versions 2013 du RID/ADR, qui font régulièrement l'objet de révisions. Cela peut entraîner des non conformités temporaires à l'EN 14025. Il est important de savoir que les exigences du RID/ADR prennent le pas sur tout article de la présente norme.

NOTE 2 La présente norme s’applique aux gaz liquéfiés, dont le GPL. Pour une norme dédiée au GPL, se reporter toutefois à l’EN 12493.

Sauf indication contraire, les dispositions qui occupent toute la largeur de la page s’appliquent à tous les types de citernes. Les dispositions qui n’occupent qu’une colonne s’appliquent uniquement aux :

camions-citernes et wagons-citernes sous pression conformément au Chapitre 6.8 du RID/ADF (colonne de gauche) ; citernes mobiles conformément au Chapitre 6.7 du RID/ADF (colonne de droite).

Cisterne za prevoz nevarnega blaga - Kovinske tlačne posode - Konstruiranje in izdelava

Ta evropski standard določa minimalne zahteve za konstruiranje in izdelavo kovinskih tlačnih posod z najvišjim delovnim ali preskusnim tlakom nad 50 kPa (0,5 bara) za prevoz nevarnega blaga po cesti, železnici in morju. Ta evropski standard zajema zahteve za odprtine, zaključke in strukturno opremo; ne vključuje zahtev za obratovalno opremo. Za posode za prevoz kriogenih tekočin se uporabljata standarda EN 13530-1 in EN 13530-2. Če ni navedeno drugače, se določbe, ki so navedene na celotni širini strani, uporabljajo za vse vrste posod. Določbe v posameznih stolpcih se uporabljajo samo za: – cestne in železniške tlačne posode v skladu s poglavjem RID/ADR 6.8 (stolpec na levi strani); – prenosne posode v skladu s poglavjem RID/ADR 6.7 (stolpec na desni strani).

General Information

- Status

- Withdrawn

- Publication Date

- 15-Oct-2013

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 296 - Tanks for transport of dangerous goods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Jun-2016

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 5173:2023 - Destructive tests on welds in metallic materials - Bend tests (ISO 5173:2023) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 14025:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tanks for the transport of dangerous goods - Metallic pressure tanks - Design and construction". This standard covers: This European Standard specifies the minimum requirements for the design and construction of metallic pressure tanks having a maximum working or test pressure exceeding 50 kPa (0,5 bar), for the transport of dangerous goods by road and rail and sea. This European Standard includes requirements for openings, closures and structural equipment; it does not cover requirements of service equipment. For tanks for the transport of cryogenic liquids, EN 13530-1 and EN 13530-2 apply. NOTE Design and construction of pressure tanks according to the scope of this European Standard are primarily subject to the requirements of RID/ADR, 6.8.2.1, 6.8.3.1 and 6.8.5, as relevant. In addition, the relevant requirements of RID/ADR, columns 12 and 13 of Table A to chapter 3.2, 4.3 and 6.8.2.4 apply. For the structural equipment subsections 6.8.2.2 and 6.8.3.2 apply, as relevant. The definitions of RID/ADR 1.2.1 are referred to. For portable tanks see also Chapter 4.2 and Sections 6.7.2 and 6.7.3 of RID and ADR. In addition, the relevant requirements of RID/ADR, columns 10 and 11 of Table A to Chapter 3.2, 4.2, 6.7.2 and 6.7.3 apply. The paragraph numbers above relate to the 2013 issue of RID/ADR which are subject to regular revisions. This can lead to temporary non-compliances with EN 14025. It is important to know that requirements of RID/ADR take precedence over any clause of this standard. If not otherwise specified, provisions which take up the whole width of the page apply to all kind of tanks. Provisions contained in a single column apply only to: road and rail pressure tanks according to RID/ADR chapter 6.8 (left-hand column); portable tanks according to RID/ADR chapter 6.7 (right-hand column).

This European Standard specifies the minimum requirements for the design and construction of metallic pressure tanks having a maximum working or test pressure exceeding 50 kPa (0,5 bar), for the transport of dangerous goods by road and rail and sea. This European Standard includes requirements for openings, closures and structural equipment; it does not cover requirements of service equipment. For tanks for the transport of cryogenic liquids, EN 13530-1 and EN 13530-2 apply. NOTE Design and construction of pressure tanks according to the scope of this European Standard are primarily subject to the requirements of RID/ADR, 6.8.2.1, 6.8.3.1 and 6.8.5, as relevant. In addition, the relevant requirements of RID/ADR, columns 12 and 13 of Table A to chapter 3.2, 4.3 and 6.8.2.4 apply. For the structural equipment subsections 6.8.2.2 and 6.8.3.2 apply, as relevant. The definitions of RID/ADR 1.2.1 are referred to. For portable tanks see also Chapter 4.2 and Sections 6.7.2 and 6.7.3 of RID and ADR. In addition, the relevant requirements of RID/ADR, columns 10 and 11 of Table A to Chapter 3.2, 4.2, 6.7.2 and 6.7.3 apply. The paragraph numbers above relate to the 2013 issue of RID/ADR which are subject to regular revisions. This can lead to temporary non-compliances with EN 14025. It is important to know that requirements of RID/ADR take precedence over any clause of this standard. If not otherwise specified, provisions which take up the whole width of the page apply to all kind of tanks. Provisions contained in a single column apply only to: road and rail pressure tanks according to RID/ADR chapter 6.8 (left-hand column); portable tanks according to RID/ADR chapter 6.7 (right-hand column).

EN 14025:2013 is classified under the following ICS (International Classification for Standards) categories: 13.300 - Protection against dangerous goods; 23.020.20 - Vessels and containers mounted on vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14025:2013 has the following relationships with other standards: It is inter standard links to EN 14025:2008, EN 14025:2013+A1:2016, ISO 7005-1:2011, EN ISO 15614-2:2025, EN 10204:2004, EN ISO 15607:2019, EN 13445-8:2021, EN ISO 14732:2025, EN ISO 15614-1:2017, EN 13445-3:2009, EN ISO 5173:2023, EN 1591-1:2024, EN ISO 9606-1:2017, EN ISO 9606-2:2004, EN ISO 3834-1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14025:2013 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14025:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.L]GHODYDTanks für die Beförderung gefährlicher Güter - Drucktanks aus Metall - Auslegung und BauCiternes destinées au transport de matières dangereuses - Citernes métalliques sous pression - Conception et fabricationTanks for the transport of dangerous goods - Metallic pressure tanks - Design and construction23.020.20Posode in vsebniki, montirani na vozilaVessels and containers mounted on vehicles13.300Varstvo pred nevarnimi izdelkiProtection against dangerous goodsICS:Ta slovenski standard je istoveten z:EN 14025:2013SIST EN 14025:2013en,fr,de01-december-2013SIST EN 14025:2013SLOVENSKI

STANDARDSIST EN 14025:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14025

October 2013 ICS 13.300; 23.020.20 Supersedes EN 14025:2008English Version

Tanks for the transport of dangerous goods - Metallic pressure tanks - Design and construction

Citernes destinées au transport de matières dangereuses -Citernes métalliques sous pression - Conception et fabrication

Tanks für die Beförderung gefährlicher Güter - Metallische Drucktanks - Auslegung und Bau This European Standard was approved by CEN on 31 August 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14025:2013: ESIST EN 14025:2013

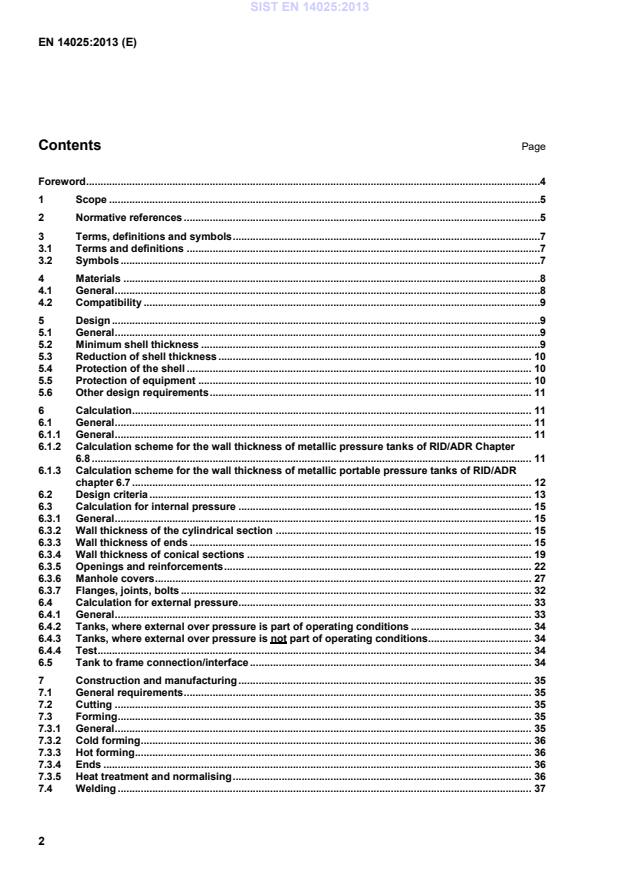

3 7.4.1 Qualification . 37 7.4.2 Welded joints . 37 7.4.3 Examination and testing of welds . 37 7.4.4 Temporary attachments . 38 7.5 Manufacturing tolerances . 39 7.5.1 Plate alignment . 39 7.5.2 Defects of form . 39 7.5.3 Thickness . 40 7.5.4 Dished ends . 40 7.5.5 Cylindrical sections . 40 8 Repairs . 40 8.1 General . 40 8.2 Repair of surface defects in the parent metal . 40 8.3 Repair of weld defects . 41 Annex A (informative)

Sample calculation for tank containers according to RID/ADR Chapter 6.8" . 42 A.1 Introduction . 42 A.2 Dimensions, characteristics of materials, operating and testing conditions . 42 A.3 Calculation according to branch A . 43 A.4 Calculation according to branch B . 44 A.5 Calculation according to branch C . 44 A.6 Calculation according to branch D . 46 A.7 Results . 54 Bibliography . 56

5 1 Scope This European Standard specifies the minimum requirements for the design and construction of metallic pressure tanks having a maximum working or test pressure exceeding 50 kPa (0,5 bar), for the transport of dangerous goods by road and rail and sea. This European Standard includes requirements for openings, closures and structural equipment; it does not cover requirements of service equipment. For tanks for the transport of cryogenic liquids, EN 13530-1 and EN 13530-2 apply. NOTE 1 Design and construction of pressure tanks according to the scope of this European Standard are primarily subject to the requirements of RID/ADR, 6.8.2.1, 6.8.3.1 and 6.8.5, as relevant. In addition, the relevant requirements of RID/ADR, columns 12 and 13 of Table A to chapter 3.2, 4.3 and 6.8.2.4 apply. For the structural equipment subsections 6.8.2.2 and 6.8.3.2 apply, as relevant. The definitions of RID/ADR 1.2.1 are referred to. For portable tanks see also Chapter 4.2 and Sections 6.7.2 and 6.7.3 of RID and ADR. In addition, the relevant requirements of RID/ADR, columns 10 and 11 of Table A to Chapter 3.2, 4.2, 6.7.2 and 6.7.3 apply. The paragraph numbers above relate to the 2013 issue of RID/ADR which are subject to regular revisions. This can lead to temporary non-compliances with EN 14025. It is important to know that requirements of RID/ADR take precedence over any clause of this standard. NOTE 2 This standard is applicable to liquefied gases including LPG, however for a dedicated LPG standard see EN 12493. If not otherwise specified, provisions which take up the whole width of the page apply to all kind of tanks. Provisions contained in a single column apply only to:

road and rail pressure tanks according to RID/ADR chapter 6.8 (left-hand column); portable tanks according to RID/ADR chapter 6.7 (right-hand column). 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 287-1, Qualification test of welders — Fusion welding — Part 1: Steels EN 1418, Welding personnel — Approval testing of welding operators for fusion welding and resistance weld setters for fully mechanized and automatic welding of metallic materials EN 1435, Non-destructive examination of welds — Radiographic examination of welded joints EN 1591-1, Flanges and their joints — Design rules for gasketed circular flange connections — Part 1: Calculation method EN 10204, Metallic products — Types of inspection documents EN 13094:2008, Tanks for the transport of dangerous goods — Metallic tanks with a working pressure not exceeding 0,5 bar — Design and construction EN 13445-2, Unfired pressure vessels — Part 2: Materials EN 13445-3:2009, Unfired pressure vessels — Part 3: Design EN 13445-4, Unfired pressure vessels — Part 4: Fabrication EN 13445-8, Unfired pressure vessels — Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys SIST EN 14025:2013

(ISO 15614-1) EN ISO 15614-2, Specification and qualification of welding procedures for metallic materials — Welding procedure test — Part 2: Arc welding of aluminium and its alloys (ISO 15614-2) EN ISO 17635, Non-destructive testing of welds — General rules for metallic materials (ISO 17635) EN ISO 17637, Non-destructive testing of welds — Visual testing of fusion-welded joints (ISO 17637) EN ISO 17640, Non-destructive testing of welds — Ultrasonic testing — Techniques, testing levels, and assessment (ISO 17640) ISO 1496-3, Series 1 freight containers — Specification and testing — Part 3: Tank containers for liquids, gases and pressurized dry bulk ISO 7005-1, Pipe flanges — Part 1: Steel flanges for industrial and general service piping systems SIST EN 14025:2013

7 3 Terms, definitions and symbols 3.1 Terms and definitions For the purposes of this document, the following term and definition applies. 3.1.1 pressure-tank tank as defined in the international regulations for the transport of dangerous goods by road or rail having a maximum working pressure or a test pressure exceeding 50 kPa (0,5 bar) 3.2 Symbols The following general symbols are used throughout the text. They are listed in alphabetical order and special symbols are explained with the relevant formulae. Additional symbols used in the text are explained in: RID/ADR Chapter 6.8 RID/ADR Chapter 6.7 A1

minimum elongation at fracture of the metal chosen under tensile stress in % di

inside diameter of an opening D

internal diameter of shell in mm DC

mean diameter of the cylindrical part of the tank at the junction of a cone De

outside diameter of the cylindrical part of the tank or the straight flange of the dished end Di inside diameter of the cylindrical part of the tank or the straight flange of dished end Di diameter of the shell (in m), but not less than 1,80 m e

minimum required wall thickness (in mm) of the shell e0

minimum shell thickness for mild steel in mm, according to 6.8.2.1.18 and 6.8.2.19 of RID/ADR e1

minimum shell thickness for the metal chosen in mm ek

wall thickness of a conical part of a shell eR

wall thickness of a hemispherical end E

Young's modulus fd

nominal design stress (allowable stress) h

inside height of an ellipsoidal dished end K

shape factor of ellipsoidal ends MWP

maximum working pressure, in MPa MAWP

maximum allowable working pressure, in MPa p

design pressure, in MPa P

design pressure, in MPa pdyn

equivalent dynamic pressure ptest

test pressure, in MPa SIST EN 14025:2013

calculation pressure in MPa as specified

in 6.8.2.1.14 of RID/ADR PT

test pressure in MPA r

inner knuckle radius, in mm R

inside spherical radius of the central part of a torispherical end Re guaranteed (upper) minimum yield strength or guaranteed minimum 0,2 % proof strength, in N/mm² (for austenitic steel the 1 % proof strength may be chosen) Re,t guaranteed (upper) minimum yield strength or guaranteed minimum 0,2 % proof strength, at the relevant design temperature, in N/mm² (for austenitic steel the 1 % proof strength at the relevant design temperature may be chosen) Rm

guaranteed minimum tensile strength, in N/mm² Rm1

minimum tensile strength of the metal chosen in N/mm2 Rm,t

guaranteed minimum tensile strength at the relevant design temperature, in N/mm² σ

permissible stress in N/mm2, as defined in 6.8.2.1.16 of RID/ADR=S

safety factor λ

welding coefficient 4 Materials 4.1 General The tank shell shall be fabricated from metallic materials which shall be resistant to brittle fracture and of adequate impact strength within the design temperature range. The material shall be suitable for forming. EN 13445-2 and -8 apply and the minimum material requirements given in RID/ADR Chapter 6.8 and Chapter 6.7 shall be fulfilled. RID/ADR Chapter 6.8 RID/ADR Chapter 6.7

Aluminium may only be used for the shells of portable tanks when indicated in a portable tank special provision assigned to a specific substance in Column (11) of Table A of Chapter 3.2 RID/ADR or when approved by the competent authority. NOTE 1 For aluminium and aluminium alloys, see also EN 14286. SIST EN 14025:2013

9 NOTE 2 RID/ADR restrict the use of materials with respect to the maximum yield and tensile strength of fine-grained steel for welded shells, maximum ratios of yield/tensile strength for welded steel shells and of the minimum elongation at fracture for welded fine- grained other steel and aluminium shells. Welded shells shall be fabricated from a material which has been shown to have acceptable welding characteristics. 4.2 Compatibility Shells, fittings, and pipework shall be constructed from materials which are: a) substantially immune to attack by the substance(s) intended to be transported; or b) properly passivated or neutralised by chemical reaction; or c) lined with corrosion-resistant material directly bonded to the shell or attached by equivalent means. They shall comply with RID/ADR 6.8.2 RID/ADR 6.7.2.2 and 6.7.3.2 Gaskets shall be made of materials not subject to attack by the substances intended to be transported. The materials of the tank, including any devices, gaskets, linings and accessories, shall not adversely affect the substances intended to be transported in the tank. Guidelines on material specifications in relation to the substances to be transported may be taken from Annex B of EN 12285-1:2003. 5 Design 5.1 General Tanks shall be designed to withstand without loss of contents the: 1) operating conditions including static and dynamic forces in normal conditions of carriage. In addition, the design of portable tanks shall account for the effects of fatigue, caused by repeated application of these loads through the expected life of the portable tank; 2) test conditions; 3) explosion pressure proof conditions (if required); under consideration of Clause 6. If sudden temperature differences are to be expected during filling or discharge of the tank the buckling effect of one sided expansion or contraction should be taken into account. 5.2 Minimum shell thickness The shell thickness shall not be less than that given in: RID/ADR 6.8.2.1.17 to 6.8.2.1.18, see Figure 1 of this standard RID/ADR 6.7.2.4 or 6.7.3.4, see Figure 2 of this standard SIST EN 14025:2013

5.5 Protection of equipment Items of equipment shall be protected against the risk of being wrenched off or damaged during transport or handling. For tanks other than rail tank wagons equipment shall be protected by strengthening rings, protective canopies or transverse or longitudinal members. This protection of equipment shall comply with 6.14 of EN 13094:2008. Items of equipment of tank containers are protected if placed within the contours of a skeleton structure (frame). RID/ADR 6.7.2.5 and 6.7.2.6 and 6.7.3.5 applies also. SIST EN 14025:2013

11 Equipment used on tanks of tank vehicles for the transport of substances to which the special provision TE 19 of ADR (see subsection 6.8.4 ADR) is allocated need additional protection. RID/ADR 6.8.2.2 applies also. NOTE For vacuum-operated waste tanks RID/ADR 6.10.3.1 applies. 5.6 Other design requirements Design criteria for: openings; see 6.3.5.1, 6.3.5.2.1 to 6.3.5.2.6, 6.3.5.3; ends; see 6.3.3.2 to 6.3.3.4; conical section of shell; see 6.3.4.1 and 6.3.4.2; hinged manhole cover and cover assemblies; see 6.3.6.5; flanges, joints and bolts; see 6.3.7. NOTE 1 RID/ADR include requirements on - thermal insulation of linkage between shell and vehicle, design of surge plates and partitions,- leakproof linings, thermal insulation, non- metallic linings, electrical earthing and secure base and lifting devices (see RID/ADR 6.7.2, 6.7.3, 6.8.2.1.22, 6.8.2.1.24 – 6.8.2.1.27 and 6.8.5.1.5) which are not considered in this standard. NOTE 2 RID/ADR require that shells of portable tanks made from aluminium shall be insulated to prevent significant loss of physical properties when subjected to a heat load of 110 kW/m2 for a period of not less than 30 min and that the insulation shall remain effective at all temperatures less than 649 °C and shall be jacketed with a material with a melting point of not less than 700 °C. 6 Calculation 6.1 General 6.1.1 General The minimum wall thickness of the tank shall be determined according to the calculation schemes of 6.1.2 and 6.1.3. Additional thickness to allow for corrosion (progressive decrease of wall thickness) shall not be taken into consideration in calculating the shell thickness. The calculation schemes given in Figures 1 and 2 show how to determine the wall thickness of a shell to meet the requirements of this standard and RID/ADR where Figure 1 applies to RID/ADR chapter 6.8 and Figure 2 applies to RID/ADR chapter 6.7. 6.1.2 Calculation scheme for the wall thickness of metallic pressure tanks of RID/ADR Chapter 6.8 The wall thickness chosen, shall not be less than the maximum value resulting from the wall thickness determined according to branches A and B (RID/ADR 6.8.2) on the one hand and according to the following formulae relevant to the test and service conditions (branches C and D) on the other. SIST EN 14025:2013

Figure 1 Calculation scheme for the wall thickness of metallic pressure tanks of chapter 6.8 of RID/ADR 6.1.3 Calculation scheme for the wall thickness of metallic portable pressure tanks of RID/ADR chapter 6.7 The wall thickness chosen, shall not be less than the maximum value resulting from the wall thickness determined according to branch B (RID/ADR 6.7.2 and 6.7.3) on the one hand and according to the following formulae relevant to the test and service conditions (branches C and D) on the other. SIST EN 14025:2013

Figure 2 Calculation scheme for the wall thickness of metallic portable pressure tanks of chapter 6.7 of RID/ADR 6.2 Design criteria Design criteria (loads, allowable stresses, design temperature etc.) to be applied shall be taken from Tables 1 and 2. SIST EN 14025:2013

Operating conditions Test conditions p MWP but not less than (pvap − 1 bar) + pdyn if applicable a ptest b fd for ferritic steels and aluminium alloys min { Re,t / 1,5; Rm / 2,4} min { 0,75 Re ; 0,5 Rm } fd for austenitic steels with 30 % ≤ A < 35 % Re,t / 1,5 fd for austenitic steels with A ≥ 35 % max { Re,t / 1,5; min (Re,t / 1,2 ; Rm,t / 3)} c Design temperature 20 C provided that the operating temperature of the tank is within the range

-20 C to +50 C. When the operating temperature is outside this range then the design temperature shall be taken as the extreme value of the operating temperature. Temperature at the pressure test (normally +20 C). a The dynamic forces shall be taken into account. This may be done by introducing an equivalent pressure pdyn determined on the basis of the forces specified in RID/ADR 6.8.2.1 but not less than 35 kPa ( 0,35 bar) and add it to the vapour gauge pressure (pvap – 1 bar) with .pvap not less than 1 bar. The largest compartment needs to be taken into account. b To be taken from RID/ADR 6.8.2.4.1. c It needs to be noted that the guaranteed minimum mechanical values differ with the temperature, and have to be chosen accordingly. If no standard values are available, applicable values have to be determined otherwise. Table 2 — Design criteria for chapter 6.7 tanks

Operating conditions Test conditions p MAWP but not less than (pvap − 1 bar) + pdyn if applicable a ptest b fd for ferritic steels and aluminium alloys min { Re,t / 1,5; Rm / 2,4} min { 0,75 Re ; 0,5 Rm } fd for austenitic steels with 30 % ≤ A < 35 % Re,t / 1,5 fd for austenitic steels with A ≥ 35 % max { Re,t / 1,5; min (Re,t / 1,2 ; Rm,t / 3)} c Design temperature 20 C provided that the operating temperature of the tank is within the range

-40 C to +50 C. When the operating temperature is outside this range then the design temperature shall be taken as the extreme value of the operating temperature. Temperature at the pressure test (normally +20 C). a The dynamic forces shall be taken into account. This may be done by introducing an equivalent pressure pdyn determined on the basis of the forces specified in RID/ADR 6.7.2.2 and 6.7.3.2 respectively but not less than 35 kPa ( 0,35 bar) and add it to the vapour gauge pressure (pvap – 1 bar) with .pvap not less than 1 bar. The largest compartment needs to be taken into account. b To be taken from RID/ADR 6.7.2.3 and 6.7.3.3 respectively. c It needs to be noted that the guaranteed minimum mechanical values differ with the temperature, and have to be chosen accordingly. If no standard values are available, applicable values have to be determined otherwise. SIST EN 14025:2013

15 6.3 Calculation for internal pressure 6.3.1 General The thickness of the cylindrical section of the shell shall be determined in accordance with 6.3.2. The thickness of the ends (including partitions) of the shell shall be determined in accordance with 6.3.3. The thickness of a conical section and the reinforcement of the cone to cylinder junction shall be determined in accordance with 6.3.4. For flanges, joints and their bolts see 6.3.6. Openings in the shell shall be designed in accordance with 6.3.5. The calculation for construction types not given hereafter shall be in accordance with EN 13445-3. 6.3.2 Wall thickness of the cylindrical section The wall thickness shall not be less than the value given by Formula (1). pfDpe−××=λdi2 (1) 6.3.3 Wall thickness of ends 6.3.3.1 General The thickness of the ends, subject to the limitations in 6.3.3.2, shall not be less than that given by 6.3.3.3 and 6.3.3.4, 6.3.3.5 or 6.3.3.6 as applicable. 6.3.3.2 Design limitations The following design limitations shall apply to the tank ends (compare Figure 3): (a) Hemispherical ends 0,001 De ≤ e ≤

0,16 De

(b) Torispherical ends 0,001 De ≤ e ≤ 0,08 De

0,06 Di

≤ r ≤ 0,2 Di

r ≥ 2 e

R ≤ De

(c) Ellipsoidal ends 0,001Di ≤ e ≤

0,08 Di

3,4

≤

Di/h ≤ 4,4 The four relationships in (b) and the two relationships in (c) shall be simultaneously fulfilled. SIST EN 14025:2013

Figure 3 — Geometry of ends 6.3.3.3 Thickness of the flange of the end The wall thickness of the cylindrical or straight flange of the end shall not be less than the thickness as determined in accordance with 6.3.2 for a cylindrical section having the same inside diameter Di. 6.3.3.4 Thickness of hemispherical ends The thickness of a hemispherical end shall be not less than that determined by Formula (2): pfDpeR−××=λdi4 (2) 6.3.3.5 Thickness of torispherical ends 6.3.3.5.1 General The minimum thickness of torispherical ends shall be the greatest of the values of ey, es or eb as determined by Formulae (3) to (5). diey)2,075,0(fDRpe×+×=β (3) where

e is calculated from Formulae (6) to (14). pfRpe×−××=5,02dsλ (4) SIST EN 14025:2013

17 ()32825,0idib111)2,075,0(×+×=rDfpDRe (5) where 5,1/2,0pdTRf= where eb is required thickness of knuckle to avoid plastic buckling; es is required thickness of end to limit membrane stress in central part; ey is required thickness of knuckle to avoid axisymmetric yielding; NOTE It is not necessary to calculate eb if ey > 0,005 Di" It is permissible to reduce the thickness of the spherical part of the end to the value es over a circular area that shall not come closer to the knuckle than the distance eR

⋅, as shown in Figure 3. The right edge cylindrical flange shall meet the requirements of 6.3.2 for a cylinder, if its length is greater than 0,2 eD

i⋅. When the length is equal or smaller than 0,2 eD

i⋅, it may be the same thickness as required for the knuckle. If ends are manufactured from several elements then the welding coefficient λ may be taken equal to 1,0 (for thickness calculations only) if the weld crosses the crown area 0,6 De (see Figure 4).

λ = 0,8, 0,9 or 1,0 according to 7.4.3 λ = 1,0 λ = 1,0, λ = 0,8, 0,9 or 1,0 according to 7.4.3 a) weld outside 0,6 De=b) weld inside 0,6 De=c) composed ends=Figure 4 — Position of welds in ends 6.3.3.5.2 Formulae for calculation of β e

)04,0;/(minReY= (6) SIST EN 14025:2013

19 Table 3 — Procedure for calculation of weakening factor β k for openings in the knuckle region (design) Step Kloepper type end Korbbogen type end 1 =d101000logfpV =d101000logfpV 2 }14,0592,0938,0264,0;5,0{max32VVVA+−+= 3044,041,054,0VVA−+= 3 }151,0165,291,4;2,4{min2VVB+−= 27441,053,477,7VVB+−= 4 ++=eieik3,01;maxDdBDdBAβ ++=eieik5,01;maxDdBDdBAβ

6.3.3.6 Thickness of ellipsoidal ends An ellipsoidal end is an end that is made on a former that has a true ellipsoidal shape. Ellipsoidal ends shall have a shape factor K with a value between 1,7 and 2,2. hDK2i= (17) Ellipsoidal ends shall be designed as torispherical ends in accordance with 6.3.3.5 with values of r and R as given by the following: i08,05,0DKr−= (18) i)02,044,0(DKR+= (19) 6.3.4 Wall thickness of conical sections 6.3.4.1 General The conical section of the shell shall conform to the design limitations in 6.3.4.2. The wall thickness shall be determined in accordance with 6.3.4.3. For more information compare also EN 13445-3. 6.3.4.2 Design limitations of the conical section This clause gives rules for right circular cones and cone/cylinder intersections where the cone and the cylinder are of the same axis of rotation. It applies only to cones with an apex angle not greater than 120 and cones for which: 001,0/cosc[×Deα (20) For the angle . see Figure 5. For offset cones between two cylinders the cylinders shall have parallel centrelines offset from each other by a distance not greater than the difference of the radii. A required thickness shall be calculated in accordance with 6.3.4.3.3 for the junction at the large end and in accordance with 6.3.4.3.4 for the junction at the small end. Since the thickness calculated above is the minimum allowable at that point along the case, it is SIST EN 14025:2013

Figure 5 — Junction between cylinder and cone; angle α

6.3.4.3 Determination of the wall thickness of the conical section 6.3.4.3.1 The minimum thickness of the wall of the conical section ek of the shell shall be not less than the lowest value given by Formula (21), unless otherwise required by the subclauses of 6.3.4.3. −××=αλcos12dikpfDpe (21) 6.3.4.3.2 Wall thickness at the junction of cylindrical and conical sections of the shell. The conditions and design calculations for the large end of the cone are given in 6.3.4.3.3 and for the small end of the cone in 6.3.4.3.4. 6.3.4.3.3 Large end of the cone without a knuckle at the joint. The joint shall be made with a butt weld and there shall be a smooth transition across the joint from cylindrical section to the conical section. The minimum thickness of the wall of the shell at the junction of the conical and cylindrical sections shall be determined from the following two formulae by iteration. dcc12fDpeβ××= (22) 15,0cos/11tan311cc−+=ααβeD (23) This thickness shall be maintained for a distance of at least 1,4 1, from the junction along the cylinder. The required thickness e2 of the cone adjacent to the junction is the greater of e and ek. This thickness shall be maintained for a distance of at least 1,4 2 from the junction along the cone, see Figure 5. The distance 1 and 2 are determined as follows: SIST EN 14025:2013

21 1c1eD×= (24) αcos2c2eD×= (25) 6.3.4.3.4 Minimum thickness at the small end of the cone. This clause applies provided that: a) junction is more than 2 1 along the cylinder and 2 1 along the cone from any other junction or major discontinuity, such as another cone/cylinder junction or flange, b) minimum thickness of the cylinder e1 is maintained for a distance 1 and that of the cone e2 is maintained for a distance 2 from the junction; 1 and 2 are calculated according to Formulae (24) and (25) using Figure 6 and c) thickness meets the requirements of 6.3.2 and 6.3.4.3.1.

Figure 6 — Geometry of cone/cylinder intersection; small end Minimum thickness e1 and e2 shall be chosen so that: λβ×××=dHc12fDpe (26) where 5,0tan4,01H

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...