EN 15382:2008

(Main)Geosynthetic barriers - Characteristics required for use in transportation infrastructure

Geosynthetic barriers - Characteristics required for use in transportation infrastructure

This European Standard specifies the relevant characteristics of geosynthetic barriers (polymeric, clay and bituminous geosynthetic barriers), used as fluid barriers in infrastructure works, e.g. roads, railroads, runways of airports, and the appropriate test methods to determine these characteristics. Tunnels and underground structures are addressed in EN 13491.

The intended use of these products is to control the pathway of liquids through the construction and to limit any contamination, e.g. by de-icing products, of groundwater or water sources.

This European Standard is applicable to geosynthetic barriers, but not to geotextiles or geotextile-related products, as defined in EN ISO 10318.

This European Standard provides for the evaluation of conformity of the product to this European Standard.

This European Standard defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties.

This European Standard does not cover applications where the geosynthetic barrier will be in contact with water that has been treated for human consumption. In these cases other relevant standards, requirements and/or regulations should be observed.

Geosynthetische Dichtungsbahnen - Eigenschaften, die für die Anwendung in Verkehrsbauten erforderlich sind

Diese Europäische Norm legt die relevanten Eigenschaften von geosynthetischen Dichtungsbahnen (geosynthetische

Kunststoffdichtungsbahnen, geosynthetische Tondichtungsbahnen und geosynthetische Bitumendichtungsbahnen),

die als Abdichtung gegen Flüssigkeit bei Verkehrsbauten, z. B. Straßen,

Schienenwege, Landebahnen, verwendet werden, und die geeigneten Prüfverfahren zur Bestimmung dieser

Eigenschaften fest. Tunnel und Tiefbauwerke werden in EN 13491 behandelt.

Die bestimmungsgemäße Anwendung dieser Produkte ist die Kontrolle des Weges der Flüssigkeiten durch

das Bauwerk und die Begrenzung jeglicher Kontamination des Grundwassers oder von Wasserquellen, z. B.

durch auftauende Produkte.

Diese Europäische Norm ist auf geosynthetische Dichtungsbahnen, jedoch nicht auf Geotextilien oder geotextilverwandte

Produkte, wie in EN ISO 10318 angegeben, anwendbar.

Diese Europäische Norm behandelt die Konformitätsbewertung des Produktes bezüglich dieser Europäischen

Norm.

Diese Europäische Norm legt Anforderungen fest, die von Herstellern und autorisierten Vertretern für die

Darstellung von Produkteigenschaften zu beachten sind.

Diese Europäische Norm bezieht sich nicht auf Anwendungen, bei denen die geosynthetische Dichtungsbahn

in Kontakt mit Wasser ist, welches für den menschlichen Verbrauch behandelt worden ist. In diesen Fällen

sind andere relevante Normen, Anforderungen und/oder Vorschriften in Betracht zu ziehen.

Géomembranes, géosynthétiques bentonitiques - Caractéristiques requises pour l'utilisation dans les infrastructures de transport

Geosintetične ovire - Zahtevane lastnosti za uporabo v infrastrukturi transporta

General Information

- Status

- Withdrawn

- Publication Date

- 05-Aug-2008

- Withdrawal Date

- 16-Jul-2013

- Technical Committee

- CEN/TC 189 - Geotextiles and geotextile-related products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-Jul-2013

- Completion Date

- 17-Jul-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 14415:2004 - Geosynthetic barriers - Test method for determining the resistance to leaching - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Bureau Veritas Bangladesh

Bureau Veritas certification services in Bangladesh.

ECOCERT France

Leader in organic and sustainability certification worldwide.

Sponsored listings

Frequently Asked Questions

EN 15382:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Geosynthetic barriers - Characteristics required for use in transportation infrastructure". This standard covers: This European Standard specifies the relevant characteristics of geosynthetic barriers (polymeric, clay and bituminous geosynthetic barriers), used as fluid barriers in infrastructure works, e.g. roads, railroads, runways of airports, and the appropriate test methods to determine these characteristics. Tunnels and underground structures are addressed in EN 13491. The intended use of these products is to control the pathway of liquids through the construction and to limit any contamination, e.g. by de-icing products, of groundwater or water sources. This European Standard is applicable to geosynthetic barriers, but not to geotextiles or geotextile-related products, as defined in EN ISO 10318. This European Standard provides for the evaluation of conformity of the product to this European Standard. This European Standard defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties. This European Standard does not cover applications where the geosynthetic barrier will be in contact with water that has been treated for human consumption. In these cases other relevant standards, requirements and/or regulations should be observed.

This European Standard specifies the relevant characteristics of geosynthetic barriers (polymeric, clay and bituminous geosynthetic barriers), used as fluid barriers in infrastructure works, e.g. roads, railroads, runways of airports, and the appropriate test methods to determine these characteristics. Tunnels and underground structures are addressed in EN 13491. The intended use of these products is to control the pathway of liquids through the construction and to limit any contamination, e.g. by de-icing products, of groundwater or water sources. This European Standard is applicable to geosynthetic barriers, but not to geotextiles or geotextile-related products, as defined in EN ISO 10318. This European Standard provides for the evaluation of conformity of the product to this European Standard. This European Standard defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties. This European Standard does not cover applications where the geosynthetic barrier will be in contact with water that has been treated for human consumption. In these cases other relevant standards, requirements and/or regulations should be observed.

EN 15382:2008 is classified under the following ICS (International Classification for Standards) categories: 59.080.70 - Geotextiles; 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15382:2008 has the following relationships with other standards: It is inter standard links to EN 15382:2013, EN ISO 12957-1:2018, EN 13492:2018, EN 13491:2018, EN ISO 10318:2005, EN 14415:2004, EN 14150:2019, EN 14414:2004, EN 13493:2018, EN 13361:2018, EN 495-5:2013, EN ISO 13438:2018, EN 12224:2000, EN 14575:2005, EN ISO 12957-2:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15382:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/107. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15382:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geosynthetische Dichtungsbahnen - Eigenschaften, die für die Anwendung in Verkehrsbauten erforderlich sindGéomembranes, géosynthétiques bentonitiques - Caractéristiques requises pour l'utilisation dans les infrastructures de transportGeosynthetic barriers - Characteristics required for use in transportation infrastructure93.080.20Materiali za gradnjo cestRoad construction materials59.080.70GeotekstilijeGeotextilesICS:Ta slovenski standard je istoveten z:EN 15382:2008SIST EN 15382:2009en,fr,de01-januar-2009SIST EN 15382:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15382August 2008ICS 59.080.70; 93.080.20 English VersionGeosynthetic barriers - Characteristics required for use intransportation infrastructureGéomembranes, géosynthétiques bentonitiques -Caractéristiques requises pour l'utilisation dans lesinfrastructures de transportGeosynthetische Dichtungsbahnen - Eigenschaften, die fürdie Anwendung in Verkehrsbauten erforderlich sindThis European Standard was approved by CEN on 4 July 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15382:2008: ESIST EN 15382:2009

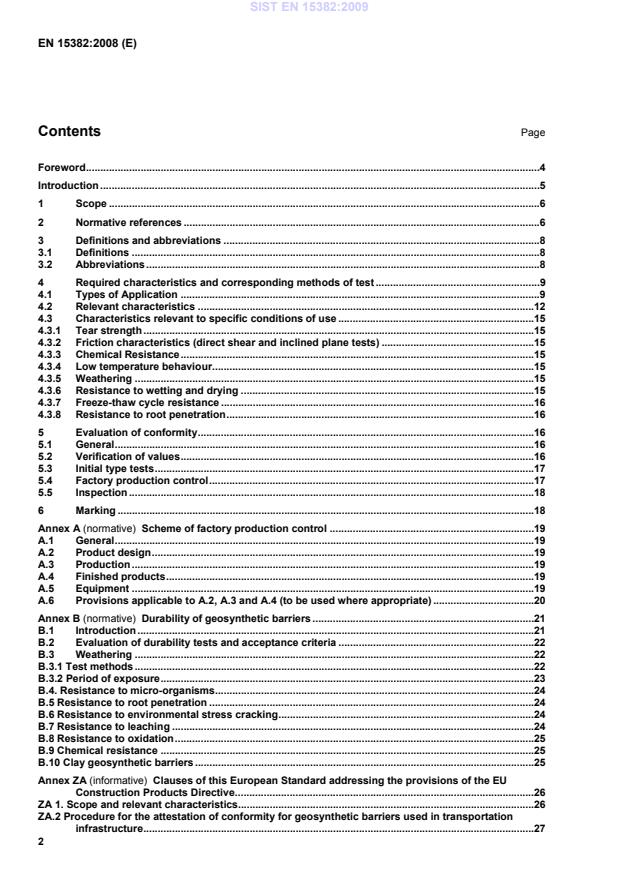

2 Contents Page Foreword.4 Introduction.5 1 Scope.6 2 Normative references.6 3 Definitions and abbreviations.8 3.1 Definitions.8 3.2 Abbreviations.8 4 Required characteristics and corresponding methods of test.9 4.1 Types of Application.9 4.2 Relevant characteristics.12 4.3 Characteristics relevant to specific conditions of use.15 4.3.1 Tear strength.15 4.3.2 Friction characteristics (direct shear and inclined plane tests).15 4.3.3 Chemical Resistance.15 4.3.4 Low temperature behaviour.15 4.3.5 Weathering.15 4.3.6 Resistance to wetting and drying.15 4.3.7 Freeze-thaw cycle resistance.16 4.3.8 Resistance to root penetration.16 5 Evaluation of conformity.16 5.1 General.16 5.2 Verification of values.16 5.3 Initial type tests.17 5.4 Factory production control.17 5.5 Inspection.18 6 Marking.18 Annex A (normative)

Scheme of factory production control.19 A.1 General.19 A.2 Product design.19 A.3 Production.19 A.4 Finished products.19 A.5 Equipment.19 A.6 Provisions applicable to A.2, A.3 and A.4 (to be used where appropriate).20 Annex B (normative)

Durability of geosynthetic barriers.21 B.1 Introduction.21 B.2 Evaluation of durability tests and acceptance criteria.22 B.3 Weathering.22 B.3.1 Test methods.22 B.3.2 Period of exposure.23 B.4. Resistance to micro-organisms.24 B.5 Resistance to root penetration.24 B.6 Resistance to environmental stress cracking.24 B.7 Resistance to leaching.24 B.8 Resistance to oxidation.25 B.9 Chemical resistance.25 B.10 Clay geosynthetic barriers.25 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.26 ZA 1. Scope and relevant characteristics.26 ZA.2 Procedure for the attestation of conformity for geosynthetic barriers used in transportation infrastructure.27 SIST EN 15382:2009

3 ZA.2.1 Systems of attestation of conformity.27 ZA2.2 Certificate and declaration of conformity.28 ZA 3. CE marking and labelling.29 Bibliography.33

4 Foreword This document (EN 15382:2008) has been prepared by Technical Committee CEN/TC 189 “Geosynthetics”, the secretariat of which is held by IBN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by February 2009, and conflicting national standards shall be withdrawn at the latest by May 2010. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EC Directive(s). For relationship with EC Directive(s), see informative Annex ZA, B, C or D, which is an integral part of this document. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

5 Introduction This European Standard allows manufacturers to describe geosynthetic barriers on the basis of declared values for characteristics relevant to the intended use and if tested to the specified method. It also includes procedures for evaluation of conformity and factory production control. This European Standard may also be used by designers, end-users and other interested parties as a tool to define relevant and appropriate characteristics for specifications and on-site quality control. It should be emphasised however that not all characteristics and test methods quoted in this European Standard are suitable for the purpose of on-site quality control.

Tests for several non-mandated characteristics are still under study and will be included when the standard is revised. The term “product” used in this standard refers to a geosynthetic barrier, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers. This European standard is part of a group of standards, addressing the requirements for geosynthetic barriers when used in a specific application.

Particular application cases may contain requirements about additional properties and – preferably standardised – test methods, if they are technically relevant and not conflicting with European Standards.

The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

1 Scope This European Standard specifies the relevant characteristics of geosynthetic barriers (polymeric, clay and bituminous geosynthetic barriers), used as fluid barriers in infrastructure works, e.g. roads, railroads, runways of airports, and the appropriate test methods to determine these characteristics. Tunnels and underground structures are addressed in EN 13491. The intended use of these products is to control the pathway of liquids through the construction and to limit any contamination, e.g. by de-icing products, of groundwater or water sources. This European Standard is applicable to geosynthetic barriers, but not to geotextiles or geotextile-related products, as defined in EN ISO 10318. This European Standard provides for the evaluation of conformity of the product to this European Standard. This European Standard defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties.

This European Standard does not cover applications where the geosynthetic barrier will be in contact with water that has been treated for human consumption. In these cases other relevant standards, requirements and/or regulations should be observed. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 495-5, Flexible sheets for waterproofing - Determination of foldability at low temperature - Part 5: Plastic and rubber sheets for roof waterproofing EN 1109, Flexible sheets for waterproofing - Bitumen sheets for roof waterproofing - Determination of flexibility at low temperature EN 1849-1, Flexible sheets for waterproofing - Determination of thickness and mass per unit area - Part 1: Bitumen sheets for roof waterproofing EN 1849-2, Flexible sheets for waterproofing – Determination of thickness and mass per unit area – Part 2: Plastic and rubber sheets for roof waterproofing EN 12224, Geotextiles and geotextile-related products – Determination of the resistance to weathering EN 12225, Geotextiles and geotextile-related products – Method for determining the microbiological resistance by a soil burial test EN 12226, Geotextiles and geotextile-related products - General tests for evaluation following durability testing EN 12310-1, Flexible sheets for waterproofing - Part 1: Bitumen sheets for waterproofing - Determination of resistance to tearing (nail shank) EN 12311-1, Flexible sheets for waterproofing - Part 1: Bitumen sheets for roof waterproofing - Determination of tensile properties EN 13361, Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams EN 13362, Geosynthetic barriers - Characteristics required for use in the construction of canals EN 13491, Geosynthetic barriers - Characteristics required for use as a fluid barrier in the construction of tunnels and underground structures SIST EN 15382:2009

7 EN 13492, Geosynthetic barriers - Characteristics required for use in the construction of liquid waste disposal sites, transfer stations or secondary containment EN 13493, Geosynthetic barriers - Characteristics required for use in the construction of solid waste storage and disposal sites EN 14150, Geosynthetic barriers - Determination of permeability to liquids EN 14196, Geosynthetics - Test methods for measuring mass per unit area of clay geosynthetic barriers EN 14414:2004, Geosynthetics - Screening test method for determining chemical resistance for landfill applications EN 14415, Geosynthetic barriers - Test method for determining the resistance to leaching CEN/TS 14416, Geosynthetic barriers - Test method for determining the resistance to roots CEN/TS 14417, Geosynthetic barriers - Test method for the determination of the influence of wetting-drying cycles on the permeability of clay geosynthetic barriers CEN/TS 14418, Geosynthetic barriers - Test method for the determination of the influence of freezing-thawing cycles on the permeability of clay geosynthetic barriers EN 14575, Geosynthetic barriers - Screening test method for determining the resistance to oxidation EN 14576, Geosynthetics - Test method for determining the resistance of polymeric geosynthetic barriers to environmental stress cracking EN ISO 527-1:1996, Plastics - Determination of tensile properties - Part 1: General principles (ISO 527-1:1993 including Corr 1:1994) EN ISO 527-3:1995, Plastics - Determination of tensile properties - Part 3: Test conditions for films and sheets (ISO 527-3:1995) EN ISO 9862, Geosynthetics - Sampling and preparation of test specimens (ISO 9862:2005) EN ISO 9863-1, Geosynthetics - Determination of thickness at specified pressures - Part 1: Single layers (ISO 9863-1:2005) EN ISO 10318:2005, Geosynthetics - Terms and definitions (ISO 10318:2005) EN ISO 10319, Geotextiles - Wide-width tensile test (ISO 10319:1993) EN ISO 10320, Geotextiles and geotextile-related products – Identification on site (ISO 10320:1999) EN ISO 12236, Geosynthetics - Static puncture test (CBR test) (ISO 12236:2006) EN ISO 12957-1, Geosynthetics - Determination of friction characteristics - Part 1: Direct shear test (ISO 12957-1:2005) EN ISO 12957-2, Geosynthetics - Determination of friction characteristics - Part 2: Inclined plane test (ISO 12957-2:2005) EN ISO 13438, Geotextiles and geotextile-related products - Screening test method for determining the resistance to oxidation (ISO 13438:2004) ISO 34-1:2004, Rubber, vulcanized or thermoplastic - Determination of tear strength - Part 1: Trouser, angle and crescent test pieces ASTM D696-03, Standard test method for coefficient of linear thermal expansion of plastics between -30 °C and 30 °C with a vitreous silica dilatometer SIST EN 15382:2009

8 ASTM D5887-04, Standard test method for measurement of index flux through saturated geosynthetic clay liner specimens using a flexible wall permeameter ASTM D5890-95, Standard test method for swell index of clay mineral component of geosynthetic clay liners 3 Definitions and abbreviations 3.1 Definitions For the purposes of this document, the definitions given in EN ISO 10318:2005 and the following apply. 3.1.1 product geosynthetic barrier, including polymeric, bituminous and clay barriers 3.1.2 specification document in which the works, functions, specific conditions and required material property values of the geosynthetic barrier of use are described 3.1.3 infrastructure basic transportation system that is necessary for the operation of any kind of traffic 3.1.4 embankment shoulder

slope extending from the edge of a pavement to a linear ditch made of packed soil built above the natural ground 3.2 Abbreviations For the purposes of this document, the abbreviations given in EN ISO 10318:2005 and the following apply. GBR-P: polymeric geosynthetic barrier GBR-B: bituminous geosynthetic barrier GBR-C: clay geosynthetic barrier SIST EN 15382:2009

9 4 Required characteristics and corresponding methods of test 4.1 Types of Application

The main function of geosynthetic barriers used in these types of application is to control the pathway of liquids through the construction and to limit contamination of groundwater or water sources.

The following types of application can be distinguished: deep laying GBR on side slopes: application where the GBR is installed under the drainage collection system and covers the entire slope as well as the ditch area (see figure 1).; high laying GBR on side slopes: application where the GBR is installed above the drainage collection system as a high laying sealing system and covers the opposite side slope of the road to prevent an overflow of the road surface run-off (see figure 2); deep laying GBR between two roads: application where the GBR is installed under the drainage collection system and covers the section between two roads, where a sealing is required (see figure 3);

high laying GBR between two roads: application where the GBR is installed above the drainage collection system as a high laying sealing system and covers the section between two roads where sealing is required (see figure 4).

Key 1 Pavement and/or track bed 2 Rain water collection 3 Geosynthetic barrier (GBR) 4 Cover soil 5 Fill soil 6 Collection pipe 7 Manhole Fig. 1 – Deep laying GBR on side slopes SIST EN 15382:2009

Key 1 Pavement and/or track bed 3 Geosynthetic barrier (GBR) 4 Cover soil 5 Sealing connection 6 Collection pipe 7 Manhole Fig. 2 – High laying GBR on side slopes SIST EN 15382:2009

Key 1 Pavement and/or track bed 2 Rain water collection 3 Geosynthetic barrier (GBR) 4 Cover soil 5 Fill soil 6 Collection pipe Fig. 3 – Deep laying GBR between two roads SIST EN 15382:2009

Key 1 Pavement and/or track bed 2 Sealing connection 3 Geosynthetic barrier (GBR) 4 Cover soil 5 Fill soil 6 Manhole Fig. 4 – High laying GBR between two roads 4.2 Relevant characteristics The characteristics and the test methods to be used are given in Table 1. The list of characteristics in Table 1 includes those relevant to all conditions of use and subject to regulation (H), those relevant to all conditions of use and not subject to regulation (A), and those relevant to specific conditions of use and not subject to regulation (S). Damage during installation has not been addressed in this document. The functions and conditions of use, corresponding with the characteristics, marked with “S” in Table 1, are specified in 4.3.

The manufacturer shall provide the data based on the results of tests specified in this standard and where relevant, in accordance with 5.1. The manufacturer shall provide information on how functioning joints can be made. Where products are jointed in the factory the water permeability and, if relevant, the strength of the joints shall be tested and data presented. SIST EN 15382:2009

Requirement Test Methods Remarks no. Property to be tested GBR-P GBR-B GBR-C GBR-P GBR-B GBR-C

Physical Properties 1 Thickness A A A EN 1849-2 EN 1849-1 EN ISO 9863-1

2 Mass per unit area A A A EN 1849-2 EN 1849-1 EN 14196

Hydraulic Properties 3 Water permeability (liquid tightness)

H H H EN 14150 EN 14150 ASTM D5887-04

4 Swell Index - - A - - ASTM D5890-95

Mechanical Properties 5 Tensile strength

H H H EN ISO 527 EN 12311-1 EN ISO 10319 For GBR-P use EN ISO 527 parts 1 and 3, test specimen type 5 at a speed of 100 mm/min 6 Elongation A A A EN ISO 527 EN 12311-1 EN ISO 10319 For GBR-P use EN ISO 527 parts 1 and 3, test specimen type 5 at a speed of 100 mm/min; calculation of elongation as defined in EN ISO 527-1:1996, 10.2, using grip separation measurement. 7 Static Puncture H H H EN ISO 12236 EN ISO 12236 EN ISO 12236

9 Tear strength S S - ISO 34-1 EN 12310-1 - For GBR-P use ISO 34-1 method B, angle specimen (Fig 2) without nick at a speed of 50 mm/min 10 Friction Direct shear S S S EN ISO 12957-1 EN ISO 12957-1 EN ISO 12957-1 11 Friction Inclined

Plane S

S

S

EN ISO 12957-2 EN ISO 12957-2 EN ISO 12957-2 Thermal Properties 12 Low temp behaviour (flexure) S S - EN 495-5 EN 1109 -

13 Thermal expansion A - - ASTM D696-03 - -

Durability and Chemical Resistance 14 Weathering H H - EN 12224 EN 12224 EN 12224 GBR-C: see 4.3.5 SIST EN 15382:2009

Requirement Test Methods Remarks no. Property to be tested GBR-P GBR-B GBR-C GBR-P GBR-B GBR-C

15 Micro organisms A A A EN 12225 EN 12225 EN 12225

16 Oxidation H H H EN 14575 EN 14575 EN ISO 13438

EN ISO 13438 is applicable for the geotextile elements and reinforcement yarns of GBR-C barriers

17 Environmental stress cracking H - H EN 14576

- EN 14576 GBR-C: Only applicable to polymeric membrane element of the GBR-C 18 Leaching (water soluble) A A A EN

14415 EN

EN 14415

19 Wetting/drying - - A - - CEN/TS 14417

20 Freezing / thawing - - A

- - CEN/TS 14418

21 Root penetration A A A CEN/TS 14416 CEN/TS 14416 CEN/TS 14416

22 Chemical resistance S S S EN 14414:2004, Annex B EN 14414:2004, Annex B EN 14414:2004, Annex B

NOTE Particular application cases may call for additional requirements, e.g. due to specific design features or conditions of use. These additional requirements should be technically relevant and preferably be measured by standardised test methods, described in European or international Standards.

The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

NOTE 1 In addition to the friction characteristics information on the internal bonding strength of GBR-C in the direction of the actual stress may be relevant. A shear (EN 12957 and ASTM D6243) or peel (EN 13426-1 and -2 and/or ASTM D6496 (for needle punched GBR-C)) test may be appropriate, particularly on slopes or in applications where shear stress may occur (i.e. during installation).

NOTE 2 Site specific testing should be carried out to establish the friction characteristics between all the materials used.

4.3.3 Chemical Resistance Depending on the application and the liquids involved, chemical testing according to EN 14414 may be applicable. 4.3.4 Low temperature behaviour Data on low temperature behaviour are required for applications where polymer and bituminous products may be exposed to low temperatures in storage, construction, and use. NOTE 1 Tests which set simple pass/fail criteria at a single temperature condition may not be appropriate for this purpose.

NOTE 2 Prehydrated GBR-C should not be stored or installed when the ambient temperature is below 0° C. 4.3.5 Weathering Data on weathering (combined effects of cycles of wetting, temperature change, and exposure to UV light) are required for applications where a GBR-C will be exposed to weathering without adequate protective cover. It should be noted that in all normal situations GBR-C barriers should be covered with soil on the same working day or prior to any circumstances which could cause a hydration of the clay component. 4.3.6

Resistance to wetting and drying

Data on the resistance of GBR-C to repeated wetting and drying is required when the conditions of use will subject the product to this sequence of actions. SIST EN 15382:2009

Data on the resistance of GBR-C to freeze/thaw is required when the conditions of use will subject the product to this sequence of actions. 4.3.8 Resistance to root penetration

Data on root penetration are required in all applications where the geosynthetic barrier is exposed to soils containing restorative vegetation.

NOTE 1 Slopes in infrastructure will usually be vegetated. Therefore an "A", as defined in 4.2, is recommended.

NOTE 2 Only applications underneath embankments of infrastructure or in the central area of multilane highways form an exception: no frost, no roots, no drying effects, no traffic loads after installation.

5 Evaluation of conformity 5.1 General The compliance of the geosynthetic barriers with the requirements of this European Standard and with the stated values shall be demonstrated by: Initial type testing (5.3); Factory production control (5.4) by the manufacturer, including product assessment. The characteristics specified in Table 2, except for durability, expressed as mean values and tolerance limit(s) corresponding to the 95% confidence level, shall be provided by the manufacturer, based on the statistical interpretation of his internal quality control measurements. Physical examination or preliminary testing, according to one of the test methods referenced in Table 1, may indicate that values obtained for a product lie below (or above) the sensitivity threshold established for that test method. In these particular circumstances the manufacturer may declare a value as being less (or greater) than this sensitivity threshold value. Information about durability shall be expressed in accordance with the guidelines of Annex B. 5.2 Verification of values The marking and labelling of the rolls and of the products shall be checked. The marking of the products shall be according to EN ISO 10320. NOTE The method described in this clause is not compulsory for an on-site control procedure. The compliance of characteristics with the values defined in 5.1 shall be based on measurements made on two representative samples (A and B), taken from two different rolls. Sampling shall be made in accordance with EN ISO 9862. The characteristics given in Table 2 shall be measured in accordance with the corresponding European standards on specimens prepared from sample A.

If the test result(s) for a particular characteristic is (are) within the tolerance limit(s) given by the manufacturer, the product is accepted as complying with respect to this characteristic. SIST EN 15382:2009

Functions tensile strength fluid barrier static puncture (CBR test)fluid barrier liquid tightness fluid barrier durability fluid barrier a For the durability aspects of these characteristics, see

Table 1, clause 4.3.and Annex B.

The results of initial type tests shall be recorded and be available for inspection. The sample for the type tests shall be drawn according to EN ISO 9862 from a normal production run using the materials and forming processes to be used for the full production process. The size of the sample shall be big enough to allow the determination of the characteristics specified in Table 2. Handmade samples, short trial batches and other development prototypes may be tested by the same methods, but shall not be used for establishing characteristic values in type tests.

5.4 Factory production control A factory production control scheme shall be established and documented in a manual prior to a product type being placed on the market. Subsequently, any fundamental changes in raw materials and additives, manufacturing procedures or the control scheme that affects the properties or use of a product shall be recorded in the manual. The manual shall include the factory production control procedures relevant to the declared properties, as confirmed by the initial type tests.

The factory production control procedures shall consist of a system for the permanent internal control of the production of the products to ensure that such products comply with this standard and that the measured values conform with the declared values.

When relevant the procedure given in clause 5.2 shall be used to check the conformity of the product, for one or more of the characteristics. 5.5 Inspection

When required, inspection of the factory and of the factory production control shall be made on the provisions contained in 5.4 and Annex A. 6

Marking

The manufacturer shall clearly and indelibly mark the geosynthetic barrier with the information specified in EN ISO 10320. NOTE For CE Marking see ZA.3. SIST EN 15382:2009

Scheme of factory production control

A.1 General The items to be addressed in the factory production control manual relating to the system of control determined from clause 5.4, are given below. A.2 Product design A.2.1 The manufacturer shall describe how design requirements and criteria are identified, checked, controlled and updated to be unambiguous and relevant to the use of the product and its specification. A.2.2

The manufacturer shall describe the communication of the design to the internal production departments or external sub-contractors. A.3 Production A.3.1

Raw or incoming materials: the manufacturer shall define the acceptance criteria of incoming materials and the procedures that he operates to ensure that these are met. A.3.2

Production process: the relevant features of the plant and production process shall be defined giving the frequency of the inspections, checks and tests, together with the values or criteria required, both on equipment and on work in the process. The action to be taken when control values or criteria are not obtained, shall be recorded. These records shall be available for inspection by relevant parties. A.4 Finished products A.4.1

Tests on the finished product: the size of the samples and the frequency of sampling, together with the results obtained, shall be recorded. These records shall be available for inspection by relevant parties. A.4.2

Alternative tests: where alternative tests to the reference tests are used, details of the alternative tests and procedures together with their correlation with the reference tests shall be recorded and shall be made available upon request from a relevant party. A.5 Equipment Equipment: test equipment having a bearing on test results shall be calibrated to traceable national or international standards. The manufacturer shall have or have available the installations, equipment and personnel which enable him to carry out the necessary verifications and tests. He may meet this requirement by concluding a subcontracting agreement with one or more organisations or persons having the necessary skills and equipment.

The manufacturer shall calibrate or verify and maintain the control, measuring or test equipment in good operating condition, whether or not it belongs to him, with a view to demonstrating conformity of the product SIST EN 15382:2009

Records: the dates, together with details and results of inspections, checks and tests carried out during the factory production control shall be properly recorded. These records shall be maintained for 10 years. The product description, the date of manufacture, test method adopted, test results and acceptance or rejection criteria shall be entered under the signature of the person responsible for control who carried out the verification. A.6.2

Assessment of results: where possible and applicable, the results of inspections, checks and tests shall be interpreted statistically by attributes or by variables to determine whether the corresponding production conforms with the requirements and the declared values for the products. A.6.3

Traceability: systems of traceability and control of designs, incoming materials, and the use of materials shall be given in the manual. The stock control system of manufactured products shall be given in the manual. A.6.4

Corrective action for non-conforming materials and products. The immediate actions to be taken when incoming materials or finished products do not conform to specified requirements shall be described and recorded. These actions shall include the steps necessary to rectify the deficiency, modify the manual if required, identify and isolate the deficient raw or incoming materials and finished products and determine whether they shall be discarded or re-specified under a concessionary system. A.6.5

Personnel: the manufacturer shall ensure that the personnel involved in the process are suitably trained. The job description and responsibility of the operatives shall be given in the manual. A.6.6 Quality management: the activities to ensure that all of the above requirements operate shall be described in the manual. SIST EN 15382:2009

Durability of geosynthetic barriers B.1 Introduction This Annex provides requirements and information on the evaluation criteria and levels of acceptability to be used in the interpretation and use of the results of durability testing carried out in accordance with the following European Standards (and with the test methods defined in Table 1 thereof): — EN 13361, Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams; — EN 13362, Geosynthetic barriers - Characteristics required for use in the construction of canals; — EN 13491, Geosynthetic barriers - Characteristics required for use as a fluid barrier in the construction of tunnels and underground structures; — EN 13492, Geosynthetic barriers - Characteristics required for use in the construction of liquid waste disposal sites, transfer stations or secondary containment; — EN 13493, Geosynthetic barriers - Characteristics required for use in the construction of solid waste storage and disposal sites; — EN 15382, Geosynthetic barriers- Characteristics required for use in transportation infrastructure. NOTE This Annex is based primarily on the current industry practice applicable to polymeric geosynthetic barriers but addendum notes are provided where appropriate to the evaluation requirements for the testing of bituminous and clay geosynthetic barriers. The durability of a geosynthetic barrier depends on its ability to resist the various mechanisms that cause degradation, i.e. reduction of mechanical properties, of its component materials. This Annex does not cover evaluation by change in permeability. These mechanisms may be summarized as the following:

a) Oxidative attack accelerated by elevated temperature, exposure to UV light, or repetitive mechanical stress;

b) Solvation, i.e. change in physical properties due to absorption of liquid chemicals; c) Environmental stress cracking, i.e. the mechanical failure of the geosynthetic barrier at stresses less than its yield strength in the presence of certain chemical species; d) Microbiological attack which includes the action of bacteria and fungi, and penetration by plant roots; e) Leaching of the soluble components of the geosynthetic barrier, thereby directly or indirectly affecting its mechanical properties or its resistance to other forms of degradation; f) Ionic exchange and degradation of additives. The relevant test methods referred to in this Annex are the following: — Resistance to weathering (EN 12224); SIST EN 15382:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...