EN 13361:2018

(Main)Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams

Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams

This document specifies the characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, when used as fluid barriers and separation layer for water, in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics.

The intended use of these products is to control the leakage of potable, fresh or saline water through the construction.

This document is not applicable to geotextiles or geotextile-related products, as defined in EN ISO 10318 1.

This document provides for the assessment and verification of constancy of performance (AVCP) of the product to this European Standard including factory production control procedures.

This document defines characteristics to be considered with regard to the presentation of performance.

NOTE Where potable water is or can be in direct contact with the product, other relevant standards, requirements and/or regulations can be considered for the design.

Geosynthetische Dichtungsbahnen - Eigenschaften, die für die Anwendung beim Bau von Rückhaltebecken und Staudämmen erforderlich sind

Dieses Dokument legt die relevanten Eigenschaften von geosynthetischen Dichtungsbahnen, einschließlich geosynthetische Kunststoff-, Ton- und Bitumendichtungsbahnen, die als Abdichtung beim Bau von Rückhaltebecken und Staudämmen für Trink-, Süß- oder Salzwasser verwendet werden, und die geeigneten Prüfverfahren zur Bestimmung dieser Eigenschaften fest.

Die bestimmungsgemäße Anwendung dieser Produkte ist das Durchsickern von Trink-, Süß- oder Salzwasser durch das Bauwerk zu kontrollieren.

Dieses Dokument ist nicht anwendbar auf Geotextilien oder geotextilverwandte Produkte im Sinne der Definition von EN ISO 10318-1.

Dieses Dokument behandelt die Bewertung und Überprüfung der Leistungsbeständigkeit des Produkts nach dieser Europäischen Norm und Verfahren für die werkseigene Produktionskontrolle.

Dieses Dokument legt die Anforderungen fest, die von den Herstellern und ihren autorisierten Vertretern in Bezug auf die Darstellung der Produkteigenschaften eingehalten werden müssen.

Wo Trinkwasser in direkten Kontakt mit dem Produkt kommt oder kommen soll, muss sich der Planer auf andere zutreffende Normen, Anforderungen und/oder Bestimmungen beziehen.

Géomembranes et géosynthétiques bentonitiques - Caractéristiques requises pour l'utilisation dans la construction des réservoirs et des barrages

Le présent document spécifie les caractéristiques applicables aux géosynthétiques d'étanchéité incluant les géomembranes polymériques, les géosynthétiques bentonitiques et les géomembranes bitumineuses utilisés comme barrière aux fluides ou couche de séparation pour l’eau dans la construction de réservoirs et de barrages, ainsi que les méthodes d'essai appropriées pour déterminer ces caractéristiques.

Ces produits sont destinés à contrôler les fuites d'eau potable, douce ou saline à travers la construction.

Le présent document ne s'applique pas aux géotextiles ou produits apparentés, tels que définis dans l'EN ISO 10318-1.

Le présent document permet d'évaluer et de vérifier la constance des performances (AVCP) du produit à la présente Norme européenne et les procédures de contrôle de la production en usine.

Le présent document établit les caractéristiques à considérer au regard des performances à vérifier.

NOTE Si de l'eau potable est ou peut être en contact direct avec le produit, il convient que le concepteur se réfère également aux normes, exigences et/ou règlements applicables.

Geosintetične zapore - Zahtevane lastnosti pri gradnji rezervoarjev in nasipov

Ta dokument določa ustrezne lastnosti geosintetičnih ovir, vključno s polimernimi, opečnati in bitumenskimi geosintetičnimi ovirami, ki se uporabljajo za zaščito pred tekočinami za pitno, sladko ali slano vodo, pri gradnji zbiralnikov in jezov, in ustrezne preskusne metode za določanje teh lastnosti. Ti proizvodi se predvidoma uporabljajo za nadzor uhajanja vode skozi konstrukcijo. Ta dokument ne velja za geotekstilije ali sorodne izdelke. Ta dokument omogoča vrednotenje skladnosti izdelka s tem dokumentom. Ta dokument določa zahteve, ki jih morajo izpolniti proizvajalci in njihovi pooblaščeni zastopniki glede predstavitve lastnosti izdelka. Ta dokument ne zajema uporabe, kjer bodo geosintetične zapore v stiku s pitno vodo, ki je namenjena ljudem. OPOMBA: Če je oz. bo lahko proizvod v stiku s pitno vodo, mora projektant upoštevati tudi druge ustrezne standarde, zahteve in/ali predpise.

General Information

- Status

- Published

- Publication Date

- 13-Mar-2018

- Withdrawal Date

- 30-Dec-2019

- Technical Committee

- CEN/TC 189 - Geotextiles and geotextile-related products

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 06-Oct-2023

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

CEN/TS 14416:2014 - Geosynthetic barriers - Test method for determining the resistance to roots - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 14415:2004 - Geosynthetic barriers - Test method for determining the resistance to leaching - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13361:2018 (CEN) defines the characteristics and test methods for geosynthetic barriers used as fluid barriers and separation layers in the construction of reservoirs and dams. It covers polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers intended to control leakage of potable, fresh or saline water. The standard also establishes procedures for assessment and verification of constancy of performance (AVCP), including factory production control (FPC) and requirements for presenting declared performance.

Key topics and requirements

- Scope and applicability

- Specifies intended use: leakage control for potable/fresh/saline water in reservoirs and dams.

- Not applicable to geotextiles or geotextile-related products (see EN ISO 10318‑1).

- Notes additional regulatory requirements when in direct contact with potable water.

- Characteristics and test methods

- Defines relevant characteristics to declare and verify (e.g., permeability, tensile/burst behaviour, mass per unit area, thickness and durability aspects) and references harmonised test methods.

- Normative references include test standards such as EN 14150 (permeability), EN 14151 (burst strength), EN ISO 10319 (tensile), EN 14196 (mass per unit area for clay barriers) and EN 16416 (water flux index for geosynthetic clay barriers).

- Includes methods for assessing resistance to chemicals, roots and environmental cycles (see EN 14414, CEN/TS 14416–14418).

- Durability

- Annex A addresses durability topics such as weathering, ageing and service-life considerations, and links durability testing to intended design life.

- Conformity and AVCP

- Procedures for type testing, factory production control and presentation of performance are provided to support CE marking and regulatory compliance (see Annex ZA for CPR alignment).

- Safety/environment

- Addresses release of dangerous substances and relevant assessment where applicable.

Applications

- Use cases: lining and sealing of reservoirs, dam cores, secondary containment for water storage, separation layers where water control is critical.

- Functions covered: fluid barrier, separation layer and leakage control for potable, freshwater and saline environments.

Who should use this standard

- Manufacturers of polymeric, clay and bituminous geosynthetic barriers

- Designers and engineers specifying reservoir and dam sealing systems

- Contractors and installers implementing barrier systems

- Testing laboratories, notified bodies and regulators carrying out AVCP, conformity assessment and performance verification

Related standards

- EN ISO 10318‑1 (terms/definitions for geosynthetics)

- EN 14414 / EN 14575 (chemical/oxidation resistance)

- EN 16416 (geosynthetic clay barrier permeability)

- Annex ZA links EN 13361 to Regulation (EU) No 305/2011 (Construction Products Regulation)

Keywords: EN 13361, geosynthetic barriers, reservoirs dams, polymeric geosynthetic barriers, clay geosynthetic barriers, bituminous geosynthetic barriers, AVCP, factory production control, permeability, durability, test methods.

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

EN 13361:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams". This standard covers: This document specifies the characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, when used as fluid barriers and separation layer for water, in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics. The intended use of these products is to control the leakage of potable, fresh or saline water through the construction. This document is not applicable to geotextiles or geotextile-related products, as defined in EN ISO 10318 1. This document provides for the assessment and verification of constancy of performance (AVCP) of the product to this European Standard including factory production control procedures. This document defines characteristics to be considered with regard to the presentation of performance. NOTE Where potable water is or can be in direct contact with the product, other relevant standards, requirements and/or regulations can be considered for the design.

This document specifies the characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, when used as fluid barriers and separation layer for water, in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics. The intended use of these products is to control the leakage of potable, fresh or saline water through the construction. This document is not applicable to geotextiles or geotextile-related products, as defined in EN ISO 10318 1. This document provides for the assessment and verification of constancy of performance (AVCP) of the product to this European Standard including factory production control procedures. This document defines characteristics to be considered with regard to the presentation of performance. NOTE Where potable water is or can be in direct contact with the product, other relevant standards, requirements and/or regulations can be considered for the design.

EN 13361:2018 is classified under the following ICS (International Classification for Standards) categories: 59.080.70 - Geotextiles; 91.100.50 - Binders. Sealing materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13361:2018 has the following relationships with other standards: It is inter standard links to EN 13361:2013, EN ISO 9864:2005, EN ISO 527-1:2012, EN 13254:2016, EN 12225:2000, CEN/TS 14416:2014, EN ISO 10319:2015, EN 14415:2004, EN 13249:2016, EN 1296:2000, EN 16416:2013, EN 13252:2016, EN 12311-2:2013, EN 14399-4:2005, EN 13255:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13361:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/107. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13361:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geosynthetische Dichtungsbahnen - Eigenschaften, die für die Anwendung beim Bau von Rückhaltebecken und Staudämmen erforderlich sindBarrières géosynthétiques - Caractéristiques requises pour l'utilisation dans la construction des réservoirs et des barragesGeosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams91.100.50Veziva. Tesnilni materialiBinders. Sealing materials59.080.70GeotekstilijeGeotextilesICS:Ta slovenski standard je istoveten z:EN 13361:2018SIST EN 13361:2018en,fr,de01-maj-2018SIST EN 13361:2018SLOVENSKI

STANDARDSIST EN 13361:20131DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13361

March

t r s z ICS

w {ä r z rä y râ

{ sä s r rä w r Supersedes EN

s u u x sã t r s uEnglish Version

Geosynthetic barriers æ Characteristics required for use in the construction of reservoirs and dams Géomembranes et géosynthétiques bentonitiques æ Caractéristiques requises pour l 5utilisation dans la construction des réservoirs et des barrages

Geosynthetische Dichtungsbahnen æ Eigenschaftená die für die Anwendung beim Bau von Rückhaltebecken und Staudämmen erforderlich sind This European Standard was approved by CEN on

t u October

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u u x sã t r s z ESIST EN 13361:2018

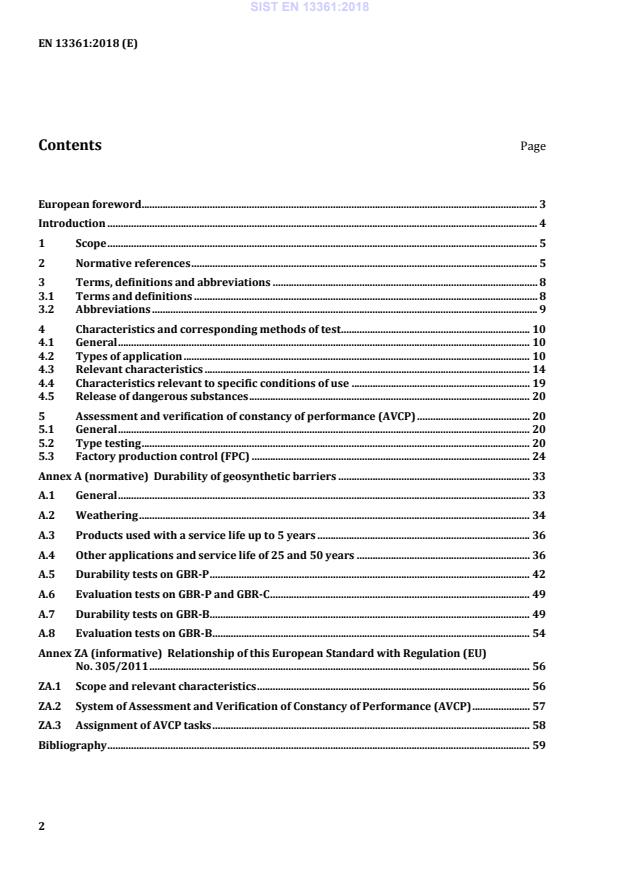

European foreword . 3 Introduction . 4 1 Scope . 5 2 Normative references . 5 3 Terms, definitions and abbreviations . 8 3.1 Terms and definitions . 8 3.2 Abbreviations . 9 4 Characteristics and corresponding methods of test . 10 4.1 General . 10 4.2 Types of application . 10 4.3 Relevant characteristics . 14 4.4 Characteristics relevant to specific conditions of use . 19 4.5 Release of dangerous substances . 20 5 Assessment and verification of constancy of performance (AVCP) . 20 5.1 General . 20 5.2 Type testing . 20 5.3 Factory production control (FPC) . 24 Annex A (normative)

Durability of geosynthetic barriers . 33 A.1 General . 33 A.2 Weathering . 34 A.3 Products used with a service life up to 5 years . 36 A.4 Other applications and service life of 25 and 50 years . 36 A.5 Durability tests on GBR-P . 42 A.6 Evaluation tests on GBR-P and GBR-C . 49 A.7 Durability tests on GBR-B . 49 A.8 Evaluation tests on GBR-B . 54 Annex ZA (informative)

Relationship of this European Standard with Regulation (EU) No. 305/2011 . 56 ZA.1 Scope and relevant characteristics . 56 ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 57 ZA.3 Assignment of AVCP tasks . 58 Bibliography . 59

the list of normative references has been updated;

in 3.1 three terms have been added;

in 3.2 list of abbreviations has been updated;

in 4.3, Table 1, has been modified to comply with the modified mandate M/386 (inclusion of elongation in separation and filtration functions) and has been technically revised, all H-coded characteristics have been replaced by “A”;

figures and keys have been revised;

Clause 5 “Evaluation of conformity” has been superseded by new Clause 5 “Assessment and verification of constancy of performance (AVCP)”

Annex A “Factory production control – Factory production control scheme” has been deleted;

former Annex B “Durability” becomes Annex A, which has been totally revised;

Annex ZA has been updated according to new template to fulfil requirements of CPR, also examples for CE-marking have been deleted. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 13361:2018

¯ y v °C and 30 °C ASTM D4603, Standard Test Method for Determining Inherent Viscosity of Poly(Ethylene Terephthalate) (PET) by Glass Capillary Viscometer

ASTM D5890, Standard test method for swell index of clay mineral component of geosynthetic clay liners ASTM D6141, Standard guide for screening clay portion of geosynthetic clay liner (GCL) for chemical compatibility to liquids1 ASTM D7409, Standard Test Method for Carboxyl End Group Content of Polyethylene Terephthalate (PET) Yarns 3 Terms, definitions and abbreviations 3.1 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 10318-1 and the following apply. 3.1.1 product geosynthetic barrier, including polymeric, bituminous and clay barriers 3.1.2 geosynthetic barrier barrier with at least one of whose components is made from a synthetic or natural polymer, in the form of a sheet, a strip or a three dimensional structure, used in contact with soil and/or other materials in geotechnical and civil engineering applications 3.1.3 project specification document in which the work, functions, specific conditions and required material property values of the geosynthetic barrier are described 3.1.4 reservoir naturally occurring space or construction for storage, regulation and control of water 3.1.5 dam barrier constructed to hold back water to raise its level, form a reservoir or reduce or prevent flooding

1 http://www.astm.org/Standards/D6141.htm SIST EN 13361:2018

Key 1 top water level 2 upstream face 3 revetment 4 geosynthetic barrier 5 dam body 6 protection geosynthetic (optional) Figure 1 — Geosynthetic barrier on a reservoir or dam slope (shallow), covered in service SIST EN 13361:2018

Key 1 top water level face of dam 2 protection geosynthetic (optional) 3 geosynthetic barrier 4 facing 5 body of dam Figure 2 — Geosynthetic barrier on a reservoir or dam slope (steep), covered in service 4.2.3 Application 2: “not covered in service” As in application 1, but with the GBR not covered in service with a revetment or other protective layers. Figure 3 and Figure 4 show typical installations. SIST EN 13361:2018

Key 1 top water level 2 upstream face 3 geosynthetic barrier 4 dam body 5 protection geosynthetic (optional) Figure 3 — Geosynthetic barrier on a reservoir or dam slope (shallow), exposed in service

Key 1 top water level 2 geosynthetic barrier 3 body of dam 4 protection geosynthetic (optional) Figure 4 — Geosynthetic barrier on a reservoir or dam slope (steep), exposed in service SIST EN 13361:2018

Where products are jointed in the factory the liquid tightness and if relevant the strength of the joints shall be tested and data presented. SIST EN 13361:2018

Covered in service Not covered in service Test methods Remarks No Property to be testeda GBR-P GBR-B GBR-C GBR-P GBR-B GBR-P GBR-B GBR-C

Physical properties

1 Thickness A A A A A EN ISO 9863-1 EN 1849–1 EN ISO 9863-1 For products which cannot be tested according to EN ISO 9863-1, such as geotextile backed GBR-P, EN 1849–2 is applicable. 2 Mass per unit area A A A A A EN 1849–2 EN 1849–1 EN 14196

Hydraulic properties

3 Liquid tightness A A A A A EN 14150 EN 14150 EN 16416 Test liquid is water. Report value index flux for GBR-C and permeability for GBR-P and GBR-B. 4 Swell index — — A — — — — ASTM D5890

Mechanical properties

5 Tensile strength A A A A A PE-HD and PE-LLD EN ISO 527-3, specimen type 5 FPO, PVC-P homogenous EN ISO 527-3, specimen type 5 (reference test method) equivalent to EN 12311–2, method B FPO, PVC-P multicomponent EN 12311–2 method A (reference test EN 12311–1 EN ISO 10319 PE-HD and PE-LLD v = 100 mm/min Tensile stress at break in N/mm2 to be reported FPO, PVC-P homogenous v = 100 mm/mm if elongation at break is > 400 % the test speed is 500 mm/min maximum tensile strength in N/mm2 to be reported FPO, PVC-P multicomponent v = 100 mm/min maximum tensile force in N/50 mm to be reported EPDM homogenous v = 100 mm/min SIST EN 13361:2018

Covered in service Not covered in service Test methods Remarks No Property to be testeda GBR-P GBR-B GBR-C GBR-P GBR-B GBR-P GBR-B GBR-C

method) equivalent to EN ISO 527-4; specimen type 2; width: 50 mm,

EPDM homogenous EN 12311–2, method B EPDM multicomponent EN 12311–2, method A if elongation at break is > 400 % the test speed is 500 mm/min maximum tensile strength in N/mm2 to be reported EPDM multicomponent v = 100 mm/min maximum tensile force in N/50 mm to be reported 6 Elongation A A A A A PE-HD and PE-LLD EN ISO 527-3, specimen type 5 FPO, PVC-P homogenous EN ISO 527-3, specimen type 5 (reference test method)equivalent to EN 12311–2, method B FPO, PVC-P multicomponent EN 12311–2 method A (reference test method)equivalent to EN ISO 527-4; specimen type 2;

width: 50 mm EN 12311–1 EN ISO 10319 PE-HD and PE-LLD with reference length

(l0)50 mm,

v = 100 mm/min Elongation at break to be reported FPO, PVC-P homogenous v = 100 mm/min if elongation at break is > 400 % the test speed is 500 mm/min – Elongation at break to be reported FPO, PVC-P multicomponent v = 100 mm/min Elongation at maximum tensile force

in % to be reported EPDM homogenous v = 100 mm/min if elongation at break is > 400 % the test speed is 500 mm/min Elongation at break to be reported SIST EN 13361:2018

Covered in service Not covered in service Test methods Remarks No Property to be testeda GBR-P GBR-B GBR-C GBR-P GBR-B GBR-P GBR-B GBR-C

EPDM homogenous EN 12311–2, method B EPDM multicomponent EN 12311–2, method A EPDM multicomponent v = 100 mm/min Elongation at maximum tensile force

in % to be reported 7 Static puncture A A A A A EN ISO 12236 EN ISO 12236 EN ISO 12236

8 Burst strength and elongation S S S S S EN 14151 EN 14151 EN 14151 This test applies to GBR-C only if they contain a polymeric or bituminous barrier element. 9 Tear strength S S — S S ISO 34-1 EN 12310–1 — For GBR-P use ISO 34-1:2015, Method B, angle specimen (Figure 2) without nick at a speed of 50 mm/min. 10 Friction direct shear S S S — — EN ISO 12957-1 EN ISO 12957-1 EN ISO 12957-1 For determining the bonding strength of GBR-C, an internal shear or peel bond test may be applicable. 11 Friction inclined

plane S S S — — EN ISO 12957-2 EN ISO 12957-2 EN ISO 12957-2

Thermal properties

12 Low temperature behaviour (flexure) S S — S S EN 495–5 EN 1109 —

13 Thermal expansion A — — A — ASTM D696 — —

Durability

14 Weathering A A S A A EN 12224 EN 12224 EN 12224

15 Microorganisms A A A A A EN 12225 EN 12225 EN 12225

16 Oxidation A A A A A EN 14575 EN 14575 EN ISO 13438 EN ISO 13438 is applicable for the geotextile elements and reinforcement yarns of GBR-C. EN 14575 with test conditions as stated in Annex A of SIST EN 13361:2018

Covered in service Not covered in service Test methods Remarks No Property to be testeda GBR-P GBR-B GBR-C GBR-P GBR-B GBR-P GBR-B GBR-C

this standard. 17 Environmental stress cracking A — S A — EN 14576 — EN 14576 EN 14576 is applicable to GBR-P with a semi-crystalline structure. If GPR-P is between 0,5 mm and 1,0 mm the test EN 14576 shall be performed with the same composition at a thickness greater than 1,0 mm. 18 Chemical resistance S S S — — EN 14414 EN 14414 ASTM D6141 In accordance with Annex A. Chemical resistance testing should be conducted in line with site specific circumstances. This should be restricted to a consideration of the substrate onto which the material is laid and/or chemicals contained. 19 Leaching (water soluble) A A A A A EN 14415 EN 14415 EN 14415

20 Wetting/drying — — S — — — — CEN/TS 14417

21 Freezing/thawing — — S — — — — CEN/TS 14418

22 Root penetration S S S S S CEN/TS 14416 CEN/TS 14416 CEN/TS 14416

a NOTE The 95 % confidence level corresponds to the mean value minus (and/or plus) a tolerance value (see Annex ZA, Table ZA.1 column Notes). Both the mean value and the tolerance value are defined by the manufacturer to be representative of the performance of the product for the corresponding characteristic (these two values are not necessarily based on a statistical calculation). Relevance of codes: A: relevant to all conditions of use S: relevant to specific conditions of use “—”: indicates that the characteristic is not relevant for that product Particular site-specific application cases may contain requirements for additional properties and - preferably standardized - test methods, if they are technically relevant and not conflicting with European Standards. The design life of the product should be determined, since its function may be temporary, as construction expediency, or permanent, for the lifetime of the structure. SIST EN 13361:2018

(CBR test) 4.3, Table 1 According to 4.3, Table 1 5 Not defined Liquid tightness (Water permeability respective water flux index)- 4.3, Table 1 According to 4.3, Table 1 1 Not defined Elongation 4.3, Table 1 According to 4.3, Table 1 5 MD/5 CMD Not defined Durability 4.3, Table 1 and Annex A According to 4.3, Table 1 and Annex A See Annex A See Annex A 5.2.3 Test reports The results of the determination of the product type shall be documented in test reports. All test reports shall be retained by the manufacturer for at least 10 years after the last date of production of the geosynthetic barriers, for use in the construction of reservoirs and dams to which they relate. 5.2.4 Shared other party results A manufacturer may use the results of the product type determination (in consistency with this standard) obtained by someone else (e.g. by another manufacturer, as a common service to manufacturers, or by a product developer), to justify his own declaration of performance regarding a product that is manufactured according to the same design (e.g. dimensions) and with raw materials, constituents and manufacturing methods of the same kind, provided that: — the results are known to be valid for products with the same essential characteristics relevant for the product performance; — in addition to any information essential for confirming that the product has such same performances related to specific essential characteristics, the other party who has carried out the determination of the product type concerned or has had it carried out, has expressly accepted 2) to transmit to the manufacturer the results and the test report to be used for the latter’s product type determination, as well as information regarding production facilities and the production control process that can be taken into account for FPC; — the manufacturer using other party results accepts to remain responsible for the product having the declared performances and he also: a) ensures that the product has the same characteristics relevant for performance as the one that has been subjected to the determination of the product type, and that there are no significant

2) The formulation of such an agreement can be done by license, contract, or any other type of written consent. SIST EN 13361:2018

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...