EN 15381:2008

(Main)Geotextiles and geotextile-related products - Characteristics required for use in pavements and asphalt overlays

Geotextiles and geotextile-related products - Characteristics required for use in pavements and asphalt overlays

This European Standard specifies the relevant characteristics of metallic and non-metallic geotextiles and geotextile-related products used in the construction of pavements and asphalt overlays and the appropriate test methods to determine these characteristics.

The intended use of these geotextiles and geotextile-related products is to fulfil one or more of the following functions: reinforcement, stress relief and barrier. The use of geotextiles and geotextile-related products is to be considered as a part of an interlayer and asphalt overlay system.

This standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318.

This standard provides for evaluation of conformity of the product to this European Standard and for factory production control procedures.

This standard defines requirements to be met by manufacturers and distributors with regard to the presentation of product properties.

NOTE 1 Particular application cases or national specifications may contain additional requirements regarding product application or installation and specifying preferably standardized test methods, if they are technically relevant and not conflicting with European Standards.

Geotextilien und geotextilverwandte Produkte - Eigenschaften, die für die Anwendung beim Bau von Fahrbahndecken und Asphaltdeckschichten erforderlich sind

Diese Europäische Norm legt die relevanten Eigenschaften von metallischen und nicht metallischen Geotextilien und geotextilverwandten Produkten, die beim Bau von Fahrbahndecken und Asphaltdeckschichten verwendet werden, sowie die geeigneten Prüfverfahren zur Bestimmung dieser Eigenschaften fest.

Die bestimmungsgemäße Anwendung dieser Geotextilien und geotextilverwandten Produkte besteht in der Erfüllung einer oder mehrerer der folgenden Funktionen: Bewehren, Spannungsentlastung und Abdichten. Die Verwendung von Geotextilien und geotextilverwandten Produkten ist als ein Bestandteil eines Zwischenschicht und Asphalt¬deckschichtsystems zu betrachten.

Diese Europäische Norm ist nicht auf geosynthetische Dichtungsbahnen, wie in EN ISO 10318 festgelegt, anwendbar.

Diese Europäische Norm behandelt die Konformitätsbewertung des Produktes bezüglich dieser Europäischen Norm und die werkseigene Produktionskontrolle.

Diese Europäische Norm legt Anforderungen fest, die von Herstellern und Händlern für die Darstellung von Produkteigenschaften zu beachten sind.

ANMERKUNG Besondere Anwendungen oder nationale Bestimmungen können Anforderungen hinsichtlich zusätzlicher Eigenschaften und — vorzugsweise genormter — Prüfverfahren enthalten, wenn diese technisch relevant sind und sie Europäischen Normen nicht entgegenstehen.

Géotextiles et produits apparentés - Caractéristiques requises pour l'utilisation dans les chaussées et couches de roulement en enrobés

La présente Norme européenne spécifie les caractéristiques applicables des géotextiles et produits apparentés utilisés dans la construction des chaussées et de couches de roulement en enrobés et les méthodes d'essai appropriées pour la détermination de ces caractéristiques.

L'utilisation prévue de ces géotextiles et produits apparentés est de satisfaire l'une ou plusieurs des fonctions suivantes : le renforcement, la réduction de contraintes et l’utilisation en tant que couche d'étanchéité. L'utilisation de géotextiles et produits apparentés doit être considérée comme faisant partie d'un complexe intercouches et de couche de roulement en enrobé.

La présente norme ne s'applique pas aux géomembranes définies dans l’EN ISO 10318.

La présente norme donne les informations permettant d'évaluer la conformité du produit à la présente Norme européenne et définissant les procédures de contrôle de fabrication en usine.

La présente norme définit les exigences auxquelles les fabricants et distributeurs doivent satisfaire pour la présentation des propriétés du produit.

NOTE 1 Dans certains cas particuliers d'application ou pour des spécifications nationales, des propriétés et des méthodes d'essai supplémentaires - de préférence normalisées - peuvent être définies à condition qu'elles soient pertinentes d'un point de vue technique et qu'elles ne soient pas en opposition avec les Normes européennes.

Geotekstilije in geotekstilijam sorodni izdelki - Zahtevane lastnosti za uporabo na voziščih in asfaltnih prevlekah

General Information

- Status

- Published

- Publication Date

- 19-Aug-2008

- Withdrawal Date

- 30-May-2010

- Technical Committee

- CEN/TC 189 - Geotextiles and geotextile-related products

- Drafting Committee

- CEN/TC 189/WG 1 - ad hoc group Asphalt reinforcement

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 20-Aug-2008

- Due Date

- 11-Jul-2008

- Completion Date

- 20-Aug-2008

- Directive

- 89/106/EEC - Construction products

Relations

- Refers

EN 10080:2005 - Steel for the reinforcement of concrete - Weldable reinforcing steel - General - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15381:2008 (CEN) defines the characteristics and test methods for metallic and non‑metallic geotextiles and geotextile‑related products intended for use in pavements and asphalt overlays. The standard covers products used as part of an interlayer and overlay system to provide reinforcement, stress relief and/or a barrier to water ingress. It sets out requirements for product declaration, evaluation of conformity, factory production control and marking. EN 15381:2008 is not applicable to geosynthetic barriers (see EN ISO 10318).

Key topics and technical requirements

- Intended functions: reinforcement, stress relief (paving fabrics to delay crack propagation), and interlayer barrier performance.

- Required characteristics: mechanical and durability properties relevant to pavement use (tensile strength, elongation, puncture resistance, melting point, alkaline resistance, resistance to weathering, corrosion for metallic elements).

- Test methods referenced: a range of harmonized test standards for sampling and performance measurement, for example EN ISO 10319 (wide‑width tensile), EN ISO 12236 (static puncture/CBR), EN ISO 13433 (dynamic perforation), EN 12224 (weathering), EN 14030 (acid/alkaline resistance) and EN ISO 9862 (sampling). The standard lists which test applies to each declared property.

- Conformity and quality control: procedures for initial type testing, factory production control (Annex A), inspection and verification of declared values. The standard supports product evaluation under EU Construction Products Directive provisions (informative Annex ZA) and CE marking requirements.

- Product information and marking: requirements for how manufacturers and distributors must present product properties and labelling on site (EN ISO 10320 referenced).

Applications and who uses this standard

EN 15381:2008 is directly relevant to:

- Civil engineers and pavement designers specifying interlayer systems and overlays.

- Geosynthetic manufacturers and distributors declaring product properties and implementing factory production control.

- Contractors and installers selecting paving fabrics and geotextiles for rehabilitation and new pavements.

- Test laboratories performing conformity and performance testing.

- Highway authorities and asset owners establishing procurement specifications that require documented test methods and durability evidence.

Practical benefits include better specification of interlayer materials, improved performance prediction for overlays, and a harmonized basis for procurement and CE marking across Europe.

Related standards

- EN ISO 10318 (terms/definitions) - note: geosynthetic barriers excluded from EN 15381.

- EN ISO 10319, EN ISO 12236, EN ISO 13433, EN 12224, EN 14030, EN ISO 9862 - referenced test and sampling standards.

- Informative Annex ZA addresses links to the EU Construction Products Directive.

Keywords: EN 15381:2008, geotextiles, geotextile-related products, pavements, asphalt overlays, reinforcement, stress relief, interlayer, test methods, factory production control, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Bureau Veritas Bangladesh

Bureau Veritas certification services in Bangladesh.

ECOCERT France

Leader in organic and sustainability certification worldwide.

Sponsored listings

Frequently Asked Questions

EN 15381:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Geotextiles and geotextile-related products - Characteristics required for use in pavements and asphalt overlays". This standard covers: This European Standard specifies the relevant characteristics of metallic and non-metallic geotextiles and geotextile-related products used in the construction of pavements and asphalt overlays and the appropriate test methods to determine these characteristics. The intended use of these geotextiles and geotextile-related products is to fulfil one or more of the following functions: reinforcement, stress relief and barrier. The use of geotextiles and geotextile-related products is to be considered as a part of an interlayer and asphalt overlay system. This standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318. This standard provides for evaluation of conformity of the product to this European Standard and for factory production control procedures. This standard defines requirements to be met by manufacturers and distributors with regard to the presentation of product properties. NOTE 1 Particular application cases or national specifications may contain additional requirements regarding product application or installation and specifying preferably standardized test methods, if they are technically relevant and not conflicting with European Standards.

This European Standard specifies the relevant characteristics of metallic and non-metallic geotextiles and geotextile-related products used in the construction of pavements and asphalt overlays and the appropriate test methods to determine these characteristics. The intended use of these geotextiles and geotextile-related products is to fulfil one or more of the following functions: reinforcement, stress relief and barrier. The use of geotextiles and geotextile-related products is to be considered as a part of an interlayer and asphalt overlay system. This standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318. This standard provides for evaluation of conformity of the product to this European Standard and for factory production control procedures. This standard defines requirements to be met by manufacturers and distributors with regard to the presentation of product properties. NOTE 1 Particular application cases or national specifications may contain additional requirements regarding product application or installation and specifying preferably standardized test methods, if they are technically relevant and not conflicting with European Standards.

EN 15381:2008 is classified under the following ICS (International Classification for Standards) categories: 59.080.70 - Geotextiles; 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15381:2008 has the following relationships with other standards: It is inter standard links to EN 10080:2005, EN ISO 10318:2005, EN ISO 13934-1:2013, EN ISO 15630-2:2019, EN 1426:2024, EN ISO 6892-1:2019, prEN 10348-1, EN 12224:2000, EN ISO 9862:2023, EN ISO 12960:2020, EN ISO 12236:2006, EN ISO 1043-1:2001, EN ISO 10320:2019, EN ISO 3146:2022, EN ISO 13433:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15381:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/107. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15381:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geotextilien und geotextilverwandte Produkte - Eigenschaften, die für die Anwendung beim Bau von Fahrbahndecken und Asphaltdeckschichten erforderlich sindGéotextiles et produits apparentés - Caractéristiques requises pour l'utilisation dans les chaussées et couches de roulement en enrobésGeotextiles and geotextile-related products - Characteristics required for use in pavements and asphalt overlays93.080.20Materiali za gradnjo cestRoad construction materials59.080.70GeotekstilijeGeotextilesICS:Ta slovenski standard je istoveten z:EN 15381:2008SIST EN 15381:2009en,fr,de01-januar-2009SIST EN 15381:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15381August 2008ICS 59.080.70; 93.080.20 English VersionGeotextiles and geotextile-related products - Characteristicsrequired for use in pavements and asphalt overlaysGéotextiles et produits apparentés - Caractéristiquesrequises pour l'utilisation dans les chaussées et couchesde roulement en enrobésGeotextilien und geotextilverwandte Produkte -Eigenschaften, die für die Anwendung beim Bau vonFahrbahndecken und Asphaltdeckschichten erforderlichsindThis European Standard was approved by CEN on 18 July 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15381:2008: ESIST EN 15381:2009

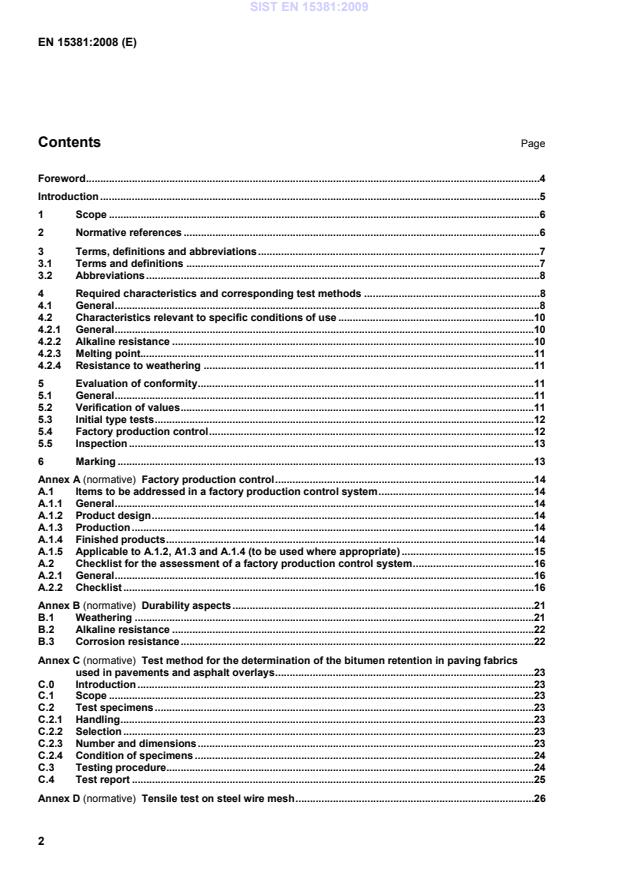

Characteristics relevant to specific conditions of use.10 4.2.1 General.10 4.2.2 Alkaline resistance.10 4.2.3 Melting point.11 4.2.4 Resistance to weathering.11 5 Evaluation of conformity.11 5.1 General.11 5.2 Verification of values.11 5.3 Initial type tests.12 5.4 Factory production control.12 5.5 Inspection.13 6 Marking.13 Annex A (normative)

Factory production control.14 A.1 Items to be addressed in a factory production control system.14 A.1.1 General.14 A.1.2 Product design.14 A.1.3 Production.14 A.1.4 Finished products.14 A.1.5 Applicable to A.1.2, A1.3 and A.1.4 (to be used where appropriate).15 A.2 Checklist for the assessment of a factory production control system.16 A.2.1 General.16 A.2.2 Checklist.16 Annex B (normative)

Durability aspects.21 B.1 Weathering.21 B.2 Alkaline resistance.22 B.3 Corrosion resistance.22 Annex C (normative)

Test method for the determination of the bitumen retention in paving fabrics used in pavements and asphalt overlays.23 C.0 Introduction.23 C.1 Scope.23 C.2 Test specimens.23 C.2.1 Handling.23 C.2.2 Selection.23 C.2.3 Number and dimensions.23 C.2.4 Condition of specimens.24 C.3 Testing procedure.24 C.4 Test report.25 Annex D (normative)

Tensile test on steel wire mesh.26 SIST EN 15381:2009

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.27 ZA.1 Scope and relevant characteristics.27 ZA.2 Procedure for the attestation of conformity of geotextiles and geotextile-related products used in pavements and asphalt overlays.30 ZA.2.1 Systems of attestation of conformity.30 ZA2.2 Certificate and declaration of conformity.31 ZA.3 CE-marking and labelling.32 Bibliography.36

The intended use of these geotextiles and geotextile-related products is to fulfil one or more of the following functions: reinforcement, stress relief and barrier. The use of geotextiles and geotextile-related products is to be considered as a part of an interlayer and asphalt overlay system. This standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318. This standard provides for evaluation of conformity of the product to this European Standard and for factory production control procedures. This standard defines requirements to be met by manufacturers and distributors with regard to the presentation of product properties. NOTE 1 Particular application cases or national specifications may contain additional requirements regarding product application or installation and specifying preferably standardized test methods, if they are technically relevant and not conflicting with European Standards. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1426, Bitumen and bituminous binders – Determination of needle penetration EN 10002-1, Metallic materials – Tensile testing – Part 1: Method of test at ambient temperature EN 10080, Steel for the reinforcement of concrete – Weldable reinforcing steel – General EN 10223-3, Steel wire and wire products for fences – Part 3: Hexagonal steel wire netting for engineering purposes EN 10244-2, Steel wire and wire products – Non ferrous metallic coatings on steel wire – Part 2: Zinc or zinc alloy coatings prEN 10348, Steel for the reinforcement of concrete – Galvanized reinforcing steel EN 12224, Geotextiles and geotextile-related products – Determination of the resistance to weathering EN 14030, Geotextiles and geotextile-related products – Screening test method for determining the resistance to acid and alkaline liquids (ISO/TR 12960:1998, modified) EN ISO 1043-1:2001, Plastics – Symbols and abbreviated terms – Part 1: Basic polymers and their special characteristics (ISO 1043-1:2001) EN ISO 3146, Plastics –– Determination of melting behaviour (melting temperature or melting range) of semi-crystalline polymers by capillary tube and polarizing-microscope methods (ISO 3146:2000) EN ISO 9862, Geosynthetics – Sampling and preparation of test specimens (ISO 9862:2005) EN ISO 10318:2005, Geosynthetics – Terms and definitions (ISO 10318:2005) SIST EN 15381:2009

STR function provided by a bitumen-saturated paving fabric (non-woven or purpose-built composite) which – when properly installed between a road surface and a new asphalt overlay – allows for slight differential movements SIST EN 15381:2009

polyamide PE:

polyethylene PET:

polyethylene terephthalate (“polyester”) PP:

polypropylene PVA:

polyvinyl alcohol Furthermore the following abbreviations apply: MD:

machine direction CMD:

cross machine direction 4 Required characteristics and corresponding test methods 4.1 General The main function of geotextiles and geotextile-related products used in the construction and rehabilitation of roads and pavements subjected to thermal, fatigue and reflective cracking is to reduce the amount of cracking in a new pavement or asphalt overlay. In addition, a barrier to top-down water ingress to the subbase and/or subgrade may be provided for.

This is achieved by reinforcement, stress relief, (interlayer) barrier or a combination of these functions.

The producer of the geotextiles and geotextile-related products shall provide the data based on the results of tests specified in this standard. The characteristics, their relevance to the conditions of use, and the test methods to be used, are given in Tables 1 and 2. The list of characteristics in these tables includes those needed for regulatory purposes (H) (see also [1]), those relevant to all conditions of use (A), and those relevant to specific conditions of use (S). ”- -” indicates that the characteristic is not relevant for that function. Where, for the same property, data for more than one function shall be provided, the following ranking order shall be observed: H overrules A, A overrules S, and S overrules "--". The functions and conditions of use, corresponding with the characteristics, marked with “S” in Table 1, are specified in 4.2. SIST EN 15381:2009

Characteristic Test method Function

Reinforce-ment Stress relief Interlayer barrier

(1) Tensile strength

EN ISO 10319 a H H H (2) Elongation at maximum load

EN ISO 10319 a

H H H (3) Dynamic perforation

b EN ISO 13433 H - - H (4) Static puncture strength b

EN ISO 12236 H H H (5) Durability Annex B H H H (6) Resistance to weathering c

EN 12224

B.1 of this standard S S S (7) Bitumen retention

Annex C - - H A (8) Melting point

EN ISO 3146

S S S (9) Alkaline resistance (see remark 3) EN 14030 B.2 of this standard S S S Relevance H: required for regulatory purposes

A: relevant to all conditions of use, but not mandatory for design or specifications S: relevant to specific conditions of use “- - “ indicates that the characteristic is not relevant for that function. a

EN ISO 10319 may not be suitable for specific products (e.g. glass fibre grids). In these cases the more appropriate methods EN ISO 13934-1 or ASTM D6637-01 shall be used. In any case, tensile tests shall be performed on finished products. b

The principle of this test may not be applicable for all materials and the validity of the test for some types of products, e.g. grids, should be considered. If tensile strength and static puncture are coded "H" in this table, the producer shall be able to provide data for both. In a specification the use of only one property – either tensile strength or static puncture – is sufficient. c

Required for regulatory purposes (H) if relevant to conditions of use (see 4.2). SIST EN 15381:2009

Characteristic Test method Function

Reinforcement (1) Tensile strength

- steel wire mesh a - parallel to mesh orientation - transverse to mesh orientation - steel welded fabric b

Annex D EN 10002-1 EN ISO 15630-2 H (2) Elongation at maximum load - steel wire mesh - parallel to mesh orientation - transverse to mesh orientation - steel welded fabric

Annex D EN 10002-1 EN ISO 15630-2 H (3) Dynamic perforation

c EN ISO 13433 -- (4) Static puncture strength c

EN ISO 12236 -- (5) Durability Annex B3 H Relevance H: required for regulatory purposes [1] “- - “ indicates that the characteristic is not relevant for that function. a As defined in EN 10223-3. b As defined in EN 10080. c The principle of this test characteristic is not applicable.

4.2

Characteristics relevant to specific conditions of use 4.2.1 General The specification shall define which functions and conditions of use are relevant (see Tables 1 and 2). The producer of the product shall provide the necessary data based on the requirements and test methods described in this standard. The list of characteristics in Tables 1 and 2 includes those required for regulatory purposes (H), those relevant to all conditions of use (A), and those relevant to specific conditions of use (S).These specific conditions of use are listed from 4.2.2 to 4.2.4. NOTE “Damage during installation” is being influenced by the paving procedure and by the compaction of the asphalt. Relevant test methods are under preparation.

4.2.2 Alkaline resistance Data on the alkaline resistance is needed for all functions if the product is to be used in direct contact with an unprotected concrete or cement stabilised surface. SIST EN 15381:2009

If the test results for a particular characteristic are within the tolerance value(s) given by the manufacturer, the product is accepted as complying with respect to this characteristic. If the test results for a particular characteristic are outside 1,5 times the tolerance value(s), the product does not comply with respect to that characteristic. If the test results for a particular characteristic are within 1 and 1,5 times the tolerance value(s), specimens prepared from sample B shall be tested. NOTE The 95 % confidence level corresponds to the mean value minus (and/or plus) 1,0 tolerance value(s). If the test results of the sample B specimens for the same characteristic are within the given tolerance value(s), the product is accepted as complying with respect to that characteristic. If the test results are outside the tolerance value(s), the product is not accepted. SIST EN 15381:2009

The results of initial type tests shall be recorded and be available for inspection. The sample for the type tests shall be drawn according to EN ISO 9862 from a normal production run using the materials and forming processes to be used for the full production process. The size of the sample shall be big enough to allow the determination of the characteristics specified in Table 1 or 2. Handmade samples, short trial batches and other development prototypes may be tested by the same methods, but shall not be used for establishing characteristic values in type tests.

5.4 Factory production control A factory production control scheme shall be established and documented in a manual prior to a product type being placed on the market. Subsequently, any fundamental changes in raw materials and additives, manufacturing procedures or the control scheme that affect the properties or use of a product shall be recorded in the manual. The manual shall include the factory production control procedures relevant to the declared properties, as confirmed by the initial type tests.

The factory production control procedures shall consist of a permanent internal production control system to ensure that such products comply with this standard and that the measured values conform with the declared values.

Annex A (normative) lists all the items that shall be considered to determine which is appropriate for the control exercised for a product. The manufacturer shall establish the applicable items and record them in his factory production control manual.

When relevant, the procedure given in 5.2 shall be used to check the conformity of the product for one or more characteristics. SIST EN 15381:2009

When required, inspection of the factory and of the factory production control shall be made on the provisions contained in 5.4 and Annex A. 6 Marking

The manufacturer shall clearly and indelibly mark the geotextiles and geotextile related products with the information specified in EN ISO 10320. NOTE For CE-marking see ZA.3. SIST EN 15381:2009

Factory production control A.1 Items to be addressed in a factory production control system A.1.1 General This normative annex specifies the items to be addressed in the manufacturer's factory production control manual relating to the control scheme determined in 5.4. The manufacturer shall determine which items apply to his particular situation, depending on the stages of design, production and product storage he assumes responsibility for. This annex also provides a check-list for the operation of such a control scheme (see A.2). NOTE Manufacturers operating a quality system conforming to EN ISO 9001 [4] are presumed to be able to meet the requirements of this Annex A.

A.1.2 Product design The manufacturer shall describe how design requirements and criteria are identified, checked, controlled and updated to be unambiguous and relevant to the use of the product and its specification. The manufacturer shall describe the communication of the design to the internal production departments or to external subcontractors. A.1.3 Production Raw or incoming materials: the manufacturer shall define the acceptance criteria of raw or incoming materials and the procedures that he operates to ensure that these are met. Production process: the relevant features of the plant and production process shall be defined giving the frequency of the inspections, checks and tests, together with the values or criteria required, both on equipment and on work in the process. The actions to be taken when control values or criteria are not obtained, shall be recorded. These records shall be kept available. A.1.4 Finished products A.1.4.1 Tests on the finished product The size of the samples and the frequency of sampling, together with the results obtained, shall be recorded and shall be kept available. A.1.4.2 Alternative tests Where alternative tests to the reference tests are used, details of the alternative tests and procedures together with their correlation with the reference tests shall be recorded and shall be kept available. SIST EN 15381:2009

The manufacturer shall calibrate or verify, measuring or test equipment and maintain it in good operating condition, whether or not it belongs to him, with a view to demonstrating conformity of the product with its technical specification. The appropriate calibrations shall be carried out with defined measuring and test instruments according to standards or the manufacturer’s test procedures.

The equipment shall be used in conformity with the specification or the test reference system to which the specification refers. A.1.5 Applicable to A.1.2, A1.3 and A.1.4 (to be used where appropriate) A.1.5.1 Records

The dates, together with details and results of inspections, checks and tests carried out during the factory production control shall be properly recorded. These records shall be maintained for 10 years. The product description, the date of manufacture, test method adopted, test results and acceptance or rejection criteria shall be entered under the signature of the person responsible for control who carried out the verification. A.1.5.2 Assessment of results

Where possible and applicable, the results of inspections, checks and tests shall be interpreted statistically by attributes or by variables to determine whether the corresponding production conforms with the requirements and the declared values for the products. A.1.5.3 Traceability

Systems of traceability and control of designs, incoming materials, and the use of materials shall be given in the manual. The stock control system of manufactured products shall be given in the manual. A.1.5.4 Corrective action for non-conforming materials and products The immediate actions to be taken when incoming materials or finished products do not conform to specified requirements shall be described and recorded. These actions shall include the steps necessary to rectify the deficiency, modify the manual if required, identify and isolate the deficient raw or incoming materials and finished products and determine whether they shall be discarded or re-specified under a concessionary system. A.1.5.5 Personnel The manufacturer shall ensure that the personnel involved in the process are suitably trained. The job description and responsibility of the operatives shall be given in the manual. A.1.5.6 Quality management The activities to ensure that all of the above requirements operate shall be described in the manual. SIST EN 15381:2009

Checklist for the assessment of a factory production control system A.2.1 General A factory production control certificate (FPC certificate) can only be issued for one production site. In case of several production lines at the same site, all of them shall be checked. In order to have all production lines covered by the same FPC certificate number, the homogeneity of the products produced by different lines at the same production site shall be proven by the manufacturer. The results of audits performed by a quality management system certification body (e.g. for EN ISO 9001 certification) shall be taken into account, although such certificate is not compulsory. The FPC certificate shall cover specified product ranges produced on the same production site. Each product covered by the certificate shall be clearly identified in the certificate. To add a new product to the covered range, the producer shall inform the notified body and submit the results of the initial type testing of the new product for an extension of the FPC certificate. This shall be taken into account at the next follow-up inspection. In case of a new production process the manufacturer shall apply for a new inspection visit. Follow-up inspections shall take place once a year. All the questions in this checklist shall be checked at the first inspection visit and at each follow-up inspection. A.2.2 Checklist The items marked with "E" are considered to be of essential importance, i.e. immediate corrective actions are needed if the requirement is not fulfilled. The assessment can lead to A-, B- or C-type remarks: A: an immediate corrective action is needed to obtain or renew the certificate; B: corrective action shall be taken within 3 months; C: corrective action shall be taken before the next inspection visit If a B-type remark is not corrected in due time, it becomes an "A" and if a C-type remark is not corrected in due time, it becomes a "B".

Question Relevance Comment 1

Design 1.1 - Has the manufacturer a description how design requirements and criteria are identified, checked, controlled and updated to be unambiguous and relevant to the use of the product and its specification?

To be assessed only if claimed by the manufacturer. The assessment body shall refer to the manufacturer's documentation. 1.2 - Has the manufacturer a description of the communication of the design to the internal production departments or to external subcontractors?

To be assessed only if claimed by the manufacturer. The assessment body shall refer to the manufacturer's documentation. SIST EN 15381:2009

3 Production process control 3.1 -Are there documents which define the production process parameters which could affect quality? E Refer to the manufacturer's documentation.

3.2 -Are the standards, quality plan and procedures implemented? E

3.3 -Are the specified requirements concerning process validation, including the associated personnel and equipment, documented? E Refer to the manufacturer's documentation. 4 Inspection and testing on receipt of raw materials 4.1 - Are there specification sheets concerning incoming raw materials? E Refer to the manufacturer's documentation. 4.2 - Are there documents which define what shall be done in case of non-conformance of raw materials? E Refer to the manufacturer's documentation. 4.3 - Are the nature and frequency of the evaluation of incoming raw materials described and followed? E Refer to the manufacturer's documentation. 5 Inspection and testing during manufacturing 5.1 - Are there inspections or tests during the manufacturing process with specific requirement for the results? E Refer to the manufacturer's documentation. 5.2 - Are there documents concerning inspection or testing during the manufacturing process with requirement for the results? E Refer to the manufacturer's documentation. 5.3 - Do they define what shall be done in case of non-conformance of the product with the requirements? E Refer to the manufacturer's documentation. 5.4 - Are non-conforming products discarded from conform products when they are detected during manufacturing? E Refer to the manufacturer's documentation. SIST EN 15381:2009

This requirement may be fulfilled by concluding a subcontracting agreement with one or more organisations or persons having the necessary skills and equipment. 6.2 - Are there standards and methods for final inspection and testing? Have they been implemented? E Refer to the manufacturer's documentation. 6.3 - What tests are implemented (standard used) and at what frequency? These tests should preferably be called up in the harmonised standards. If the tests are not performed to these European Standards, does there exist a proven correlation between the test(s) used for FPC and the corresponding EN? • EN ISO 13433, Geosynthetics – Dynamic perforation test (cone drop test) (ISO 13433:2006) • EN ISO 10319, Geotextiles – Wide-width tensile test (ISO 10319:1993) • EN ISO 12236, Geosynthetics – Static puncture test (CBR test) (ISO 12236:2006) • EN ISO 3146, Plastics – Determination of melting behaviour (melting temperature or melting range) of semi-crystalline polymers by capillary tube and polarizing-microscope methods (ISO 3146:2000) • Bitumen retention (see Annex C of this standard)

• EN 12224,

Geotextiles and geotextile-related products – Determination of the resistance to weathering E Refer to the manufacturer's documentation.

Procedure given in Annex C to this standard. 6.4 - Are the characteristics tested in accordance with the announced "application/function" combination(s) (see the relevant harmonised standard(s))? E Refer to the manufacturer's documentation. 6.5 - Are there documented specifications concerning the results for final inspection and testing? What are they? E Refer to the manufacturer's documentation. SIST EN 15381:2009

E Refer to the manufacturer's documentation. 6.8 - Are there documented procedures which define what shall be done in case of non-conformance of the final product with the specified requirements? E Refer to the manufacturer's documentation. 6.9 - Are there appropriated records which complete evidence that a product has been tested and is in conformance with the specified requirements? E Refer to the manufacturer's documentation. 6.10 - Is it possible through these records to identify the accredited persons responsible for testing final products and for releasing the products for the market? E Refer to the manufacturer's documentation. 7 Control of inspection, measuring and test equipment 7.1 - Are there defined procedures to control, calibrate and maintain the equipment used, to bring evidence of the conformance of the products with the specified requirements? E Refer to the manufacturer's documentation. 7.2 - Are inspection, measuring and test equipment calibrated and adjusted against equipment having a known and valid relationship to nationally or internationally recognized standards? E Refer to the manufacturer's documentation. (Check calibration records for inspection, measuring and test equipment and – if existing – round robin test results.) 8 Control of non-conforming products 8.1 - Are there documented procedures to ensure that non-conforming products cannot be inadvertently used or delivered? E Refer to the manufacturer's documentation. 8.2 - In particular, are non-conforming products identified, documented and segregated from the rest of the production? E Refer to the manufacturer's documentation. SIST EN 15381:2009

8.3 - Are there documented procedures (organisation charts) which define responsibilities for the examination of non-conforming products and who has the authority to take decision concerning them? E Refer to the manufacturer's documentation. 9 Corrective actions 9.1 - Are there documented procedures to implement proper corrective and preventive actions concerning non-conformity? E Refer to the manufacturer's documentation. 9.2 - In this case are these procedures implemented and the corrective or preventive actions recorded (mainly these concerning customer complaints)? E Refer to the manufacturer's documentation. 9.3 - Have corrective actions been carried out from the previous audit? With which result? E Refer to the manufacturer's documentation. 10 Handling, storage and packaging 10.1 - Are the methods which permit to protect the product during handling, storage and packaging described?

Refer to the manufacturer's documentation. 10.2 - Are handling, storage and packaging methods and means appropriate to prevent final products from being damaged or deteriorated?

10.3 - Is the labelling of final products in conformance with the provisions of the harmonised standards? E

11 Control of quality records 11.1 - Are quality records legible and retained for at least 10 years period so as to be easily available on request? E Electronically stored records shall be protected against ch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...