EN 12953-6:2024

(Main)Shell Boilers - Part 6: Requirements for equipment for the boiler

Shell Boilers - Part 6: Requirements for equipment for the boiler

This document specifies the minimum requirements for safety related equipment for shell boilers (generator and/or assemblies) as specified in EN 12953-1:2012, to ensure the boiler operates within the allowable limits (pressure, temperature, etc.) and if the limits are exceeded the energy supply is automatically interrupted and locked out, irrespective of the degree of intervention.

NOTE 1 For this document, the term “boiler” is applicable for generator and/or assemblies.

NOTE 2 The maximum time of operation without manual (human) intervention can be specified for each boiler system.

NOTE 3 Annex C gives recommendations of operation and testing of the boiler system with a maximum time of operation without manual (human) intervention of 24 h and 72 h.

Großwasserraumkessel - Teil 6: Anforderungen an die Ausrüstung für den Kessel

Dieses Dokument legt die Mindestanforderungen an die sicherheitstechnische Ausrüstung (Dampf-/Heißwassererzeuger und/oder Baugruppen) der in EN 12953 1:2012 definierten Großwasserraumkessel fest, um sicherzustellen, dass der Kessel innerhalb der zulässigen Grenzen (Druck, Temperatur usw.) arbeitet und, sofern die Grenzen überschritten werden, die Energiezufuhr automatisch am Kessel unterbrochen und verriegelt wird, unabhängig vom Grad des Eingriffs.

ANMERKUNG 1 In diesem Dokument ist der Begriff „Kessel“ für Dampf-/Heißwassererzeuger und/oder Baugruppen anwendbar.

ANMERKUNG 2 Die maximale Betriebsdauer ohne manuelles (menschliches) Eingreifen kann für jedes Kesselsystem festgelegt werden.

ANMERKUNG 3 Anhang C enthält Empfehlungen zum Betrieb und zur Prüfung des Kesselsystems mit einer maximalen Betriebsdauer ohne manuelles (menschliches) Eingreifen von 24 h und 72 h.

Chaudières à tubes de fumée - Partie 6: Exigences pour l'équipement de la chaudière

Le présent document spécifie les exigences minimales pour l'équipement relatif à la sécurité des chaudières à tubes de fumée (générateurs et/ou ensembles) spécifiées dans l'EN 12953 1:2012, afin de garantir que la chaudière fonctionne dans les limites admissibles (pression, température, etc.) et, dans le cas où les limites seraient dépassées, que l'alimentation en énergie est interrompue et verrouillée automatiquement, indépendamment du degré d'intervention.

NOTE 1 Dans le cadre du présent document, le terme « chaudière » s'applique aux générateurs et/ou ensembles.

NOTE 2 La durée maximale de fonctionnement sans intervention manuelle (humaine) peut être spécifiée pour chaque système de chaudière.

NOTE 3 L'Annexe C donne des recommandations de fonctionnement et d'essai du système de chaudière avec une durée maximale de fonctionnement sans intervention manuelle (humaine) de 24 h et 72 h.

Mnogovodni kotli - 6. del: Zahteve za opremo kotla

Ta dokument določa minimalne zahteve za varnostno opremo mnogovodnih kotlov (generator in/ali sklope), kot je določeno v standardu EN 12953-1:2012, da se zagotovi obratovanje kotla v dovoljenih mejah (tlak, temperatura itd.); če so te meje presežene, mora ta oprema prekiniti in varnostno zaustaviti oskrbo z energijo, ne glede na stopnjo človeške intervencije.

OPOMBA 1: V tem dokumentu se izraz »kotel« uporablja za generator in/ali sklope.

OPOMBA 2: Za vsak kotlovski sistem je mogoče določiti najdaljši čas obratovanja brez ročne (človekove) intervencije.

OPOMBA 3: V dodatku C so podana priporočila glede obratovanja in preskušanja kotlovskega sistema z najdaljšim časom obratovanja brez ročne (človekove) intervencije 24 in 72 ur.

General Information

- Status

- Published

- Publication Date

- 17-Dec-2024

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 2 - Shell boilers

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 18-Dec-2024

- Due Date

- 26-Feb-2024

- Completion Date

- 18-Dec-2024

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 61140:2016 - Protection against electric shock - Common aspects for installation and equipment - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 12953-2:2012 - Shell boilers - Part 2: Materials for pressure parts of boilers and accessories - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 14597:2012 - Temperature control devices and temperature limiters for heat generating systems - Effective Date

- 28-Jan-2026

Overview - EN 12953-6:2024 (Shell Boilers: Equipment Requirements)

EN 12953-6:2024 reproduces EN 12953-6:2024 and specifies the minimum requirements for safety-related equipment for shell boilers (generators and/or assemblies) as covered by EN 12953-1:2012. The standard ensures boilers operate within allowable limits (pressure, temperature, water level, etc.) and that, if limits are exceeded, the energy supply is automatically interrupted and locked out, regardless of the degree of human intervention. Annex C gives recommendations for operation and testing for systems allowed up to 24 h and 72 h without manual intervention.

Key technical topics and requirements

- Safety valves and safeguards: minimum performance and materials requirements for overpressure protection.

- Materials and fittings: materials for valves, flanges and bolting used in safety-critical equipment.

- Protective systems and energy supply: requirements for automatic shutdown, start-up, normal shutdown and energy interruption logic.

- Water quality and water protection: monitoring, conductivity, make-up/feedwater and condensate handling to prevent corrosion, scaling and unsafe operation.

- Furnace temperature monitoring: detection and control to prevent overheating.

- Steam- and hot-water-specific controls: water level indication, pressure/temperature indication, feedwater supply and control, limiting/monitoring devices (low/high water protection, pressure and temperature limitation, flow monitoring).

- Monitoring devices (Annex F): normative requirements for design, materials, electrical equipment, testing, marking and operating instructions for monitoring and flow/water quality devices.

- Alarms, monitoring and operating instructions: plant alarm conditions, monitoring arrangements and guidance on maintenance and testing (Annexes E and C).

- Informative annexes: typical system diagrams, expansion-space dimensioning, drain/blowdown design, and changes from the previous edition.

Practical applications and target users

EN 12953-6:2024 is used for:

- Boiler manufacturers specifying safety and monitoring equipment during design and fabrication.

- Plant designers and integrators developing boiler systems, control logic and safety interlocks.

- Commissioning, maintenance and operations teams applying recommended testing, alarm setup, and maintenance intervals.

- Safety engineers, inspectors and notified bodies assessing compliance with boiler safety requirements.

- Procurement and specification writers who need standardized requirements for valves, monitoring devices and protective systems.

Keywords: EN 12953-6:2024, shell boilers, boiler safety, boiler monitoring, steam boilers, hot water boilers, safety valves, water quality monitoring.

Related Standards (if applicable)

- EN 12953-1:2012 (referenced for boiler definitions and scope)

- Other parts of the EN 12953 series covering design, manufacture and testing of shell boilers

- Relationship to EU Pressure Equipment Directive 2014/68/EU (see Annex ZA)

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12953-6:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shell Boilers - Part 6: Requirements for equipment for the boiler". This standard covers: This document specifies the minimum requirements for safety related equipment for shell boilers (generator and/or assemblies) as specified in EN 12953-1:2012, to ensure the boiler operates within the allowable limits (pressure, temperature, etc.) and if the limits are exceeded the energy supply is automatically interrupted and locked out, irrespective of the degree of intervention. NOTE 1 For this document, the term “boiler” is applicable for generator and/or assemblies. NOTE 2 The maximum time of operation without manual (human) intervention can be specified for each boiler system. NOTE 3 Annex C gives recommendations of operation and testing of the boiler system with a maximum time of operation without manual (human) intervention of 24 h and 72 h.

This document specifies the minimum requirements for safety related equipment for shell boilers (generator and/or assemblies) as specified in EN 12953-1:2012, to ensure the boiler operates within the allowable limits (pressure, temperature, etc.) and if the limits are exceeded the energy supply is automatically interrupted and locked out, irrespective of the degree of intervention. NOTE 1 For this document, the term “boiler” is applicable for generator and/or assemblies. NOTE 2 The maximum time of operation without manual (human) intervention can be specified for each boiler system. NOTE 3 Annex C gives recommendations of operation and testing of the boiler system with a maximum time of operation without manual (human) intervention of 24 h and 72 h.

EN 12953-6:2024 is classified under the following ICS (International Classification for Standards) categories: 27.060.30 - Boilers and heat exchangers. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12953-6:2024 has the following relationships with other standards: It is inter standard links to EN 12953-6:2011, EN 60529:1991/A2:2013, EN 50156-1:2015, EN 61140:2016, EN 60730-1:2016, EN 61558-2-6:2009, EN 60529:1991, EN 61558-2-16:2009, EN 60529:1991/A1:2000, EN 12953-2:2012, EN 12953-3:2016, EN 12953-9:2024, EN 16198:2012, EN 12953-13:2012, EN 14597:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12953-6:2024 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12953-6:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2025

Nadomešča:

SIST EN 12953-6:2011

Mnogovodni kotli - 6. del: Zahteve za opremo kotla

Shell Boilers - Part 6: Requirements for equipment for the boiler

Großwasserraumkessel - Teil 6: Anforderungen an die Ausrüstung für den Kessel

Chaudières à tube de fumée - Partie 6: Exigences pour l'équipement de la chaudière

Ta slovenski standard je istoveten z: EN 12953-6:2024

ICS:

27.060.30 Grelniki vode in prenosniki Boilers and heat exchangers

toplote

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12953-6

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2024

EUROPÄISCHE NORM

ICS 27.060.30 Supersedes EN 12953-6:2011

English Version

Shell Boilers - Part 6: Requirements for equipment for the

boiler

Chaudières à tubes de fumée - Partie 6: Exigences pour Großwasserraumkessel - Teil 6: Anforderungen an die

l'équipement de la chaudière Ausrüstung für den Kessel

This European Standard was approved by CEN on 20 October 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12953-6:2024 E

worldwide for CEN national Members.

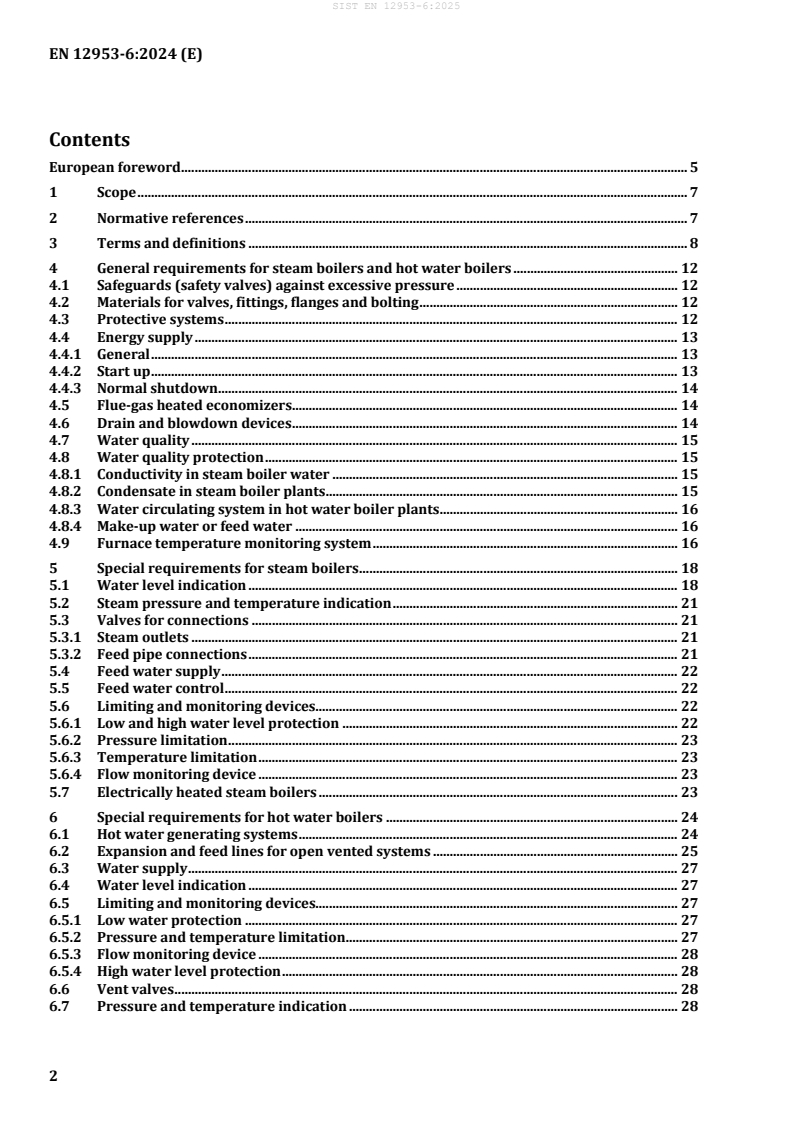

Contents

European foreword . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 General requirements for steam boilers and hot water boilers . 12

4.1 Safeguards (safety valves) against excessive pressure . 12

4.2 Materials for valves, fittings, flanges and bolting . 12

4.3 Protective systems . 12

4.4 Energy supply . 13

4.4.1 General . 13

4.4.2 Start up . 13

4.4.3 Normal shutdown . 14

4.5 Flue-gas heated economizers. 14

4.6 Drain and blowdown devices . 14

4.7 Water quality . 15

4.8 Water quality protection . 15

4.8.1 Conductivity in steam boiler water . 15

4.8.2 Condensate in steam boiler plants . 15

4.8.3 Water circulating system in hot water boiler plants . 16

4.8.4 Make-up water or feed water . 16

4.9 Furnace temperature monitoring system . 16

5 Special requirements for steam boilers . 18

5.1 Water level indication . 18

5.2 Steam pressure and temperature indication . 21

5.3 Valves for connections . 21

5.3.1 Steam outlets . 21

5.3.2 Feed pipe connections . 21

5.4 Feed water supply . 22

5.5 Feed water control . 22

5.6 Limiting and monitoring devices. 22

5.6.1 Low and high water level protection . 22

5.6.2 Pressure limitation . 23

5.6.3 Temperature limitation . 23

5.6.4 Flow monitoring device . 23

5.7 Electrically heated steam boilers . 23

6 Special requirements for hot water boilers . 24

6.1 Hot water generating systems . 24

6.2 Expansion and feed lines for open vented systems . 25

6.3 Water supply . 27

6.4 Water level indication . 27

6.5 Limiting and monitoring devices. 27

6.5.1 Low water protection . 27

6.5.2 Pressure and temperature limitation . 27

6.5.3 Flow monitoring device . 28

6.5.4 High water level protection . 28

6.6 Vent valves . 28

6.7 Pressure and temperature indication . 28

6.8 Electrically heated hot water boilers . 29

6.9 Parallel mode of operation of hot water boilers . 29

7 Operating instructions and operational aspects including maintenance and testing . 29

8 Alarms and monitoring from the boiler plant . 30

Annex A (informative) Typical examples of steam and hot water boiler systems . 31

A.1 General . 31

A.2 Key to figures. 31

A.3 Plant with open vented system . 33

A.4 Plant with closed system . 34

A.4.1 Hot water system with external pressure generating and expansion system . 34

A.4.2 Hot water system with internal pressure generating and expansion system - Steam

cushion in the boiler . 35

A.4.3 Steam boiler . 36

A.5 Superheater and economizer . 37

A.5.1 Superheater . 37

A.5.2 Economizer . 38

Annex B (informative) Dimensioning of expansion space . 39

B.1 General . 39

B.2 Required data . 39

B.3 Formulas for dimensioning . 40

Annex C (informative) Aspects of boiler operation . 42

C.1 General . 42

C.2 Maintenance . 42

C.3 Boiler operation and testing . 42

Annex D (informative) Drain and blowdown devices. 47

D.1 General . 47

D.2 Design of the drain and blowdown devices . 47

Annex E (informative) Alarms and monitoring from the boiler plant. 49

E.1 General . 49

E.2 Conditions for alarms and monitoring . 49

Annex F (normative) Requirements for monitoring devices . 52

F.1 General requirements for monitoring devices . 52

F.1.1 General . 52

F.1.2 Components . 52

F.1.3 Materials and design . 52

F.1.4 Electrical equipment . 53

F.1.5 Test procedure . 54

F.1.6 Marking . 55

F.1.7 Operating instructions . 55

F.2 Additional requirements for water monitoring devices. 55

F.2.1 Functional requirements. 55

F.2.2 Special requirements for water hardness monitoring devices . 55

F.2.3 Special requirements for devices for detecting and monitoring water for ingress of

harmful foreign matter . 56

F.2.4 Special requirements for water conductivity monitoring devices. 56

F.3 Additional requirements for flow monitoring devices . 57

F.3.1 Design . 57

F.3.2 Examination of functional capability . 58

G.1 General . 60

G.2 Key to figures . 60

G.3 Recommendations for expansion system. 61

G.4 Expansion and pressure holding for hot water boiler system . 62

G.4.1 Pressure pump-controlled system with pressureless membrane type expansion

vessel . 63

G.4.2 Pressure pump-controlled system with open expansion vessel . 64

G.4.3 Membrane type expansion vessel with pre-pressurized gas cushion. 65

G.4.4 Membrane type expansion vessel with controlled gas cushion . 66

G.4.5 Closed expansion vessel with pre-pressurized gas cushion . 67

G.4.6 Closed expansion vessel with gas or steam cushion. 68

Annex H (informative) Significant technical changes between this document and the

previous edition . 69

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2014/68/EU aimed to be covered. 70

Bibliography . 72

European foreword

This document (EN 12953-6:2024) has been prepared by Technical Committee CEN/TC 269 “Shell and

water-tube boilers”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2025, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12953-6:2011.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Annex H provides details of significant technical changes between this document and the previous

edition.

The series concerning shell boilers consists of the following parts:

— Part 1: General

— Part 2: Materials for pressure parts of boilers and accessories

— Part 3: Design and calculation for pressure parts

— Part 4: Workmanship and construction of pressure parts of the boiler

— Part 5: Inspection during construction, documentation and marking of pressure parts of the boiler

— Part 6: Requirements for equipment for the boiler

— Part 7: Requirements for firing systems for liquid and gaseous fuels for the boiler

— Part 8: Requirements for safeguards against excessive pressure

— Part 9: Requirements for limiting devices of the boiler and accessories

— Part 10: Requirements for boiler feed water and boiler water quality

— Part 11: Acceptance tests

— Part 12: Requirements for firing systems for solid fuels for the boiler

— Part 13: Operating instructions

Although these parts can be obtained separately, it should be recognized that the parts are inter-

dependent. As such, the design and manufacture of shell boilers requires the application of more than

one part in order for the requirements of the standard to be satisfactorily fulfilled.

NOTE A “Boiler Helpdesk” has been established in CEN/TC 269 which can be contacted for any questions

regarding the application of the European Standards series EN 12952 and EN 12953 see the following website:

http://www.boiler-helpdesk.din.de.

Any feedback and questions on this document should be directed to the users’national standards body. A

complete listing of these bodies can be found on the CENwebsite.

According to the CEN-CENELEC Internal Regulations, the national standardsorganisations of the

following countries are bound to implement this EuropeanStandard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark,Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia,Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic ofNorth

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,Türkiye and the United

Kingdom.

1 Scope

This document specifies the minimum requirements for safety related equipment for shell boilers

(generator and/or assemblies) as specified in EN 12953-1:2012, to ensure the boiler operates within the

allowable limits (pressure, temperature, etc.) and if the limits are exceeded the energy supply is

automatically interrupted and locked out, irrespective of the degree of intervention.

NOTE 1 For this document, the term “boiler” is applicable for generator and/or assemblies.

NOTE 2 The maximum time of operation without manual (human) intervention can be specified for each boiler

system.

NOTE 3 Annex C gives recommendations of operation and testing of the boiler system with a maximum time of

operation without manual (human) intervention of 24 h and 72 h.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 5167-1:2022, Measurement of fluid flow by means of pressure differential devices inserted in

circular cross-section conduits running full - Part 1: General principles and requirements (ISO 5167-1:2022)

EN 12953-1:2012, Shell boilers - Part 1: General

EN 12953-2:2012, Shell boilers - Part 2: Materials for pressure parts of boilers and accessories

EN 12953-3:2016, Shell boilers - Part 3: Design and calculation for pressure parts

EN 12953-7:2002, Shell boilers - Part 7 : Requirements for firing systems for liquid and gaseous fuels for the

boilers

EN 12953-8:2001, Shell boilers - Part 8: Requirements for safeguards against excessive pressure

EN 12953-9:2024, Shell boilers - Part 9: Requirements for limiting devices of the boiler and accessories

EN 12953-10:2003, Shell boilers - Part 10 : Requirements for feedwater and boiler water quality

EN 12953-12:2003, Shell boilers - Part 12: Requirements for grate firing systems for solid fuels for the boiler

EN 12953-13:2012, Shell boilers - Part 13: Operating instructions

EN 14597:2012, Temperature control devices and temperature limiters for heat generating systems

EN 50156-1:2015, Electrical equipment for furnaces and ancillary equipment - Part 1: Requirements for

application design and installation

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60730-1:2016, Automatic electrical controls - Part 1: General requirements (IEC 60730-1:2013)

Document impacted by A1:2000, A2:2013 and AC:2016.

EN 61140:2016, Protection against electric shock - Common aspects for installation and equipment

(IEC 61140:2016)

EN 61558-2-6:2009, Safety of transformers, reactors, power supply units and similar products for supply

voltages up to 1 100 V - Part 2-6: Particular requirements and tests for safety isolating transformers and

power supply units incorporating safety isolating transformers (IEC 61558-2-6:2009)

EN 61558-2-16:2009, Safety of transformers, reactors, power supply units and similar products for supply

voltages up to 1 100 V - Part 2-16: Particular requirements and tests for switch mode power supply units

and transformers for switch mode power supply units (IEC 61558-2-16:2009)

ISO 2186:2007, Fluid flow in closed conduits — Connections for pressure signal transmissions between

primary and secondary elements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12953-1:2012 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

control

device used for maintaining the variable to be controlled (pressure, temperature, etc.) at a specific value

(set point)

3.2

monitoring system

monitoring device

system which checks given parameters and draws attention to those which are outside normal operating

limits but which are below the limiting values determined by the hazard and risk analysis and specified

e.g. in the operation manual

Note 1 to entry: Normal operating conditions of the process can be restored either directly by the system or by a

boiler attendant depending on the individual requirements.

3.3

safety accessory

device designed to protect pressure equipment against the allowable limits being exceeded, including

devices for direct pressure limitation, such as safety valves, bursting disc safety devices, buckling rods,

controlled safety pressure relief systems (CSPRS), and limiting devices, which either activate the means

for correction or provide for shutdown or shutdown and lockout, such as pressure switches or

temperature switches or fluid level switches and safety related measurement control and regulation

(SRMCR) devices

[SOURCE: PED 2014/68/EU]

3.4

pressure accessory

device with an operational function and having pressure-bearing housings

[SOURCE: PED 2014/68/EU]

3.5

limiter

limiting device

safety accessory which, on reaching a limiting value (water level, pressure, temperature, flow, water

quality), is used to interrupt and lock out the energy supply

Note 1 to entry: A limiter is an element of a safety device and a safety accessory for shell boilers as specified in

the Pressure Equipment Directive 2014/68/EU, Article 2, Clause 4. A limiter contains a sensor, possibly a sensor

control unit and ends at the output contact. The following safety logic and actuating element are not components of

this part of the standard, see EN 12953-9:2024, Figure A.1.

Note 2 to entry: A limiting device comprises

— a measuring function and

— optional with a display and

— an activation function for correction, or shut-down, or safety shut-down and fault shut-down, and which

is used to carry out safety related functions as specified in the PED 2014/68/EU. These functions may be on their

own or as part of a safety (protective) system (e.g. sensors, limiters). If this is achieved by multichannel systems,

then all items or limiters for safety purposes are included within the safety (protective) system.

3.6

lock-out

safety shut-down condition of the protective device, such that a restart can only be accomplished by a

manual reset of the limiter or by a manual reset of the safety logic on site and by no other means

3.7

functional check

testing of the safety device to ensure it performs its intended function

3.8

electrically heated boiler

boiler in which water is heated by an electric current flowing between electrodes or by immersion

heaters

3.9

expansion vessel

vessel to compensate for temperature dependent changes in water volume of a hot water boiler, where

— a closed expansion vessel is pressurised and

— an open expansion vessel is vented to atmospheric pressure and is not pressurised

3.10

allowable heat output

maximum heat output (water mass flow times the difference between outlet and inlet enthalpy) that can

be generated during continuous operation and at which hot water boilers can be operated

3.11

maximum allowable temperature

TS

maximum temperature for which the pressure equipment is designed, as specified by the manufacturer

Note 1 to entry For hot water boiler, TS means the maximum allowable flow temperature measured at the outlet

branch.

Note 2 to entry For steam generator, TS means the maximum allowable saturated steam temperature at PS.

Note 3 to entry For superheater, TS means the maximum allowable temperature of the hot steam measured at

the outlet branch.

Note 4 to entry For economizer, TS means the maximum allowable flow temperature measured at the outlet

branch.

Note 5 to entry TS corresponds to Pressure Equipment Directive 2014/68/EU, Article 2, indent (9).

3.12

maximum allowable pressure

PS

maximum pressure for which the pressure equipment is designed, as specified by the manufacturer, and

defined at a location specified by him, being either the connection of protective and/or limiting devices,

or the top of equipment or, if not appropriate, any point specified

Note 1 to entry PS corresponds to Pressure Equipment Directive 2014/68/EU, Article 2, indent (8).

3.13

maximum continuous rating

maximum continuous steam output that can be generated during continuous operation taking the

specified steam condition into consideration

3.14

internal steam cushion

steam filled space located within the steam boiler to accommodate changes in volume

3.15

external steam cushion

steam filled space located outside the steam boiler to accommodate changes in volume

3.16

gas cushion

gas-filled space to accommodate changes in volume

3.17

effective heat transfer

energy supply is on and

— for a hot water boiler, flow of water is greater than or equal to a specified minimum value or

— for a steam boiler, the start-up or steam valve is open and the temperature is greater than the

saturation temperature at ambient pressure

3.18

normal operation

automatic operation, with all regulating circuits and controls (open loops/closed loops) in automatic

mode and with the set points and parameters valid for normal operation

Note 1 to entry: Normal operation also includes the automatic switching on and off of the assigned actuators (e.g.

burner).

3.19

normal shut down

controlled switch off of the boiler either operated manually or automatically

3.20

make-up water

water which compensates for losses of water and steam from the system

Note 1 to entry: Definition from EN 12953-10:2003.

3.21

feed water

mixture of returned condensate and/or make up water supplied to the boiler inlet

Note 1 to entry: Definition from EN 12953-10:2003.

3.22

pressurization equipment

external system for keeping the hot water system pressure within the required pressure limits

Note 1 to entry: In order to prevent corrosion caused by oxygen infiltration, systems that prevent the system

water being in direct contact with air should be preferred.

3.23

boiler attendant

boiler operator skilled person appointed for operating the boiler plant

3.24

temperature monitoring of the furnace shell

measurement system for monitoring the temperature of the furnace shell in the area of the highest heat

flux

3.25

minimum flow rate

minimum flow of water in the piping required for hot water boilers and economisers to avoid overheating

of the boiler or economiser

3.26

cold start

starting the boiler from ambient pressure at room temperature to normal operating condition

4 General requirements for steam boilers and hot water boilers

4.1 Safeguards (safety valves) against excessive pressure

Each steam boiler and hot water boiler, except open vented hot water boiler, shall be equipped with

safeguards (safety valves) against excessive pressure in accordance with EN 12953-8:2001.

Superheaters and economizers shall be protected in accordance with EN 12953-8:2001. Where a

superheater or an economizer can be isolated a pressure gauge connection shall be provided.

NOTE For example, see Annex A (Figures A.5 and A.6).

4.2 Materials for valves, fittings, flanges and bolting

The conditions and requirements to select the material shall be in accordance with EN 12953-2:2012.

4.3 Protective systems

4.3.1 All limiters and their installation shall be designed in accordance with EN 12953-9:2024. Limiters

shall function independently of each other and of controls unless their safety function cannot be affected

by other such functions.

The protective systems shall be in accordance with EN 50156-1:2015.

4.3.2 The application design and installation of the electrical safety circuit as well as the electrical and

control equipment for the energy supply and its auxiliary equipment shall be in accordance with

EN 50156-1:2015.

A hazard analysis SIL classification shall be carried out for each limiting device function and appropriate

levels of functional safety implemented.

Typical Safety Integrity Level (SIL) requirements cannot be less than 2.

It shall be possible to stop the boiler by additional devices outside the boiler such as shut-off valve,

emergency stop device, fire detectors, etc.

4.3.3 Functional check of all limiters shall be possible at any time during operation e.g. by simulation

in accordance with operating instructions as specified in Clause 7.

4.3.4 When a limiter mentioned in this document activates, information shall be given to indicate which

limiter has activated.

4.3.5 After lock out, the steam boiler/hot water boiler shall be physically checked by the boiler

attendant (operator), before start-up (see 4.4.2).

4.3.6 Any valves that may isolate a limiter or monitoring device from the boiler system during normal

operation shall be prevented from unintended closure (e.g. by wire and seal, locked in open position or

position switches integrated in a safety circuit, etc.).

4.3.7 For purpose of function testing a bypassing of limiters at the boiler shall be allowed for a time not

exceeding:

— for both channels of a two channels water level limiter, 30 s;

— for one channel of a two channels water level limiter, 5 min;

— for a maximum pressure limiter if there is a second channel in operation (e.g. safety valve or second

pressure limiter), 5 min;

— for all other limiters, 5 min.

In all cases above:

— if the above times are exceeded, the energy supply shall be shut down and locked-out.

— the bypassing system which is implemented shall not alter the safety integrity level SIL of the safety

functions concerned.

4.4 Energy supply

4.4.1 General

The requirements for energy supply to steam boilers and hot water boilers shall be in accordance with

either EN 12953-7:2002 or EN 12953-12:2003 depending on fuel type.

The combustion process shall be completed within the furnace.

The energy supply shall be automatically controlled and in all operating stages rapidly adapted to the

variation of the heat demand. Steam pressure influences heat demand of steam boilers and hot water

boilers with internal steam cushion. For other hot water boilers, heat demand is influenced by flow

temperature.

NOTE For examples of steam and hot water boiler systems, see Annex A (Figures A.1 to A.4).

In the event of normal shutdown or lock out, residual heat accumulated in the furnace and flue-gas passes

shall not cause unacceptable metal or fluid temperatures (e.g. by evaporation of the water) in the steam

boiler/hot water generator.

This requirement is fulfilled:

a) if a fast acting combustion system is used e.g. oil, gas or pulverised fuel firing systems (except slag-

tap firing or heavy brickwork in the furnace or flue-gas passes) or electrical heated system; or

b) if it is proved that, after interruption of the energy supply from the full load steady-state condition,

the fluegas temperature at the highest point of the heating surface (HHS) falls to below 400 °C before

the water level has sunk from the lowest permissible water level (LWL) to 50 mm above the highest

point of the heating surface (HHS); or

c) if a reliable feed water supply is installed to ensure adequate cooling of the heating surfaces

in case of a sudden loss of essential operational parameters (see e.g. 5.4.4); or

d) if it is only heated with gases not exceeding a temperature of 400 °C; or

e) if, in case of fully flooded hot water generators, the water temperature does not exceed the maximum

allowable temperature (TS) with or without emergency cooling system and without release of

residual heat via the safety valve. The function of the emergency cooling system shall ensure that no

adverse side effects can occur.

In case of a combination of energy supply, highest requirements of this document shall be applied.

4.4.2 Start up

When a boiler is started-up locally or remotely after lockout or from cold condition (cold start), the boiler

attendant (operator) shall be present and remain with the boiler until it is operating correctly under

normal operation.

When designing the controls for the start-up sequence, it shall be taken into account the effective heat

transfer to avoid unacceptable local over heating or thermal stresses or other stresses of any pressurized

parts of the boiler or parts connected to the boiler, with particular regard to the heating up sequence and

flow rates. These controls shall be in the form of installed control systems and/or software and/or

operating instructions.

The manual or automatic start-up sequence shall consider as a minimum the following points which shall

be specified in the operating instructions:

a) lock out by limiters;

b) minimum flow of water for hot water boilers to avoid overheating and to reach effective heat transfer;

c) minimum temperature of water for hot water boilers to avoid corrosion;

d) minimum temperature of critical parts of boilers to avoid unacceptable thermal stresses;

e) steam output as a function of pressure of steam boilers to improve internal mixing (flow) and to avoid

thermal stresses (effective heat transfer);

f) sequence shall contain times (or pressures) and burner loads for a gentle start-up to avoid thermal

stresses;

g) additional energy supply requirements like e.g. maximum permitted low loads, minimum number of

burner steps for stepped burner or minimum burner adjustment time between low and high load for

infinitely variable burners.

NOTE For remote system, see informative Annex E.

4.4.3 Normal shutdown

The control sequence designed for normal shutdown shall involve the low load position of energy supply

before switching off the boiler.

4.5 Flue-gas heated economizers

Economizers shall be fitted with a temperature indicating device on the water outlet.

4.6 Drain and blowdown devices

4.6.1 Drain and blowdown equipment shall be installed to prevent accidents.

NOTE Drain and blowdown devices, see Annex D.

4.6.2 Each steam boiler shall be fitted with drain lines placed at, or as near as practicable to, the lowest

point of the steam boiler.

NOTE On some steam boilers, drain valves can be used for blowdown purposes.

4.6.3 Where lines from two or more steam boilers are connected to a common discharge, two valves

shall be fitted to each drain line, one being of a non-return type to prevent the contents of one steam

boiler passing to another.

4.6.4 The drain line between the steam boiler and the drain valve shall, if exposed to furnace heat, be

protected by brickwork or other insulating material so arranged that the pipe may be inspected and is

not constrained against expansion.

4.6.5 Taper-plug valves where fitted, shall be of the bolted cover type with separately packed glands

and shall not be used with design pressures over 13 bar.

4.6.6 Where drain or the steam boiler blowdown valves are not self closing or capable of being locked

in the closed position, a further shut-off device shall be installed in the line.

4.7 Water quality

4.7.1 The water quality shall be in accordance with EN 12953-10:2003 and operating instructions.

4.7.2 It shall be possible at any time during operation to safely take reliable samples of the boiler water,

feed-water, make-up water and if relevant the condensate and/or the recirculation water. Depending on

the temperature of the media the samples shall be taken through one or more sample coolers.

4.8 Water quality protection

4.8.1 Conductivity in steam boiler water

The boiler water conductivity shall be monitored to ensure the water quality remains within the

allowable limits prescribed by the operating instructions and EN 12953-10:2003.

If the limit values can be exceeded the following monitoring methods shall be used:

a) without manual (human) intervention ≤ 24 h or permanent supervision, the boiler water shall be

manually daily tested and appropriate actions shall be taken. If additional operation conditions shall

be considered according to EN 12953-3:2016, 5.5.4, at least a monitoring device shall be used as

specified in Annex F, which measures continuously and which shut down and locks out the energy

supply if the limits are exceeded.

b) without manual (human) intervention > 24 h and ≤ 72 h, a continuous monitoring device shall be

used as specified in Annex F. If the limit values are exceeded for more than the time specified in the

operating instructions, the boiler shall be shut down and the energy supply shall be locked out (based

on the result from the risk and hazard analysis the time delay to shut down may be extended).

c) without manual (human) intervention > 72 h, a hazard and risk analysis shall be carried out to

specify if a limiter according to EN 12953-9:2024 or a monitoring device shall be used. If the limit

values are exceeded for more than the time specified in the operating instructions, the boiler shall be

shut down and the energy supply shall be locked out (based on the result from the risk and hazard

analysis the time delay to shut down may be extended).

For operational aspects, it is recommended to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...