EN 1561:2011

(Main)Founding - Grey cast irons

Founding - Grey cast irons

This European Standard specifies the properties of unalloyed and low-alloyed grey cast irons used for castings, which have been manufactured in sand moulds or in moulds with comparable thermal behaviour.

This European Standard specifies the characterizing properties of grey cast irons by either

a) the tensile strength of cast samples, or

b) the hardness measured on the castings or on a cast-on knob.

If agreed by the manufacturer and the purchaser, the combination of both tensile strength from option a) and hardness from option b) may be specified.

This European Standard specifies six grades of grey cast iron by a classification based on tensile strength measured on machined test pieces prepared from cast samples (see Table 1) and six grades of grey cast iron by a classification based on Brinell hardness (see Table 2).

This European Standard does not cover technical delivery conditions for iron castings; see EN 1559-1 [3] and

EN 1559-3 [4].

This European Standard does not apply to grey cast irons used for pipes and fittings according to EN 877 [5].

Gießereiwesen - Gusseisen mit Lamellengraphit

Diese Europäische Norm legt die Eigenschaften von unlegiertem und niedrig legiertem Gusseisen mit Lamellengraphit für Gussstücke fest, die in Sandformen oder Formen mit vergleichbarem thermischen Verhalten hergestellt wurden. Diese Europäische Norm legt die kennzeichnenden Eigenschaften von Gusseisen mit Lamellengraphit fest, hinsichtlich entweder a) der Zugfestigkeit von gegossenen Probestücken; oder b) der Härte, gemessen am Gussstück oder an einem angegossenen Probestück. Wenn zwischen dem Hersteller und dem Käufer vereinbart, kann eine Kombination aus Zugfestigkeit nach Möglichkeit a) und Härte nach Möglichkeit b) festgelegt werden. Diese Europäische Norm legt sechs Sorten des Gusseisens mit Lamellengraphit fest, deren Klassifizierung auf der Zugfestigkeit beruht, die an bearbeiteten Proben aus gegossenen Probestücken gemessen wird (siehe Tabelle 1), und sechs Sorten des Gusseisens mit Lamellengraphit, deren Klassifizierung auf der Bri-nellhärte beruht (siehe Tabelle 2). Diese Europäische Norm behandelt nicht die technischen Lieferbedingungen für Gusseisen mit Lamellengraphit; siehe dafür EN 1559-1 [3] und EN 1559-3 [4]. Diese Europäische Norm gilt nicht für Gusseisen mit Lamellengraphit, das für Rohre und Formstücke nach EN 877 [5] verwendet wird.

Fonderie - Fontes à graphite lamellaire

La présente Norme européenne spécifie les propriétés des fontes à graphite lamellaire non alliées et

faiblement alliées, utilisées pour les pièces moulées qui ont été coulées dans des moules en sable ou des

moules ayant un comportement thermique comparable.

La présente Norme européenne spécifie les propriétés permettant de caractériser les fontes à graphite

lamellaire soit :

a) par la résistance à la traction des échantillons coulés ; ou

b) par la dureté mesurée sur des pièces ou sur un appendice attenant à la pièce.

Par accord entre le fabricant et l'acheteur, on peut spécifier la combinaison de résistance à la traction, à partir

de l'option a) et de dureté, à partir de l'option b).

La présente Norme européenne spécifie six nuances de fonte à graphite lamellaire grâce à une classification

basée sur la résistance à la traction mesurée sur des éprouvettes usinées, élaborées à partir d'échantillons

coulés (voir Tableau 1) et six nuances de fonte à graphite lamellaire, grâce à une classification basée sur la

dureté Brinell (voir Tableau 2).

La présente Norme européenne ne couvre pas les conditions techniques de fourniture des pièces moulées en

fonte; voir l'EN 1559-1 [3] et l'EN 1559-3 [4].

La présente Norme européenne ne s'applique pas aux fontes à graphite lamellaire utilisée pour les tuyaux et

les raccords conformément à l'EN 877 [5].

Livarstvo - Siva litina (z lamelastim grafitom)

Ta evropski standard določa lastnosti nelegirane in malolegirane sive litine (z lamelastim grafitom), ki se uporablja za ulitke, izdelane v peščenih kalupih ali v kalupih s primerljivimi toplotnimi lastnostmi. Dokument ne velja za sive litine (z lamelastim grafitom), ki se uporabljajo za cevi in fitinge v skladu z EN 877.

General Information

- Status

- Withdrawn

- Publication Date

- 18-Oct-2011

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 190 - Foundry technology

- Drafting Committee

- CEN/TC 190/WG 5 - Grey cast iron and compacted graphite cast iron

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Dec-2023

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Replaced By

EN 1561:2023 - Founding - Grey cast irons - Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 50216-9:2009 - Power transformer and reactor fittings - Part 9: Oil-to-water heat exchangers - Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 15502-1:2021+A1:2023 - Gas-fired heating boilers - Part 1: General requirements and tests - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 1561:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Founding - Grey cast irons". This standard covers: This European Standard specifies the properties of unalloyed and low-alloyed grey cast irons used for castings, which have been manufactured in sand moulds or in moulds with comparable thermal behaviour. This European Standard specifies the characterizing properties of grey cast irons by either a) the tensile strength of cast samples, or b) the hardness measured on the castings or on a cast-on knob. If agreed by the manufacturer and the purchaser, the combination of both tensile strength from option a) and hardness from option b) may be specified. This European Standard specifies six grades of grey cast iron by a classification based on tensile strength measured on machined test pieces prepared from cast samples (see Table 1) and six grades of grey cast iron by a classification based on Brinell hardness (see Table 2). This European Standard does not cover technical delivery conditions for iron castings; see EN 1559-1 [3] and EN 1559-3 [4]. This European Standard does not apply to grey cast irons used for pipes and fittings according to EN 877 [5].

This European Standard specifies the properties of unalloyed and low-alloyed grey cast irons used for castings, which have been manufactured in sand moulds or in moulds with comparable thermal behaviour. This European Standard specifies the characterizing properties of grey cast irons by either a) the tensile strength of cast samples, or b) the hardness measured on the castings or on a cast-on knob. If agreed by the manufacturer and the purchaser, the combination of both tensile strength from option a) and hardness from option b) may be specified. This European Standard specifies six grades of grey cast iron by a classification based on tensile strength measured on machined test pieces prepared from cast samples (see Table 1) and six grades of grey cast iron by a classification based on Brinell hardness (see Table 2). This European Standard does not cover technical delivery conditions for iron castings; see EN 1559-1 [3] and EN 1559-3 [4]. This European Standard does not apply to grey cast irons used for pipes and fittings according to EN 877 [5].

EN 1561:2011 is classified under the following ICS (International Classification for Standards) categories: 77.080.10 - Irons; 77.140.80 - Iron and steel castings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1561:2011 has the following relationships with other standards: It is inter standard links to EN 1561:1997, EN 1561:2023, EN ISO 6892-1:2019, EN ISO 6506-1:2014, EN ISO 945-1:2019, EN 10204:2004, EN 50216-9:2009, EN 12516-4:2014+A1:2018, EN 303-5:2021+A1:2022, EN 15776:2011+A1:2015, EN 15776:2022, EN 303-5:2021, EN 15502-1:2021+A1:2023, EN 15502-1:2021, EN 16668:2016+A1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1561:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Livarstvo - Siva litina (z lamelastim grafitom)Gießereiwesen - Gusseisen mit LamellengraphitFonderie - Fontes à graphite lamellaireFounding - Grey cast irons77.140.80Železni in jekleni ulitkiIron and steel castingsICS:Ta slovenski standard je istoveten z:EN 1561:2011SIST EN 1561:2011en,fr,de01-december-2011SIST EN 1561:2011SLOVENSKI

STANDARDSIST EN 1561:1998SIST EN 1561:1997/prA1:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1561

October 2011 ICS 77.080.10 Supersedes EN 1561:1997English Version

Founding - Grey cast irons

Fonderie - Fontes à graphite lamellaire

Gießereiwesen - Gusseisen mit Lamellengraphit This European Standard was approved by CEN on 17 September 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1561:2011: ESIST EN 1561:2011

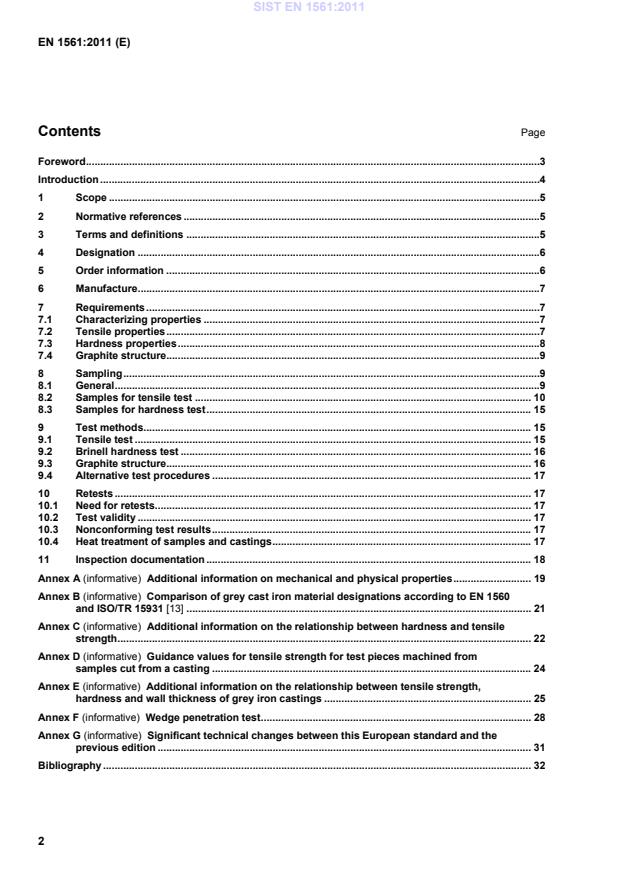

Additional information on mechanical and physical properties . 19Annex B (informative)

Comparison of grey cast iron material designations according to EN 1560 and ISO/TR 15931 [13] . 21Annex C (informative)

Additional information on the relationship between hardness and tensile strength . 22Annex D (informative)

Guidance values for tensile strength for test pieces machined from samples cut from a casting . 24Annex E (informative)

Additional information on the relationship between tensile strength, hardness and wall thickness of grey iron castings . 25Annex F (informative)

Wedge penetration test . 28Annex G (informative)

Significant technical changes between this European standard and the previous edition . 31Bibliography . 32 SIST EN 1561:2011

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

Compared with the previous edition of this standard, for relevant wall thicknesses from 50 mm to 200 mm, the relationship with the 30 mm separately cast sample has been abandoned and instead of that, cast-on samples with a size corresponding to the relevant wall thickness ranges are specified. Additionally the minimum tensile properties to be obtained in these cast-on samples, are increased. In this standard a new designation system by number, as established in EN 1560 [1], is given.

NOTE

This designation system by number is based on the structure and rules of EN 10027-2 [2] and so corresponds with the European numbering system for steel and other materials. The mechanical properties of the material can be evaluated on machined test pieces prepared from: separately cast samples;

side by side cast samples; cast-on samples; samples cut from a casting. Hardness of the material can also be evaluated on the casting. However, for many applications tensile strength or hardness are not the only interesting or determining properties. Other mechanical or physical properties can be decisive for the use of grey cast irons, for example: thermal capacity, thermal diffusivity, damping capacity or thermo-cycle fatigue. Therefore, Annex A (informative) provides additional information of interest to casting designers. SIST EN 1561:2011

This European Standard specifies six grades of grey cast iron by a classification based on tensile strength measured on machined test pieces prepared from cast samples (see Table 1) and six grades of grey cast iron by a classification based on Brinell hardness (see Table 2). This European Standard does not cover technical delivery conditions for iron castings; see EN 1559-1 [3] and

EN 1559-3 [4]. This European Standard does not apply to grey cast irons used for pipes and fittings according to EN 877 [5]. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 10204, Metallic products — Types of inspection documents EN ISO 945-1, Microstructure of cast irons — Part 1: Graphite classification by visual analysis

(ISO 945-1:2008) EN ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method (ISO 6506-1:2005) EN ISO 6892-1, Metallic materials — Tensile testing — Part 1: Method of test at room temperature

(ISO 6892-1:2009) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 grey cast iron cast material, mainly iron and carbon based, carbon being present mainly in the form of flake (lamellar) graphite particles

NOTE 1 Grey cast iron is also known as flake graphite cast iron, and less commonly as lamellar graphite cast iron. NOTE 2 Graphite form, distribution and size are specified in EN ISO 945-1. 3.2

cast sample quantity of material cast to represent the cast material, including separately cast sample, side by side cast sample and cast-on sample SIST EN 1561:2011

separately cast sample sample cast in a separate sand mould under representative manufacturing conditions and material grade 3.4

side-by-side cast sample

sample cast in the mould alongside the casting, with a joint running system 3.5

cast-on sample sample attached directly to the casting

3.6 relevant wall thickness wall thickness representative of the casting, defined for the determination of the size of the cast samples to which the mechanical properties apply 4 Designation The material shall be designated either by symbol or by number as given in either Table 1 or Table 2. In the case of samples cut from the casting the letter C is added at the end of the designation by symbol. NOTE Comparison of EN 1561 grade designations to the grades from the ISO standard for grey cast irons (ISO 185:2005) [6] is given in Annex B.

5 Order information The order shall specify, in an unambiguous manner, whether the tensile strength measured on cast samples, or the Brinell hardness measured on the casting, is the characterizing property. If it does not do so, then the manufacturer shall characterize the material according to tensile strength. The following information shall be supplied by the purchaser: a) the number of this European Standard; b) the designation of the material; c) the relevant wall thickness; NOTE 1 For castings which have been designed before the date of issue of this standard, the information regarding the relevant wall thickness can be omitted. d) any special requirements. All requirements shall be agreed between the manufacturer and the purchaser by the time of acceptance of the order e.g. technical delivery conditions according to EN 1559-1 and EN 1559-3. NOTE 2 When specifying a combination of tensile strength and hardness, it is recommended to consult the information in Annex E. In case of castings which have been designed before the date of issue of this standard, for the verification of the minimum tensile strength of the specified grey cast iron grade, separately cast samples with a diameter of 30 mm are used. The order shall specify the number and year of the previous edition (EN 1561:1997) of this European Standard. SIST EN 1561:2011

Relevant wall thickness t mm Tensile strengtha Rm mandatory values in cast sample Symbol Number > < MPa min. EN-GJL-100 5.1100 5 40 100 EN-GJL-150 5.1200 2,5b

50 150 50 100 130 100 200 110 EN-GJL-200 5.1300 2,5b 50 200 50 100 180 100 200 160 EN-GJL-250 5.1301 5b 50 250 50 100 220 100 200 200 EN-GJL-300 5.1302 10b 50 300 50 100 260 100 200 240 EN-GJL-350 5.1303 10b 50 350 50 100 310 100 200 280 NOTE 1 The designation is irrespective of the type of cast sample. NOTE 2 For high damping capacity and thermal conductivity, EN-GJL-100 (5.1100) is the most suitable material. NOTE 3 The figures given in bold indicate the minimum tensile strength to which the material designation of the grade is related. The values relate to an as-cast sample diameter corresponding to the applicable relevant wall thickness range according to Table 3. NOTE 4 For relevant wall thicknesses more than 200 mm, the manufacturer and the purchaser shall agree on the type and size of cast sample and the minimum values to be obtained. a If tensile strength is specified as a characterizing property, the type of the sample (see 8.2) should also be stated in the order. If not stated in the order, the type of sample is left to the discretion of the manufacturer. b This value is included as the lower limit of the relevant wall-thickness range.

7.3 Hardness properties The Brinell hardness of the six grades of grey cast iron specified by hardness, when measured according to 9.2, shall be as given in Table 2. This classification is applicable principally where machinability or wear resistance are of importance. If a casting is ordered on the basis of hardness, the relevant wall thickness and the position of the test shall be agreed.

Minimum and maximum Brinell hardness values, for the relevant wall thickness specified by the purchaser, shall be mandatory for the castings covered by the order. NOTE For a relevant wall thickness t

> 100 mm, grades are not classified by hardness. If it is not possible to use the Brinell test method in accordance with EN ISO 6506-1, alternative test methods may be used, which shall have correlated values with Brinell hardness. SIST EN 1561:2011

7.4 Graphite structure If the graphite structure is agreed upon, the determination shall be carried out in accordance with 9.3. 8 Sampling 8.1 General Samples shall be made from the same material as that used to produce the casting(s) which they represent.

Several types of samples (separately cast samples, cast-on samples, side-by-side cast samples, samples cut from a casting) can be used, depending on the mass and wall thickness of the casting.

When relevant, the type of sample should be agreed between the manufacturer and the purchaser. Unless otherwise agreed, the choice of option is left to the discretion of the manufacturer. When the mass of the casting exceeds 1 000 kg and its thickness exceeds 50 mm, cast-on samples should preferably be used; the dimensions and the location of the sample shall be agreed between the manufacturer and the purchaser by the time of acceptance of the order. SIST EN 1561:2011

The samples shall be subject to the same heat treatment, as that of the castings they represent, if any. 8.2 Samples for tensile test 8.2.1 Size of cast samples The size of the sample shall be in correspondence with the relevant wall thickness of the casting as shown in Table 3.

If other sizes are used, this, and the minimum tensile value to be obtained, shall be agreed between the manufacturer and purchaser. Table 3 — Types and size of cast sample and size of tensile test pieces in relation to relevant wall thickness of the casting Relevant wall thickness t mm Type of cast sample Preferred diameter of tensile test piecea d mm Separately Side by side Cast-on Type 1 Cast-on Type 2 > ≤ (see Figure 1) (see Figure 1) (see Figure 2) (see Figure 3) – 10 I I b b 10 10 20 II II 20 20 35 III III 32 35 50 IV IV 32 50 100 c c 30 mm 30 mm 20 100 200 50 mm 50 mm 32 a Other diameters, in accordance with Table 4, may be agreed between the manufacturer and the purchaser. Unless otherwise agreed, the preferred diameter for the test piece shall be used. b Not to be used. c Diameter of cast sample, diameter of tensile test piece and minimum tensile strength to be obtained shall be agreed between manufacturer and purchaser.

Unless otherwise agreed, the choice of the type is left to the discretion of the manufacturer. 8.2.2 Frequency and number of tests Samples representative of the material shall be produced at a frequency in accordance with the process quality assurance procedures adopted by the manufacturer or as agreed with the purchaser. In the absence of a process quality assurance procedure or any other agreement between the manufacturer and the purchaser, a minimum of one cast sample for the tensile test shall be produced to confirm the material grade, at a frequency to be agreed between the manufacturer and the purchaser. 8.2.3 Separately cast samples The samples shall be cast separately in sand moulds and under representative manufacturing conditions. The moulds used to cast the separately cast samples shall have comparable thermal behaviour to the moulding material used to cast the castings. The moulds may be made for casting several samples simultaneously.

Dimension Type

I II III lV d (+2/-0) 15 30 45 75

L a

A function of the test piece length D (+/-5) 40 50 70 105 H ≥ 40 ≥ 50 ≥ 60 ≥ 90 A ≥ 40 ≥ 50

≥ 60

≥ 90

Preferred diameter d of tensile test piece (see Table 4) 10 20 32 32 a L shall be chosen to allow a test piece of dimensions shown in Figu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...