EN 10253-4:2008

(Main)Butt-welding pipe fittings - Part 4: Wrought austenitic and austenitic-ferritic (duplex) stainless steels with specific inspection requirements

Butt-welding pipe fittings - Part 4: Wrought austenitic and austenitic-ferritic (duplex) stainless steels with specific inspection requirements

1.1 This European Standard specifies the technical delivery requirements for seamless and welded butt-welding fittings (elbows, concentric and eccentric reducers, equal and reducing tees, caps) made of austenitic and austenitic-ferritic (duplex) stainless steel which are intended for pressure and corrosion resisting purposes at room temperature, at low temperature or at elevated temperatures.

It specifies:

the type of fittings;

type A (see 7.2)

type B (see 7.3)

the steel grades;

the mechanical properties;

the dimensions and tolerances;

the requirements for inspection and testing;

the inspection documents;

the marking;

the handling and packaging.

NOTE In the case of a harmonised supporting standard for materials, presumption of conformity to the Essential Requirement(s) (ESRs) is limited to technical data of materials in the standard and does not presume adequacy of the material to a specific item of equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive (PED) are satisfied.

1.2 Unless otherwise specified in this European Standard the general technical delivery requirements in EN 10021 apply.

Formstücke zum Einschweißen - Teil 4: Austenitische und austenitisch-ferritische (Duplex-)Stähle mit besonderen Prüfanforderungen

1.1 Diese Europäische Norm legt die technischen Lieferbedingungen für nahtlose und geschweißte Formstücke zum Einschweißen (Rohrbogen, konzentrische und exzentrische Reduzierstücke, T Stücke mit gleichem Abzweig und T Stücke mit reduziertem Abzweig, Kappen) aus nicht rostendem austenitischem und austenitisch ferritischem (Duplex )Stahl fest, die für druck und korrosionsbeständige Anwendungsfälle bei Raumtemperatur, Niedrigtemperatur oder bei erhöhten Temperaturen vorgesehen sind.

Diese Norm legt fest:

die Bauart der Formstücke;

Bauart A (siehe 7.2);

Bauart B (siehe 7.3);

die Stahlsorten;

die mechanischen Eigenschaften;

die Maße und Grenzabmaße;

die Anforderungen an die Prüfungen;

die Prüfbescheinigungen;

die Kennzeichnung;

die Versandvorbereitung und Verpackung.

ANMERKUNG Bei einer harmonisierten unterstützenden Norm für Werkstoffe ist die Konformitätsvermutung hinsichtlich der grundlegenden Sicherheitsanforderungen (ESR) auf die in der Norm angegebenen technischen Daten von Werkstoffen begrenzt und setzt nicht die Eignung des Werkstoffes auf ein bestimmtes Geräteteil voraus. Folglich sollten die in der Werkstoffnorm angegebenen technischen Daten in Bezug auf die Anforderungen für die Berechnung dieses bestimmten Geräteteils bewertet werden, um zu überprüfen, ob die grundlegenden Sicherheitsanforderungen der Druckgeräterichtlinie (PED) erfüllt sind.

1.2 Falls in dieser Europäischen Norm nichts anderes festgelegt ist, gelten die allgemeinen technischen Lieferbedingungen nach EN 10021.

Raccords à souder bout à bout - Partie 4: Aciers inoxydables austénitiques et austéno-ferritiques (duplex) avec contrôle spécifique

1.1 La présente Norme européenne spécifie les conditions techniques de livraison pour les raccords à souder bout à bout sans soudure et soudés (coudes, réductions concentriques et excentriques, tés égaux et tés réduits, fonds) en acier inoxydable austénitique et austéno-ferritique (duplex) utilisés pour des applications sous pression avec résistance à la corrosion à température ambiante, à basse température ou à des températures élevées.

Elle spécifie:

le type de raccord ;

type A (voir 7.2)

type B (voir 7.3)

les nuances d'acier ;

les caractéristiques mécaniques ;

les dimensions et tolérances ;

les prescriptions relatives aux contrôles et essais ;

les documents de contrôle ;

le marquage ;

la manutention et le conditionnement.

NOTE Dans le cas d'une norme harmonisée support de matériaux, la présomption de conformité aux exigences essentielles (ESR) est limitée aux données techniques des matériaux indiquées dans la norme et ne présume pas de l'adéquation du matériau à une partie spécifique de l'équipement. Par conséquent, il convient de vérifier les données techniques figurant dans la norme du matériau par rapport aux exigences de conception de cette partie spécifique afin de vérifier que les ESR de la Directive Equipements sous Pression (DESP) sont satisfaites.

1.2 Sauf spécification contraire dans la présente Norme européenne, les conditions techniques générales de livraison de l’EN 10021 s’appliquent.

Cevni fitingi za soležne zvare - 4. del: Kovna avstenitna in avstenitno-feritna (dupleksna) nerjavna jekla s posebnimi zahtevami glede pregledov

General Information

- Status

- Withdrawn

- Publication Date

- 18-Mar-2008

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Jul-2025

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 5173:2023 - Destructive tests on welds in metallic materials - Bend tests (ISO 5173:2023) - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 10253-4:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Butt-welding pipe fittings - Part 4: Wrought austenitic and austenitic-ferritic (duplex) stainless steels with specific inspection requirements". This standard covers: 1.1 This European Standard specifies the technical delivery requirements for seamless and welded butt-welding fittings (elbows, concentric and eccentric reducers, equal and reducing tees, caps) made of austenitic and austenitic-ferritic (duplex) stainless steel which are intended for pressure and corrosion resisting purposes at room temperature, at low temperature or at elevated temperatures. It specifies: the type of fittings; type A (see 7.2) type B (see 7.3) the steel grades; the mechanical properties; the dimensions and tolerances; the requirements for inspection and testing; the inspection documents; the marking; the handling and packaging. NOTE In the case of a harmonised supporting standard for materials, presumption of conformity to the Essential Requirement(s) (ESRs) is limited to technical data of materials in the standard and does not presume adequacy of the material to a specific item of equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive (PED) are satisfied. 1.2 Unless otherwise specified in this European Standard the general technical delivery requirements in EN 10021 apply.

1.1 This European Standard specifies the technical delivery requirements for seamless and welded butt-welding fittings (elbows, concentric and eccentric reducers, equal and reducing tees, caps) made of austenitic and austenitic-ferritic (duplex) stainless steel which are intended for pressure and corrosion resisting purposes at room temperature, at low temperature or at elevated temperatures. It specifies: the type of fittings; type A (see 7.2) type B (see 7.3) the steel grades; the mechanical properties; the dimensions and tolerances; the requirements for inspection and testing; the inspection documents; the marking; the handling and packaging. NOTE In the case of a harmonised supporting standard for materials, presumption of conformity to the Essential Requirement(s) (ESRs) is limited to technical data of materials in the standard and does not presume adequacy of the material to a specific item of equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive (PED) are satisfied. 1.2 Unless otherwise specified in this European Standard the general technical delivery requirements in EN 10021 apply.

EN 10253-4:2008 is classified under the following ICS (International Classification for Standards) categories: 23.040.40 - Metal fittings; 77.140.20 - Stainless steels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10253-4:2008 has the following relationships with other standards: It is inter standard links to EN 10253-4:2025, EN 10088-2:2024, EN ISO 6708:1995, EN 10168:2004, EN 10021:2006, EN ISO 9606-1:2017, EN ISO 3166-1:2020, EN 10204:2004, EN ISO 14732:2025, EN ISO 3651-2:1998, EN 13480-3:2002, EN ISO 15614-1:2017, EN 10216-5:2021, EN ISO 6892-1:2019, EN ISO 5173:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10253-4:2008 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10253-4:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Butt-welding pipe fittings - Part 4: Wrought austenitic and austenitic-ferritic (duplex) stainless steels with specific inspection requirementsCevni fitingi za soležne zvare - 4. del: Kovna avstenitna in avstenitno-feritna (dupleksna) nerjavna jekla s posebnimi zahtevami glede pregledovRaccords a souder bout a bout - Partie 4: Aciers inoxydables austénitiques et austéno-ferritiques avec contrôle spécifiqueFormstücke zum Einschweissen - Teil 4: Austenitischen und austenitisch- ferritischen nichtrostenden Stähle mit besonderen PrüfanforderungenTa slovenski standard je istoveten z:EN 10253-4:2008SIST EN 10253-4:2008en77.140.2023.040.40ICS:SLOVENSKI

STANDARDSIST EN 10253-4:200801-maj-2008

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10253-4March 2008ICS 23.040.40; 77.140.20 English VersionButt-welding pipe fittings - Part 4: Wrought austenitic andaustenitic-ferritic (duplex) stainless steels with specificinspection requirementsRaccords à souder bout à bout - Partie 4: Aciersinoxydables austénitiques et austéno-ferritiques aveccontrôle spécifiqueFormstücke zum Einschweißen - Teil 4: Austenitische undaustenitisch-ferritische (Duplex-)Stähle mit besonderenPrüfanforderungenThis European Standard was approved by CEN on 5 January 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10253-4:2008: E

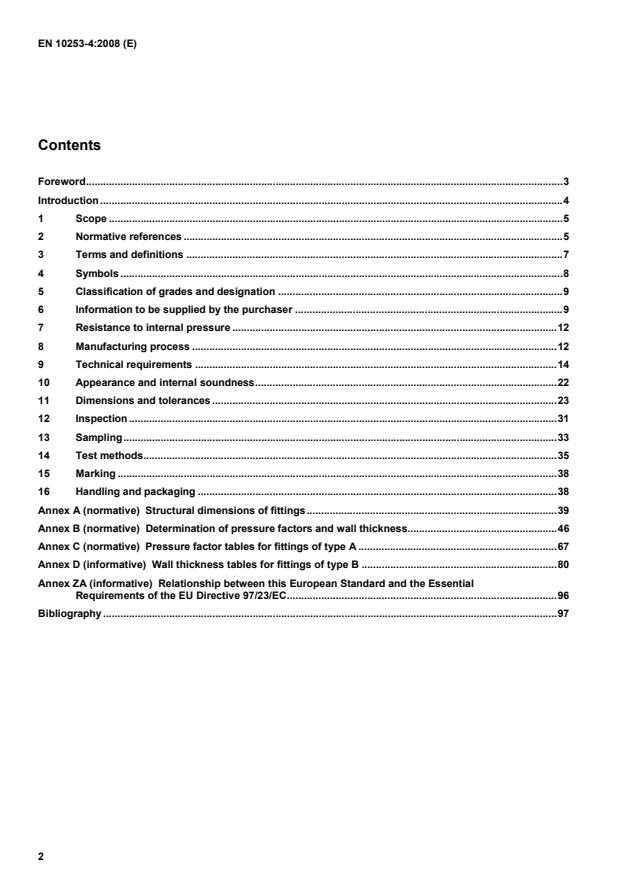

Structural dimensions of fittings.39 Annex B (normative)

Determination of pressure factors and wall thickness.46 Annex C (normative)

Pressure factor tables for fittings of type A.67 Annex D (informative)

Wall thickness tables for fittings of type B.80 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of the EU Directive 97/23/EC.96 Bibliography.97

The holder of these patent rights has assured CEN that they are willing to negotiate licences, under reasonable and non-discriminatory terms and conditions, with applicants throughout the world. In this respect, the statements of the holders of these patent rights are registered with CEN. Information may be obtained from:

Sandvik AB SE-811 81 SANDVIKEN Sweden

Attention is drawn to the possibility that some of the elements within this document may be the subject of patent rights other than those indicated above. CEN shall not be responsible for identifying any or all such patents rights.

NOTE In the case of a harmonised supporting standard for materials, presumption of conformity to the Essential Requirement(s) (ESRs) is limited to technical data of materials in the standard and does not presume adequacy of the material to a specific item of equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive (PED) are satisfied. 1.2 Unless otherwise specified in this European Standard the general technical delivery requirements in EN 10021 apply. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 287-1, Qualification test of welders - Fusion welding - Part 1: Steels EN 473, Non destructive testing - Qualification and certification of NDT personnel - General principles EN 910, Destructive tests on welds in metallic materials – Bend test EN 1418, Welding personnel - Approval testing of welding operators for fusion welding and resistance weld setters for fully mechanized and automatic welding of metallic materials EN 10002-1, Metallic materials - Tensile testing - Part 1: Method of test at ambient temperature

steel tubes EN 10217-7, Welded steel tubes for pressure purposes - Technical delivery conditions - Part 7: Stainless steel tubes EN 10266:2003,Steel tubes, fittings and structural hollow sections - Symbols and definitions of terms for use in product standards EN 10272, Stainless steel bars for pressure purposes EN 13445-3, Unfired pressure vessels - Part 3: Design EN 13480-3:2002, Metallic industrial piping - Part 3: Design and calculation EN ISO 377:1997, Steel and steel products - Location and preparation of samples and test pieces for mechanical testing (ISO 377:1997) EN ISO 1127, Stainless steel tubes - Dimensions, tolerances and conventional masses per unit length (ISO 1127:1992) EN ISO 3166-1, Codes for the representation of names of countries and their subdivisions - Part 1: Country codes (ISO 3166-1:2006) EN ISO 3651-2, Determination of resistance to intergranular corrosion of stainless steels - Part 2: Ferritic, austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in media containing sulfuric acid (ISO 3651-2:1998) EN ISO 6708, Pipework components - Definition and selection of DN (nominal size) (ISO 6708:1995) EN ISO 14284, Steel and iron - Sampling and preparation of samples for the determination of chemical composition (ISO 14284:1996) EN ISO 15614-1, Specification and qualification of welding procedures for metallic materials - Welding procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys (ISO 15614-1:2004)

3.2.1 fittings made from welded tubes 3.2.2 fittings made from sheet/plate or strip where welding is a part of the manufacturing process 3.3 seamless fitting fittings manufactured without welding from starting material which is not welded

3.4 purchaser person or organisation that orders products in accordance with this European Standard.

NOTE The purchaser is not necessarily, but may be, a manufacturer of pressure equipment in accordance with the EU Directive listed in Annex ZA. Where a purchaser has responsibilities under this EU Directive, this standard will provide a presumption of conformity with the essential requirements of the Directive so identified in Annex ZA

3.5 employer organisation for which a person works on a regular basis.

NOTE The employer may be either the fitting manufacturer or supplier or a third party organisation providing a service, e.g. NDT

Minimum 0,2 % proof strength at room temperature, expressed in MPa; Rp1,0 Minimum 1,0 % proof strength at room temperature, expressed in MPa; A Percentage of elongation after rupture, with reference to gauge length of 5,65 oS; W0 Welded from hot or cold rolled plate, sheet or strip 1 D, 2 D, 2 E, 2 B (Symbols of flat products

fittings covered by this European Standard the designation shall consist of: the number of this European Standard (EN 10253-4)

plus either: the steel name in accordance with EN 10027-1; or: the steel number allocated in accordance with EN 10027-2. 6 Information to be supplied by the purchaser 6.1 Mandatory information

6.1.1 Designation of fittings 6.1.1.1 General Fittings may be designated by their outside diameter D (and D1 ) or by their inside diameter ID (and I D1). 6.1.1.2 Elbows and return bends Elbows and return bends are designated by the model, the angle and the inside diameter (D or I D) (Inside diameter related to metric series). Models of elbows designated by their outside diameter D are: 2D, 3 D and 5 D1)

Models of elbows designated by their inside diameter I D are: I D + 100, 3 I D and 5 I D

6.1.2 Information The following information shall be supplied by the purchaser at the time of enquiry and order: a) the quantity required (number of pieces); b) the designation of fittings (see 6.1.1) and the wall thickness T(T1 ); c) the structural dimensions according to 11.1.2; d) the designation of the steel grade according to this European Standard; e) the reference to this European Standard; f) the type of fitting, A or B; g) seamless (s) or welded (w). 6.2 Options A number of options are specified in this European Standard and these are listed below. In the event that the purchaser does not indicate a wish to implement any of these options at the time of enquiry and order, the fittings shall be supplied in accordance with the basic specification (see 6.1). 1) method of manufacture of the fitting (see 8.2.1 ); 2) starting product form and /or delivery condition (see 8.2.1); 3) heat treatment of the fittings (see 8.2.3.1); 4) product analysis (see 9.2.2); 5) verification of impact properties at room temperature (see 9.3.1); 6) agreed mechanical properties at room temperature for austenitic stainless steel fittings with wall

thicknesses greater than 60 mm (see Table 6); 7) verification of tensile properties at elevated temperature (see 9.3.2); 8) verification of impact properties at low temperature (see 9.3.3); 9) intergranular corrosion test (see 9.4);

smaller than those specified in Table 11 (see Table 11); 17) verification of tensile properties on the weld at room temperature (see Table 12); 18) verification of impact properties transverse to the weld (see 13.2.6); 19) liquid penetrant examination of weld and weld ends (see 14.9.2); 20) liquid penetrant examination of surfaces (see 14.9.2); 21) ultrasonic testing of strip or plates (see 14.9.2); 22) additional marking (see 15.1); 23) special packaging (see Clause 16). 6.3 Examples of an order 6.3.1 Example 1 1000 welded elbows in accordance with this European Standard of model 3D with angle 90° and dimensions 60,3 x 2,9 not having an increased wall thickness at the body of the fitting (type A) and with a bending radius according to Annex A made of steel grade 1.4436. 1000 elbows – w – EN 10253-4 – type A – model 3D – 90°°°° – 60,3 x 2,9 – 1.4436. 6.3.2 Example 2 2000 seamless concentric reducers in accordance with this European Standard with dimensions 219,1 x 6,3 – 139,7 x 4,0 with an increased wall thickness at the body of the fitting (type B) and with a length according to Annex A made of steel grade X2CrNi19-11. 2000 concentric reducers – s– EN 10253-4 – type B – 219,1 x 6,3 – 139,7 x 4,0 – X2CrNi19-11. 6.3.3 Example 3 3000 welded and pulled equal tees in accordance with this European Standard with dimension ID 40,0 x 2,0 not having an increased wall thickness at the body of the fitting (type A) made of steel grade 1.4301 with their surface pickled. 3000 equal tees – w – EN 10253-4 – type A – ID 40,0 x 2,0 – 1.4301 – option 10

Bending b Pressed in die c Rolled, forged followed by machining Bending b Pressed in die c Machining from round bars ( DN < 50 )

Elbows 1, 2, 4, 5 1, 2, 3, 4, 5 - 1, 2, 4, 5 1, 2, 3, 4, 5 - Tees - 1, 2, 3, 4, 5 4, 5 - 1, 2, 3, 4, 5 - Reducers - 1, 2, 3, 4, 5 4, 5 - 1, 2, 3, 4, 5 5 Caps - 1, 2, 3, 4, 5 4, 5 - 1, 2, 3, 4, 5 5 a Starting product forms

1 Seamless pipe

2 Welded pipe

3 Plate and strip

4 Forging

5 Bar b When producing elbows from welded pipe, the position of the weld is at the discretion of the manufacturer.

c For these processes welding with or without filler metal may be used (see 8.2.2). When filler metal is used it shall be compatible with the parent

metal. Option 1: The method of manufacturing and/or details of the manufacturing process, e.g. welding operations or position of the weld before forming shall be as specified on the purchase order. Option 2: The starting product form to be used and/or its delivery condition shall be as specified on the purchase order. 8.2.2 Welding as part of the manufacturing process of the fitting 8.2.2.1 General When producing fittings from plate or strip, welding is considered being a part of the manufacturing of fittings, the following criteria are valid: welding process/procedures shall be qualified in accordance with EN ISO 15614-1; welders and/or welding operators shall be qualified in accordance with EN 287-1 and/or EN 1418. All welds carried out during the manufacture of the fitting shall be fusion weld type. All welds shall have complete penetration. Local repair of weld seam which have been made with filler metal is permitted provided that the repair procedure/welders are qualified in accordance with the relevant part of the above mentioned standards. If heat treatment is required, the repair welding shall be carried out in advance. 8.2.2.2 Finished joint requirement As welded surfaces are permitted provided the surface imperfections permit proper interpretation of radiographic or other non-destructive examination. A reduction in thickness due to the welding process is acceptable provided that the material of the joining surfaces shall not be reduced below minimum required thickness at any point. Concavity due to the welding process on the root side of a single welded joint is permitted when the resulting thickness of the weld is at least equal to the minimum thickness of the thinner part of the parts being joined and the contour of the concavity is smooth.

Dimensions in millimetres Base metal thickness ( T ) Reinforcement T < 2,5 1,0 2,5 ≤ T ≤ 5,0 1,5 5,0 < T ≤ 10,0 2,0 10,0 < T ≤ 25,0 2,5 25,0 < T ≤ 50,0 3,5 8.2.3 Heat treatment 8.2.3.1 Cold forming Fittings, produced from solution annealed and quenched or stabilised materials using cold forming as manufacturing method, do not require heat treatment afterwards, if in the case of austenitic steels with required minimum values for elongation A5 > 30 %, a 15 % level of cold deformation is not exceeded on the base material or if evidence is supplied that there is a minimum post cold-forming residual elongation A5 of 15 %. In any case, the post cold-forming residual elongation shall be at least 14 %. If heat treatment still will be demanded, this shall be agreed at the time of enquiry and order. Option 3: Heat treatment of the fittings shall be carried out. 8.2.3.2 Hot forming Fittings shall be solution annealed after forming operations. 9 Technical requirements 9.1 General Fittings supplied and inspected in accordance with Clauses 7, 11 and 12, shall comply with the requirements of this European Standard. In addition to the requirements of this European Standard, the general technical delivery requirements specified in EN 10021 shall apply. 9.2 Chemical composition 9.2.1 Cast analysis The cast analysis reported by the steel manufacturer shall apply and comply with the requirements of Table 3 for austenitic steels and of Table 4 for austenitic-ferritic steels. 9.2.2 Product analysis Option 4: A product analysis shall be supplied. Table 5 specifies the permissible deviations of the product analysis from the specified cast analysis given in Tables 3 and 4.

name Steel number max. max.max.max. max.

X2CrNi18-9 1.4307 0,030 1,00 2,00 0,045b 0,015b ≤ 0,11 17,50-19,50 _ _ _ 8,00-10,00 _ _ X2CrNi19-11 1.4306 0,030 1,00 2,00 0,045b 0,015b ≤ 0,11 18,00-20,00 _ _ _ 10,00-12,00 _ _ X2CrNiN18-10 1.4311 0,030 1,00 2,00 0,045b 0,015b 0,12-0,22 17,00-19,50 _ _ _ 8,50-11,50 _ _ X5CrNi18-10 1.4301 0,07 1,00 2,00 0,045b 0,015b ≤ 0,11 17,00-19,50 _ _ _ 8,00-10,50 _ _ X6CrNiTi18-10 1.4541 0,08 1,00 2,00 0,045b 0,015b _ 17,00-19,00 _ _ _ 9,00-12,00 5xC-0,70 _ X6CrNiNb18-10 1.4550 0,08 1,00 2,00 0,045b 0,015b _ 17,00-19,00 _ _ 10xC-1,00 9,00-12,00 _ _ X1CrNi25-21 1.4335 0,020 0,25 2,00 0,025 0,010 ≤ 0,11 24,00-26,00 _ ≤ 0,20 _ 20,00-22,00 _ _ X2CrNiMo17-12-2 1.4404 0,030 1,00 2,00 0,045b 0,015b ≤ 0,11 16,50-18,50 _ 2,00-2,50 _ 10,00-13,00 _ _ X5CrNiMo17-12-2 1.4401 0,07 1,00 2,00 0,045b 0,015b ≤ 0,11 16,50-18,50 _ 2,00-2,50 _ 10,00-13,00 _ _ X6CrNiMoTi17-12-2 1.4571 0,08 1,00 2,00 0,045b 0,015b _ 16,50-18,50 _ 2,00-2,50 _ 10,50-13,50 5xC-0,70 _ X2CrNiMo17-12-3 1.4432 0,030 1,00 2,00 0,045b 0,015b ≤ 0,11 16,50-18,50 _ 2,50-3,00 _ 10,50-13,00 _

X2CrNiMoN17-13-3 1.4429 0,030 1,00 2,00 0,045b 0,015b 0,12-0,22 16,50-18,50 _ 2,50-3,00 _ 11,00-14,00 _ _ X3CrNiMo17-13-3 1.4436 0,05 1,00 2,00 0,045b 0,015b ≤ 0,11 16,50-18,50 _ 2,50-3,00 _ 10,50-13,00 _ _ X2CrNiMo18-14-3 1.4435 0,030 1,00 2,00 0,045b 0,015b ≤ 0,11 17,00-19,00 _ 2,50-3,00 _ 12,50-15,00 _ _

X2CrNiMoN17-13-5 1.4439 0,030 1,00 2,00 0,040b 0,015b 0,12-0,22 16,50-18,50 _ 4,00-5,00_ 12,50-14,50 _ _ X2CrNiMo18-15-4 1.4438 0,030 1,00 2,00 0,040b 0,015b ≤ 0,11 17,50-19,50 _ 3,00-4,00_ 13,00-16,00 _ _ X1NiCrMoCu31-27-4 1.4563 0,020 0,70 2,00 0,030 0,010 ≤ 0,11 26,00-28,00 0,70-1,50 3,00-4,00_ 30,00-32,00 _ _ X1NiCrMoCu25-20-5 1.4539 0,020 0,70 2,00 0,030 0,010 ≤ 0,15 19,00-21,00 1,20-2,00 4,00-5,00_ 24,00-26,00 _ _ X1CrNiMoCuN20-18-7 1.4547 0,020 0,70 1,00 0,030 0,010 0,18-0,25 19,50-20,50 0,50-1,00 6,00-7.00_ 17.50-18,50 _ _ X1NiCrMoCuN25-20-7 1.4529 0,020 0,50 1,00 0,030 0,010 0,15-0,25 19,00-21,00 0,50-1,50 6,00-7,00_ 24,00-26,00 _ _ a Elements not listed in this table shall not be intentionally added to the steel without the agreement of the purchaser except for finishing the cast. All appropriate precautions are to be taken to avoid the addition of such elements from scrap and other materials used in production which would impair mechanical properties and the suitability of the steel. b For fittings welded without filler material the sum of sulphur and phosphorus shall be maximum 0,040 %. Table 4 — Chemical composition (cast analysis)a of austenitic-ferritc stainless steels, in % by mass Steel grade C Si Mn P S N Cr Cu Mo Ni Others Steel name Steel number max. max. max. Max. max.

X2CrNiMoN22-5-3 1.4462 0,030 1,00 2,00 0,035 0,015 0,10-0,22 21,00-23,00 _ 2,50-3,50 4,50-6,50 _ X2CrNiN23-4 1.4362 0,030 1,00 2,00 0,035 0,015 0,05-0,20 22,00-24,00 0,10-0,60 0,10-0,60 3,50-5,50 _ X2CrNiMoN25-7-4b 1.4410 0,030 1,00 2,00 0,035 0,015 0,20-0,35 24,00-26,00 _ 3,00-4,50 6,00- 8,00 _ X2CrNiMoCuWN25-7-4 1.4501 0,030 1,00 1,00 0,035 0,015 0,20-0,30 24,00-26,00 0,50-1,00 3,00-4,00 6,00-8,00 W: 0,50- 1,00 X2CrNiMoCuN25-6-3 1.4507 0,030 0,70 2,00 0,035 0,015 0,15-0,30 24,00-26,00 1,00-2,50 2,70-4,00 5,50-7,50 _ a Elements not listed in this table shall not be intentionally added to the steel without the agreement of the purchaser except for finishing the cast. All appropriate precautions are to be taken to avoid the addition of such elements from scrap and other materials used in production which would impair mechanical properties and the suitability of the steel. B Patented steel grade

on cast analysis given in Tables 3 and 4 Element Limiting value for the cast analysis in accordance width Tables 3 and 4 Permissible deviation of the product analysis a

% by mass % by mass Carbon ≤ 0,030 + 0,005

> 0,030 ≤ 0,08 ± 0,01 Silicon ≤ 1,00 ± 0,05 Manganese ≤ 1,00 + 0,03

> 1,00 ≤ 2,00 +0,04 Phosphorus

≤ 0,030 + 0,003

> 0,030 to ≤ 0,045 + 0,005 Sulphur ≤ 0,015 + 0,003 Nitrogen ≤ 0,35 ± 0,01 Chromium > 16,50 ≤ 20,00 ± 0,20

> 20,00 ≤ 28,00 ± 0,25 Copper ≤ 1,00 ± 0,07

> 1,00 ≤ 2,50 ± 0,10 Molybdenum ≤ 0,60 ± 0,03

> 0,60 ≤ 1,75 ± 0,05

> 1,75 ≤ 7,00 ± 0,10 Niobium ≤ 1,00 ± 0,05 Nickel ≤ 1,00 ± 0,03

>1,00 ≤ 5,00 ± 0,07

> 5,00 ≤ 10,00 ± 0,10

> 10,00 ≤ 20,00 ± 0,15

> 20,00 ≤ 32,00 ± 0,20 Titanium ≤ 0,70 ± 0,05 Tungsten ≤ 1,00 ± 0,05 a If several product analyses are carried out on one cast, and the contents of an individual element determined lie outside the permissible range of the chemical composition specified for the cast analysis, then it is only allowed to exceed the permissible maximum value or to fall short of the permissible minimum value, but not both for one cast. 9.3 Mechanical properties 9.3.1 At room temperature The mechanical properties at room temperature of the fittings of this European Standard shall conform to the requirements given in Tables 6 and 7. Option 5: Impact properties shall be verified out at room temperature (see Tables 6 and 7). For fittings manufactured from welded tubes the location of the test pieces, from the weld or opposite to the weld, shall be agreed at the time of enquiry and order. Option 6: (see Table 6).

values at elevated temperature are specified in the relevant standard for the starting material dependent on the delivery form being used.

Option 7: Proof strength Rp0,2 or Rp1,0

shall be verified at elevated temperature for austenitic steels. Proof strength Rp0,2

shall be verified at elevated temperature for austenitic-ferritic steels. The temperature for tensile testing shall be agreed at the time of enquiry and order. 9.3.3 At low temperature Impact energy values at specified low temperature shall conform to the requirements in Tables 6 and 7. Option 8: Impact properties shall be verified at low temperature (See Tables 6 and 7). For fittings manufactured from welded tubes the location of the test pieces, from the weld or opposite to the weld, shall be agreed at the time of enquiry and order.

Tensile properties at room temperaturebImpact propertiesb Steel grade Hardness Proof strength Tensile strengthh Elongationc

Minimum average absorbed energy

Reference heat treatment conditions Resistance to intergranular corrosion Limit temp.

HB Rp0,2 Rp1,0 Rm A KV

MPa MPa MPa % J °Ci

max. min. min.

min. min. Solution temperature d Cooling ine f Method of EN ISO 3651-2

at RT at-196 °°°°C°°°°C

Steel name Steel number

l t l t t

X2CrNi18-9 1.4307 200 180 215 470-670 40 35 100 60 60 1000-1100 w, a yes A 350 X2CrNi19-11 1.4306 200 180 215 460-680 40 35 100 60 60 1000-1100 w, a yes A 350 X2CrNiN18-10 1.4311 210 270 305 550-760 35 30 100 60 60 1000-1100 w, a yes A 400 X5CrNi18-10 1.4301 200 195 230 500-700 40 35 100 60 60 1000-1100 w, a yesg A 300 X6CrNiTi18-10 1.4541 210 200 235 500-730 35 30 100 60 60 1020-1120 w, a yes A 400 X6CrNiNb18-10 1.4550 210 205 240 510-740 35 30 100 60 60 1020-1120 w, a yes A 400 X1CrNi25-21 1.4335 220 180 210 470-670 45 40 100 60 60 1030-1110 w, a yes A 400 X2CrNiMo17-12-2 1.4404 200 190 225 490-690 40 30 100 60 60 1020-1120 w, a yes A 400 X5CrNiMo17-12-2 1.4401 200 205 240 510-710 40 30 100 60 60 1020-1120 w, a yesg A 300 X6CrNiMoTi17-12-2 1.4571 210 210 245 500-730 35 30 100 60 60 1020-1120 w, a yes A 400 X2CrNiMo 17-12-3 1.4432 200 190 225 490-690 40 30 100 60 60 1020-1120 w, a yes A 400 X2CrNiMoN17-13-3 1.4429 220 295 330 580-800 35 30 100 60 60 1020-1120 w, a yes A 400 X3CrNiMo17-13-3 1.4436 200 205 240 510-710 40 30 100 60 60 1020-1120 w, a yesg A 300 X2CrNMo18-14-3 1.4435 200 190 225 490-690 40 30 100 60 60 1020-1120 w, a yes A 400 X2CrNiMoN17-13-5 1.4439 200 285 315 580-800 35 30 100 60 60 1100-1140 w, a yes C 400 X2CrNiMo18-15-4 1.4438 200 220 250 490-690 35 30 100 60 60 1100-1160 w, a yes C 400 X1CrMoCu31-27-4 1.4563 220 215 245 500-750 40 35 120 90 60 1100-1160 w, a yes C 400

Tensile properties at room temperaturebImpact propertiesb Steel grade Hardness Proof strength Tensile strengthh Elongationc

Minimum average absorbed energy

Reference heat treatment conditions Resistance to intergranular corrosion Limit temp.

HB Rp0,2 Rp1,0 Rm A KV

MPa MPa MPa % J °Ci

max. min. min.

min. min. Solution temperature d °°°°C Cooling ine f Method of EN ISO 3651-2

at RT at-196 °°°°C

Steel name Steel number

l t l t t

X1NiCrMoCu25-20-5 1.4539 220 220 250 520-720 35 30 120 90 60 1100-1150 w, a yes C 400 X1CrNiMoCuN20-18-7 1.4547 220 300 340 650-850 35 30 100 60 60 1180-1230 w, a yes C 400 X1NiCrMoCuN25-20-7 1.4529 220 300 340 600-800 40 40 120 90 60 1120-1180 w, a yes C 400 a For wall thicknesses greater than 60 mm the mechanical properties are subject to agreement at the time of enquiry and order.

Option 6:

Agreed mechanical properties for wall thicknesses

greater than 60 mm apply. b l = longitudinal ; t = transverse. c See also 8.2.3.1. d The maximum temperatures are for guidance only. e w = water ; a = air ; cooling sufficiently rapid. f When tested in accordance with EN ISO 3651-2 (Appropriate method, A or B or C, shall be as indicated) up to the limit temperatures indicated in the last column of this table. g In delivery condition. (Normally not fulfilled in the sensitized condition). h For the delivery conditions W 0, W 1 and W 2 which do not include solution annealing, the upper Rm

limit may be exceeded by 70 MPa . i Up to these temperatures, the material should, within 100 000 h, not have changed so as to show susceptibility of intergranular corrosion, when tested in conformity with EN ISO 3651-2.

Tensile properties at room temperaturea Impact propertiesa Limit temp. Steel grade Hardness Proof strengthTensile strengthElongationb Minimum average absorbed energy

Reference heat treatment conditions Resistance to intergranular corrosion f

HB Rp0,2 Rm A KV

MPa MPa % J °C

max. min.

min. min.

Solution temperaturec Cooling ind e Method in

EN ISO 3651-2

at RT at -40 °°°°C °°°°C

Steel name Steel number

l t l T t

X2CrNiMoN22-5-3 1.4462 290 450 700-920 25 20 120 90 40 1020-1100 w, a yes B 250 X2CrNiN23-4

1.4362 290 400 600-820 25 25 120 90 40 950-1050 w, a yes A 250 X2CrNiMoCuN25-6-3 1.4507 310 500 700-900 20 20 100 100 40 1080-1160 w yes B 250 X2CrNiMoN25-7-4

1.4410 310 550 800-100020 20 100 100 40 1040-1120 w yes B or C 250 X2CrNiMoCuWN 25-7-4 1.4501 310 550 800-100020 20 100 100 40 1080-1160 w yes B or C 250 a l = longitudinal ; t = transverse. b See also 8.2.3.1. c The maximum temperatures are for guidance only. d w = water ; a = air ; cooling sufficiently rapid. e When tested in accordance with EN ISO 3651-2 (Appropriate method, A or B or C, shall be as indicated) up to 250 °C. f Up to these temperatures, the material should, within 100 000 h, not have changed so as to show susceptibility of intergranular corrosion, when tested in conformity with EN ISO 3651-2.

to EN ISO 3651-2 to the indicated method A or B or C. Guideline values for the limit temperature for susceptibility to intergranular corrosion are indicated in Tables 6 and 7. Option 9: A test for the resistance to intergranular corrosion shall be carried out. If other specific corrosion tests are required, they shall be agreed at the time of enquiry and order. 9.5 Weldability Fittings covered by this European Standard are weldable; however account should be taken of the fact that the behaviour of the steel during and after welding is dependent not only on the steel, but also essentially on the conditions of preparing and carrying out the welding. 10 Appearance and internal soundness 10.1 Appearance 10.1.1 The fittings shall be free from internal and external surface defects that can be detected by visual inspection in accordance with this European Standard. 10.1.2 The internal and external surface finish of the fittings shall be typical of the manufacturing process and, where applicable, the heat treated condition employed. Normally the finish and surface condition shall be such, that any surface imperfections or marks requiring dressing shall be identified. 10.1.3 It shall be permissible to dress, by grinding or machining, surface marks and imperfections provided that, the wall thickness of the fitting in the dressed area is not less than the specified minimum wall thickness. 10.1.4 All dressed areas shall blend smoothly into the contour of the fitting. 10.1.5 Any surface imperfection, which demonstrates to be deeper than 5 % of the nominal thickness or 3 mm whichever is the lesser, but not less than 0,3 mm, shall be dressed. For mechanical marks the acceptance limit is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...