EN 13236:2019

(Main)Safety requirements for superabrasive products

Safety requirements for superabrasive products

This document applies to superabrasives products containing natural or synthetic diamond or cBN (cubic boron nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It also applies to reconditioned superabrasive cutting-off wheels.

This document specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the superabrasive products.

This document contains also procedures and tests for verification of the compliance with the requirements as well as safety information for use, which will be made available to the user by the manufacturer.

This document does not apply to bonded abrasive products, coated abrasive products, rotating dressing tools, truers or any non-rotating superabrasive products.

Sicherheitsanforderungen für Schleifwerkzeuge mit Diamant oder Bornitrid

Dieses Dokument gilt für Schleifwerkzeuge mit Diamant oder Bornitrid, die natürlichen oder synthetischen Diamant oder cBN (kubisches Bornitrid) enthalten. Dies beinhaltet Präzisionsschleif- und trennschleif-scheiben, Trennschleifscheiben zur Bearbeitung von Naturstein und zum Einsatz im Hoch- und Tiefbau, Sägeseile, Schleifstifte und andere Schleifwerkzeuge mit Diamant oder Bornitrid zum Schleifen von Naturstein und zum Einsatz im Hoch- und Tiefbau. Es gilt auch für wiederbelegte Trennschleifscheiben mit Diamant oder Bornitrid.

Dieses Dokument legt Anforderungen und/oder Maßnahmen zur Beseitigung oder Verringerung von Gefährdungen fest, die von der Gestaltung und Anwendung der Schleifwerkzeuge mit Diamant oder Bornitrid herrühren.

Dieses Dokument umfasst auch Verfahren und Prüfungen zur Feststellung der Übereinstimmung mit den Anforderungen sowie Benutzerinformationen, die der Hersteller dem Anwender zur Verfügung stellt.

Dieses Dokument gilt nicht für Schleifkörper aus gebundenem Schleifmittel, Schleifmittel auf Unterlagen, rotierende Abrichtwerkzeuge, Handfeilen und andere nicht rotierende Schleifwerkzeuge mit Diamant oder Bornitrid.

Prescriptions de sécurité pour les produits superabrasifs

Le présent document s'applique uniquement aux produits superabrasifs contenant du diamant naturel ou synthétique ou du cBN (nitrure de bore cubique). Il comprend les meules et meules à tronçonner de précision, meules à tronçonner ordinaires, câbles diamantés, meules sur tige et autres produits superabrasifs pour meulage ordinaire. Il s'applique également aux meules à tronçonner superabrasives reconditionnées.

Le présent document spécifie les prescriptions et/ou mesures pour la suppression ou la réduction des phénomènes dangereux résultant de la conception et de l'utilisation des produits superabrasifs.

Le présent document contient également les procédures et essais pour la vérification de la conformité aux prescriptions ainsi que les informations de sécurité pour l'utilisation qui seront mises à la disposition de l'utilisateur par le fabricant.

Le présent document ne s'applique pas aux produits abrasifs agglomérés, produits abrasifs appliqués, outils à dresser rotatifs, outils à dresser, ni aux produits superabrasifs non rotatifs.

Varnostne zahteve za superabrazive

Ta evropski standard se uporablja le za superabrazive, ki vsebujejo naravne ali sintetične diamante ali kubne borove nitride (cBN). Vključuje plošče za precizno brušenje in rezanje, neprecizne plošče za rezanje, diamantne žice, nameščene konice in druge superabrazive za neprecizno brušenje. Prav tako se uporablja za superabrazivne obnovljene plošče za rezanje.

Ta evropski standard določa zahteve in/ali ukrepe za odpravo ali zmanjševanje nevarnosti, ki so posledica načrtovanja in uporabe superabrazivov.

Ta evropski standard vključuje tudi postopke in preskuse za preverjanje skladnosti z zahtevami in varnostnimi informacijami za uporabo, ki jih mora proizvajalec priskrbeti uporabniku.

Obravnavane nevarnosti so naveden v točki 4.

Ta evropski standard se ne uporablja za vezane abrazive, prevlečene abrazive, rotacijsko orodje za brušenje, brusilce niti za katere koli druge nerotacijske superabrazive.

General Information

- Status

- Published

- Publication Date

- 23-Apr-2019

- Withdrawal Date

- 30-Oct-2019

- Technical Committee

- CEN/TC 143 - Machine tools - Safety

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 17-Jun-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 01-May-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13236:2019 - "Safety requirements for superabrasive products" is a European Standard published by CEN that sets safety, testing and information requirements for superabrasive products containing natural or synthetic diamond or cubic boron nitride (cBN). The scope covers precision grinding and cutting-off wheels, non‑precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non‑precision grinding, including reconditioned cutting‑off wheels. It excludes bonded and coated abrasives, rotating dressing tools, truers and any non‑rotating superabrasive products.

Key Topics

- Safety requirements and hazard reduction - requirements and measures to remove or reduce hazards arising from product design and application (e.g., burst, kickback).

- Product types covered - precision and non‑precision wheels, diamond wires, mounted points and similar superabrasive tools.

- Mechanical requirements - bore/spindle tolerances, safety factors, sequences of maximum operating speeds and limits for different constructions (including vacuum‑brazed products).

- Verification and testing - procedures such as ring tests, strength/bending moment verification, and methods for diamond wire testing to demonstrate compliance.

- Marking and user information - mandatory marking content, execution, and safety information for use that manufacturers must provide to users; Annex A details marking requirements.

- Reconditioning rules - normative guidance for reconditioning cutting‑off wheels (Annex C) including preconditions and additional marking.

- Supporting materials - informative annexes (mounted point examples, speed conversion tables) and normative references (e.g., EN ISO 286‑2 and ISO 22917).

Applications

- For designers and manufacturers of superabrasive products to ensure safe product design and conformity with EU product safety frameworks (General Product Safety Directive, Machinery Directive).

- For suppliers and reconditioners to meet marking, testing and safety information obligations when placing products on the market or reconditioning cutting‑off wheels.

- For machine builders and safety engineers selecting compatible superabrasive tools and specifying maximum operating speeds and guarding to reduce risks like bursting or kickback.

- For testing laboratories and conformity assessors performing ring tests, destructive strength tests and verifying product marking.

Related Standards

- EN ISO 286‑2:2010 (tolerances for holes/shafts)

- ISO 22917 (precision superabrasives - limit deviations and run‑out tolerances)

- EN 13236:2019 complements machinery and product safety directives and helps demonstrate conformity with essential safety requirements.

Keywords: EN 13236:2019, superabrasive safety, diamond wheels, cBN, cutting‑off wheels, diamond wire, mounted points, verification tests, product marking, reconditioning.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 13236:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety requirements for superabrasive products". This standard covers: This document applies to superabrasives products containing natural or synthetic diamond or cBN (cubic boron nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It also applies to reconditioned superabrasive cutting-off wheels. This document specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the superabrasive products. This document contains also procedures and tests for verification of the compliance with the requirements as well as safety information for use, which will be made available to the user by the manufacturer. This document does not apply to bonded abrasive products, coated abrasive products, rotating dressing tools, truers or any non-rotating superabrasive products.

This document applies to superabrasives products containing natural or synthetic diamond or cBN (cubic boron nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It also applies to reconditioned superabrasive cutting-off wheels. This document specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the superabrasive products. This document contains also procedures and tests for verification of the compliance with the requirements as well as safety information for use, which will be made available to the user by the manufacturer. This document does not apply to bonded abrasive products, coated abrasive products, rotating dressing tools, truers or any non-rotating superabrasive products.

EN 13236:2019 is classified under the following ICS (International Classification for Standards) categories: 25.100.70 - Abrasives. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13236:2019 has the following relationships with other standards: It is inter standard links to EN 13236:2010+A1:2015, EN 1434-6:2015/prA1, EN ISO 286-2:2010, EN 13218:2002+A1:2008, EN 12418:2021, EN 14886:2008, EN 15163-2:2022, EN 15163-1:2022, EN 13862:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13236:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2019

Nadomešča:

SIST EN 13236:2011+A1:2016

Varnostne zahteve za superabrazive

Safety requirements for superabrasive products

Sicherheitsanforderungen für Schleifwerkzeuge mit Diamant oder Bornitrid

Prescriptions de sécurité pour les produits superabrasifs

Ta slovenski standard je istoveten z: EN 13236:2019

ICS:

25.100.70 Brusiva Abrasives

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13236

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 25.100.70 Supersedes EN 13236:2010+A1:2015

English Version

Safety requirements for superabrasive products

Prescriptions de sécurité pour les produits Sicherheitsanforderungen für Schleifwerkzeuge mit

superabrasifs Diamant oder Bornitrid

This European Standard was approved by CEN on 26 November 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13236:2019 E

worldwide for CEN national Members.

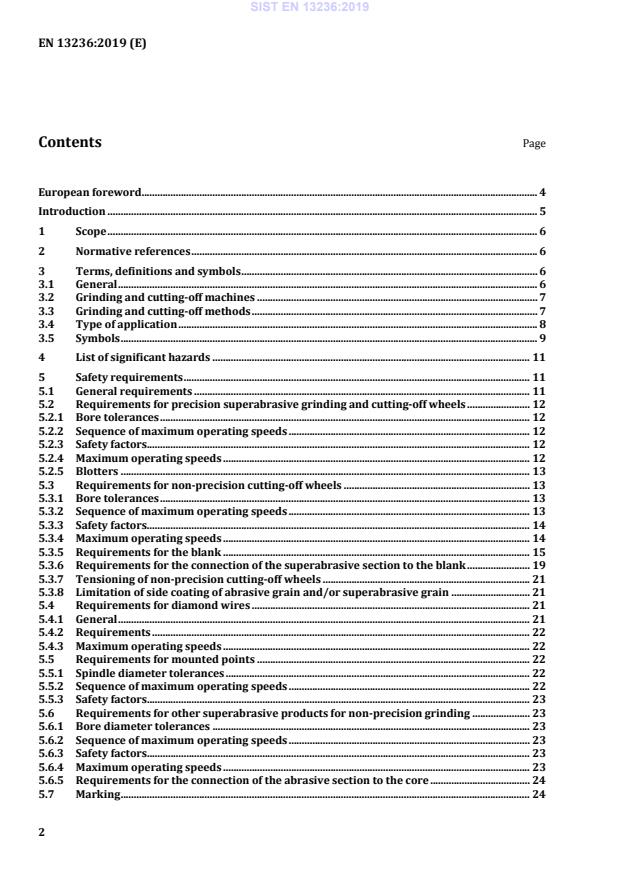

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols . 6

3.1 General . 6

3.2 Grinding and cutting-off machines . 7

3.3 Grinding and cutting-off methods . 7

3.4 Type of application . 8

3.5 Symbols . 9

4 List of significant hazards . 11

5 Safety requirements . 11

5.1 General requirements . 11

5.2 Requirements for precision superabrasive grinding and cutting-off wheels . 12

5.2.1 Bore tolerances . 12

5.2.2 Sequence of maximum operating speeds . 12

5.2.3 Safety factors. 12

5.2.4 Maximum operating speeds . 12

5.2.5 Blotters . 13

5.3 Requirements for non-precision cutting-off wheels . 13

5.3.1 Bore tolerances . 13

5.3.2 Sequence of maximum operating speeds . 13

5.3.3 Safety factors. 14

5.3.4 Maximum operating speeds . 14

5.3.5 Requirements for the blank . 15

5.3.6 Requirements for the connection of the superabrasive section to the blank . 19

5.3.7 Tensioning of non-precision cutting-off wheels . 21

5.3.8 Limitation of side coating of abrasive grain and/or superabrasive grain . 21

5.4 Requirements for diamond wires . 21

5.4.1 General . 21

5.4.2 Requirements . 22

5.4.3 Maximum operating speeds . 22

5.5 Requirements for mounted points . 22

5.5.1 Spindle diameter tolerances . 22

5.5.2 Sequence of maximum operating speeds . 22

5.5.3 Safety factors. 23

5.6 Requirements for other superabrasive products for non-precision grinding . 23

5.6.1 Bore diameter tolerances . 23

5.6.2 Sequence of maximum operating speeds . 23

5.6.3 Safety factors. 23

5.6.4 Maximum operating speeds . 23

5.6.5 Requirements for the connection of the abrasive section to the core . 24

5.7 Marking . 24

6 Verification of the safety requirements . 24

6.1 Verification of the general requirements . 24

6.1.1 General . 24

6.1.2 Visual inspection . 25

6.1.3 Ring test . 25

6.2 Verification of the strength requirements . 25

6.2.1 Verification of the safety factor . 25

6.2.2 Verification of the bending moment of non-precision cutting-off wheels . 25

6.2.3 Verification of the strength requirements for other superabrasive products for non-

precision grinding . 29

6.2.4 Verification methods for diamond wires . 30

6.3 Verification of marking . 33

6.4 Verification of the requirements for blotters . 33

6.5 Verification of the tensioning of non-precision cutting-off wheels . 33

7 Information for use . 35

Annex A (normative) Marking . 36

A.1 Content of the marking . 36

A.1.1 Marking requirements . 36

A.1.2 Additional inscriptions . 39

A.1.2.1 General . 39

A.1.2.2 Multiple or gang mounted wheels . 39

A.2 Execution of marking . 39

Annex B (informative) Mounted points . 41

B.1 Example of calculation of the maximum permissible speed of rotation . 41

B.2 Example for the application of the calculation method . 45

B.2.1 Types of mounted points . 45

B.2.2 Assumptions for the calculation . 46

B.2.3 Maximum permissible speeds of rotation . 47

Annex C (normative) Reconditioning of cutting-off wheels according to 5.3.6.4 . 49

C.1 Preconditions for reconditioning . 49

C.2 Additional marking requirements . 49

Annex D (informative) Speed conversion table . 50

Bibliography . 53

European foreword

This document (EN 13236:2019) has been prepared by Technical Committee CEN/TC 143 “Machine

tools — Safety”, the secretariat of which is held by SNV.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2019, and conflicting national standards shall

be withdrawn at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13236:2010+A1:2015.

Significant changes between EN 13236:2010+A1:2015 and EN 13236:2019 are as follows:

a) added the hazard “kickback” in Table 4;

b) added vacuum brazed products in Table 6 for maximum operating speeds;

c) added mobile cutting-off machines in Table 10;

d) revised the definitions and requirements for openings to achieve a better distinction and to avoid

different interpretations;

e) merged the tables for bending strength and bending moment for cutting-off wheels for the use on

hand-held cutting-off machines into one table and updated the values for minimum requirements

for destructive testing.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

This European Standard has been prepared to provide one means of conforming with essential safety

requirements, e.g. of the General Product Safety Directive and associated EFTA regulations.

This European Standard is addressed to designers, manufacturers and suppliers of the superabrasive

products described in the scope as well as to those who are reconditioning superabrasive cutting-off

wheels. In addition, it helps designers, manufacturers and suppliers of grinding machines in the

selection of superabrasive products, in order to reduce the risks and achieve conformity of the

respective machinery with the essential health and safety requirements of the Machinery Directive.

The extent to which hazards are covered is indicated in the scope of this European Standard.

1 Scope

This document applies to superabrasives products containing natural or synthetic diamond or cBN

(cubic boron nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off

wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It

also applies to reconditioned superabrasive cutting-off wheels.

This document specifies requirements and/or measures for the removal or reduction of hazards

resulting from the design and application of the superabrasive products.

This document contains also procedures and tests for verification of the compliance with the

requirements as well as safety information for use, which will be made available to the user by the

manufacturer.

This document does not apply to bonded abrasive products, coated abrasive products, rotating dressing

tools, truers or any non-rotating superabrasive products.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 286-2:2010, Geometrical product specifications (GPS) - ISO code system for tolerances on linear

sizes - Part 2: Tables of standard tolerance classes and limit deviations for holes and shafts (ISO 286-

2:2010)

ISO 22917, Precision superabrasives — Limit deviations and run-out tolerances for grinding wheels with

diamond or cubic boron nitride

3 Terms, definitions and symbols

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 General

3.1.1

superabrasive product

abrasive product containing natural or synthetic diamond or cubic boron nitride in a bond

3.2 Grinding and cutting-off machines

3.2.1

stationary machine

machine being fixed in position during operation

Note 1 to entry: See, for example, EN ISO 16089.

Note 2 to entry: Included are fixed swing frame machines and mobile machines clamped firmly in position

during use.

Note 3 to entry: Transportable machines are fixed in position during operation and therefore considered to be

stationary machines.

3.2.2

stationary machine with totally enclosed working area

stationary machine being protected by separating guards in such a way that machining processes

including loading and unloading of workpieces are carried out inside them and persons are protected

against hazards generated by bursting of an abrasive product

3.2.3

mobile machine

machine not being fixed in position during operation

Note 1 to entry: Mobile machines are manually guided (but not hand-held) by the operator during use, e.g. floor

grinding machines.

3.2.4

hand-held machine

machine being held in the hand during operation

Note 1 to entry: Included are machines with flexible drives.

Note 2 to entry: See for example EN ISO 11148-7, EN ISO 11148-9, EN 60745-2-3 and EN ISO 19432.

3.3 Grinding and cutting-off methods

3.3.1

peripheral grinding

grinding with the periphery of the wheel with no or limited side loads

3.3.2

face grinding

grinding with the face of the wheel

3.3.3

cutting-off

cutting-off or slotting with the periphery of the cutting-off wheel

3.4 Type of application

3.4.1

mechanically guided grinding and cutting-off

process with feed movements of the abrasive product and/or workpiece guided by mechanical means

Note 1 to entry: See Table 1.

3.4.2

manually guided grinding and cutting-off

process with feed movements of the abrasive product and/or the workpiece manually guided by the

operator

Note 1 to entry: See Table 1.

3.4.3

hand-held grinding and cutting-off

process with the machine entirely guided by the operator

Note 1 to entry: See Table 1.

Table 1 — Type of application

Super-

Grinding Type of Type of Examples for

abrasive Workpiece

method machine application application/machines

product

Surface grinding, centerless

mechanically grinding, creep feed grinding,

fixed

guided bevel grinding on glass (glass

bevelling machine)

mechanically Profile grinding of stone and

stationary mechanically fixed

guided concrete

grinding guided

machines grinding Internal grinding, external,

plunge and traverse grinding, jig

mechanically mechanically grinding, decorative stone

guided guided milling and polishing, pencil

edging of glass (automotive

grinding

glass)

Roughing and polishing of stone

manually

fixed floors (carriage/floor grinding

stationary

guided

manually

machine)

and mobile

guided

grinding

Tool grinding (bench grinding

grinding

manually

machines

fixed machine), decorative glass

guided

grinding

hand-held Stone and concrete milling and

hand-held manually

grinding fixed polishing (angle/straight

grinding guided

machines grinder)

mechanically Cutting-off of bricks and tiles

fixed

guided (table saw)

stationary mechanically Cutting-off of stone and concrete

mechanically

cutting-off guided fixed (bridge-type saw, floor and wall

guided

machines cutting-off saw, wire saw)

mechanically mechanically

Cutting-off of semi-conductors

guided guided

cutting-

off

manually Cutting-off of stone and concrete

stationary

fixed

manually

guided (table saw, floor saw)

and mobile

guided

cutting-off

manually

cutting-off

fixed Cutting-off of bricks (table saw)

machines

guided

hand-held Cutting-off of stone and concrete

hand-held manually

cutting-off fixed (angle grinder, hand-held

cutting-off guided

machines cutting-off machine)

3.5 Symbols

For the purposes of this document, the symbols listed in Table 2 and Table 3 apply.

Table 2 — Symbols

Symbol Designation Definition Unit

Bursting speed divided by maximum

operating speed:

f

burst speed factor —

br

v

br

f =

br

v

s

Revolutions per minute at which the

deflection speed of

n

spindle of mounted points is deflecting 1/min

ab

mounted points

under centrifugal force

Revolutions per minute of a new

maximum permissible

n

abrasive product at maximum 1/min

max

speed of rotation

operating speed

Deflection speed divided by maximum

permissible speed of rotation:

safety factor against

S

spindle deflection for —

ab

n

ab

mounted points

S =

ab

n

max

Bursting speed divided by maximum

operating speed, all squared:

safety factor against

S

bursting due to centrifugal —

br

v

br

force

S =

br

v

s

Maximum permissible peripheral

v

maximum operating speed m/s

s

speed of a rotating abrasive product

Peripheral speed at which an abrasive

v

bursting speed product breaks due to centrifugal m/s

br

force

Peripheral speed which an abrasive

v

minimum bursting speed product shall at least reach without m/s

br,min

bursting due to centrifugal force

Table 3 — Other symbols

Symbol Designation Unit

F force N

F

shearing force N

A

L

lever arm mm

F

M

bending moment Nm

b

σ

bending strength N/mm

b

τ

shear strength N/mm

S

4 List of significant hazards

The significant hazards are listed in Table 4.

Table 4 — List of significant hazards

Hazard designation Hazardous situations Relevant clauses in this standard

(Examples)

Ejection of parts 1. Abrasive product breakage —

caused by:

— improper design 5.1, 5.2, 5.3, 5.4, 5.5, 5.6, 5.7,

Annex B and Annex C

— manufacturing defects 5.1

— wrong selection Clause 7, Annex A

— improper handling and storage Clause 7

— improper use (mounting and Clause 7

grinding process)

2. Grinding debris Clause 7

Vibration Hand arm vibration on hand- —

held machines caused by:

— improper use Clause 7

— incorrect mounting Clause 7

Kickback Kickback effect of cutting-off —

wheels on hand-held

machines caused by:

— improper use Clause 7

— wobbling of cutting-off wheels 5.3.7

due to wrong tensioning

— side coating of cutting-off 5.3.8

wheels

5 Safety requirements

5.1 General requirements

Superabrasive products shall be designed and manufactured in such a way that they resist the forces

and loads that are to be expected when used as intended. They shall not present visible defects affecting

safety and shall comply with the requirements listed in the following clauses.

5.2 Requirements for precision superabrasive grinding and cutting-off wheels

5.2.1 Bore tolerances

The tolerance class for bores on precision superabrasive grinding and cutting-off wheels is given in

ISO 22917.

5.2.2 Sequence of maximum operating speeds

Precision superabrasive grinding and cutting-off wheels shall be manufactured for maximum operating

speeds according to the following sequence:

< 16 — 20 — 25 — 32 — 35 — 40 — 45 — 50 — 63 — 80 — 100 — 125 — 140 — 160 — 180 — 200

— 225 — 250 — 280 — 320 in m/s.

Intermediate maximum operating speeds should only be used where the application requirements

demand it.

NOTE For conversion of peripheral speeds into speeds of rotation for different outside diameters D of the

abrasive product, see Annex D.

5.2.3 Safety factors

Precision superabrasive grinding and cutting-off wheels shall have a safety factor against bursting due

to centrifugal forces at their maximum operating speed as given in Table 5.

Table 5 — Safety factors for precision superabrasive grinding and cutting-off wheels

Maximum

Type of machine Type of application Safety factor Burst speed factor

operating speed

v S f

s br br

m/s

mechanically

guided grinding ≤ 80 3,0 1,73

and cutting-off

mechanically

stationary

guided grinding

machines

and cutting-off

≤ 320 1,75 1,32

with totally

enclosed working

area

manually guided ≤ 63 3,0 1,73

stationary and

grinding and

mobile machines

80 3,5 1,87

cutting-off

5.2.4 Maximum operating speeds

Precision superabrasive grinding and cutting-off wheels shall comply with the classification of the

sequence of maximum operating speeds in 5.2.2 up to the maximum values given in Table 6.

In the totally enclosed working area, the maximum operating speeds given in Table 6 may be exceeded,

if the safety factor required in Table 5 is complied with.

Table 6 — Maximum operating speeds as a function of the bond type

Maximum operating speed

v

s

m/s

Core Abrasive section

Single layer:

electroplated

Vitrified Resinoid Metal

and vacuum

V B M brazed

G

Manufactured on core, e.g.

— 100 100 200

sintered or electroplated

Metal

Connected to core, e.g.

180 80 100 —

cemented, screwed,

clamped, brazed or welded

Manufactured on core, e.g.

— 100 — —

pressed

Resinoid

Connected to core, e.g.

80 80 80 80

cemented, screwed, clamped

Manufactured on core, e.g.

80 — — —

pressed

Vitrified

Connected to core, e.g.

80 80 80 —

cemented, screwed, clamped

5.2.5 Blotters

Blotters shall be supplied by the manufacturer, supplier or importer where these are required for a safe

mounting and use of the superabrasive product.

Blotters shall be made of suitable compressible material. Shape, dimensions and material shall be

adapted to application and intended use. When water-based coolants are used the blotter material shall

not be affected in the way that it loses its compressibility and physical function.

Blotters can serve as a label for the marking provided the marking requirements of this standard are

met and the blotter is firmly attached to the wheel.

5.3 Requirements for non-precision cutting-off wheels

5.3.1 Bore tolerances

The tolerance class for bores for non-precision cutting-off wheels is H9 as per EN ISO 286-2:2010.

5.3.2 Sequence of maximum operating speeds

Non-precision cutting-off wheels shall be manufactured for maximum operating speeds conforming to

the following sequence:

20 — 25 — 32 — 35 — 40 — 45 — 50 — 63 — 80 — 100 in m/s.

Intermediate maximum operating speeds should only be used where the application requirements

demand it.

NOTE For conversion of peripheral speeds into speeds of rotation for different outside diameters D of the

abrasive product, see Annex D.

5.3.3 Safety factors

Non-precision cutting-off wheels shall have a safety factor against bursting due to centrifugal forces at

their maximum operating speed as given in Table 7.

Table 7 — Safety factors for non-precision cutting-off wheels

Maximum Safety factor Burst speed factor

operating speed

Type of machine Type of application

v S f

s br br

m/s

mechanically guided

≤ 100 2,0 1,41

cutting-off

stationary

mechanically guided

cutting-off

cutting-off with

machines

≤ 100 1,75 1,32

totally enclosed

working area

stationary and

manually guided

mobile cutting-off ≤ 100 3,5 1,87

cutting-off

machines

hand-held

hand-held

cutting-off ≤ 100 3,5 1,87

cutting-off

machines

5.3.4 Maximum operating speeds

Non-precision cutting-off wheels shall comply with the sequence of maximum operating speeds in 5.3.2

up to the maximum values given in Table 8.

Table 8 — Maximum operating speeds as a function of the bond type

Maximum operating speed

v

s

m/s

Cutting rim

Single layer:

(abrasive Type of application

electroplated

section)

Metal

and vacuum

M

brazed

G

mechanically and manually

continuous 100 100

guided cutting-off

mechanically and manually

segmented 100 100

guided cutting-off

continuous or

hand-held cutting-off 100 100

segmented

5.3.5 Requirements for the blank

5.3.5.1 Requirements for the blank of cutting-off wheels for dry cutting-off

5.3.5.1.1 Dimensions

Dimensions of blanks of non-precision cutting-off wheels for dry cutting-off, see Table 9.

Table 9 — Dimensions of blanks for dry cutting-off

Outside diameter of the blank Blank thickness

D E

Type of machine 1

mm mm

D ≤ 115 ≥ 0,7

Hand-held cutting-off

115 < D ≤ 200 ≥ 0,9

machines

200 < D ≤ 230 ≥ 1,2

Hand-held and 230 < D ≤ 300 ≥ 1,2

stationary cutting-off

300 < D ≤ 400

≥ 1,6

machines 1

350 < D ≤ 400 ≥ 1,6

400 < D ≤ 500 ≥ 2,0

Stationary and mobile

500 < D ≤ 600 ≥ 2,5

cutting-off machines

600 < D ≤ 900 ≥ 3,0

900 < D ≤ 1 600 ≥ 3,5

5.3.5.1.2 Material and hardness of blanks for laser welded cutting-off wheels

The material used for the blank shall be steel which shall have the necessary properties enabling it to

produce adequate joint strength when welding it to the segments. For example, alloyed cold worked

steels having a maximum carbon content of 0,27 % are suitable.

Blanks shall have a minimum hardness of 20 HRC for outside diameter D ≤ 230 mm and a minimum

hardness of 24 HRC for outside diameter D > 230 mm.

5.3.5.1.3 Material and hardness of blanks for sintered and direct melted cutting-off wheels

The material used for the blank shall be tool steel.

5.3.5.1.4 Surface finish of the entire slot area

Cutting-off wheels shall be manufactured in such a way that the surface finish in the area of the slots

does not cause crack formation.

5.3.5.1.5 Other requirements

Blanks shall be free from visible defects.

5.3.5.2 Requirements for the blank of cutting-off wheels for wet cutting-off

5.3.5.2.1 Dimensions

Dimensions of blanks for non-precision cutting-off wheels for wet cutting-off, see Table 10.

Table 10 — Dimensions of blanks for wet cutting-off

Outside diameter of the blank Blank thickness

D E

Type of machine

mm mm

D ≤ 300 ≥ 1,2

300 < D ≤ 400 ≥ 1,6

400 < D ≤ 500 ≥ 2,0

500 < D ≤ 600 ≥ 2,5

stationary and mobile

cutting-off machines

600 < D ≤ 900 ≥ 2,8

900 < D ≤ 2 500 ≥ 3,5

2 500 < D ≤ 3 500 ≥ 7,0

3 500 < D ≤ 5 000 ≥ 9,0

D ≤ 230 ≥ 0,006 D

1 1

hand-held cutting-off

machines

230 < D ≤ 400 ≥ 0,005 D

1 1

5.3.5.2.2 Material

The material used for the blank shall be tool steel.

5.3.5.2.3 Surface finish of the entire slot area

See 5.3.5.1.4.

5.3.5.2.4 Other requirements

See 5.3.5.1.5.

5.3.5.3 Design and position of openings in the blank of cutting-off wheels for hand-held

applications

5.3.5.3.1 General

A distinction is made between different types of openings in the blank regarding crack propagation. The

different types are:

1) Cuts: A cut is an opening with a width of less than 0,8 mm;

2) Circular and elliptical openings with a ratio of large to small radius ≤ (2:1);

3) “Other openings”: All openings other than types 1) and 2).

Circular and elliptical openings minimize crack propagation whereas “other openings” and cuts might

support it due to a higher notch effect (stress concentration). Therefore, circular and elliptical openings

are treated in a different way compared to “other openings” and cuts.

Openings in blanks of cutting-off wheels for hand-held applications designed for any reasons such as

noise dampening shall comply with the following limitations:

a) The total area of openings in blanks excluding the bore shall be ≤ 20 % of the area of the blank;

b) Openings outside the flange area shall end at a distance x ≥ 0,25 D/2 outside of the diameter of the

bore, where D is the outside diameter of the cut-off wheel. See also Figure 1;

c) Openings outside the flange area other than circular and elliptical openings shall end at a distance

of ≥ 15 % of the blank radius D /2 away from the closest slot or outside diameter of the blank. See

also Figure 1;

d) Inside the flange area no openings other than drive pin holes or holes for fixing of functional

elements are allowed. No more than 2 drive pin holes and 8 fixing holes are allowed. Maximum hole

diameter for fixing holes is 8 mm. See also Figure 1.

Peripheral slots with or without holes at their ends and the bore shall not be considered as openings

according to this subclause.

Key

restricted area, see limitations b) and c) above

D outside diameter

D outside diameter of the blank

Figure 1 — Position of openings in blanks

5.3.5.3.2 Dimensions and distribution of cuts

a) Cuts outside the flange area shall have a dimension in radial direction of ≤ 40 % of the blank radius

D /2.

b) The minimum distance between cuts outside the flange area at any point of the cut shall be ≥ 15 %

of the radius D/2 of the cutting-off wheel.

c) Cuts shall start and end with a spiral.

5.3.5.3.3 Dimensions and distribution of “other openings”

“Other openings” in blanks shall have a dimension in radial direction of ≤ 15 % of the radius D/2 of the

cutting-off wheel with an opening angle of 15° at maximum, see Figure 2 as an example.

Key

1 flange area

Figure 2 — Example of “other openings”

5.3.5.4 Heat treatment of all blanks

If slots or openings are produced by laser cutting, the blank shall be annealed if the micro hardness

is > 500 HV in the heat affected zone, in order to achieve a hardness of ≤ 500 HV.

5.3.6 Requirements for the connection of the superabrasive section to the blank

5.3.6.1 Connection of segments to the blank

The segments for hand-held cutting-off wheels for dry cutting-off shall be connected to the blank by

welding, sintering, direct melting or infiltration attachment processes.

5.3.6.2 Tolerances and bending moment for segmented non-precision cutting-off wheels

For segmented non-precision cutting-off wheels for the use on hand-held cutting-off machines, the ratio

of segment height to thickness of the blank, X /E shall be ≤ 8,5.

For segmented non-precision cutting-off wheels the strength of the joint between the blank and the

segment or the strength of the segment itself shall be designed to comply with the following bending

moment M :

b

LE⋅ ⋅ σ

vb

M = (1)

b

where

M is the bending moment, expressed in Nm;

b

L is the length of the bond interface between segment and blank, expressed in m;

v

E is the thickness of the blank, expressed in mm;

σ is the bending strength value, expressed in N/mm².

b

The bending strength values to be included in Formula (1) are:

a) for cutting-off wheels for the use on stationary and mobile cutting-off machines: σ = 450 N/mm ,

b

and

b) for cutting-off wheels for the use on hand-held cutting-off machines σ according to Table 11. Both

b

values for the minimum bending strength and minimum bending moment shall be achieved.

Table 11 — Bending strength σ and bending moment M for cutting-off wheels for the use on

b b

hand-held cutting-off machines

Blank thickness Minimum Minimum

bending bending

moment strength

E M σ

b b

mm Nm N/mm

≤ 1,5 6

1,5 < E < 2 8

≥ 2 10 600

5.3.6.3 Bending moments for cutting-off wheels with continuous cutting rim in metal bond

For non-precision cutting-off wheels with continuous rim, the strength of the joint between the metal

bond and the blank or within the abrasive layer shall be designed to comply with the following bending

moment M :

b

M = F × D / 2 (2)

b

where

M is the bending moment, expressed in Nm;

b

F is the force, here: F = 125 N;

D is the outside diameter of the cutting-off wheel, expressed in m.

5.3.6.4 Requirements for reconditioned non-precision cutting-off wheels

Segmented cutting-off wheels which have been equipped with new abrasive sections due to wear of the

abrasive sections shall comply with the same requirements as unused cutting-off wheels.

They shall comply with the marking requirements in Annex A and in addition carry the data for marking

the reconditioned state given in C.2.

Reconditioning is only permitted, if the preconditions in C.1 are complied with.

5.3.7 Tensioning of non-precision cutting-off wheels

All non-precision cutting-off wheels, marked with maximum operating speed of 100 m/s for hand-held

cutting-off machines and blank diameter in the range of 260 mm to 400 mm shall be in a tensioned state

in order to minimize the risk of wobbling (excessive vibration).

The exact position of the neutral point depends on blank type and blank thickness and shall have a

value in the range of 90° to 160° from position (B) (Figure 11) in order to have a correct tensioning of

the non-precision cutting-off wheel.

5.3.8 Limitation of side coating of abrasive grain and/or superabrasive grain

Side coating of abrasive grain and/or superabrasive grain is only allowed at the periphery of the blank

within a limit ≤ 0,05 D (see figure 3) for all non-precision cutting-off wheels marked with maximum

operating speed of 100 m/s for hand-held cutting-off machines and blank diameter in the range of

260 mm to 400 mm.

Key

D outside diameter

Figure 3 — Limitation of side coating (≤ 0,05 D)

5.4 Requirements for diamond wires

5.4.1 General

Wires with diamond or materials with comparable properties are used on wire sawing machines for

sawing (cutting-off) of natural stone, industrial ceramics, concrete and other materials. Diamond wires

shall not be used on hand-held machines.

5.4.2 Requirements

5.4.2.1 Requirements for the support cable

Support cables for diamond wire are subject to frequent breakage due to mechanical stress or wire

fatigue, depending on their construction, type of application and their operating conditions. Therefore, a

cable shall be selected which has proven fatigue resistance, e.g. preferably a multi-strand cable made of

fine multiple wires, for example: 6 × 7 on a 19 wire core.

Support cables shall have a minimum tensile strength of 800 N/mm in relation to the wire diameter.

5.4.2.2 Requirements for spring mounted diamond wire

For diamond wires where the abrasive beads are held by means of springs, press rings and spacer rings,

the bore diameters of the abrasive beads shall have the following limit deviations:

a) for the new diamond wire: bore of the abrasive beads by 0,4 mm greater than the wire diameter;

b) for the used diamond wire: bore of the abrasive beads by 0,6 mm greater than the wire diameter.

A maximum of 5 abrasive beads shall be mounted between two press rings.

After mounting on the support cable, the support cable and the press rings shall not show any sign of

breakage.

The spring ends shall be close-coiled and ground at each end.

5.4.2.3 Requirements for plastic and vulcanised rubber mounted diamond wires

All abrasive beads shall be mounted on the support cable by means of plastic or vulcanized rubber.

5.4.2.4 Requirements for wire couplings and press rings

The wire couplings shall be capable of withstanding at least 30 % of the load capacity of the support

cable.

The press rings shall be capable of withstanding / the load capacity of the support cable without

moving.

5.4.3 Maximum operating speeds

The maximum operating speed for diamond wires shall not exceed v = 40 m/s.

s

5.5 Requirements for mounted points

5.5.1 Spindle diameter tolerances

The tolerance class for spindle diameters for mounted points is given in ISO 22917.

5.5.2 Sequence of maximum operating speeds

Mounted points shall be manufactured for maximum operating speeds conforming to the following

sequence:

5 — 6 — 8 — 10 — 12 — 16 — 20 — 25 — 32 — 35 — 40 — 45 — 50 — 63 in m/s

NOTE For conversion of peripheral speeds into speeds of rotation for different outside diameters D of the

abrasive product, see Annex D.

5.5.3 Safety factors

Mounted points shall have a safety factor against bursting due to centrifugal forces of S = 3. The

br

spindle shall have a safety factor against deflection of S = 1,3. Further requirements see Annex B.

ab

5.6 Requirements for other superabrasive products for non-precision grinding

5.6.1 Bore diameter tolerances

The tolerance class for bores for other superabrasive products for non-precision grinding is H9 for bore

sizes H ≤ 80 mm and H7 for bore sizes H > 80 mm.

5.6.2 Sequence of maximum operating speeds

Other superabrasive products for non-precision grinding shall be manufactured for maximum

operating speeds conforming to the following sequence:

40 — 45 — 50 — 63 — 80 — 100 in m/s

NOTE For conversion of peripheral speeds into speeds of rotation for different outside diameters D of the

abrasive product, see Annex D.

5.6.3 Safety factors

Other superabrasive products for non-precision grinding shall have a safety factor against bursting due

to centrifugal forces at their maximum operating speed as given in Table

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...