EN 13236:2010+A1:2015

(Main + Amendment)Safety requirements for superabrasive products

Safety requirements for superabrasive products

This European Standard only applies to superabrasives products containing natural or synthetic diamond or cBN (cubic boron Nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It also applies to reconditioned superabrasive cutting-off wheels.

This European Standard specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the superabrasive products.

This European Standard contains also procedures and tests for verification of the compliance with the requirements as well as safety information for use which is to be made available to the user by the manufacturer.

The hazards taken into consideration are listed in Clause 4.

This European Standard does not apply to bonded abrasive products, coated abrasive products, rotating dressing tools, truers nor any non-rotating superabrasive products.

Sicherheitsanforderungen für Schleifwerkzeuge mit Diamant oder Bornitrid

Diese Europäische Norm wird nur für Schleifwerkzeuge angewendet, die natürliche oder synthetische Diamanten oder CBN (kubisches Bornitrid) enthalten. Das schließt Präzisionsschleif- und Trennschleifscheiben, Trennschleifscheiben zur Bearbeitung von Naturstein und zum Einsatz im Hoch- und Tiefbau, Sägeseile, Schleifstifte und sonstige Schleifwerkzeuge zur Bearbeitung von Naturstein und zum Einsatz im Hoch- und Tiefbau ein. Sie gilt auch für wiederbelegte Trennschleifscheiben."

Diese Europäische Norm legt Anforderungen und/oder Maßnahmen zur Beseitigung oder Verminderung von Gefährdungen fest, die von der Gestaltung und Anwendung der Schleifwerkzeuge mit Diamant oder Bornitrid herrühren.

Diese Europäische Norm umfasst auch Verfahren und Prüfungen zur Feststellung der Übereinstimmung mit den Anforderungen sowie Benutzerinformationen, die der Hersteller dem Anwender zur Verfügung zu stellen hat.

Die berücksichtigten Gefährdungen sind in Abschnitt 4 aufgeführt.

Diese Europäische Norm gilt nicht für Schleifkörper aus gebundenem Schleifmittel, Schleifmittel auf Unterlagen, rotierende Abrichtwerkzeuge, Handfeilen und andere nicht rotierende Schleifwerkzeuge mit Diamant oder Bornitrid.

Prescriptions de sécurité pour les produits superabrasifs

La présente Norme européenne est applicable uniquement aux produits superabrasifs contenant du diamant naturel ou synthétique ou du cBN (nitrure de bore cubique). Elle inclut les meules et meules à tronçonner de précision, meules à tronçonner ordinaires, câbles diamantés, meules sur tige et autres produits superabrasifs pour meulage ordinaire. Elle s'applique également aux meules à tronçonner superabrasives reconditionnées.

La présente Norme européenne spécifie les prescriptions et/ou mesures pour la suppression ou la réduction des phénomènes dangereux résultant de la conception ou de l'utilisation des produits superabrasifs.

La présente Norme européenne contient également les procédures et essais pour la vérification de la conformité aux prescriptions ainsi que les informations de sécurité pour l'utilisation qui doivent être mises à la disposition de l'utilisateur par le fabricant.

Les phénomènes dangereux à prendre en considération sont définis à l'Article 4.

La présente Norme européenne ne s'applique pas aux produits abrasifs agglomérés, produits abrasifs appliqués, outils à dresser rotatifs, outils à dresser ou autres produits superabrasifs non rotatifs.

Varnostne zahteve za superabrazive (vključno z dopolnilom A1)

Ta evropski standard velja le za superabrazive, ki vsebujejo naravne ali sintetične diamante ali kubne borove nitride (cBN). Vključuje plošče za precizno brušenje in rezanje, neprecizne plošče za rezanje, diamantne žice, nameščene konice in druge superabrazive za neprecizno brušenje. Prav tako velja za superabrazivne obnovljene plošče za rezanje.

Ta evropski standard določa zahteve in/ali ukrepe za odpravo ali zmanjševanje nevarnosti, ki so posledica načrtovanja in uporabe superabrazivov.

Ta evropski standard vsebuje tudi postopke in preskuse za preverjanje skladnosti z zahtevami in varnostnimi informacijami za uporabo, ki jih mora proizvajalec priskrbeti uporabniku.

Obravnavane nevarnosti so naveden v klavzuli 4.

Ta evropski standard ne velja za vezane abrazive, prevlečene abrazive, vrteče se orodje za brušenje, brusilce niti za katere koli druge nevrteče superabrazive.

General Information

- Status

- Withdrawn

- Publication Date

- 22-Dec-2015

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 143 - Machine tools - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-Apr-2019

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 01-May-2019

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 13236:2010+A1:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety requirements for superabrasive products". This standard covers: This European Standard only applies to superabrasives products containing natural or synthetic diamond or cBN (cubic boron Nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It also applies to reconditioned superabrasive cutting-off wheels. This European Standard specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the superabrasive products. This European Standard contains also procedures and tests for verification of the compliance with the requirements as well as safety information for use which is to be made available to the user by the manufacturer. The hazards taken into consideration are listed in Clause 4. This European Standard does not apply to bonded abrasive products, coated abrasive products, rotating dressing tools, truers nor any non-rotating superabrasive products.

This European Standard only applies to superabrasives products containing natural or synthetic diamond or cBN (cubic boron Nitride). It includes precision grinding and cutting-off wheels, non-precision cutting-off wheels, diamond wires, mounted points and other superabrasive products for non-precision grinding. It also applies to reconditioned superabrasive cutting-off wheels. This European Standard specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the superabrasive products. This European Standard contains also procedures and tests for verification of the compliance with the requirements as well as safety information for use which is to be made available to the user by the manufacturer. The hazards taken into consideration are listed in Clause 4. This European Standard does not apply to bonded abrasive products, coated abrasive products, rotating dressing tools, truers nor any non-rotating superabrasive products.

EN 13236:2010+A1:2015 is classified under the following ICS (International Classification for Standards) categories: 25.100.70 - Abrasives. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13236:2010+A1:2015 has the following relationships with other standards: It is inter standard links to EN 13236:2010, EN 13236:2010/FprA1, EN 13236:2019, ISO 22917:2004, EN ISO 286-2:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13236:2010+A1:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheitsanforderungen für Schleifwerkzeuge mit Diamant oder BornitridPrescriptions de sécurité pour les produits superabrasifsSafety requirements for superabrasive products25.100.70BrusivaAbrasivesICS:Ta slovenski standard je istoveten z:EN 13236:2010+A1:2015SIST EN 13236:2011+A1:2016en,fr,de01-marec-2016SIST EN 13236:2011+A1:2016SLOVENSKI

STANDARDSIST EN 13236:20111DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13236:2010+A1

December

t r s w ICS

t wä s r rä y r Supersedes EN

s u t u xã t r s rEnglish Version

Safety requirements for superabrasive products Prescriptions de sécurité pour les produits superabrasifs

Sicherheitsanforderungen für Schleifwerkzeuge mit Diamant oder Bornitrid This European Standard was approved by CEN on

s x October

t r s r and includes Amendment

s approved by CEN on

s y November

t r s wä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s w CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u t u xã t r s r ªA sã t r s w ESIST EN 13236:2011+A1:2016

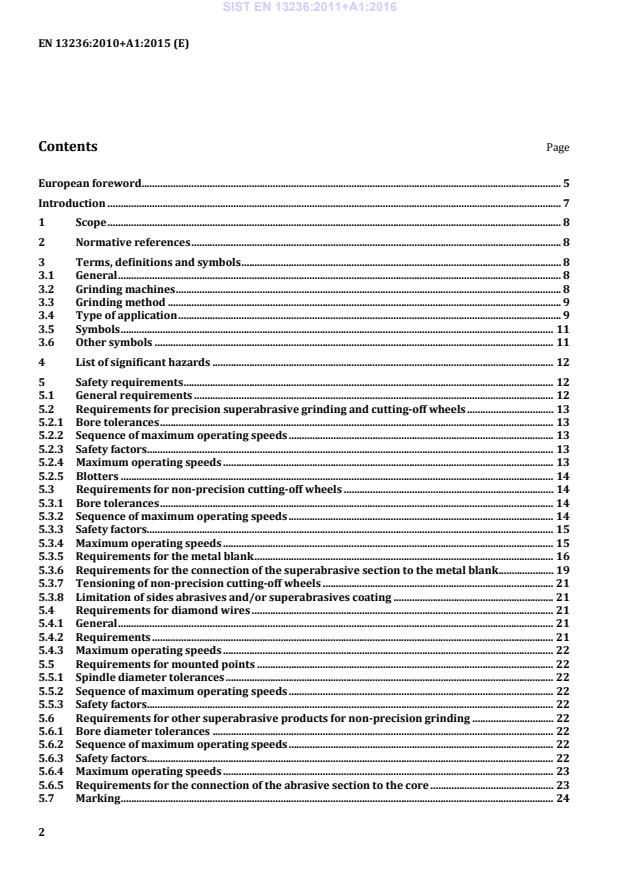

3 6 Verification of the safety requirements . 24 6.1 Verification of the general requirements . 24 6.1.1 Visual inspection . 24 6.1.2 Ring test . 24 6.2 Verification of the strength requirements . 24 6.2.1 Verification of the safety factor . 24 6.2.2 Verification of the bending moment of non-precision cutting-off wheels . 24 6.2.3 Verification of the strength requirements for other superabrasive products for non-precision grinding . 27 6.2.4 Verification methods for diamond wires . 28 6.3 Verification of marking . 30 6.4 Verification of the requirements for blotters . 30 6.5 Verification of tensioning of non-precision cutting-off wheels . 30 7 Information for use . 31 Annex A (normative)

Marking . 32 A.1 Content of the marking . 32 A.1.1 Marking requirements . 32 A.1.2 Additional inscriptions . 34 A.1.3 Multiple or gang mounted wheels . 34 A.2 Execution of the marking . 35 Annex B (normative)

Colour codes . 36 Annex C (informative)

Mounted points . 37 C.1 Example of calculation of the maximum permissible speed of rotation . 37 C.2 Example for the application of the calculation method . 40 C.2.1 Types of mounted points . 40 C.2.2 Assumptions for the calculation . 41 C.2.3 Maximum permissible speeds of rotation . 42 Annex D (normative)

Reconditioning of cutting-off wheels according to 5.3.6.4 . 44 D.1 Preconditions for reconditioning . 44 D.2 Additional marking requirements . 44 Annex E (informative)

Speed conversion table . 46 Bibliography . 49

Figures Figure 1 — Position of cuts and openings in steel blanks . 18 Figure 2 — Example of cut-outs and openings . 19 Figure 3 — Segmented cutting-off wheels: Dimensions of segment height X1 . 25 Figure 4 — Example of a bending test device for segmented cutting-off wheels . 25 Figure 5 — Cutting-off wheels with continuous rim: Dimensions of segment height X1 . 26 Figure 6 — Example of a bending test device for cutting-off wheels with continuous rim . 27 Figure 7 — Example of a shearing force test device . 28

Tables Table 1 — Grinding method, type of machine, type of application . 10 SIST EN 13236:2011+A1:2016

5 European foreword This document (EN 13236:2010+A1:2015) has been prepared by Technical Committee CEN/TC 143 “Machine tools - Safety”, the secretariat of which is held by SNV. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by June 2016 and conflicting national standards shall be withdrawn at the latest by June 2016. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. The provisions of this European Standard need not be mandatory to superabrasive products manufactured the first 12 months after publication of this European Standard. This document includes Amendment 1 approved by CEN on 17 November 2015. This document supersedes !EN 13236:2010". The start and finish of text introduced or altered by amendment is indicated in the text by tags !". !Significant changes between EN 13236:2001 and EN 13236:2010 were as follows:" a) the standard was technically and editorially revised and partly adapted to EN 12413:2007 about bonded abrasive products and EN 13743:2009 about coated abrasive products; b) the term "burst speed factor" was included in Table 2, Table 5, Table 7 and Table 13; c) in the requirements it is now distinguished between precision and non-precision cutting-off wheels; d) new 5.3.5.3 defines restrictions in design and position of cuts and openings in the metal blank of cutting-off wheels for hand-held applications; e) changed 5.3.6.2 on dimensional limitations and bending moment for segmented non-precision cutting-off wheels for hand-held applications, with requirements now depending on segment height and segment length; f) requirements for reconditioned non-precision cutting-off wheels were included in new 5.3.6.4 and new normative Annex D; g) Clause 6 was shortened to verification of safety requirements. The scope of inspection and testing has been deleted because it is the responsibility of the manufacturer to put in place respective test procedures that give them the confidence that all safety requirements defined in this standard are respected; h) the requirements for colour code stripes were deleted in Annex A and are now presented in new Annex B; i) Table A.3 and Table A.4 about restrictions for use were combined to one table and thereby adapted to EN 12413 and EN 13743; j) Clause A.2 about execution of the marking was simplified; SIST EN 13236:2011+A1:2016

7 Introduction This European Standard has been prepared to provide one means of conforming with essential safety requirements, e.g. of the General Product Safety Directive and associated EFTA regulations. This European Standard is addressed to designers, manufacturers and suppliers of the superabrasive products described in the scope as well as to those who are reconditioning superabrasive cutting-off wheels. In addition, it helps designers, manufacturers and suppliers of grinding machines in the selection of superabrasive products, in order to reduce the risks and achieve conformity of the respective machinery with the Essential Safety Requirements of the Machinery Directive. The extent to which hazards are covered is indicated in the scope of this European Standard. SIST EN 13236:2011+A1:2016

9 3.2.3 hand-held grinding machine grinding machine being held in the hand during the grinding process !Note 1 to entry: "See for example EN 792-7, EN 792-9, EN 60745-2-3 and EN ISO 19432. 3.2.4 grinding machine with totally enclosed working area stationary grinding machine being protected in such a way by separating guards that machining processes including loading and unloading of workpieces are carried out inside them and persons are protected against hazards generated by bursting of an abrasive product

3.3 Grinding method 3.3.1 peripheral grinding grinding with the periphery of the wheel with no or limited side loads 3.3.2 face grinding grinding with the face of the wheel 3.3.3 cutting-off slotting with the periphery of the cutting-off wheel 3.4 Type of application See Table 1. 3.4.1 mechanically guided grinding grinding process with feed movements of the abrasive product and/or workpiece guided by mechanical means 3.4.2 manually guided grinding grinding process with feed movements of the abrasive product and/or the workpiece manually guided by the operator 3.4.3 hand-held grinding grinding process with grinding machine entirely guided by the operator's hands SIST EN 13236:2011+A1:2016

creep feed grinding, bevel grinding on glass

(glass bevelling machine) Mechanically guided Fixed Profile grinding of stone and concrete Mechanically guided Mechanically guided Internal grinding, external, plunge and traverse grinding, jig grinding, decorative stone milling and polishing, pencil edging of glass (automotive glass) Stationary and mobile grinding machines Manually guided grinding Manually guided Fixed Roughing and polishing of stone floors

(carriage/floor grinding machine) Fixed Manually guided Tool grinding (bench grinding machine)

decorative glass grinding Hand-held grinding machines Hand-held grinding Manually guided Fixed Stone and concrete milling and polishing

(angle/straight grinder) Cutting-off Stationary cutting-off machines Mechanically guided cutting-off Fixed Mechanically guided Cutting-off of bricks and tiles (table saw) Mechanically guided Fixed Cutting-off of stone and concrete (bridge-type saw, floor and wall saw, wire saw) Mechanically guided Mechanically guided Cutting-off of semi-conductors Stationary and mobile cutting-off machines Manually guided cutting-off Manually guided Fixed Cutting-off of stone and concrete (table saw, floor saw) Fixed Manually guided Cutting-off of bricks (table saw) Hand-held cutting-off machines Hand-held cutting-off Manually guided Fixed Cutting-off of stone and concrete (angle grinder, hand-held cutting-off machine) SIST EN 13236:2011+A1:2016

11 3.5 Symbols The symbols used in this European Standard are listed in Table 2. Table 2 — Symbols Symbol Designation Definition Unit nab Deflection speed of a mounted point Revolutions per minute at which the spindle of a rotating mounted point is deflecting under centrifugal force 1/min nmax Maximum permissible speed of rotation Revolutions per minute of a rotating new abrasive product at maximum operating speed 1/min Sab Safety factor against spindle deflection for mounted points Deflection speed divided by maximum permissible speed of rotation: maxnnSabab= — vs Maximum operating speed Maximum permissible peripheral speed of a rotating abrasive product m/s vbr Bursting speed Peripheral speed at which a rotating abrasive product breaks due to centrifugal force m/s vbr min Minimum bursting speed Peripheral speed, which a rotating abrasive product shall at least reach without bursting due to centrifugal force m/s fbr Burst speed factor Bursting speed divided by maximum operating speed: sbrrvvfb= — Sbr Safety factor against bursting due to centrifugal force Bursting speed divided by maximum operating speed, all squared: 2=sbrbrvvS —

3.6 Other symbols Other symbols used in this European Standard are listed in Table 3. SIST EN 13236:2011+A1:2016

4 List of significant hazards Table 4 — List of significant hazards Hazard designation Hazardous situations (Examples) Relevant clauses

in this standard Ejection of parts 1. Abrasive product breakage caused by:

— improper design 5.1, 5.2, 5.3, 5.4, 5.5, 5.6, 5.7, Annex C and Annex D — manufacturing defects 5.1 — wrong selection Clause 7, Annex A and Annex B — improper handling and storage Clause 7 — improper use (mounting and grinding process) Clause 7 2. Grinding debris Clause 7 Vibration 3. Hand arm vibration on hand-held machines caused by:

— improper use Clause 7 — incorrect mounting Clause 7

5 Safety requirements 5.1 General requirements Superabrasive products shall be designed and manufactured in such a way that they resist the forces and loads that are to be expected when used as intended. They shall not present visible defects affecting safety and shall comply with the requirements listed in the following clauses. SIST EN 13236:2011+A1:2016

13 5.2 Requirements for precision superabrasive grinding and cutting-off wheels 5.2.1 Bore tolerances The tolerance class for bores on precision superabrasive grinding and cutting-off wheels is given in ISO 22917. 5.2.2 Sequence of maximum operating speeds Precision superabrasive grinding and cutting-off wheels shall be manufactured for maximum operating speeds conforming to the following sequence: < 16 — 20 — 25 — 32 — 35 — 40 — 45 — 50 — 63 — 80 — 100 — 125 — 140 — 160 — 180 — 200 — 225 — 250 — 280 — 320 in m/s. NOTE For conversion of maximum operating speeds into speeds of rotation for different outside diameters D of the abrasive product, see Annex E. 5.2.3 Safety factors Precision superabrasive grinding and cutting-off wheels shall have a safety factor against bursting due to centrifugal forces at their maximum operating speed as given in Table 5. Table 5 — Safety factors for precision superabrasive grinding and cutting-off wheels Type of machine Type of application Maximum operating speed vs m/s Safety factor Sbr Burst speed factor fbr Stationary grinding machines Mechanically guided grinding

¶

z r 3,0 1,73 Mechanically guided grinding with totally enclosed working area

¶

u t r

1,75 1,32 Stationary and mobile grinding machines Manually guided grinding

¶

x u

3,0 1,73 80

3,5 1,87

5.2.4 Maximum operating speeds Precision superabrasive grinding and cutting-off wheels shall comply with the classification of the sequence of maximum operating speeds in 5.2.2 up to the maximum values given in Table 6. In the totally enclosed working area, the maximum operating speeds given in Table 6 may be exceeded, if the safety factor required in Table 5 is complied with. SIST EN 13236:2011+A1:2016

M Electroplated G Metal Manufactured on core,

e.g. sintered or electroplated — 100 100 200 Connected to core,

e.g. cemented, screwed, clamped, brazed or welded 180 80 100 — Resinoid Manufactured on core,

e.g. pressed — 100 — — Connected to core,

e.g. cemented, screwed, clamped 80 80 80 80 Vitrified Manufactured on core,

e.g. pressed 80 — — — Connected to core,

e. g. cemented, screwed, clamped 80 80 80 —

5.2.5 Blotters Blotters shall be supplied by the manufacturer, supplier or importer where these are required for a safe mounting and use of the superabrasive product. Blotters shall be made of suitable compressible material. Shape, dimensions and material shall be adapted to application and intended use. When water-based coolants are used the blotter material shall not be affected in the way that it loses its compressibility and physical function. Blotters can serve as a label for the marking provided the marking requirements of this standard are met and the blotter is firmly attached to the wheel. 5.3 Requirements for non-precision cutting-off wheels 5.3.1 Bore tolerances The tolerance class for bores for non-precision cutting-off wheels is H9 as per EN ISO 286-2:2010. 5.3.2 Sequence of maximum operating speeds Non-precision cutting-off wheels shall be manufactured for maximum operating speeds conforming to the following sequence: 20 — 25 — 32 — 35 — 40 — 45 — 50 — 63 — 80 — 100 in m/s. NOTE For conversion of maximum operating speeds into speeds of rotation for different outside diameters D of the abrasive product, see Annex E. SIST EN 13236:2011+A1:2016

15 5.3.3 Safety factors Non-precision cutting-off wheels shall have a safety factor against bursting due to centrifugal forces at their maximum operating speed as given in Table 7. Table 7 — Safety factors for non-precision cutting-off wheels Type of machine Type of application Maximum operating speed vs Safety factor Sbr Burst speed factor fbr m/s Stationary cutting-off machines Mechanically guided cutting-off

¶

s r r 2,0 1,41 Mechanically guided cutting-off with totally enclosed working area

¶

s r r 1,75 1,32 Stationary and mobile cutting-off machines Manually guided cutting-off

¶

s r r 3,5 1,87 Hand-held cutting-off machines Hand-held cutting-off

¶

s r r 3,5 1,87

5.3.4 Maximum operating speeds Non-precision cutting-off wheels shall comply with the sequence of maximum operating speeds in 5.3.2 up to the maximum values given in Table 8. Table 8 — Maximum operating speeds as a function of the bond type Core Cutting rim

(abrasive

section) Type of

application Maximum operating speed vs m/s Metal M Electroplated G Metal blank, e.g. cast, rolled, forged continuous Mechanically and manually guided cutting-off 100 100 segmented Mechanically and manually guided cutting-off 100 100 continuous or segmented Hand-held cutting-off 100 100

·

rá y 115 200

·

rá { 200 230

·

sá t Hand-held and stationary cutting-off machines 230 300

·

sá t 300 400

·

sá x Stationary and mobile cutting-off machines 350 400

·

sá x 400 500

·

tá r 500 600

·

tá w 600 900

·

uá r 900 1 600

·

uá w

5.3.5.1.2 Material and hardness of blanks for laser welded cutting-off wheels The material used for the blank shall be steel which shall have the necessary properties enabling it to produce adequate joint strength when welding it to the segments. For example, alloyed cold worked steels having a maximum carbon content of 0,27 % are suitable. Blanks shall have a minimum hardness of 20 HRC for outside diameter D1

¶ 230 mm and a minimum hardness of 24 HRC for outside diameter D1> 230 mm. 5.3.5.1.3 Material and hardness of blanks for sintered and direct melted cutting-off wheels Tool steels, grade to the choice of the manufacturer. 5.3.5.1.4 Surface finish of the entire slot area Cutting-off wheels shall be manufactured in such a way that the surface finish in the area of the slots does not cause crack formation. 5.3.5.1.5 Other requirements Blanks shall be free from visible defects. SIST EN 13236:2011+A1:2016

17 5.3.5.2 Requirements for the metal blank of cutting-off wheels for wet cutting-off 5.3.5.2.1 Dimensions Dimensions of metal blanks for non-precision cutting-off wheels for wet cutting-off, see Table 10. Table 10 — Dimensions of blanks for wet cutting-off Machine type Outside diameter D1 of the blank mm Blank thickness E mm more than up to and including

Stationary cutting-off machine — 300

·

sá t 300 400

·

sá x 400 500

·

tá r 500 600

·

tá w 600 900

·

tá z 900 2 500

·

uá w 2 500 3 500

·

yá r 3 500 5 000

·

{á r Hand-held cutting-off machine — 230

·

rá r r x D1 230 400

·

rá r r w D1

5.3.5.2.2 Material Tool steels, grade to the choice of the manufacturer. 5.3.5.2.3 Surface finish of the entire slot area See 5.3.5.1.4. 5.3.5.2.4 Other requirements See 5.3.5.1.5. 5.3.5.3 Design and position of cuts and openings in the metal blank of cutting-off wheels for hand-held applications 5.3.5.3.1 General Cuts and openings in steel blanks of cutting-off wheels for hand-held applications designed for any reasons such as noise dampening shall comply with the following limitations: a) Cuts located outside the flange area with more or less radial orientation shall end at a distance x

· 0,25 D/2 outside of the diameter of the bore, where D is the outside diameter of the cut-off wheel. See also Figure 1. SIST EN 13236:2011+A1:2016

¶

% of the blank radius D1/2 away from the closest gullet or outside diameter of the blank. See also Figure 1. c)

Inside the flange area no cuts or holes other than one drive pin hole or two circular cuts with approximately radial orientation for fixing of functional elements are allowed.

Key

no cuts allowed in this area Figure 1 — Position of cuts and openings in steel blanks 5.3.5.3.2 Dimensions and distribution of narrow laser cuts a) Cuts outside the flange area shall have a dimension in radial direction of

¶

v r

¨ of the blank radius D1/2. b) The minimum distance between cuts outside the flange area at any point of the cut-out shall be

·

s w

¨ of the radius D/2 of the cutting-off wheel. c) Laser cuts shall start and end with a spiral. 5.3.5.3.3 Dimensions and distribution of wide cut-outs and openings a) Wide cut-outs and openings in blanks shall have a dimension in radial direction of

¶ 15 % of the radius D/2 of the cutting-off wheel with an opening angle of 15° at maximum, see Figure 2 as an example. SIST EN 13236:2011+A1:2016

Key 1 flange area Figure 2 — Example of cut-outs and openings b) The total area of wide cut-outs and openings in blanks shall be

¶ 20 % of the area of the blank. 5.3.5.4 Heat treatment of all metal blanks If slots or openings are produced by laser cutting, the steel blank shall be annealed if the micro hardness is > 500 HV in the heat affected zoneá in order to achieve a hardness of

¶ 500 HV. 5.3.6 Requirements for the connection of the superabrasive section to the metal blank 5.3.6.1 Connection of segments to the metal blank The segments for hand-held cutting-off wheels for dry cutting-off shall be connected to the metal blank by welding, sintering, direct melting or infiltration attachment processes. 5.3.6.2 Tolerances and bending moment for segmented non-precision cutting-off wheels For segmented non-precision cutting-off wheels for the use on hand-held cutting-off machines, the ratio of segment height to thickness of the core, X1/E shall be

¶

zá wä

For segmented non-precision cutting-off wheels the strength of the joint between the metal blank and the segment shall be designed to comply with the following bending moment: 6b2vbσ⋅⋅=ELM (1) where Mb is the bending moment; Lv is the length of the bond interface between segment and core; E is the thickness of the core; b

is the bending strength value, see a) and b) below.

·

x r r

·

t

·

y w r 1,5 to < 2

·

{ r r 1,0 to < 1,5

If for cutting-off wheels for the use on hand-held cutting-off machines the bending moment values Mb resulting from Equation (1) are smaller than the values given in Table 12 as a function of the core thickness E of the cutting-off wheel, then the values given in Table 12 shall be fulfilled at minimum. Table 12 — Minimum bending moment Mb Core thickness E mm Minimum bending moment Mb Nm < 1,2 6 1,2 to < 1,4 8

·

sá v 10

5.3.6.3 Bending moments for cutting-off wheels with continuous cutting rim in metal bond For non-precision cutting-off wheels with continuous rim, the strength of the joint between the metal bond and the blank shall be designed to comply with the following bending moment: Mb = F × D/2 (2) where F is the force, here: F = 125 N; D is the outside diameter of the cutting-off wheel, expressed in m. 5.3.6.4 Requirements for reconditioned non-precision cutting-off wheels Segmented cutting-off wheels which have been equipped with new abrasive sections due to wear of the abrasive sections shall comply with the same requirements as unused cutting-off wheels. They shall comply with the marking requirements in Annex A and in addition carry the data for marking the reconditioned state given in D.2. Reconditioning is only permitted, if the preconditions in D.1 are complied with. SIST EN 13236:2011+A1:2016

21 !

5.3.7 Tensioning of non-precision cutting-off wheels All non-precision cutting off wheels, marked with maximum operating speed of 100 m/s for hand held cutting-off machines and steel centre diameter 300 mm to 400 mm, shall be in a tensioned state in order to minimize the risk of wobbling (excessive vibrations). The position of neutral point shall be in an angle range between 90° to 160° in order to have a correct tensioning of the non-precision cutting off wheel." !

5.3.8 Limitation of sides abrasives and/or superabrasives coating Side abrasives and/or superabrasives coating is only allowed at periphery of the steel centre within a limit x

¶ 0,05 D (distance of 5%) of steel centre diameter for all non-precision cutting off wheels marked with maximum operating speed of 100 m/s for hand held cutting-off machines and steel centre diameter 300 mm to 400 mm." 5.4 Requirements for diamond wires 5.4.1 General Wires with diamond or materials with comparable properties are used on wire sawing machines for sawing (cutting-off) of natural stone, industrial ceramics, concrete and other materials. Diamond wires shall not be used on hand-held machines. 5.4.2 Requirements 5.4.2.1 Requirements for the support cable Support cables for dia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...