EN 1495:1997+A2:2009

(Main)Lifting platforms - Mast climbing work platforms

Lifting platforms - Mast climbing work platforms

This standard specifies the special safety requirements for Mast Climbing Work Platforms (MCWP) which are temporarily installed and are manuelly or power operated and which are designed to be used by one or more persons from which to carry out work. The vertical moving components (work platform) are also used to move those same persons and their equipmenet and materials to and from a single boarding point. These restrictions differentiate MCWPs from Builder's hoists.

Hebebühnen - Mastgeführte Kletterbühnen

1.1 Die vorliegende Norm legt besondere Sicherheitsanforderungen an mastgeführte Kletterbühnen (MKB)

fest, die vorübergehend aufgestellt werden, Hand- oder Kraftantrieb haben und zur Benutzung von einer oder

mehreren Personen vorgesehen sind, die von der Kletterbühne aus Arbeiten durchführen. Die sich vertikal

bewegenden Arbeitsbühne wird auch dazu verwendet, dieselben Personen und deren Ausrüstung sowie

Materialien von einer einzigen Einstiegsstelle und zurück zu transportieren. Diese Einschränkungen

unterscheiden MKB von Bauaufzügen.

Die Norm kann auch für dauerhaft installierte MKB angewendet werden.

1.2 Diese Norm ist auf Arbeitsbühnen anwendbar, die mit Zahnstange/Ritzel angehoben und von den sie

tragenden Masten geführt und an ihnen entlang bewegt werden, wobei für die Maste seitliche Abstützungen

durch separate Tragkonstruktionen erforderlich sein können oder nicht.

1.3 Diese Norm ist für jede Kombination der folgenden Varianten anwendbar:

- ein Mast oder mehrere Maste

- verankerter oder freistehender Mast

- Mast mit unveränderlicher oder veränderlicher Länge

- vertikal stehende Maste oder zwischen 0° und 30° zur Vertikalen geneigte Maste

- stehende oder hängende Maste

- fahrbare oder feststehende Untergestelle (Fahrgestelle oder Grundrahmen)

- Hubvorgang mit Hand- oder Kraftantrieb

- Umsetzen durch Schleppen oder eigenen Antrieb am Einsatzort außerhalb der geltenden Straßenverkehrsordnung

- Antrieb mit Elektro-, Druckluft- oder Hydromotor

1.4 Diese Norm gibt die Gefährdungen an, die in den verschiedenen Phasen der Lebensdauer derartiger

Einrichtungen auftreten, und beschreibt Verfahren zur Beseitigung oder Verringerung dieser Gefährdungen

sowie zur Anwendung sicherer Arbeitsweisen.

1.5 Diese Norm legt keine Anforderungen an das Problem von Gefährdungen fest, die beim Umsetzen,

Auf- oder Abbau, Befestigen oder Abnehmen von Materialien oder Ausrüstungen auftreten, die kein Bestandteil

(...)

Matériels de mise à niveau - Plates-formes de travail se déplaçant le long de mât(s)

1.1 La norme spécifie les règles de sécurité particulières aux plates-formes de travail se déplaçant le long de mât(s) (PTDM), installées d'une manière provisoire, mues manuellement ou mécaniquement et utilisées par une ou plusieurs personnes pour réaliser des travaux à partir de celles ci. Les parties se déplaçant verticalement (plates formes de travail) sont aussi utilisées pour déplacer ces mêmes personnes avec leur équipement et matériaux jusqu'à et depuis un point d'accès unique. Les PTDM se différencient des ascenseurs de chantiers par ces restrictions.

La norme peut également être utilisée pour les PTDM installées de manière permanente.

1.2 Cette norme s'applique aux plates formes de travail élevées par pignon et crémaillère guidées et se déplaçant le long de mât(s) porteur(s) ancré(s) ou non à des structures porteuses séparées.

1.3 Cette norme s'applique à toute combinaison des possibilités suivantes :

- un ou plusieurs mâts ;

- mât ancré ou non ancré ;

- mât fixe ou de longueur variable ;

- mâts verticaux ou inclinés entre 0 et 30 par rapport à la verticale ;

- mâts posés ou suspendus ;

- base fixe ou mobile (châssis de base ou châssis mobile) ;

- élévation manuelle ou motorisée ;

- déplacement au sol tracté ou automoteur sur le chantier, sans exigence de suivi des règles de circulation sur la voie publique ;

- système d'entraînement utilisant des moteurs électriques, pneumatiques, ou hydrauliques.

1.4 Cette norme identifie les risques pouvant survenir lors des différentes phases de la vie de tels équipements, et décrit des méthodes permettant de les éliminer ou de les réduire, et de mettre en œuvre des procédés de travail sûrs.

1.5 Les risques liés à la mise en œuvre, au montage ou démontage, à la fixation ou l'enlèvement de tout matériel ou équipement qui n'est pas un élément constitutif de la plate-forme, ne sont pas couverts par cette norme. De même, la manipulation de substance à risque n'est pas prise en compte. (...)

Dvižne ploščadi - Delovne ploščadi, ki se vzpenjajo ob jamboru

Ta standard določa posebne varnostne zahteve za delovne ploščadi, ki se vzpenjajo ob jamboru (MCWP), ki so nameščene začasno in so vodene ročno ali gnano in so načrtovane, da jih uporablja ena ali več oseb, ki izvajajo delo. Sestavni deli, ki se gibljejo navpično (delovne ploščadi), se uporabljajo tudi za premik teh istih oseb ter njihove opreme in materialov na ali z ene točke vkrcanja. Te omejitve razlikujejo MCWP od gradbenih dvigal. Ta standard se prav tako lahko uporabi za stalno nameščene MCWP. Ta standard velja za delovne ploščadi, ki so zvišane s podstavkom in zobnikom ter so vodene in se gibljejo vzdolž svojih podpornih jamborov, kjer jambori lahko ali ne potrebujejo bočne omejitve iz ločenih podpornih objektov. Ta standard velja za vse kombinacije naslednjih možnosti: en ali več jamborov; vezan ali nevezan jambor; jambor fiksne ali spremenljive dolžine; navpičen ali nagnjen jambor med 0° in 30° glede na vertikalo; jambori ki stojijo ali visijo; premikajoča ali statična baza (podvozje ali nosilni okvir); ročno ali gnano vodenje dviga; vlečeno ali samo gnano kopensko gibanje na delovišču, razen predpisanih zahtev za cestni promet; gnano z uporabo električnih, pnevmatičnih ali hidravličnih motorjev. Ta standard opredeljuje nevarnosti, ki nastanejo med različnimi fazami življenjske dobe take opreme in predpisuje metode za odpravo ali zmanjšanje teh nevarnosti in za uporabo varnih delovnih postopkov.

General Information

- Status

- Published

- Publication Date

- 14-Jul-2009

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 8 - Mast climbing work platforms

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 01-Aug-2023

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized89/392/EEC - Machinery - Safety of machinery: general essential health and safety requirements

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 30-May-2009

- Effective Date

- 30-May-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1495:1997+A2:2009 (EN 1495:1997+A2:2009) is the harmonized European standard that specifies special safety requirements for Mast Climbing Work Platforms (MCWP). It covers temporarily installed (and can be used for permanently installed) rack-and-pinion guided platforms that carry one or more persons, equipment and materials vertically from a single boarding point. The standard was prepared by CEN/TC 98 and includes subsequent corrigenda and amendments up to 2009. It is intended to support conformity with the European Machinery Directive.

Key topics and technical requirements

The standard defines hazards, safety measures and verification methods for MCWPs. Major technical topics include:

- Definitions and scope: what constitutes an MCWP and how it differs from builder’s hoists, lifts and MEWPs.

- Structural and stability calculations: requirements and guidance for mast, platform and base-frame strength (see informative Annex A).

- Base frame, chassis and mast design: stability, outriggers, rail-mounted chassis and transfer/transport configurations.

- Work platform design: main platform, platform extensions, available platform area and multilevel configurations (normative Annex B).

- Elevation drive systems: rack-and-pinion drives, electric/hydraulic/pneumatic drive options and rated speed specifications.

- Overspeed protection and safety gear: overspeed governors, safety gear, buffers and automatic brakes to prevent uncontrolled descent.

- Emergency systems: means for emergency lowering/raising and transfer/transport interlocks.

- Overload and moment detection: devices and requirements to prevent overload and structural over‑moment.

- Electrical and hydraulic system requirements: including control systems, protection (IP ratings), and requirements for safety-related parts (Annex C covers electrical/electronic aspects of overload devices).

- Verification and testing: examinations and tests for each new MCWP model, plus user information, marking and instructions for use.

Practical applications and users

This standard is essential for:

- Manufacturers and designers of MCWPs - to design safe, compliant equipment.

- Site managers, contractors and building maintenance teams - to select and operate platforms safely.

- Safety managers, inspectors and certification bodies - for conformity assessment and verification testing.

- Procurement teams specifying technical and safety requirements for temporary access equipment.

Benefits include improved on-site safety, reduced risk of falls or platform failure, clearer user instructions and a harmonized way to demonstrate compliance with EU regulatory requirements.

Related standards

Relevant references and companion standards cited include:

- EN ISO 12100 (machine safety basics)

- EN 60204-1 (electrical equipment of machines)

- EN 954-1 / EN 614-1 (control system safety / ergonomic principles)

- ISO 4301 / ISO 4302 / ISO 6336 (crane loads, wind loads, gear calculations) Note: EN 1495 explicitly excludes MEWPs (EN 280), suspended access (EN 1808) and lifting tables (EN 1570) which are covered by their own standards.

Keywords: Mast Climbing Work Platforms, MCWP, EN 1495, EN 1495:1997+A2:2009, safety requirements, overspeed protection, platform design, mast stability, machinery directive.

Frequently Asked Questions

EN 1495:1997+A2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Lifting platforms - Mast climbing work platforms". This standard covers: This standard specifies the special safety requirements for Mast Climbing Work Platforms (MCWP) which are temporarily installed and are manuelly or power operated and which are designed to be used by one or more persons from which to carry out work. The vertical moving components (work platform) are also used to move those same persons and their equipmenet and materials to and from a single boarding point. These restrictions differentiate MCWPs from Builder's hoists.

This standard specifies the special safety requirements for Mast Climbing Work Platforms (MCWP) which are temporarily installed and are manuelly or power operated and which are designed to be used by one or more persons from which to carry out work. The vertical moving components (work platform) are also used to move those same persons and their equipmenet and materials to and from a single boarding point. These restrictions differentiate MCWPs from Builder's hoists.

EN 1495:1997+A2:2009 is classified under the following ICS (International Classification for Standards) categories: 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1495:1997+A2:2009 has the following relationships with other standards: It is inter standard links to EN 1495:1997/A1:2003, EN 1495:1997, EN 1495:1997/AC:1997, EN 60529:1991, EN 60204-1:1992, EN 60947-5-1:1991, EN ISO 10960:1996, EN 954-1:1996, EN 953:1997, EN 349:1993, EN 614-1:1995, EN 982:1996, EN 418:1992, EN ISO 12100-2:2003, EN 294:1992. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1495:1997+A2:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 89/392/EEC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1495:1997+A2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Hebebühnen - Mastgeführte KletterbühnenMatériels de mise à niveau - Plates-formes de travail se déplaçant le long de mât(s)Lifting platforms - Mast climbing work platforms53.020.99Druga dvigalna opremaOther lifting equipmentICS:Ta slovenski standard je istoveten z:EN 1495:1997+A2:2009SIST EN 1495:1999+A2:2010en,fr,de01-februar-2010SIST EN 1495:1999+A2:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1495:1997+A2

July 2009 ICS 53.020.99 Supersedes EN 1495:1997English Version

Lifting platforms - Mast climbing work platforms

Matériels de mise à niveau - Plates-formes de travail se déplaçant le long de mât(s)

Hebebühnen - Mastgeführte Kletterbühnen This European Standard was approved by CEN on 21 April 1997 and includes Corrigendum 1 issued by CEN on 11 December 1997, Amendment 1 approved by CEN on 1 September 2003 and Amendment 2 approved by CEN on 19 June 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1495:1997+A2:2009: ESIST EN 1495:1999+A2:2010

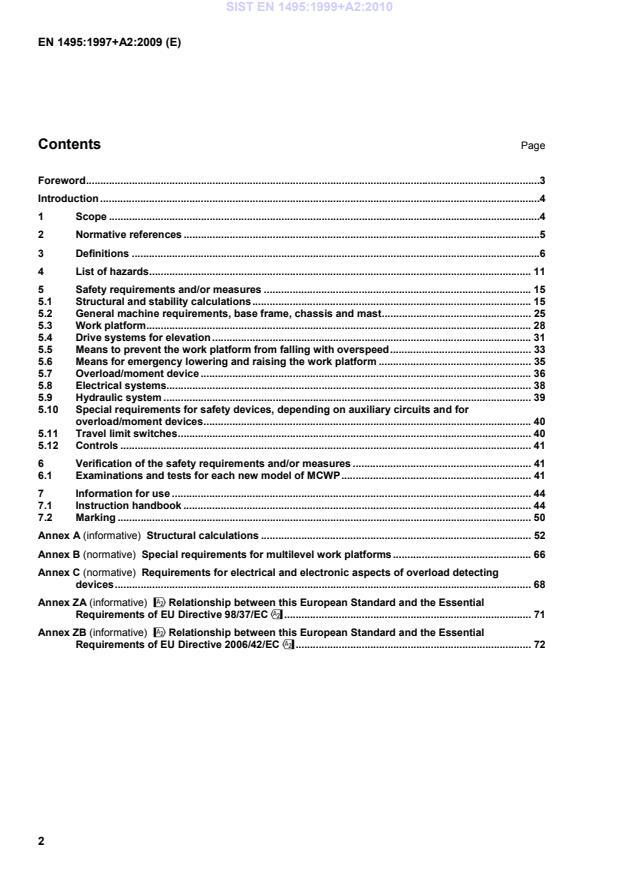

Structural calculations . 52Annex B (normative)

Special requirements for multilevel work platforms . 66Annex C (normative)

Requirements for electrical and electronic aspects of overload detecting devices . 68Annex ZA (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC$ . 71Annex ZB (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC$ . 72 SIST EN 1495:1999+A2:2010

and # $. The modifications of the related CEN Corrigendum have been implemented at the appropriate places in the text and are indicated by the tags ˜ ™. This European Standard has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). #For relationship with EU Directive(s), see informative Annexes ZA and ZB, which are integral parts of this document.$ It is a type C- standard related to safety for Mast Climbing Work Platforms. #deleted text$ According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Figure 1 — Typical single mast MCWP

Figure 2 — Typical twin mast MCWP

HAZARDS RELEVANT CLAUSES IN THIS STANDARD

Mechanical hazards (caused for example by:

1.1 Crushing 5.2.1.3; 5.3.2; 5.4.1

1.2 Shearing 5.2.1.3; 5.3.2; 5.4.1

1.3 Cutting or severing 5.3.2; 5.4.1

1.4 Entanglement 5.4.1

1.5 Drawing-in or trapping 5.2.1.3; 5.3.2; 5.4.1

1.6 Impact 5.4.4

1.7 Stabbing or puncture NA

1.8 Friction or abrasion NA

1.9 High pressure fluid ejection 5.9.7; 5.9.8; 5.9.9; 5.9.10 1.10 Ejection of parts 5.2.1.4; 5.2.1.5 1.11 Loss of stability 5.1.5; 5.2.2.4; 5.2.2.5 1.12 Slip, trip and fall 5.2.2.1; 5.3.1

2 Electrical hazards

2.1 Electrical contact 5.8; 7.1.2.7 2.2 Electrostatic phenomena NA 2.3 Thermal radiation NA 2.4 External influences 5.7.15 Annex C

3 Thermal hazards Relevant but not dealt with

4 Hazards generated by noise Relevant but not dealt with

5 Hazards generated by vibration 5.1.2.3.2

6 Hazards generated by radiation NA

7 Hazards generated by materials and substances processed, used or exhausted by machinery:

7.1 Contact with or inhalation of harmful fluids, gases, mists, fumes and dusts 5.9

7.2 Fire or explosion NA

7.3 Biological and microbiological NA

8 Hazards generated by neglecting ergonomic principles in machine design:

(continued) SIST EN 1495:1999+A2:2010

HAZARDS RELEVANT CLAUSES IN THIS STANDARD

8.1 Unhealthy postures or excessive efforts 5.2.1.6; 5.2.5.2; 5.6.2; 5.12; 5.12.8

8.2 Inadequate consideration of human hand/arm or foot/leg anatomy NA

8.4 Inadequate area lighting 7.1.2.6

8.5 Mental overload or underload, stress NA

8.6 Human error 5.2.2.1; 5.12

9 Hazard combinations

5.1.1.1; 5.1.1.2; 5.1.3

10 Hazards caused by failure of energy supply, breaking down of machinery parts and other functional disorders 5.1 10.1 Failure of energy supply 5.2.2.1; 5.6; 5.8.1.4; 5.12.7 10.2 Unexpected ejection of machine parts or fluids 5.9.7; 5.9.8; 5.9.9; 5.9.10 10.3 Failure or malfunction of control system 5.2.1.5 10.4 Errors of fitting 5.1.5.1.5 10.5 Overturn, unexpected loss of machine stability

5.1.1.2; 5.1.5; 5.7 11 Hazards caused by missing and/or incorrectly positioned safety related measures/means

8.3 Neglected use of personal protection equipment 5.12.8; 7.1.2.7; 7.1.2.12 11.1 Guards

11.2 Safety related (protection) devices 5.7 11.3 Starting and stopping devices 5.1.1; 5.3.4.9; 5.12 11.4 Safety signs and signals 5.2.2.7; 7.1.2.9 11.5 Information or warning devices 7.1.2.9 11.6 Energy supply disconnecting devices

5.2.1.2; 5.8.1.2 11.7 Emergency devices 5.5; 5.6 11.8 Feeding/removal means of workpieces

NA 11.9 Essential equipment and accessories for safe adjusting and/or maintaining 5.2.3.1; 5.4.2.10 11.10 Equipment evacuating gases NA

HAZARDS RELEVANT CLAUSES IN THIS STANDARD 12 Inadequate lighting of moving/working area (continued) 7.1.2.6 13 Hazards due to sudden movement instability etc during handling 5.1.5; 5.2.2.1; 5.2.2.3; 5.2.2.4; 5.4.3 14 Inadequate/non-ergonomic design of operating position

14.1 Hazards due to dangerous environments (contact with moving parts, exhaust gases etc) 5.2.2 14.2 Inadequate visibility from operators position 5.12.2; 5.12.5 14.3 Inadequate seat/seating NA 14.4 Inadequate/non-ergonomic design/positioning of controls5.12 14.5 Starting/moving of self-propelled machinery 5.12 14.6 Road traffic of self-propelled machinery 7.1.2.6; 7.1.2.12 14.7 Movement of pedestrian controlled machinery 7.1.2.6; 7.1.2.12 15 Mechanical hazards 5.1.1.1 15.1 Hazards to exposed persons due to uncontrolled movement 5.2.2.1; 5.2.4; 5.3.1.5, 5.4.1; 7.1.2.7 15.2 Hazards due to break-up and/or ejection of parts 5.2.1.4; 5.2.1.5; 5.2.2.3 15.3 Hazards due to rolling over (ROPS) 5.1.5 15.4 Hazards due to falling objects (FOPS) 7.1.2.7 15.5 Inadequate means of access 5.3.3; 5.3.4 15.6 Hazards due to towing, coupling, connecting, transmission etc 5.2.2.6 15.7 Hazards due to batteries, fire, emissions etc NA 16 Hazards due to lifting operations

16.1 Lack of stability 5.1.5; 5.1.1.2; 5.2.2.4; 5.2.2.5; 5.2.5.1 16.2 Derailment of machinery 5.2.2.4; 5.4.1.5; 5.4.2 16.3 Loss of mechanical strength of machinery and lifting accessories 5.1; 5.2.1.7; 5.2.1.8; 5.2.2.2; 5.2.2.3; 5.2.3.2; 5.2.3.3; 5.2.5.2; 5.2.5.3; 5.3.1.4; 5.4.2; 5.4.3 16.4 Hazards caused by uncontrolled movement 5.2.2.5; 5.2.4; 5.4.1; 5.11 17 Inadequate view of trajectories of the moving parts 5.12 18 Hazards caused by lightning 7.1.2 19 Hazards due to loading/overloading 5.7

HAZARDS RELEVANT CLAUSES IN THIS STANDARD 20 Overloading or overcrowding of the carrier 5.1.2; 5.7; 5.10 Annex C 21 Unexpected movement of the carrier in response to external controls or other movements of the machine 5.12.7 22 Excess speed 5.4.1; 5.5; 5.6.3 23 Persons falling from the carrier 5.3 24 The carrier falling or overturning 5.2.2.3; 5.4.1; 5.5; 5.10; 5.11 25 Excess acceleration or braking of the carrier 5.2.2.4; 5.4.3.1.2; 5.4.4 26 Due to imprecise markings 5.2.2.7; 7.2

5 Safety requirements and/or measures 5.1 Structural and stability calculations 5.1.1 General 5.1.1.1 All loads and forces which can occur in any allowed configuration during erection, operation, out-of-service, dismantling and transfer shall be considered. This shall also include inclined or hanging masts. 5.1.1.2 The manufacturer shall be responsible for: Stability calculations, in order to identify the various configurations of the MCWP and the combinations of loads and deflections, which together create conditions of instability; Structural calculations, to evaluate the individual forces and to make allowance for deflections. All combinations of forces shall be considered including those which produce the most unfavourable stresses in the components. 5.1.2 Loads and forces The following loads and forces shall be taken into account: 5.1.2.1 Structural loads The masses of the components of the MCWP when they are not moving are considered to be static structural loads. The masses of the components of the MCWP when they are moving are considered to be dynamic structural loads. SIST EN 1495:1999+A2:2010

mp = 80 kg; mass of each person

me = 40 kg; mass of personal equipment (for the first two persons only)

T = mass (kg) of material and equipment on the work platform (excluding personal equipment)

n = number of persons on the work platform The mass of persons and the mass of equipment and material shall act simultaneously. The minimum number of persons shall be: Two (2) for single mast platforms and four (4) for multiple mast platforms. The mass of the personal equipment (me) shall be assumed to act on the point coincident with each of the two persons which give the highest stresses. 5.1.2.2.2 The mass of each person is assumed to act as a point load on the MCWP at a horizontal distance 0,1 m from the upper inside edge of the top guard rail. The distance between the point loads shall be 0,5 m (see figure 3 as an example). 5.1.2.2.3 The mass T shall be evenly distributed over the whole area of the main platform giving a specific load per length t. The centre of gravity of the mass T shall be assumed to act on a point 0,15 B (where B is the width of the main platform) away from the longitudinal centre line of the main platform, on the side giving the highest stresses.

See figure 4. Calculations must allow for the possibility that a reduced load giving an unbalanced loadcase may result in higher stresses in some parts of the MCWP than a balanced rated load case would give. For single mast machines the bending moment, M, on masts and platforms shall be calculated according to formula 1, where Lmax is the greater of the distances L1 and L2 in figure 5. For multiple mast machines the bending moment M, on masts and platforms shall be calculated according to formulas 2, 3, 4 and figure 6. The factors 1,15 and 1,2 are used in the formulas 1, 2, 3, 4 in order to cover the situations in use where, instead of a uniformly distributed load, a concentration of the same load is placed elsewhere within that individual length. SIST EN 1495:1999+A2:2010

Figure 3 — Example of the distribution of persons on the main platform or platform extensions

Figure 4 — Eccentric loading normal to the centre line

Specific load t = LT Formula (1): Mmax = 215,12max××Lt Figure 5 — Loading in the longitudinal direction. Single mast machines

Specific load t = LT Formulas: (2) M1 = 215,121××Lt (3) M2 = 82,122××Lt (4) M3 = 215,123××Lt Figure 6 — Loading in the longitudinal direction. Multiple mast machines SIST EN 1495:1999+A2:2010

Key 1 main platform 2 platform-extension Figure 7 — Long cantilever extensions™ 5.1.2.2.6 Where the manufacturer includes in his design, provision for the use of a handling crane then the mass of the crane and the crane's rated load shall together be treated as part of the rated load of the MCWP. The location of the force resulting from the use of the crane shall be dictated by the manufacturer's chosen mounting positions for the crane supports. 5.1.2.3 Horizontal forces 5.1.2.3.1 Manual forces The minimum value for the manual force is assumed to be 200 N for each of the first two persons on the platform and 100 N for each additional person permitted to be on the work platform. It is assumed that the force is applied at a height of 1,1 m above the floor of the work platform and acts in a horizontal direction. SIST EN 1495:1999+A2:2010

ISO 4302. The windforce coefficient for persons exposed to the wind is 1,0. 5.1.2.5.4 The full area of one person is 0,7 m2 (0,4 m average width × 1,75 m height) with the centre of area 1,0 m above the work platform floor. 5.1.2.5.5 The exposed area of one person standing on a work platform behind an imperforate section of fencing 1,1 m high is 0,35 m2 with the centre of area 1,45 m above the work platform floor. 5.1.2.5.6 The number of persons directly exposed to the wind is calculated as: a) The length of the side of the work platform exposed to the wind, rounded to the nearest 0,5 m and divided by 0,5 m, or b) The number of persons allowed on the work platform if less than the number calculated in a). 5.1.2.5.7 If the number of persons permitted on the work platform is greater than in 5.1.2.5.6 a), a reducing coefficient of 0,6 may be applied to the extra number of persons. 5.1.2.5.8 The wind force on exposed equipment and material on the work platform is calculated as 3 % of the mass (T), acting horizontally at a height of 1,0 m above the work platform floor. 5.1.2.6 Loads and forces occurring during transfer conditions Inertia forces plus any load permitted by the manufacturer on the work platform shall be taken into account when the MCWP is subject to transfer conditions. 5.1.2.7 Erection and dismantling loads The load for which the MCWP has been designed during erection and dismantling. Erection load may be higher than rated load. If the handling crane, as carried in 5.1.2.2.6, is used during erection and dismantling of the MCWP, then the crane's mass and the rated load shall together be treated as part of the erection load. 5.1.2.8 Out of service wind loads Whilst out of service, with the work platform in a safe position, the wind pressure for the calculations shall be in accordance with table 3. The limiting wind pressure shall be considered in the most unfavourable direction. SIST EN 1495:1999+A2:2010

Height of member above ground level (m) Wind Velocity (m/s) Wind Pressure {N/m2) 0 to 20 over 20 to 100 over 100 35,8 42 45,9 800 1100 1300 NOTE The wind values given in table 3 are minimum values for the central European area and at low altitudes. In special cases, e.g. coastal areas or at higher altitudes, information set out in specific national standards shall be used until relevant European standards are available.

5.1.2.9 Buffer zones Buffer forces shall be calculated taking into account the characteristics of the buffer. 5.1.2.10 Action of the safety means according to 5.5 To determine the forces produced by an operation of these means, the sum total of all travelling masses shall be multiplied by a factor of 2. A lower factor, but not less than 1,2 may be used if it can be verified by test under all conditions of loading up to 1,5 times the rated load. 5.1.2.11 Inaccuracies in setting up For the purposes of calculation an allowance of an additional 0,5° shall be made to allow for user inaccuracy when erecting the mast. 5.1.3 Load combinations and safety factors The load combinations to be taken into consideration shall be as follows: Load combination A1: MCWP in service without wind, static. Load combination A2: MCWP in service without wind, dynamic. Load combination B1: MCWP in service with wind, static. Load combination B2: MCWP in service with wind, dynamic. Load combination B3: MCWP during erection or dismantling. Load combination B4: MCWP during transfer condition. Load combination C1: MCWP striking the buffer whilst in service. Load combination C2: MCWP during action of the safety means whilst in service. Load combination C3: MCWP out of service. SIST EN 1495:1999+A2:2010

Load combination Loads Ref. clause A1 A2 B1 B2 B3 B4 C1 C2 C3 Structural loads 5.1.2.1 X X X X X X X X X Rated load 5.1.2.2 X X X X

X X

Horizontal forces 5.1.2.3 X

X

Dynamic forces 5.1.2.4

X

X X X

In service wind loads 5.1.2.5

X X X X

Loads and forces during transfer condition 5.1.2.6

X X

Erection and dismantling loads 5.1.2.7

X

Out of service wind loads 5.1.2.8

X Buffer forces 5.1.2.9

X

Action of safety means 5.1.2.10

X

Inaccuracies in setting up 5.1.2.11 X X X X X X

Table 5 — Safety factors for structural steels

Load case Safety factorA1, A2 1,5 B1, B2, B3, B41,33 C1, C2, C3 1,25

Load case Safety factorA1, A2 1,7 B1, B2, B3, B41,55 C1, C2, C3 1,4

5.1.4 Structural calculations See Annex A (informative). 5.1.5 Stability calculations 5.1.5.1 Calculation of forces 5.1.5.1.1 Forces causing overturning moments shall, when created by structural masses, be multiplied by a factor of 1,1 and when created by rated loads be multiplied by a factor of 1,2. It must be remembered here that an inclination of mast from the vertical will result in an increasing overturning moment as the work platform travels upwards. All forces causing stabilizing moments shall be multiplied by a factor of 1,0. 5.1.5.1.2 Wind forces shall be multiplied by a factor of 1,2 and assumed to be acting horizontally. 5.1.5.1.3 Horizontal forces as detailed in clause 5.1.2.3 shall be multiplied by a factor of 1,2 and assumed to be acting in the direction creating the greatest overturning moment. 5.1.5.1.4 Forces according to 5.1.2.6 shall be treated in the same way as specified in 5.1.5.1.1, 5.1.5.1.2 and 5.1.5.1.3 as appropriate. 5.1.5.1.5 Inaccuracies in setting-up according to 5.1.2.11 shall be taken into account in the stability calculation. 5.1.5.2 Calculation of overturning and stabilizing moments 5.1.5.2.1 The maximum overturning and corresponding stabilizing moments shall be calculated about the most unfavourable tipping lines. The calculations shall be made with the MCWP in the most unfavourable configurations with the maximum allowable inclination of the chassis defined by the manufacturer. Every load and force combination including inaccuracy in setting-up shall be taken into account in their most unfavourable combinations. In each case the calculated stabilizing moment shall be greater than the calculated overturning moment. SIST EN 1495:1999+A2:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...