EN 14010:2003+A1:2009

(Main)Safety of machinery - Equipment for power driven parking of motor vehicles - Safety and EMC requirements for design, manufacturing, erection and commissioning stages

Safety of machinery - Equipment for power driven parking of motor vehicles - Safety and EMC requirements for design, manufacturing, erection and commissioning stages

1.1 This European Standard deals with the technical requirements to minimise the risks due to the hazards listed in clause 4, which can arise during installation , operation and maintenance of permanently installed equipment and systems for the power driven parking of motor vehicles, as defined in 3.1 to 3.4 below. Requirements are also given on the provision of information for use, which includes requirements for the drafting of the instructions. Electromagnetic compatibility requirements are also covered.

1.2 This European Standard applies to equipment and systems for the power driven parking of motor vehicles which have four wheels, are within a maximum size envelope of 5,30 m long, by 2,30 m wide, by 2,20 m high and have a mass less than 2500 kg. The equipment can be manually or automatically controlled.

1.3 This standard does not cover:

a) vehicle lifts (see EN 1493);

b) peripheral devices, which do not handle motor vehicles, e.g. parking meters, ticket machines;

c) requirements related to the building even if they support directly stored vehicles;

d) goods only lifts in accordance with EN 81-31;

e) power driven parking equipment intended for lifting and/or transporting any person;

f) transmission and interface of remote controls;

g) automatic parking equipment with transfer areas which move;

h) the use of power driven parking equipment by wheelchair users and deaf persons;

i) the workplace of any attendant.

1.4 This standard does not deal with the following:

a) hazards arising if loads, or other items fall from vehicles;

b) hazards arising if fuel or oil leaks from vehicles;

c) hazards caused by operating the equipment/system in electromagnetic fields outside the range of

EN 61000-6-2;

d) hazards caused by operating the equipment/system in areas subject to special regulations (e.g. explosive atmospheres, fire risks);

e) hazards caused by the use of dangerous/toxic materials, e.g. special hydraulic oil;

f) hazards caused by noise;

g) (....)

Sicherheit von Maschinen - Parkeinrichtung für Kraftfahrzeuge - Sicherheits- und EMV-Anforderungen an Gestaltung, Herstellung, Aufstellung und Inbetriebnahme

1.1 Diese Europäische Norm behandelt die technischen Anforderungen zur Minimierung von Risiken aufgrund der Gefährdungen, die in Abschnitt 4 aufgeführt sind und die während der Inbetriebnahme ), des Betriebes und der Wartung von fest installierten, in 3.1 bis 3.4 definierten, kraftbetriebenen Parkeinrichtungen für Kraftfahrzeuge auftreten können. Des Weiteren sind Anforderungen bezüglich der Informations-bereitstellung für den Nutzer angegeben, hierzu gehören auch die Anforderungen für die Erstellung der Anleitungen. Diese Norm enthält auch EMV Anforderungen.

1.2 Diese Europäische Norm gilt für Einrichtungen und Systeme zum kraftbetriebenen Befördern von Kraftfahrzeugen, die vier Räder, eine maximale Fahrzeuglänge von 5,30 m haben, bis zu 2,30 m breit, bis zu 2,20 m hoch sind und eine Masse kleiner als 2 500 kg haben. Die Einrichtungen können entweder manuell oder automatisch gesteuert sein.

1.3 Diese Norm gilt nicht für:

a) Fahrzeughebebühnen (siehe EN 1493);

b) periphere Einrichtungen, die keine Kraftfahrzeuge aufnehmen, wie z. B. Parkuhren, Kartenautomaten;

c) Anforderungen in Bezug auf die Gebäude, auch wenn dort die geparkten Fahrzeuge direkt abgestellt werden;

d) Lastenaufzüge in Übereinstimmung mit EN 81-31;

e) kraftbetriebene Parkeinrichtungen, die für das Heben und/oder Befördern von Personen vorgesehen sind;

f) die Übertragung und die Schnittstelle von Fernbedienungen;

g) automatische Parkeinrichtungen mit sich bewegenden Übergabebereichen;

h) den Gebrauch von kraftbetriebenen Parkeinrichtungen durch Rollstuhlfahrer und gehörbehinderte Personen;

i) den Arbeitsplatz einer Bedienungsperson.

1.4 Diese Norm gilt nicht für die folgenden Gefährdungen:

a) Gefährdungen durch von Fahrzeugen herabfallende Ladung oder sonstige Gegenstände;

b) Gefährdungen durch das Ausfließen von Kraftstoff oder Öl aus Fahrzeugen;

c) Gefährdungen durch den Betrieb der Einrichtung/des Systems in elektromagnetischen Feldern außerhalb des (...)

Sécurité des machines - Dispositif de stationnement motorisé des véhicules automobiles - Exigences concernant la sécurité et la CEM pour les phases de conception, construction, montage et mise en service

1.1 La présente Norme européenne traite des exigences techniques permettant de minimiser les risques dus aux

phénomènes dangereux énumérés à l’article 4, susceptibles d’apparaître lors de l'installation 1), du fonctionnement

et de la maintenance des dispositifs et systèmes installés de manière permanente pour le stationnement motorisé

des véhicules automobiles, tels que définis de 3.1 à 3.4 ci-dessous. Cette norme fournit également des exigences

concernant la disposition d’informations pour l’utilisation comportant des exigences relatives à la rédaction des

instructions. Les exigences concernant la compatibilité électromagnétique sont également traitées.

1.2 La présente Norme européenne s’applique aux dispositifs et aux systèmes de stationnement motorisé des

véhicules automobiles à quatre roues, dont l’envergure maximale est de 5,30 m de long par 2,30 m de large et 2,20 m

de haut, et dont le poids est inférieur à 2 500 kg. Les dispositifs peuvent être à commande manuelle ou automatique.

1) Lorsqu'elle est effectuée par ou au nom de l'acheteur.

1.3 La présente norme ne couvre pas :

a) les monte-charges pour véhicules (voir l'EN 1493) ;

b) les dispositifs périphériques, qui ne sont pas destinés au déplacement des véhicules automobiles, par exemple

parcmètres, distributeurs automatiques de tickets ;

c) les exigences relatives aux bâtiments même s’ils supportent directement des véhicules en stationnement ;

d) les monte-charges proprement dits conformément à l'EN 81-31 ;

e) les dispositifs de stationnement motorisé destinés au levage et/ou au transport de personnes ;

f) les éléments de transmission et d'interface des télécommandes ;

g) les dispositifs de stationnement automatique à zones de transfert mobiles ;

h) l'utilisation des dispositifs de stationnement motorisé par des personnes sourdes et en fauteuil roulant ;

i) le lieu de travail de tout préposé.

Varnost strojev - Gnana oprema za parkiranje motornih vozil - Varnostne zahteve in zahteve elektromagnetne združljivosti za načrtovanje, proizvodnjo, montažo in prevzem

Ta evropski standard obravnava tehnične zahteve za zmanjšanje tveganj, povezanih z nevarnostmi, navedenimi v Klavzuli 4, ki se lahko pojavijo med nameščanjem, delovanjem in vzdrževanjem trajno nameščene opreme in sistemov za gnano parkiranje motornih koles, kot je določeno v točkah od 3.1 do 3.4 spodaj. Zahteve so podane tudi preko zbiranja informacij o uporabi, ki vključujejo zahteve za pripravo osnutka navodil. Zahteve o elektromagnetni združljivosti so prav tako zajete. Ta evropski standard velja za opremo in sisteme za gnano parkiranje motornih koles, ki imajo štiri kolesa in imajo največje dimenzije 5,30 m dolžine, 2,30 m širine, 2,20 m višine ter maso manjšo od 2500 kg. Opremo se lahko upravlja ročno ali avtomatsko.

General Information

- Status

- Published

- Publication Date

- 14-Jul-2009

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 9 - Mechanical Parking Devices

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 17-Mar-2025

- Completion Date

- 11-Feb-2026

- Directive

- Not Harmonized2004/108/EC - Directive 2004/108/EC of the European Parliament and of the Council of 15 December 2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EECOJ Ref: C 71, C 71, C 71, C 71, C 71, C 71, C 71, C 71, C, OJ Date: 19-Mar-2010

Not Harmonized2004/108/EU - DIRECTIVE 2004/108/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 15 December 2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EECOJ Ref: C 71, C 71, C 71, C 71, C 71, C 71, C 71, C 71, C, OJ Date: 19-Mar-2010

Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Harmonized Standard2014/30/EU - Directive 2014/30/EU of the European Parliament and of the Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to electromagnetic compatibility (recast)OJ Ref: C 173, C 173, C 173, C 173, C 173, C 173, C 173, C OJ Date: 13-May-2016

Not Harmonized89/336/EEC - Electromagnetic compatibility (EMC)

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14010:2003+A1:2009 is a CEN European standard specifying safety and electromagnetic compatibility (EMC) requirements for the design, manufacture, erection and commissioning of permanently installed, power‑driven parking equipment for motor vehicles. It targets systems handling typical passenger vehicles (4 wheels) up to a maximum envelope of 5.30 m × 2.30 m × 2.20 m and a mass below 2 500 kg. The standard covers risks arising during installation, operation and maintenance and requires provision of user information including instruction handbooks.

Key topics and technical requirements

- Scope and exclusions: applies to manually or automatically controlled parking equipment but excludes vehicle lifts (EN 1493), goods lifts (EN 81‑31), devices not handling vehicles (ticket machines), equipment intended to lift/transport people, remote control transmission/interface, and several other specific hazards and use-cases (see clause 1.3–1.4).

- Safety engineering: risk assessment, list of significant hazards, design measures to minimise crushing, trapping, falling and unintended movement risks.

- Control and safety devices: requirements for control panels, emergency stop, interlocks, pressure-sensitive edges and safety‑related parts of control systems.

- Electrical and EMC: electrical equipment requirements (EN 60204‑1) and EMC requirements consistent with EN 61000‑6‑2 and EN 61000‑6‑3 to ensure immunity and emissions are addressed for industrial and light‑industrial/residential environments.

- Hydraulics and mechanical elements: guidance on hydraulic systems, lifting elements, transmissions, steel wire ropes and load carriers.

- Verification and testing: procedures for verification, special checks and type testing to confirm compliance before commissioning.

- Information for use: mandatory marking and instruction handbook content to be supplied with equipment.

- Normative annexes: design criteria and informative material on automatic parking equipment; annexes also map the standard to relevant EU Directives.

Practical applications and users

Who uses EN 14010:

- Manufacturers and OEMs of power‑driven parking systems

- System integrators and control engineers

- Installation and commissioning teams

- Building owners, facility managers and car‑park operators

- Safety engineers, conformity assessors and test laboratories

- Regulators and procurement specifiers

Typical applications:

- Design and manufacture of automated and non‑automatic multi‑level or stack parking systems

- Site erection, commissioning and acceptance testing of installed parking equipment

- Preparation of safety documentation, user manuals and conformity evidence

Related standards (examples)

- EN 1493 (vehicle lifts - excluded from EN 14010 scope)

- EN 60204‑1 (electrical equipment of machines)

- EN 61000‑6‑2 / EN 61000‑6‑3 (EMC immunity/emissions)

- EN ISO 12100 (risk assessment and design principles)

- Relevant EU Directives (see informative annexes ZA / ZB / ZC for linkage to 98/37/EC, 2006/42/EC, 2004/108/EC)

Keywords: EN 14010, power driven parking, safety of machinery, EMC, parking systems, parking equipment standard, commissioning, installation, conformity.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

EN 14010:2003+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Equipment for power driven parking of motor vehicles - Safety and EMC requirements for design, manufacturing, erection and commissioning stages". This standard covers: 1.1 This European Standard deals with the technical requirements to minimise the risks due to the hazards listed in clause 4, which can arise during installation , operation and maintenance of permanently installed equipment and systems for the power driven parking of motor vehicles, as defined in 3.1 to 3.4 below. Requirements are also given on the provision of information for use, which includes requirements for the drafting of the instructions. Electromagnetic compatibility requirements are also covered. 1.2 This European Standard applies to equipment and systems for the power driven parking of motor vehicles which have four wheels, are within a maximum size envelope of 5,30 m long, by 2,30 m wide, by 2,20 m high and have a mass less than 2500 kg. The equipment can be manually or automatically controlled. 1.3 This standard does not cover: a) vehicle lifts (see EN 1493); b) peripheral devices, which do not handle motor vehicles, e.g. parking meters, ticket machines; c) requirements related to the building even if they support directly stored vehicles; d) goods only lifts in accordance with EN 81-31; e) power driven parking equipment intended for lifting and/or transporting any person; f) transmission and interface of remote controls; g) automatic parking equipment with transfer areas which move; h) the use of power driven parking equipment by wheelchair users and deaf persons; i) the workplace of any attendant. 1.4 This standard does not deal with the following: a) hazards arising if loads, or other items fall from vehicles; b) hazards arising if fuel or oil leaks from vehicles; c) hazards caused by operating the equipment/system in electromagnetic fields outside the range of EN 61000-6-2; d) hazards caused by operating the equipment/system in areas subject to special regulations (e.g. explosive atmospheres, fire risks); e) hazards caused by the use of dangerous/toxic materials, e.g. special hydraulic oil; f) hazards caused by noise; g) (....)

1.1 This European Standard deals with the technical requirements to minimise the risks due to the hazards listed in clause 4, which can arise during installation , operation and maintenance of permanently installed equipment and systems for the power driven parking of motor vehicles, as defined in 3.1 to 3.4 below. Requirements are also given on the provision of information for use, which includes requirements for the drafting of the instructions. Electromagnetic compatibility requirements are also covered. 1.2 This European Standard applies to equipment and systems for the power driven parking of motor vehicles which have four wheels, are within a maximum size envelope of 5,30 m long, by 2,30 m wide, by 2,20 m high and have a mass less than 2500 kg. The equipment can be manually or automatically controlled. 1.3 This standard does not cover: a) vehicle lifts (see EN 1493); b) peripheral devices, which do not handle motor vehicles, e.g. parking meters, ticket machines; c) requirements related to the building even if they support directly stored vehicles; d) goods only lifts in accordance with EN 81-31; e) power driven parking equipment intended for lifting and/or transporting any person; f) transmission and interface of remote controls; g) automatic parking equipment with transfer areas which move; h) the use of power driven parking equipment by wheelchair users and deaf persons; i) the workplace of any attendant. 1.4 This standard does not deal with the following: a) hazards arising if loads, or other items fall from vehicles; b) hazards arising if fuel or oil leaks from vehicles; c) hazards caused by operating the equipment/system in electromagnetic fields outside the range of EN 61000-6-2; d) hazards caused by operating the equipment/system in areas subject to special regulations (e.g. explosive atmospheres, fire risks); e) hazards caused by the use of dangerous/toxic materials, e.g. special hydraulic oil; f) hazards caused by noise; g) (....)

EN 14010:2003+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 33.100.01 - Electromagnetic compatibility in general; 53.020.99 - Other lifting equipment; 53.080 - Storage equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14010:2003+A1:2009 has the following relationships with other standards: It is inter standard links to EN 14010:2003, EN 61310-2:2008, EN 61310-1:2008, EN 60947-5-1:1997, EN IEC 61000-6-2:2019, EN 60529:1991, EN IEC 61496-1:2020, EN IEC 61000-6-3:2021, EN 60204-1:1997, prEN 13241, EN ISO 12543-2:2021, EN ISO 13856-2:2013, EN 1005-3:2002+A1:2008, EN 12433-1:1999, EN 894-2:1997+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14010:2003+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2004/108/EC, 2004/108/EU, 2006/42/EC, 2014/30/EU, 89/336/EEC, 98/37/EC; Standardization Mandates: M/079, M/396, M/404. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14010:2003+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SUHY]HPSicherheit von Maschinen - Parkeinrichtung für Kraftfahrzeuge - Sicherheits- und EMV-Anforderungen an Gestaltung, Herstellung, Aufstellung und InbetriebnahmeSécurité des machines - Dispositif de stationnement motorisé des véhicules automobiles - Exigences concernant la sécurité et la CEM pour les phases de conception, construction, montage et mise en serviceSafety of machinery - Equipment for power driven parking of motor vehicles - Safety and EMC requirements for design, manufacturing, erection and commissioning stages53.080Storage equipment53.020.99Druga dvigalna opremaOther lifting equipment33.100.01Elektromagnetna združljivost na splošnoElectromagnetic compatibility in generalICS:Ta slovenski standard je istoveten z:EN 14010:2003+A1:2009SIST EN 14010:2004+A1:2010en,fr,de01-februar-2010SIST EN 14010:2004+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14010:2003+A1

July 2009 ICS 33.100.01; 53.020.99; 53.080 Supersedes EN 14010:2003English Version

Safety of machinery - Equipment for power driven parking of motor vehicles - Safety and EMC requirements for design, manufacturing, erection and commissioning stages

Sécurité des machines - Dispositif de stationnement motorisé des véhicules automobiles - Exigences concernant la sécurité et la CEM pour les phases de conception, construction, montage et mise en service

Sicherheit von Maschinen - Kraftbetriebene Parkeinrichtungen für Kraftfahrzeuge - Sicherheits- und EMV-Anforderungen an Gestaltung, Herstellung, Aufstellung und Inbetriebnahme This European Standard was approved by CEN on 1 October 2003 and includes Amendment 1 approved by CEN on 19 June 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14010:2003+A1:2009: ESIST EN 14010:2004+A1:2010

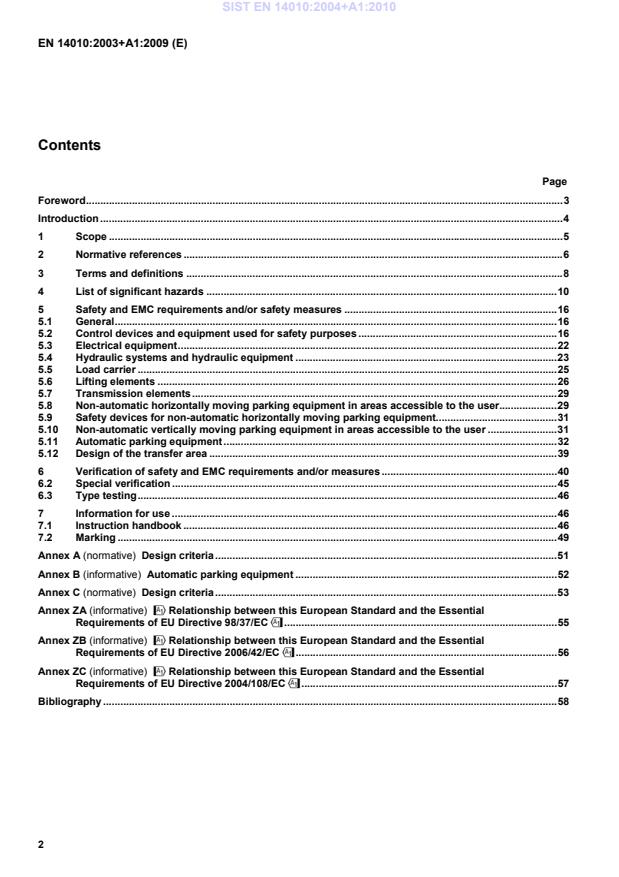

Design criteria . 51Annex B (informative)

Automatic parking equipment . 52Annex C (normative)

Design criteria . 53Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 55Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 56Annex ZC (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2004/108/EC" . 57Bibliography . 58 SIST EN 14010:2004+A1:2010

Introduction

!This European Standard is a type C standard as stated in EN ISO 12100-1:2003." The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document. When producing this standard it was assumed that negotiation will take place between the manufacturer and the purchaser of the parking equipment/systems, concerning particular conditions for the use and places of use for the equipment/system, related to health, safety and environmental conditions; erection, commissioning and testing will be carried out by suitably trained persons; only legal drivers of vehicles will use the equipment/system; no vehicles in excess of the rated load or otherwise unsuitable (see clause 1), will use the equipment/system; persons will not be lifted or transported by the machinery; the machinery and its components will be kept in good repair and working order in accordance with the manufacturers instructions, to retain specified safety characteristics throughout the intended working life of the machinery; by design of the load bearing elements, safe operation of the machinery will be assured for loading ranging from zero to 100% of the rated capacities and during the loaded tests (see 6.1f); harmful materials, such as asbestos are not used as part of the machine; all parts of the equipment/system without specific requirements will be: 1) designed in accordance with the usual engineering practice and design codes, using appropriate safety factors, taking account of all relevant forces, loads and failure modes; 2) of sound mechanical and electrical construction; 3) made from materials of adequate strength and durability and of suitable quality for their intended purpose. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over other standards, for machines that have been designed and built according to the provisions of this type C standard. SIST EN 14010:2004+A1:2010

EN 61000-6-2; d) hazards caused by operating the equipment/system in areas subject to special regulations (e.g. explosive atmospheres, fire risks); e) hazards caused by the use of dangerous/toxic materials, e.g. special hydraulic oil; f) hazards caused by noise; g) hazards arising from inadequate lighting of the surrounding of automatic parking systems and/or the place of installation of non-automatic parking equipment; h) hazards caused by earthquakes; i) hazards caused by vandalism; j) hazards due to the use of programmable electronic systems related to safety functions;

1 When carried out by or on behalf of the purchaser SIST EN 14010:2004+A1:2010

(IEC 60204-1:1997) EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) EN 60947-5-1:1997, Low-voltage switchgear and controlgear — Part 5-1: Control circuit devices and switching elements — Electromechanical control circuit devices (IEC 60947-5-1:1997) EN 61000-6-2, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for industrial environments (IEC 61000-6-2:1999, modified) EN 61000-6-3, Electromagnetic compatibility (EMC) — Part 6-3: Generic standards - Emission standard for residential, commercial and light-industrial environments (IEC 61000-6-3:1996, modified) EN 61310-1, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, auditory and tactile signals (IEC 61310-1:1995) EN 61310-2, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for marking

(IEC 61310-2:1995) EN 61496-1, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496:1997) !EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003)" EN ISO 12543-2, Glass in building — Laminated glass and laminated safety glass — Part 2: Laminated safety glass (ISO 12543-2:1998) SIST EN 14010:2004+A1:2010

annex B) 3.5.5 emergency door pedestrian door which is intended to be used solely for persons leaving the respective area in emergencies, e.g. fire (see annex B) 3.5.6 pass door part of a door leaf for pedestrians only (see EN 12433-1 and annex B) 3.6 other definitions 3.6.1 safety switch control switch having one or more break-contact elements coupled to the switch actuator via non-resilient members so that full contact opening of the break contact element(s) is obtained when the actuator is moved through the positive opening travel by applying the force stated by the switch manufacturer NOTE See annex K of EN 60947-5-1:1997. 3.6.2 rated load (carrying capacity) maximum load per parking space that power driven parking equipment has been designed to carry 3.6.3 transfer area area within automatic parking equipment in which vehicles are transferred to, or taken from, to reach the working area. The transfer area is intended to allow for at least the driver to leave or to enter the vehicle (see annex B) 3.6.4 working area area in which the vehicle is handled. Within automatic parking equipment this area is not intended to be accessed by the user(s) (see annex B) 3.6.5 user person who parks and/or retrieves a vehicle, using power driven parking equipment 3.6.6 type test testing of a representative sample of a new design or of one which incorporates deviations from an existing design, which is conducted by or on behalf of the manufacturer or his authorised representative 3.6.7 load carrier part of power driven parking equipment on which a single motor vehicle is located SIST EN 14010:2004+A1:2010

The list of significant hazards is based on EN 1050 and is using the numbering of annex A of EN 1050:1996. Also shown are the sub-clause references to the safety requirements and/or protective measures in the present standard. Before using this standard it is important to carry out a risk assessment of the equipment to check that its significant hazards are identified in this clause.SIST EN 14010:2004+A1:2010

Mechanical hazards due to machine parts or work pieces caused, for example, by:

Relative location 5.8.4, 5.8.5

Mass and stability (potential energy of elements which may move under the effect of gravity) 5.6, 5.7.5

Mass and velocity (kinetic energy of elements in controlled or uncontrolled motion) 5.5.2, 5.7.5, 5.8.1, 5.8.8, 5.9.1, 5.9.2, 5.9.4, 5.11.1, 5.11.10

Inadequacy of mechanical strength 5.1.1, 5.5.3, 5.6, 5.11.10.2, annex ‘A’ Mechanical hazards due to accumulation of energy inside the machinery, caused for example, by:

Liquids under pressure 5.4 1.1 Crushing hazard 5.2.3.1.1, 5.2.3.1.2, 5.2.3.1.4, 5.8.4, 5.8.5, 5.9.1, 5.9.3, 5.10.1, 5.11.3, 5.11.4, 5.11.5, 5.11.8, 5.11.10, 5.11.11, 5.11.12 1.2 Shearing hazard 5.7.6, 5.8.2, 5.11.3, 5.11.4, 5.11.5, 5.11.8, 5.11.10, 5.11.11, 5.11.12 1.3 Cutting or severing hazard 5.8.2, 5.11.3, 5.11.4, 5.11.5, 5.11.8, 5.11.10, 5.11.11, 5.11.12 1.4 Entanglement hazard 5.7.6, 5.11.3, 5.11.4, 5.11.5, 5.11.8, 5.11.10, 5.11.11, 5.11.12 1.5 Drawing-in or trapping hazard 5.2.3.6, 5.5.4, 5.7.6, 5.8.2, 5.8.3, 5.10.4, 5.10.6, 5.10.7, 5.11.3, 5.11.4, 5.11.5, 5.11.8, 5.11.10, 5.11.11, 5.11.12 1.6 Impact hazard 5.2.3.1.2, 5.8.1, 5.9.1, 5.11.3, 5.11.4, 5.11.5, 5.11.10, 5.11.11, 5.11.12 1.7 Stabbing or puncture hazard 5.11.10.1

continuedSIST EN 14010:2004+A1:2010

3.1 Burns and scalds and other injuries by a possible contact of persons with objects or materials with an extreme high or low temperature, by flames or explosions and also by the radiation of heat sources Not Dealt With

See 1.4d) 4 Hazards generated by noise, resulting in:

4.1 Hearing loss (deafness), other physiological disorders (e.g. loss of balance, loss of awareness) Not Dealt With

See 1.3f) & 1.4f) 4.2 Interference with speech communication, acoustic signals, etc.Not Dealt With

See 1.3f) & 1.4f) continuedSIST EN 14010:2004+A1:2010

7.2 Fire or explosion hazard Not Dealt With

See 1.4d) 8 Hazards generated by neglecting ergonomic principles in machinery design as, e.g. hazards from:

8.1 Unhealthy postures or excessive effort Not Dealt With See Clause ‘1.3i)’

& See Clause 'Introduction' -

Negotiations 8.4 Inadequate local lighting 5.11.2, 7.1.2.2

& See Clause ‘1.4g)’ 8.6 Human error, human behaviour 5.2.2, 5.2.3, 5.4.4, 5.8.8, 5.10.2, 5.10.5, 5.11.3, 5.11.4, 5.11.5, 5.11.7, 5.11.10, 5.11.11, 5.11.12, 5.11.13, 7.1.1, 7.1.3, 7.1.5, 7.2 8.7 Inadequate design, location or identification of manual controls 5.2.3, 5.11.13 8.8 Inadequate design or location of visual display units 5.2.3.1.2 9 Combinations of hazards 5.1.2 continuedSIST EN 14010:2004+A1:2010

10.1 Failure/disorder of the control system 5.2.2,

5.2.4, 5.11.6, 5.11.14 10.2 Restoration of energy supply after an interruption 5.2.3.2, 5.2.4 10.3 External influences on electrical equipment 5.2.5.2 10.5 Errors in the software Not Dealt With See Clause ‘1.4j)’

10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6 above) 5.2.2, 5.2.3 , 5.4.4, 5.8.8, 5.10.2, 5.10.5, 5.11.3, 5.11.4, 5.11.5, 5.11.6, 5.11.7, 5.11.10, 5.11.11, 5.11.12, 5.11.13, 5.11.14, 7.1.1, 7.1.3, 7.1.5 11 Impossibility of stopping the machine in the best possible conditions 5.2.3.3, 5.2.3.4, 5.11.7 13 Failure of the power supply 5.2.3.6, 5.2.4.1 14 Failure of the control circuit 5.2.2.1, 5.2.2.2, 5.2.2.3, 5.2.4, 5.11.6, 5.11.7, 5.11.14 15

Errors of fitting 5.3.4, 5.4.4, 7.1.1, 7.1.2.3, 7.1.4 16 Break-up during operation 5.1.1, 5.4.3.6, 5.4.3.7, 5.5.3, 5.6, 7.1.2.1, 7.1.3, 7.1.4, annex ‘A’ 17 Ejected fluids 5.4 18 Loss of stability/overturning of machinery5.5.2, 5.6.1.4, 7.1.1, 7.1.2.1, 7.1.2.3, 7.1.3 19 Slip, trip and fall of persons (related to machinery)5.5.3, 5.5.6, 5.5.7, 5.6.1.8, 5.8.9, 5.10.8, 5.11.9 continued SIST EN 14010:2004+A1:2010

27.1.1 Lack of stability 5.5.2, 5.6.1.4, 7.1.1, 7.1.2.1, 7.1.2.3, 7.1.3 27.1.2 Uncontrolled loading - overloading - overturning moments exceeded Not Dealt With See Clause ‘Introduction’ -

Assumptions 27.1.3 Uncontrolled amplitude of movements 5.4.3.6, 5.4.3.7, 5.10.1, 5.10.2 27.1.4 Unexpected/unintended movement of loads 5.5.5, 5.6.1.7, 5.6.1.8, 5.10.3 27.1.5 Inadequate holding devices/accessories 5.5.5, 5.6.1.7, 5.6.1.8 27.2 From access of persons to load support 5.6.1.8, 7.1.3.2 27.3 From derailment 5.5.2, 5.6.1.5, 5.6.2.6, 5.6.4.8, 5.6.5.3, 5.6.6.3 27.4 From insufficient mechanical strength of parts 5.1.1, 5.4.3.6, 5.4.3.7, 5.6, 5.11.10.2, 7.1.2.1, 7.1.4, annex ‘A’ 27.5 From inadequate design of pulleys, drums 5.6.2.4, 5.6.2.6, 5.6.4.6, 5.6.4.7, 5.6.5.1, 5.6.5.2, 5.6.5.3, 5.6.5.6, 5.6.5.7 27.6 From inadequate selection of chains, ropes, lifting and accessories and their inadequate integration into the machine5.6 27.7 From lowering of the load under the control of friction brake 5.7.5 27.8 From abnormal conditions of assembly/testing/ use/ maintenance 5.2.3.7, 5.6.1.9, 5.6.4.9, 5.6.6.5, 5.11.8, 5.11.9, 7.1.4 27.9 From the effect of load on persons (impact by load or counterweight) Not Applicable 28 Electrical hazard 28.1 From lightning 5.2.5.2 29 Hazards generated by neglecting ergonomic principles 29.1 Insufficient visibility from the driving position 5.2.3.1.2, 5.8.4

EN 60204-1:1997, 9.2.2) and prevent any movement in the relevant plane, unless stated otherwise. The stop function shall comply with EN 954-1, 5.2. After release of an actuated safety device, it shall only be possible to initiate powered movement by a new start command. 5.2.2.1.1 Electrical safety devices The switching arrangements of electrical safety devices, shall be of positive opening operation in accordance with Chapter 3 of EN 60947-5-1:1997 (i.e. "safety switches" as defined in 3.6.1 above). With the exception, on automatic parking equipment, of ultimate switches on movements with a vertical component and those on horizontal movements without mechanical limiting devices other types of switching arrangement may be used, subject to the following conditions: i) mechanically actuated electrical switches which are not "safety type" switches, shall be duplicated, shall utilise break contacts and the switches shall be wired in series. ii) If sensing devices are used they shall be automatically monitored, which shall at least ensure that an error signal or faulty operation of the sensing device shall be detected prior to the start of the associated movement, i.e. shall meet the requirements of at least EN 61496-1 type 2. iii) If the monitoring system (see 5.11.14), shall detect an error signal, or unacceptable signal deviation, the monitoring system shall automatically initiate positive interruption of the associated powered movement and prevent further movement in that direction. 5.2.2.1.2 Hydraulic safety devices Hydraulic safety devices shall be designed and installed to achieve a safety level comparable to the requirements for electrical safety devices specified above. 5.2.2.1.3 Mechanical safety devices Mechanical safety devices shall be designed and installed to achieve a safety level comparable to the requirements for electrical safety devices specified above. 5.2.2.2 Transmission elements used for safety purposes Transmission elements, e.g. safety related wiring, pipework, rods, safety ropes, chains, shall be designed so that failure shall not lead to a dangerous condition. In the event of failure or rupture, a category "0" or category "1" stop function shall be automatically initiated, as appropriate to be compatible with the design (see EN 60204-1:1997, 9.2.2). The stop function shall comply with EN 954-1:1996, 5.2. Mechanical components shall have factors of safety of at least 4 to 1 in relation to maximum intended loading, without permanent deformation or failure. All flexible piping, flexible hoses and also any rigid pipework or connections used as transmission elements for safety purposes, shall be designed to withstand at least 4 x maximum working pressure without failure or permanent deformation. SIST EN 14010:2004+A1:2010

ii) compression springs shall have both ends guided ; or

iii) compression springs shall be selected such that the wire diameter is greater than the distance between the coils, hence preventing coils from winding into each other in the event of breakage. 5.2.2.3.2 Full flow solenoid directional valves shall not be used alone for safety purposes. 5.2.3 Control devices 5.2.3.1 General The purpose/function of all control devices shall be clearly and indelibly marked by using symbols (see EN 894-2, ISO 3864 and ISO 7000), or the purpose/function shall be given in the languages of the country of use. Where intended for public use the purpose/function shall be given at least in the languages of the country of use. The way in which control devices are actuated and their relative position shall be logical and where practicable shall correspond to the resulting movement. 5.2.3.1.1 In the case of non-automatic parking equipment, control devices shall be of the hold-to-run type and shall be clearly and indelibly marked with the parking unit to which they belong.

5.2.3.1.2 "Hold-to-run" control devices on non-automatic parking equipment shall be located where the user or parking equipment attendant has an unrestricted view (direct or indirect view e.g. using viewing aids) of the area where the load carrier moves. All control devices and viewing aids shall be located on the control station. 5.2.3.1.3 In the case of non-automatic parking equipment, each parking unit shall be controlled separately. 5.2.3.1.4 For automatic parking equipment the control devices in general shall be out of reach of the users. Only the control devices needed for the use of the parking equipment shall be in reach of the user. SIST EN 14010:2004+A1:2010

Stop control devices shall be provided at all control stations and shall be clearly identifiable and visible. Stop actuators shall have positive operation and shall have a projecting headed operator. In the case of non-automatic parking equipment under the permanent control of the user a hold to run control device may be used for the stop function. Being in the released position shall actuate the stop function. When a “hold to run” control device is released, a category "0" or category "1" stop function shall be automatically initiated, as appropriate to be compatible with the design (see EN 60204-1:1997, 9.2.2) irrespective of the movement. 5.2.3.4 Emergency stop function The emergency stop function shall be in accordance with EN 418 and shall be a category "0" stop (see

EN 418:1992, 4.1.5). NOTE The provision of an emergency stop device is not an alternative to the installation of suitable guarding, see

EN 418:1992, 4.1.3. 5.2.3.4.1 When an emergency stop control device has been actuated, powered motion shall come to a halt. The parking equipment shall then remain in a stationary condition until the device has been reset and the start control device has subsequently been actuated. 5.2.3.4.2 In the case of non-automatic parking equipment; as an alternative to an emergency stop control at each control station, in accordance with EN 60204-1:1997, 10.7.5, a supply disconnecting device may be used if all the following preconditions are satisfied: it is readily accessible to the user, i.e. the distance from the supply disconnecting device to any related control station is not more than 20 m;

it is positioned at a height between 1,6 m to 1,9 m; it is of the type described in EN

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...