EN 15442:2011

(Main)Solid recovered fuels - Methods for sampling

Solid recovered fuels - Methods for sampling

This European Standard specifies methods for taking samples of solid recovered fuels for example from production plants, from deliveries or from stock. It includes manual and mechanical methods.

It is not applicable to solid recovered fuels that are formed by liquid or sludge, but it includes dewatered sludge.

Feste Sekundärbrennstoffe - Verfahren zur Probenahme

Diese Europäische Norm legt Verfahren zur Entnahme von Proben von festen Sekundärbrennstoffen, z. B. aus Produktionsanlagen, Lieferungen oder Lagervorräten, fest. Eingeschlossen sind sowohl manuelle als auch mechanische Verfahren.

Diese Europäische Norm gilt nicht für feste Sekundärbrennstoffe, die durch Flüssigkeiten oder Schlamm gebildet werden, sie gilt jedoch für entwässerten Schlamm.

Combustibles solides de récupération - Méthodes d'échantillonnage

La présente Norme décrit les méthodes d’échantillonnage d’échantillons de combustibles solides de récupération issus par exemple de sites de production, de livraisons ou de stocks. Elle comprend des méthodes manuelles et mécaniques.

Elle n’est pas applicable aux combustibles solides de récupération qui sont formés par des liquides ou des boues mais elle comprend des boues asséchées.

Trdna alternativna goriva - Metode za vzorčenje

Ta evropski standard določa metode za jemanje vzorcev trdnih alternativnih goriv, na primer iz proizvodnih obratov, iz pošiljk in iz zalog. Vključuje ročne in mehanske metode.

Ne velja za trdna alternativna goriva, ki nastanejo iz tekočine ali blata, vključuje pa blato, iz katerega je bila voda odstranjena.

General Information

- Status

- Withdrawn

- Publication Date

- 08-Mar-2011

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 343 - Solid Recovered Fuels

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Apr-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 05-Dec-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TS 15405:2010 - Solid recovered fuels - Determination of density of pellets and briquettes - Effective Date

- 28-Jan-2026

- Referred By

EN 15443:2011 - Solid recovered fuels - Methods for the preparation of the laboratory sample - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 15442:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Solid recovered fuels - Methods for sampling". This standard covers: This European Standard specifies methods for taking samples of solid recovered fuels for example from production plants, from deliveries or from stock. It includes manual and mechanical methods. It is not applicable to solid recovered fuels that are formed by liquid or sludge, but it includes dewatered sludge.

This European Standard specifies methods for taking samples of solid recovered fuels for example from production plants, from deliveries or from stock. It includes manual and mechanical methods. It is not applicable to solid recovered fuels that are formed by liquid or sludge, but it includes dewatered sludge.

EN 15442:2011 is classified under the following ICS (International Classification for Standards) categories: 01.110 - Technical product documentation; 35.240.30 - IT applications in information, documentation and publishing; 49.020 - Aircraft and space vehicles in general; 75.160.10 - Solid fuels; 75.160.40 - Biofuels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15442:2011 has the following relationships with other standards: It is inter standard links to CEN/TS 15442:2006, EN ISO 21645:2021, CEN/TS 15401:2010, EN 15357:2011, EN ISO 21646:2022, EN 15415-1:2011, CEN/TS 15405:2010, EN 15443:2011, EN ISO 10651-5:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15442:2011 is associated with the following European legislation: Standardization Mandates: M/325. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15442:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Feste Sekundärbrennstoffe - Verfahren zur ProbenahmeCombustibles solides de récupération - Méthodes d'échantillonnageSolid recovered fuels - Methods for sampling75.160.10Trda gorivaSolid fuelsICS:Ta slovenski standard je istoveten z:EN 15442:2011SIST EN 15442:2011en,de01-maj-2011SIST EN 15442:2011SLOVENSKI

STANDARDSIST-TS CEN/TS 15442:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15442

March 2011 ICS 75.160.10 Supersedes CEN/TS 15442:2006English Version

Solid recovered fuels - Methods for sampling

Combustibles solides de récupération - Méthodes d'échantillonnage

Feste Sekundärbrennstoffe - Verfahren zur Probenahme This European Standard was approved by CEN on 22 January 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15442:2011: ESIST EN 15442:2011

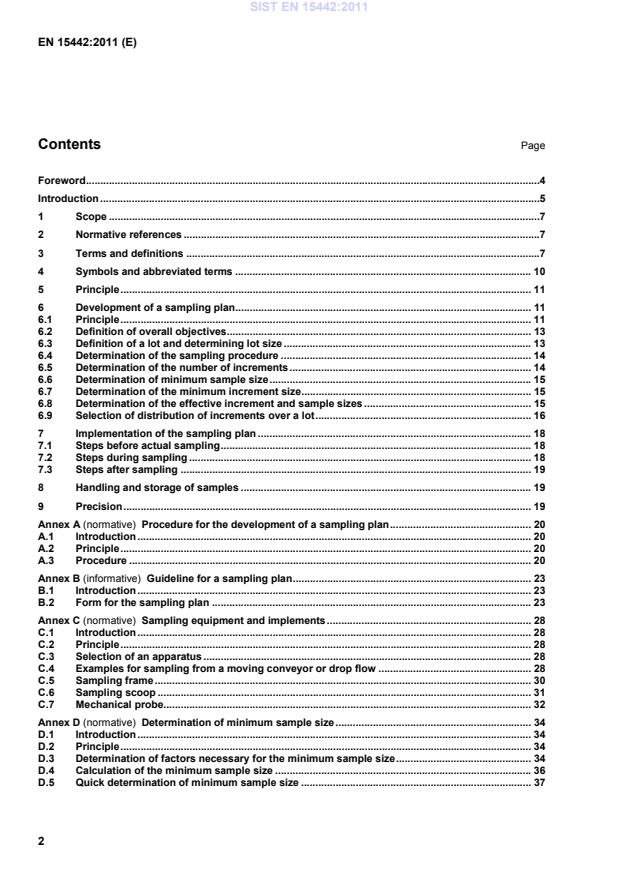

Procedure for the development of a sampling plan . 20A.1Introduction . 20A.2Principle . 20A.3Procedure . 20Annex B (informative)

Guideline for a sampling plan . 23B.1Introduction . 23B.2Form for the sampling plan . 23Annex C (normative)

Sampling equipment and implements . 28C.1Introduction . 28C.2Principle . 28C.3Selection of an apparatus . 28C.4Examples for sampling from a moving conveyor or drop flow . 28C.5Sampling frame . 30C.6Sampling scoop . 31C.7Mechanical probe. 32Annex D (normative)

Determination of minimum sample size . 34D.1Introduction . 34D.2Principle . 34D.3Determination of factors necessary for the minimum sample size . 34D.4Calculation of the minimum sample size . 36D.5Quick determination of minimum sample size . 37SIST EN 15442:2011

Determination of minimum increment size for sampling from material flows . 39E.1Introduction . 39E.2Principle. 39E.3Determination of minimum increment size for mechanical sampling from a drop flow . 39E.4Determination of minimum increment size for manual sampling from a drop flow . 40E.5Determination of minimum increment size for sampling from a conveyor . 41Annex F (normative)

Determination of minimum increment size for sampling from static lots or vehicles. 43F.1Introduction . 43F.2Principle. 43F.3Procedure . 43Annex G (normative)

Implementation of sampling plan from a material flow . 44G.1Introduction . 44G.2Principle. 44G.3Procedure verification of sampling aspects . 44G.4Procedure: Mechanical or manual sampling from the drop flow . 44G.5Procedure: Mechanical sampling from a moving conveyor . 46G.6Procedure: Manual sampling from a stationary conveyor . 47Annex H (normative)

Implementation of the sampling plan from a static lot or vehicle . 49H.1Introduction . 49H.2Principle. 49H.3Procedure . 49H.4Implementation of sampling in locations chosen in a stratified random way . 50Annex I (normative)

Minimum sample size required for analysis. 51I.1Introduction . 51I.2Principle. 51I.3Procedure . 51Annex J (normative)

Standard sampling plans for common situations . 56J.1Introduction . 56J.2Sampling of granular SRF <25 mm from a moving conveyor . 56J.3Sampling of granular SRF <25 mm from a static lot . 59J.4Sampling of granular SRF <25 mm from a vehicle . 62Annex K (informative)

Additional information about precision . 66K.1Introduction . 66K.2Scope . 66K.3Trueness . 66K.4Repeatability and reproducibility . 66K.5Robustness . 67Annex L (informative)

Distribution of increments . 69L.1Scope . 69L.2Stratified sampling . 69L.3Stratified random sampling . 70Bibliography . 72 SIST EN 15442:2011

1) To be published. SIST EN 15442:2011

Figure 1 — Links between the essential elements of a testing program SIST EN 15442:2011

Adapted from Eurachem/Citac Guide CG 4 [26]. 3.2 duplicate sample two samples taken under comparable conditions, whereby this selection can be accomplished by taking units adjacent in time or space NOTE 1

Although the replicate samples are expected to be identical, often the only thing replicated is the act of taking the physical sample. NOTE 2

A duplicate sample is a replicate sample consisting of two portions. NOTE 3

The replicate sample is usually used to estimate sample variability. 3.3 effective increment size minimum sample size divided by the number of increments

2) To be published. SIST EN 15442:2011

precision under repeatability conditions NOTE 1

Adapted from ISO 3534-2:2006. NOTE 2

Repeatability can be expressed quantitatively in terms of the dispersion characteristics of the results. 3.16 reproducibility precision under reproducibility conditions NOTE 1

Adapted from ISO 3534-2:2006. NOTE 2

Reproducibility can be expressed quantitatively in terms of the dispersion characteristics of the results. NOTE 3

Results are usually understood to be corrected results. 3.17 sample quantity of material, representative of a larger quantity for which the quality is to be determined 3.18 sample preparation actions taken to obtain representative analysis samples or test portions from the original sample 3.19 sampling process of drawing or constituting a sample NOTE Adapted from ISO 3534-1:2006 [22]. 3.20 sampling plan predetermined procedure for the selection, withdrawal, preservation, transportation and preparation of the portions to be removed from a lot as a sample

NOTE Adapted from ISO 11074:2005 [23]. 3.21 sampling record report which serves as a check list and provides the investigator with all necessary information about the sampling techniques applied at the site and any additional important information NOTE Adapted from ISO 11074:2005. SIST EN 15442:2011

Adapted from ISO 3534-2:2006. NOTE 2

The measure of trueness is usually expressed in terms of bias. NOTE 3

Trueness is sometimes referred to as “accuracy of the mean”. This usage is not recommended. NOTE 4

In practice, the accepted reference value is substituted for the true value. NOTE 5

The determination of the exact trueness for waste and from waste derived materials such as solid recovered fuels is by definition not possible. 4 Symbols and abbreviated terms For the purposes of this document, the following symbols and abbreviated terms apply. b

is the breadth of the flow, in m cv

is the coefficient of variation d05

is the nominal minimum size (a mass fraction of 5 % of the particles are smaller than d05), in mm d95

is the nominal top size of a particle (a mass fraction of 95 % of the particles are smaller than d95), in mm g

is the correction factor for distribution in the particle size G

is the conveyor load, in kg/m λb

is the bulk density of the solid recovered fuel, in kg/m3 λp

is the particle density, in kg/m3 SIST EN 15442:2011

is mass, in kg n

is the number of increments to be taken per lot p is the fraction of the particles with a specific characteristic (such as a specific contaminant), in kg/kg, and is equal to 0,1 f

is the bulk density of the flow, in kg/m3 d

is the drop flow, in kg/s

f

is the shape factor, in m3/m3

V

is volume, in m3 v

is conveyor velocity, in m/s 5 Principle Every particle in the lot or sub-lot to be represented by the sample should have an equal probability of being included in the sample. When this principle cannot be applied in practice, the sampler shall note the limitations in the sampling plan. 6 Development of a sampling plan 6.1 Principle From a pre-defined lot of solid recovered fuel, samples shall be taken representatively on the basis of a sampling plan that shall be drawn up before the sampling takes place. Annex A specifies how this sampling plan shall be made. Annex J specifies simplified sampling plans for three common situations according to this clause and Annex A. Figure 2 determines whether a simplified sampling plan can be used.

Figure 2 — Check for the standard sampling plan The sampling plan shall be drawn up on the basis of the objective for the sampling process, using the available data on a solid recovered fuel and the accessibility of the lot, see Annex B. The sampling plan shall be completed. If certain estimates concerning specific parameters relating to the lot cannot be determined with sufficient certainty on the basis of the information available, these shall be verified in the field. If necessary, the sampling plan shall be adjusted in the field and the deviations shall be reported in the sampling record. Figure 3 shows the actions that are necessary for the development of a sampling plan. SIST EN 15442:2011

Figure 3 — Necessary elements for the development of a sampling plan 6.2 Definition of overall objectives The sampling plan shall specify the objectives of the sampling program through consultation with all involved parties. These involved parties are e.g. the client, the producer of the solid recovered fuel, the sampler. The sampling plan shall specify the primary objectives of the sampling program. The sampling plan shall meet the requirements of objectives. If it is not possible to meet all requirements following the objectives for sampling in one single document sampling plan, two or more sampling plans shall be made in order to achieve adequate sampling plans for all objectives. The sampling plan(s) shall identify any special precautions to be followed where the solid recovered fuel to be sampled is hazardous to human health. 6.3 Definition of a lot and determining lot size 6.3.1 General The lot shall be defined on the basis of the way in which the material is or has been produced and/or is offered (upon delivery, upon acceptance, upon storage or in store, for instance). The lot size relates to a quantity of material delivered on the basis of one specification and production process. This material is agreed on by contract as a unit, and is identifiable as such. The maximum weight of a lot or sub-lot, for sampling purposes, shall be no more than 1,5 × 106 kg. SIST EN 15442:2011

NOTE 1 If for example 2 increments should be taken from each of the lorry, it would be very useful to take one increment at the beginning of unloading of the lorry (short stop during loading) and the second increment at the middle/end of unloading the lorry in accordance with the system for sampling from a material flow (6.9.2) or static lot (6.9.4). NOTE 2 If the dimensions of a lot are such that the number of vehicles used to transport the lot is equal to or less than the (minimum) number of required increments, at least two (or more when necessary) increments should be taken per vehicle. 6.9.4 Implementation of sampling from a static lot Implementation of sampling from a static lot or store requires the following approach: a) determine the dimensions of the lot or store; b) divide the lot or store into as many strata of equal dimensions as the number of increments to be taken; c) for each stratum, determine in a (preferably) random way the location where the increments will be taken; d) for each location, take the increments from the top, middle and bottom of the material alternately. The sampling shall be implemented by performing the complete sampling plan. SIST EN 15442:2011

not take a new one if he thinks the increment is not representative. This will influence the representativeness of the sample. In every case the upper surface of the material to be sampled shall always be removed to avoid material that has dried and/or become contaminated; c) if during the performance of the sampling anything is performed deviating from the sampling plan this shall be mentioned in the sampling report in the section for deviations. The deviations shall be sufficiently motivated. SIST EN 15442:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...