ASTM D7869-17

(Practice)Standard Practice for Xenon Arc Exposure Test with Enhanced Light and Water Exposure for Transportation Coatings

Standard Practice for Xenon Arc Exposure Test with Enhanced Light and Water Exposure for Transportation Coatings

SIGNIFICANCE AND USE

5.1 This test procedure is used to simulate the physical and environmental stresses that a coating for exterior transportation applications (for example, automotive) is exposed to in a subtropical climate, such as southern Florida. It has been found that such a subtropical climate causes particularly severe deterioration of such coatings. The long water exposures and wet/dry cycling found in southern Florida are particularly important for this deterioration, in addition to the high dosage of solar radiation (3). This practice was developed to address the deficiencies of historical tests used for transportation coatings, especially automotive coatings (4).

Note 1: This test procedure was developed through eight years of cooperative testing between automotive and aerospace OEM’s, material suppliers, and test equipment manufacturers. See References for published papers on this research.

SCOPE

1.1 This practice specifies the operating procedures for a controlled irradiance xenon arc light and water apparatus. The procedure uses one or more lamp(s) and optical filter(s) to produce irradiance similar to sunlight in the UV and visible range. It also simulates the water absorption and stress cycles experienced by automotive exterior coatings under natural weathering conditions. This practice has also been found applicable to coatings on other transportation vehicles, such as aircraft, trucks and rail cars.

1.2 This practice uses a xenon arc light source with specified optical filter(s). The spectral power distribution (SPD) for the lamp and special daylight filter(s) is as specified in Annex A1. The irradiance level used in this practice varies between 0.40 and 0.80 W/(m2·nm) at 340 nm. Water is sprayed on the specimens during portions of several dark steps. The application of water is such that the coatings will absorb and desorb substantial amounts of water during testing. In addition, the cycling between wet/dry and warm/cool will induce mechanical stresses into the materials. These test conditions are designed to simulate the physical and chemical stresses from environments in a subtropical climate, such as southern Florida.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7869 − 17

Standard Practice for

Xenon Arc Exposure Test with Enhanced Light and Water

1

Exposure for Transportation Coatings

This standard is issued under the fixed designation D7869; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice specifies the operating procedures for a

controlled irradiance xenon arc light and water apparatus. The D4517 Test Method for Low-Level Total Silica in High-

Purity Water by Flameless Atomic Absorption Spectros-

procedure uses one or more lamp(s) and optical filter(s) to

produce irradiance similar to sunlight in the UV and visible copy

G113 Terminology Relating to Natural andArtificial Weath-

range. It also simulates the water absorption and stress cycles

experienced by automotive exterior coatings under natural ering Tests of Nonmetallic Materials

G147 Practice for Conditioning and Handling of Nonmetal-

weathering conditions. This practice has also been found

applicable to coatings on other transportation vehicles, such as lic Materials for Natural and Artificial Weathering Tests

G151 Practice for Exposing Nonmetallic Materials inAccel-

aircraft, trucks and rail cars.

erated Test Devices that Use Laboratory Light Sources

1.2 This practice uses a xenon arc light source with speci-

G155 Practice for Operating XenonArc LightApparatus for

fied optical filter(s). The spectral power distribution (SPD) for

Exposure of Non-Metallic Materials

the lamp and special daylight filter(s) is as specified in Annex

A1. The irradiance level used in this practice varies between

3. Terminology

2

0.40 and 0.80 W/(m ·nm) at 340 nm. Water is sprayed on the

3.1 Definitions applicable to this standard can be found in

specimens during portions of several dark steps. The applica-

Terminology G113.

tion of water is such that the coatings will absorb and desorb

substantial amounts of water during testing. In addition, the 3.2 transportation coatings, n—exterior coatings used for

cycling between wet/dry and warm/cool will induce mechani-

vehicles subjected to natural weathering conditions such as

cal stresses into the materials. These test conditions are automobiles, aircraft, trucks, rail cars, etc.

designed to simulate the physical and chemical stresses from

4. Summary of Practice

environments in a subtropical climate, such as southern

Florida.

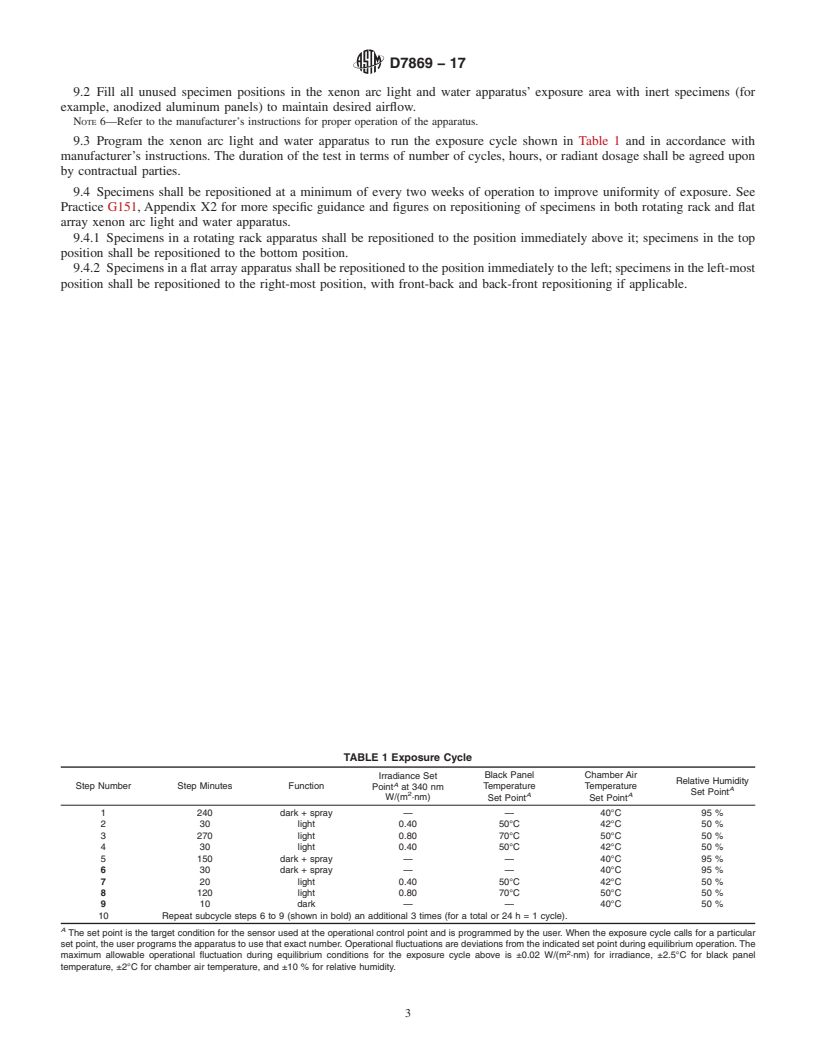

4.1 Test specimens are exposed to specific test conditions

designed to simulate the physical and chemical stresses from

1.3 The values stated in SI units are to be regarded as

environments in a subtropical climate, such as southern

standard. No other units of measurement are included in this

Florida. The test conditions consist of a primary test cycle and

standard.

a sub-cycle. The primary test cycle includes two long water

1.4 This standard does not purport to address all of the

exposures and a single, long light exposure with precise

safety concerns, if any, associated with its use. It is the

spectral match to daylight as described in Annex A1.Itis

responsibility of the user of this standard to establish appro-

designed to reproduce water penetration failures, such as

priate safety and health practices and determine the applica-

3

adhesion, blistering and diffusion of small molecules (1). The

bility of regulatory limitations prior to use.

sub-cycle consisting of shorter alternating water and light

1 2

This practice is under the jurisdiction of ASTM Committee D01 on Paint and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Related Coatings, Materials, and Applications and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D01.27 on Accelerated Testing. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2017. Published March 2017. Originally the ASTM website.

3

approved in 2013. Last previous edition approved in 2013 as D7869 – 13.DOI: The boldface numbers in parentheses refer to the list of references at the end of

10.1520/D7869-17. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7869 − 17

exposures is designed to simulate cyclic stresses such as and at least once per year thereafter. Follow the recommenda-

cracking and surface erosion

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7869 − 13 D7869 − 17

Standard Practice for

Xenon Arc Exposure Test with Enhanced Light and Water

1

Exposure for Transportation Coatings

This standard is issued under the fixed designation D7869; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice specifies the operating procedures for a controlled irradiance xenon arc light and water apparatus. The

procedure uses one or more lamp(s) and optical filter(s) to produce irradiance similar to sunlight in the UV and visible range. It

also simulates the water absorption and stress cycles experienced by automotive exterior coatings under natural weathering

conditions. This practice has also been found applicable to coatings on other transportation vehicles, such as aircraft, trucks and

rail cars.

1.2 This practice uses a xenon arc light source with specified optical filter(s). The spectral power distribution (SPD) for the lamp

and special daylight filter(s) is as specified in Annex A1. The irradiance level used in this practice varies between 0.40 and 0.80

2

W/(m ·nm) at 340 nm. Water is sprayed on the specimens during portions of several dark steps. The application of water is such

that the coatings will absorb and desorb substantial amounts of water during testing. In addition, the cycling between wet/dry and

warm/cool will induce mechanical stresses into the materials. These test conditions are designed to simulate the physical and

chemical stresses from environments in a subtropical climate, such as southern Florida.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4517 Test Method for Low-Level Total Silica in High-Purity Water by Flameless Atomic Absorption Spectroscopy

G113 Terminology Relating to Natural and Artificial Weathering Tests of Nonmetallic Materials

G147 Practice for Conditioning and Handling of Nonmetallic Materials for Natural and Artificial Weathering Tests

G151 Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources

G155 Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

3. Terminology

3.1 Definitions applicable to this standard can be found in Terminology G113.

3.2 transportation coatings, n—exterior coatings used for vehicles subjected to natural weathering conditions such as

automobiles, aircraft, trucks, rail cars, etc.

4. Summary of Practice

4.1 Test specimens are exposed to specific test conditions designed to simulate the physical and chemical stresses from

environments in a subtropical climate, such as southern Florida. The test conditions consist of a primary test cycle and a sub-cycle.

The primary test cycle includes two long water exposures and a single, long light exposure with precise spectral match to daylight

as described in Annex A1. It is designed to reproduce water penetration failures, such as adhesion, blistering and diffusion of small

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.27 on Accelerated Testing.

Current edition approved June 1, 2013Feb. 1, 2017. Published June 2013March 2017. DOI: 10.1520/D7869-13.Originally approved in 2013. Last previous edition approved

in 2013 as D7869 – 13.DOI: 10.1520/D7869-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7869 − 17

3

molecules (1). The sub-cycle consisting of shorter alternating water and light exposures is designed to simulate cyclic stresses

such as cracking and sur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.