SIST EN 1434-1:2022

(Main)Thermal energy meters - Part 1: General requirements

Thermal energy meters - Part 1: General requirements

This document is applicable for the general requirements for thermal energy meters. Thermal energy meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter indicates the quantity of thermal energy in legal units.

This document covers meters for closed systems only, where the differential pressure over the thermal load is limited.

This document is not applicable to:

- electrical safety requirements;

- pressure safety requirements; and

- surface mounted temperature sensors.

Thermische Energiemessgeräte - Teil 1: Allgemeine Anforderungen

Dieses Dokument ist auf die allgemeinen Anforderungen für thermische Energiemessgeräte anwendbar. Thermische Energiemessgeräte sind Geräte zum Messen der Energiemenge, die in einem Wärmeübertragerkreislauf von einer Flüssigkeit, der sogenannten Wärmeträgerflüssigkeit, absorbiert (Kühlung) oder abgegeben (Heizung) wird. Das thermische Energiemessgerät zeigt die Menge der thermischen Energie in gesetzlichen Einheiten an.

Dieses Dokument ist lediglich auf Messgeräte für geschlossene Systeme anwendbar, bei denen der Differenzdruck über die thermische Last begrenzt ist.

Dieses Dokument ist nicht anwendbar für:

— Anforderungen an die elektrische Sicherheit;

— Anforderungen an die Drucksicherheit;

— oberflächenmontierte Temperaturfühler.

Compteurs d'énergie thermique - Partie 1 : Prescriptions générales

Le présent document est applicable aux prescriptions générales relatives aux compteurs d’énergie thermique. Les compteurs d’énergie thermique sont des instruments destinés à mesurer l’énergie thermique qui, dans un circuit d’échange thermique, est absorbée (refroidissement) ou cédée (chauffage) par un liquide appelé « liquide caloporteur ». Le compteur d’énergie thermique fournit la quantité d’énergie thermique en unités de mesure légales.

Le présent document couvre les compteurs pour les systèmes fermés uniquement, où la pression différentielle dans la charge thermique est limitée.

Le présent document ne s’applique pas :

- aux prescriptions de sécurité électrique ;

- aux prescriptions de sécurité relatives à la pression ; ni

- aux sondes de température montées en surface.

Merilniki toplote - 1. del: Splošne zahteve

Ta dokument določa splošne zahteve za merilnike toplote. Merilniki toplote so instrumenti, namenjeni merjenju energije, ki jo v krogotoku toplotne izmenjave absorbira (hlajenje) ali oddaja (ogrevanje) tekočina, imenovana tekočina za prenos toplote. Merilnik toplote podaja količino toplote v predpisanih enotah.

Ta dokument ne zajema zahtev za električno varnost.

Ta dokument ne zajema tlačnih varnostnih zahtev.

Ta dokument ne zajema površinsko nameščenih senzorjev temperature.

Ta dokument zajema samo števce za zaprte sisteme, pri katerih je diferencialni tlak nad toplotno obremenitvijo omejen.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Nov-2020

- Publication Date

- 18-Sep-2022

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 14-Sep-2022

- Due Date

- 19-Nov-2022

- Completion Date

- 19-Sep-2022

Relations

- Effective Date

- 14-Sep-2022

- Effective Date

- 01-Nov-2020

Overview

EN 1434-1:2022 - published by CEN - defines the general requirements for thermal energy meters used to measure thermal energy transferred by a liquid (the heat‑conveying liquid) in closed heat‑exchange circuits. The standard applies to meters that indicate thermal energy in legal units and covers combined and modular meter designs for closed systems with limited differential pressure over the thermal load. It supersedes EN 1434-1:2015+A1:2018 and is the Part 1 document of the EN 1434 series (constructional requirements, pattern approval, verification, installation and maintenance are covered in other parts).

Key topics and technical requirements

EN 1434-1:2022 addresses fundamental elements and definitions that underpin safe, accurate and compliant thermal energy measurement:

- Types of instruments: definitions for complete, combined and hybrid meters and their sub‑assemblies (flow sensor, temperature sensor pair, calculator).

- Rated operating conditions: required specification of temperature ranges, temperature differences, flow rates, thermal power and working/nominal pressures.

- Technical characteristics: materials, construction, displays, fraud protection, supply voltage, reproducibility, repeatability and software considerations.

- Metrological characteristics (MPE): framework for maximum permissible errors and how they apply to complete meters and sub‑assemblies.

- Specified working range: declared temperature difference and flow rate ranges for accurate operation.

- Environmental and mechanical classification: classes for domestic/industrial use and mechanical stress levels.

- Manufacturer information requirements: installation, parameter setting, adjustment, maintenance and expanded end‑of‑life recycling/disposal instructions.

- Normative annexes: heat coefficient formulae (water and other liquids), flow conditioner package and fast response meter guidance.

- Exclusions: the document does not cover electrical safety, pressure safety or surface‑mounted temperature sensors.

Applications and who uses it

EN 1434-1:2022 is essential for:

- Meter manufacturers designing or certifying thermal energy meters for closed systems.

- Test laboratories and pattern approval bodies conducting type tests and verification per EN 1434 series.

- District heating/cooling utilities and building services engineers specifying meters for billing, energy management and performance monitoring.

- Installers and maintenance teams who require installation, calibration and lifecycle guidance.

- Regulators and procurement teams needing compliance evidence with EU directives (see Annex ZA).

Related standards

- EN 1434-2:2022 (Constructional requirements)

- EN 1434-4:2022 (Pattern approval tests)

- EN 1434-5/6 and additional parts (verification, installation and maintenance)

- Relevant references: EN 60751 (PT100 platinum RTDs), EN 61010-1 (electrical equipment safety - referenced)

This standard provides the baseline metrological and informational requirements necessary for reliable, interoperable thermal energy measurement across Europe and supports compliant product design, testing and procurement.

Frequently Asked Questions

SIST EN 1434-1:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermal energy meters - Part 1: General requirements". This standard covers: This document is applicable for the general requirements for thermal energy meters. Thermal energy meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter indicates the quantity of thermal energy in legal units. This document covers meters for closed systems only, where the differential pressure over the thermal load is limited. This document is not applicable to: - electrical safety requirements; - pressure safety requirements; and - surface mounted temperature sensors.

This document is applicable for the general requirements for thermal energy meters. Thermal energy meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter indicates the quantity of thermal energy in legal units. This document covers meters for closed systems only, where the differential pressure over the thermal load is limited. This document is not applicable to: - electrical safety requirements; - pressure safety requirements; and - surface mounted temperature sensors.

SIST EN 1434-1:2022 is classified under the following ICS (International Classification for Standards) categories: 17.200.20 - Temperature-measuring instruments. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1434-1:2022 has the following relationships with other standards: It is inter standard links to SIST EN 1434-1:2016+A1:2019, SIST EN 1434-1:2016+A1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1434-1:2022 is associated with the following European legislation: EU Directives/Regulations: 2014/32/EU; Standardization Mandates: M/541. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1434-1:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2022

Nadomešča:

SIST EN 1434-1:2016+A1:2019

Merilniki toplote - 1. del: Splošne zahteve

Thermal energy meters - Part 1: General requirements

Thermische Energiemessgeräte - Teil 1: Allgemeine Anforderungen

Compteurs d'énergie thermique - Partie 1 : Prescriptions générales

Ta slovenski standard je istoveten z: EN 1434-1:2022

ICS:

17.200.20 Instrumenti za merjenje Temperature-measuring

temperature instruments

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1434-1

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2022

EUROPÄISCHE NORM

ICS 17.200.20 Supersedes EN 1434-1:2015+A1:2018

English Version

Thermal energy meters - Part 1: General requirements

Compteurs d'énergie thermique - Partie 1 : Thermische Energiemessgeräte - Teil 1: Allgemeine

Prescriptions générales Anforderungen

This European Standard was approved by CEN on 17 July 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1434-1:2022 E

worldwide for CEN national Members.

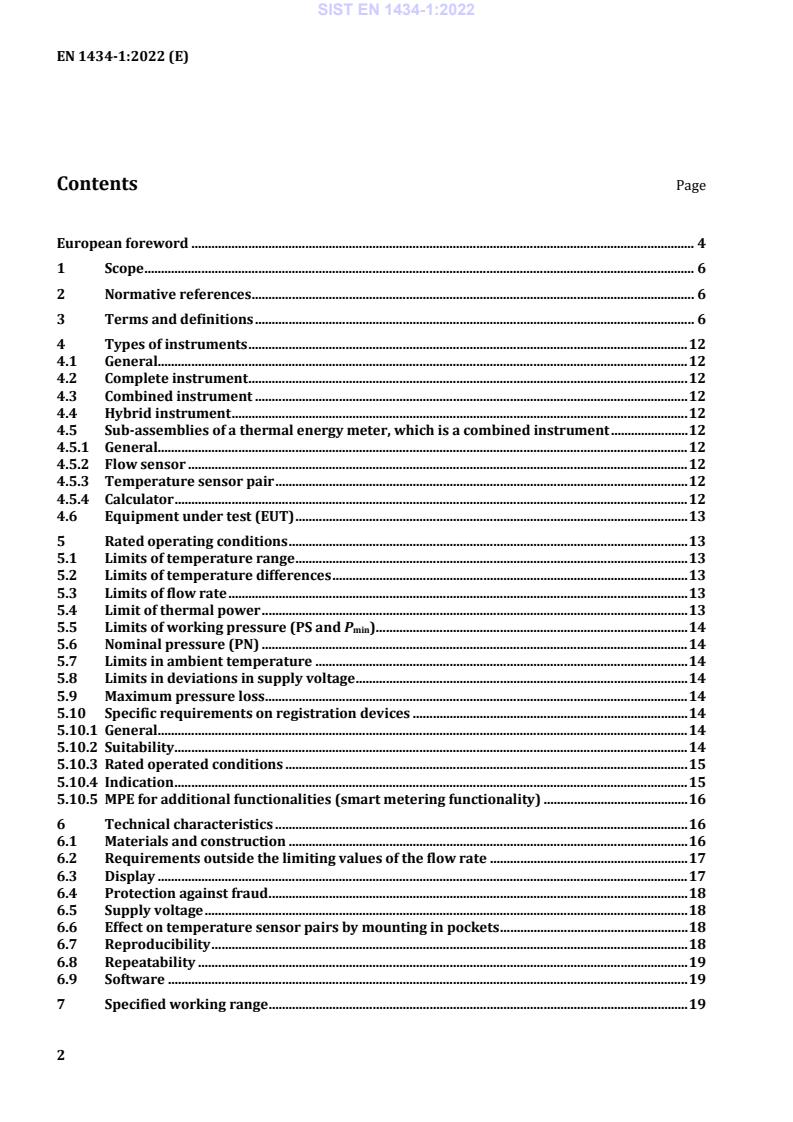

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Types of instruments . 12

4.1 General. 12

4.2 Complete instrument . 12

4.3 Combined instrument . 12

4.4 Hybrid instrument . 12

4.5 Sub-assemblies of a thermal energy meter, which is a combined instrument . 12

4.5.1 General. 12

4.5.2 Flow sensor . 12

4.5.3 Temperature sensor pair . 12

4.5.4 Calculator . 12

4.6 Equipment under test (EUT) . 13

5 Rated operating conditions . 13

5.1 Limits of temperature range . 13

5.2 Limits of temperature differences . 13

5.3 Limits of flow rate . 13

5.4 Limit of thermal power . 13

5.5 Limits of working pressure (PS and P ) . 14

min

5.6 Nominal pressure (PN) . 14

5.7 Limits in ambient temperature . 14

5.8 Limits in deviations in supply voltage . 14

5.9 Maximum pressure loss . 14

5.10 Specific requirements on registration devices . 14

5.10.1 General. 14

5.10.2 Suitability . 14

5.10.3 Rated operated conditions . 15

5.10.4 Indication . 15

5.10.5 MPE for additional functionalities (smart metering functionality) . 16

6 Technical characteristics . 16

6.1 Materials and construction . 16

6.2 Requirements outside the limiting values of the flow rate . 17

6.3 Display . 17

6.4 Protection against fraud . 18

6.5 Supply voltage . 18

6.6 Effect on temperature sensor pairs by mounting in pockets . 18

6.7 Reproducibility . 18

6.8 Repeatability . 19

6.9 Software . 19

7 Specified working range . 19

7.1 General . 19

7.2 Temperature difference . 19

7.3 Flow rate . 19

8 Heat transmission formula . 19

9 Metrological characteristics (Maximum Permissible Error, MPE) . 20

9.1 General . 20

9.2 Values of maximum permissible errors . 20

9.2.1 Maximum permissible relative errors of complete thermal energy meters. 20

9.2.2 Maximum permissible relative error of sub-assemblies . 21

9.3 Application of maximum permissible errors . 21

10 Environmental classification . 22

10.1 General . 22

10.2 Environmental class A (Domestic use, indoor installations) . 22

10.3 Environmental class B (Domestic use, outdoor installations) . 22

10.4 Environmental class C (Industrial installations) . 22

10.5 Mechanical classes M1 to M3 . 22

11 Thermal energy meter specification . 23

11.1 General . 23

11.2 Flow sensor . 23

11.3 Temperature sensor pair . 24

11.4 Calculator . 25

11.5 Complete meters . 26

12 Information to be made available by the manufacturer or supplier . 28

12.1 Installation instructions . 28

12.2 Parameter setting instructions. 29

12.3 Adjustment instructions . 30

12.4 Maintenance instructions . 30

12.5 Information required when a thermal energy meter is taken out of service for

recycling and/or disposal . 31

12.5.1 General . 31

12.5.2 Disassembly . 31

12.5.3 Recycling . 31

12.5.4 Disposal . 31

Annex A (normative) Heat coefficient formulae . 32

A.1 Water . 32

A.2 Heat-conveying liquids other than water . 34

Annex B (normative) Flow conditioner package . 35

Annex C (normative) Fast response meters . 37

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2014/32/EU aimed to be covered . 38

Bibliography . 42

European foreword

This document (EN 1434-1:2022) has been prepared by Technical Committee CEN/TC 176 “Thermal

energy meters”, the secretariat of which is held by SIS.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2023, and conflicting national standards shall

be withdrawn at the latest by March 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1434-1:2015+A1:2018.

EN 1434, Thermal energy meters, consists of the following parts:

— Part 1: General requirements;

— Part 2: Constructional requirements;

— Part 3: Data exchange and interfaces ;

— Part 4: Pattern approval tests;

— Part 5: Initial verification tests;

— Part 6: Installation, commissioning, operational monitoring and maintenance.

In comparison with EN 1434-1:2015+A1:2018, the following changes have been made:

— the wording “flow straightener” has been changed to “flow conditioner” in the whole document;

— subclause 12.5 “Hints for disposal instructions” has been replaced by the enlarged, new

subclause 12.5 “Information required when a thermal energy meter is taken out of service for

recycling and/or disposal”.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral

part of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

EN 1434-3 is maintained by CEN/TC 294.

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

1 Scope

This document is applicable for the general requirements for thermal energy meters. Thermal energy

meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed

(cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter

indicates the quantity of thermal energy in legal units.

This document covers meters for closed systems only, where the differential pressure over the thermal

load is limited.

This document is not applicable to:

— electrical safety requirements;

— pressure safety requirements; and

— surface mounted temperature sensors.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1434-2:2022, Thermal energy meters — Part 2: Constructional requirements

EN 1434-4:2022, Thermal energy meters — Part 4: Pattern approval tests

EN 60751:2008, Industrial platinum resistance thermometers and platinum temperature sensors

(IEC 60751:2008)

EN 61010-1:2010, Safety requirements for electrical equipment for measurement, control and laboratory

use — Part 1: General requirements (IEC 61010-1:2010)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

response time

τ

0,5

time interval between the instant when flow or temperature difference is subjected to a specified

abrupt change and the instant when the response reaches 50 % of the step value

3.2

fast response meter

meter suitable for heat exchanging circuits with rapid dynamic variations in the exchanged heat

Note 1 to entry: See also Annex C.

Document is impacted by /A1:2019 and /A1:2019/AC:2019-04.

3.3

rated voltage

U

n

voltage of the external power supply required to operate the thermal energy meter, conventionally the

voltage of the AC mains supply

3.4

rated operating conditions

conditions of use, giving the range of values of influence quantities, for which the metrological

characteristics of the instrument are within the specified maximum permissible errors

3.5

reference conditions

set of specified values of influence factors, fixed to ensure valid inter-comparison of results of

measurements

3.6

influence quantity

quantity, which is not the subject of the measurement, but which influences the value of the

measurement and or the indication of the measuring instrument

3.7

influence factor

influence quantity having a value within the rated operating conditions

3.8

disturbance

influence quantity having a value outside the rated operating conditions

3.9

types of errors

3.9.1

error of indication

indication of the measuring instrument minus the conventional true value of the measurand

3.9.2

intrinsic error

error of a measuring instrument determined under reference conditions

3.9.3

initial intrinsic error

error of a measuring instrument as determined once prior to performance tests and durability tests

3.9.4

durability error

difference between the intrinsic error after a period of use and the initial intrinsic error

3.9.5

maximum permissible error

MPE

highest values of the error (positive or negative) permitted

3.10

types of faults

3.10.1

fault

difference between the error of indication and the intrinsic error of the instrument

3.10.2

transitory fault

momentary variations in the indication, which cannot be interpreted, memorized or transmitted as

measurements

3.10.3

significant fault

fault greater than the absolute value of the MPE and not being a transitory fault

Note 1 to entry: If the MPE is ± 2 % then the significant fault is a fault larger than ± 2 %.

3.11

reference values of the measurand

RVM

specified value of the flow rate, the outlet temperature and the temperature difference, fixed to ensure

valid intercomparison of the results of measurements

3.12

conventional true value

quantity value attributed by agreement to a quantity for a given purpose

Note 1 to entry: A conventional true value is, in general, regarded as sufficiently close to the true value for the

difference to be insignificant for the given purpose.

EXAMPLE A true value is the heat coefficient according to Annex A.

3.13

meter model

different sizes of thermal energy meters or sub-assemblies having a family similarity in the principles of

operation, construction and materials

3.14

electronic device

device employing electronic elements and performing a specific function

3.15

electronic element

smallest physical entity in an electronic device which uses electron hole conduction in semi-conductors,

or electron conduction in gases or in a vacuum

3.16

qualifying immersion depth of a temperature sensor

immersion depth over which the sensor measures with an accurate temperature value

Note 1 to entry: The conditions to define the qualified immersion depth are written in EN 1434-4:2022, 7.4.4.1.

3.17

self-heating effect

increase in temperature signal that is obtained by subjecting each temperature sensor of a pair to a

continuous power dissipation of 5 mW when immersed to the qualifying immersion depth in a water

bath, having a mean water velocity of 0,1 m/s

3.18

thermal energy meter

instrument intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or

given up (heating) by a liquid called the heat-conveying liquid

3.19

meters other than for heating

3.19.1

cooling meter

thermal energy meter designed for cooling applications at low temperatures, normally covering the

temperature range 2 °C to 30 °C and ΔΘ up to 20 K

3.19.2

bifunctional meters for change-over systems between heating and cooling

instrument measuring heating and cooling energy in two separate registers

Note 1 to entry: The functionality of the bifunctional meter is described in Figure 1 as an example.

Note 2 to entry: In other directives and requirements, bifunctional meters are called combined meters.

Key

No energy recording

Heating

Cooling

θInlet temperature of the inlet respectively outlet

θ switching temperature for heating/cooling (e.g. 25 °C)

hc

ΔΘ starting temperature difference of energy accumulation (e.g. 0,1 K)

hc

ΔΘmin minimum approved temperature difference (e.g. 3 K)

Figure 1 — Example for function of heating and cooling register

3.20

flow direction

direction of the liquid going through the system from inlet to outlet

Note 1 to entry: The inlet is for the heating case the hot side and for the cooling case the cold side.

Note 2 to entry: In the literature the word “flow” is also being used for “inlet”, and the word “return” is also being

used for “outlet”.

Note 3 to entry: Different temperature values for θ for heating and cooling applications may also occur.

hc

3.21

electrical pulse

electrical signal (voltage, current or change in resistance), that departs from an initial level for a limited

duration of time and ultimately returns to the original level

3.22

pulse output and input devices

3.22.1

pulse output device

functional part of flow sensor, calculator or auxiliary devices

EXAMPLE Remote displays or input devices of control systems.

3.22.2

pulse input device

functional part of flow sensor, calculator or auxiliary devices

EXAMPLE Pulse input for external water meter.

3.23

maximum admissible temperature

maximum temperature of the heat conveying liquid the meter can withstand in combination with the

maximum admissible working pressure and the permanent flow rate for short periods of time

(< 1 h/day; < 200 h/year) without a significant fault after the exposure to this maximum admissible

temperature

3.24

durability

characteristic of a measuring instrument to keep the metrological characteristics over time (e.g. to fulfil

the double of MPE), provided that it is properly installed, maintained and used within the permissible

environmental conditions

3.25

long life flow sensor

flow sensor designed to have a longer lifetime than a normal flow sensor, which typically has a

durability of 5 years under the specified operating conditions

3.26

user interface

interface forming part of the instrument that enables information to be passed between a human user

and the measuring instrument or its components (e.g. display)

3.27

communication interface

electronic, optical, radio or other technical interface that enables information via correct transceiving of

at least thermal energy to be passed between measuring instruments, sub-assemblies or external

devices

3.28

meter for smart metering

thermal energy meter with the capability of data communication and support of smart metering

functionalities

Note 1 to entry: Data could be transmitted via user interface and/ or communication interface in fixed time

intervals and/or on request.

Note 2 to entry: For more information on smart meters, see standard series EN 13757 and

CEN/CLC/ETSI TR 50572.

3.29

registration device

optional additional device fitted to the meter as an integral part or separate device, in order to register

the amount of thermal energy accumulated in additional registers during periods, depending on

conditions, e. g. flow rate, inlet or outlet temperatures, temperature differences or time points

3.30

register

component of a registration device which contains accumulated or actual values e. g. thermal energy,

volume, maximum flow rate, power or temperature

3.31

interval register

register which contains frequently accumulated or copied values used for registration of billing

purposes and/ or for controlling processes

Note 1 to entry: During consecutive time intervals values could be achieved by copying from an accumulating

main register which contains actual values of e.g. thermal energy or volume.

Note 2 to entry: During consecutive time intervals the measured process values of flow rate and/or temperature

could be additionally stored.

3.32

maximum flow

highest rate of flow which is expected at operating conditions

Note 1 to entry: For the limits of flow rates, see 5.3.

3.33

heat-conveying liquids other than water (mixed fluids, e.g. water glycol mixtures)

mixture of water with a defined proportion of another fluid e.g. mono-ethylene or propylene glycol

Note 1 to entry: Typical heat conveying liquids on the market consist of a base liquid (e.g. water with propylene

glycol) and additives to prevent corrosion or counteract chemical reactions like acid formation. The liquids often

differ in their constitution regarding their additives

Note 2 to entry: For many topics within this document the liquids can be classified in liquid categories according

to their base liquid (e.g. mono ethylene-based products, propylene glycol-based products, ethanol-based

products)

4 Types of instruments

4.1 General

For the purposes of this document, thermal energy meters are defined either as complete instruments

or as combined instruments.

4.2 Complete instrument

A thermal energy meter, which does not have separable sub-assemblies as defined in 4.5.

4.3 Combined instrument

A thermal energy meter, which has separable sub-assemblies as defined in 4.5.

4.4 Hybrid instrument

A thermal energy meter, which for the purpose of pattern approval and verification can be treated as a

combined instrument as defined in 4.3 or combinations between sub-assemblies. However, after

verification, its sub-assemblies shall be treated as inseparable.

NOTE Hybrid instruments are often called “compact instruments”.

4.5 Sub-assemblies of a thermal energy meter, which is a combined instrument

4.5.1 General

The flow sensor, the temperature sensor pair and the calculator or a combination of these.

4.5.2 Flow sensor

A sub-assembly through which the heat-conveying liquid flows, at either the inlet or outlet of a heat-

exchange circuit, and which emits a signal, which is a function of the volume or the mass or the

volumetric or mass flow rate.

4.5.3 Temperature sensor pair

A sub-assembly (for mounting with or without pockets), which senses the temperatures of the heat-

conveying liquid at the inlet and outlet of a heat-exchange circuit.

4.5.4 Calculator

A sub-assembly, which receives signals from the flow sensor, and the temperature sensors and

calculates and indicates the quantity of thermal energy exchanged.

4.6 Equipment under test (EUT)

A sub-assembly, a combined sub-assembly or a complete meter subject to a test.

5 Rated operating conditions

5.1 Limits of temperature range

5.1.1 The upper limit of the temperature range, θ , is the highest temperature of the heat conveying

max

liquid, at which the thermal energy meter shall function without the maximum permissible errors being

exceeded.

5.1.2 The lower limit of the temperature range, θ , is the lowest temperature of the heat-conveying

min

liquid, at which the thermal energy meter shall function without the maximum permissible errors being

exceeded.

5.1.3 The optional switching over temperature, θ , is for switching over between heating and cooling

hc

in bifunctional meters.

5.2 Limits of temperature differences

5.2.1 The temperature difference, ΔΘ, is the absolute value of the difference between the

temperatures of the heat-conveying liquid at the inlet and outlet of the heat-exchange circuit.

5.2.2 The upper limit of the temperature difference, ΔΘ , is the highest temperature difference, at

max

which the thermal energy meter shall function within the upper limit of thermal power, without the

maximum permissible errors being exceeded.

5.2.3 The lower limit of the temperature difference, ΔΘ , is the lowest temperature difference, above

min

which the thermal energy meter shall function, without the maximum permissible errors being

exceeded.

5.2.4 The value ΔΘ for switching over between heating and cooling energy and reversed is the

hc

threshold in bifunctional meters for change-over systems between heating and cooling.

5.3 Limits of flow rate

5.3.1 The upper limit of the flow rate, q , is the highest flow rate, at which the thermal energy meter

s

shall function for short periods (<1 h / day; < 200 h / year), without the maximum permissible errors

being exceeded.

5.3.2 The permanent flow rate, q , is the highest flow rate, at which the thermal energy meter shall

p

function continuously without the maximum permissible errors being exceeded.

5.3.3 The lower limit of the flow rate, q, is the lowest flow rate, above which the thermal energy

i

meter shall function without the maximum permissible errors being exceeded.

5.4 Limit of thermal power

The upper limit of the thermal power is the highest power at which the thermal energy meter shall

function without the maximum permissible errors being exceeded.

The lower limit of the thermal power is where the flow sensor is operating at its minimum limit, q ,

i

simultaneously when the temperature difference measured by the temperature sensor pair is at their

minimum limit, ΔΘ , and without the maximum permissible errors being exceeded.

min

5.5 Limits of working pressure (PS and Pmin)

PS is the maximum positive internal pressure that the thermal energy meter can withstand

permanently at the upper limit of the temperature range, expressed in bar. P is the lowest pressure

min

permitted in order to avoid deterioration of its metrological performance, e.g. cavitation.

NOTE P is depending on flow rate and temperature.

min

5.6 Nominal pressure (PN)

A numerical designation, which is a convenient rounded number for reference purposes.

All equipment of the same nominal size (DN) designated by the same PN number shall have compatible

mating dimensions.

5.7 Limits in ambient temperature

The ambient temperature range in which the thermal energy meter shall function without the

maximum permissible errors being exceeded.

5.8 Limits in deviations in supply voltage

The supply voltage range in which the thermal energy meter shall function without the maximum

permissible errors being exceeded.

5.9 Maximum pressure loss

The loss of pressure in the heat conveying liquid passing through the flow sensor, when the flow sensor

is operating at the permanent flow rate q .

p

5.10 Specific requirements on registration devices

5.10.1 General

A registration device is an additional functionality of smart meters outside of the requirements of the

Measuring Instruments Directive (MID). For a registration device, the essential requirements for meters

shall apply, if applicable. In addition, the requirements 5.10.2 to 5.10.5 shall apply.

5.10.2 Suitability

a) The registration device shall register energy in different registers activated by:

1) signals of an internal time switch;

2) signals of an internal quantity dependent threshold indication;

3) remote control signals at peripheral interface terminals; and/or

4) signal of a result or measurement or an internal register.

b) A registration device shall be designed to provide:

1) one or several non-resettable registers counting, e.g. the thermal energy and volume after

activation, starting with the value registered at the last deactivation; and/or

2) a set of interval registers for controlling processes.

c) A registration device shall be able to provide the time and date at which an interval value and/ or

the related error status have been registered.

d) The number of interval registers shall be sufficient to cover sufficient time intervals. If a new

interval value is memorized, the oldest value shall be deleted.

e) Thermal power shall be determined on basis of discrete interval values. Peak values shall be

determined for separate periods, e.g. as a day, or a week, or a month or a year and stored in

particular registers.

f) In addition to the interval values, a registration device can determine and register average values of

quantities, if measured by the meter.

5.10.3 Rated operated conditions

Taking into account the internal resolution of the thermal energy meter and the properties of the used

interface, the manufacturer shall specify the rated operating conditions, in particular the minimum

length of measuring intervals, in order to avoid inadmissible errors for the intended measurement task.

5.10.4 Indication

The registration device shall provide on a legally controlled display:

— the information which register(s) is (are) currently activated;

— the information which register(s) is (are) intended for billing purposes;

— values of registers and / or interval registers;

— the unit of values, which are assigned to the displayed values;

and, if applicable:

— information identifying the direction of thermal energy flow belonging to the values for delivered

and absorbed energy;

— date and time;

— lifetime of internal battery supply;

— list of registers and their definitions;

— the threshold values used for activating registers; and

— parameters and information important for the correct working of the registration device and the

inability of changing legally parameters in use.

The description of the main identifiers shall be on the nameplate or in the documentation

accompanying the instrument.

The registration device itself or an appropriate associated software for use by the consumer shall allow

to verify the correct assignment of single interval values or sums of interval values to rates (like the

maximum consumption or the sum of consumption during daily periods), if such processed values serve

as basis for the price to pay.

And if applicable other registers can also be displayed.

5.10.5 MPE for additional functionalities (smart metering functionality)

5.10.5.1 Clock

If applicable for the instrument:

For frequent time-based tariff switches between registers (e.g. for day and night tariff) within a billing

period, the deviation from legal time shall be one of the following three options:

Option 1: deviation less than 1 h/year

Option 2: deviation less than 6 min from legal time

Option 3: deviation less than 7 s from legal time

NOTE The above chosen maximum time deviations are derived from the physical inertia (thermal capacity to

be heated or cooled) of the heat conveying liquid, within the heat and cooling circuits.

For periodic interval registers for a billing period (e.g. hourly, daily, weekly or monthly registers), the

time deviation shall not be more than 1 % of the length of this period. In this case the deviation of the

internal clock from legal time is the accumulated deviation of all measurement periods.

5.10.5.2 Required accuracy when the measured temperature is used for additional energy

accumulations

1,0 K for temperature measurement in case of a complete meter (calculator with single

temperature sensor); up to 100 °C

0,7 K for temperature measurement in case of a combined meter (single temperature

sensor); up to 100 °C

NOTE In applications of smart metering, one or both single sensors of the pair are used as additional single

sensor. In case of Platinum (Pt) sensors, according to EN 60751:2008, at least class B with 4 wire connections is

recommended.

6 Technical characteristics

6.1 Materials and construction

6.1.1 All the constituent elements of thermal energy meters shall be solidly constructed of materials

having appropriate qualities to resist the various forms of corrosion and wear which occur under rated

operating conditions, especially those due to impurities in the heat conveying liquid. Correctly installed

meters shall also be able to withstand normal external influences. Meters shall, in all circumstances,

withstand the maximum admissible pressure and the temperatures for which they are designed,

without malfunction.

6.1.2 The manufacturer of the thermal energy meter shall declare any limitations with regard to

installation of the thermal energy meter and its orientation.

6.1.3 The casing of a thermal energy meter shall protect the interior parts against water and dust

ingress. The minimum forms of enclosure protection shall be IP54 for heating applications and IP65 for

cooling applications for equipment that is to be installed into pipe work and IP52 for other enclosures,

all in accordance with EN 61010-1:2010.

6.1.4 Thermal energy meters may be fitted with interfaces allowing the connection of supplementary

devices. Such connections shall not modify the metrological qualities of the thermal energy meter.

6.1.5 The maximum pressure loss for water at 15 °C ± 5 °C shall not exceed 0,25 bar at q . For heat-

p

conveying liquids other than water at various temperatures, the pressure loss can differ significantly

due to the properties of the liquid. It is specified in the type examination certificate of the meter or the

partial device for specific liquids or liquid categories.

6.2 Requirements outside the limiting values of the flow rate

When the true value of the flow rate is less than a threshold value declared by the manufacturer, no

registration is allowed.

The flow rate through a “nominally” closed valve or the movement of liquid in the pipe behind a closed

valve caused by thermal expansion and contraction should not be recorded.

For flow rates greater than q , the behaviour of the meter, e.g. by producing spurious or zero signals

s

shall be declared by the manufacturer. Flow rates greater than q until declared maximum flow shall not

s

result in an error greater than 10 % of the actual flow rate.

6.3 Display

6.3.1 The quantity of thermal energy shall be indicated in Joules, Watt-hours or in decimal multiples

of those units. The name or symbol of the unit, in which the quantity of thermal energy is given, shall be

indicated adjacent to the figures of the display.

6.3.2 Thermal energy meters shall be designed that in the event of a failure or interruption of the

external power supply (mains or external DC) the meter indication of energy remains accessible for a

minimum of one year (totally). The manufacturer shall specify how the indication of energy is handled

in case of a failure or interruption in the external power supply (mains or external DC).

NOTE The energy indication can either be stored in a permanent way (memory) at certain intervals, or it may

be stored through a controlled shut-down process (powered from an internal source).

6.3.3 The reading of the indication shall be sure, easy and unambiguous.

6.3.4 The real or apparent height of the figures on the display for energy shall not be less than 4 mm.

6.3.5 The figures indicating decimal fractions of a unit shall be separated from the others, either by a

comma or by a point. In addition, the figures indicating decimal fractions of energy shall be clearly

distinguishable from the others.

6.3.6 Where the display is of the roller-type, the advance of a figure of a particular significance shall

be completed during the time, when the figure of next lower significance changes from 9 to 0. The roller

carrying the figures of lowest significance may have a continuous movement, of which the visible

d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...