oSIST prEN 14716:2014

(Main)Stretched ceilings - Requirements and test methods

Stretched ceilings - Requirements and test methods

This document specifies the characteristics, specifications and test methods for stretched ceilings made up of single or multi-layer sheets, coated fabrics or fabrics made up of coated or monofilament yarn with a fastening system intended for internal finishes of ceilings.

It also specifies the method of conformity assessment for stretched ceilings.

Spanndecken - Anforderungen und Prüfverfahren

Plafonds tendus - Exigences et méthodes d'essai

Napeti stropovi - Zahteve in preskusne metode

General Information

- Status

- Not Published

- Public Enquiry End Date

- 29-Dec-2014

- Technical Committee

- ISS SPL.GPO - Building construction

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 03-Nov-2014

- Due Date

- 23-Mar-2015

- Completion Date

- 30-Jan-2015

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 01-Dec-2014

Overview

oSIST prEN 14716:2014 is a European standard developed by CEN, titled "Stretched ceilings - Requirements and test methods." This standard specifies the essential characteristics, specifications, and test methods for stretched ceilings, including those made from single or multi-layer sheets, coated fabrics, and fabrics made from coated or monofilament yarns. The standard focuses on stretched ceilings used for internal ceiling finishes and includes guidelines for fastening systems. Additionally, it outlines the method for conformity assessment of these products.

The standard aims to ensure product quality, safety, durability, and compliance with fire performance criteria, supporting manufacturers, installers, building designers, and regulatory bodies in applying consistent testing and evaluation methods for stretched ceiling systems.

Key Topics

Product Characteristics: Defines physical and functional properties of stretched ceilings, including:

- Reaction to fire performance

- Presence and control of dangerous substances

- Water vapour permeability and resistance to micro-organisms

- Durability expectations for internal applications

- Attachment system requirements (edge profiles and anchoring devices)

Testing Methods:

- Standardized procedures for assessing reaction to fire (ignitability, SBI single burning item test)

- Determination of mechanical properties such as tensile strength and dimensional stability after exposure to moisture and heat

- Sampling and preparation conditions for consistent test results

Conformity Assessment:

- Type testing protocols

- Factory production control (FPC) requirements to maintain performance consistency

- Initial factory inspection and ongoing surveillance mechanisms

- Procedures for modifications to product or manufacturing processes

Marking and Labelling: Clear directives on product marking to aid traceability and compliance verification.

Normative Annexes: Detailed test method descriptions, including:

- Mass and thickness determination of sheets

- Dimensional stability after environmental exposure

- Calculation of operating stresses and elongation metrics

- Extended application rules for fire performance variations within product groups

Applications

oSIST prEN 14716:2014 is vital for professionals involved in architectural design, interior finishing, construction, and manufacturing, enabling:

- Manufacturers to design and produce stretched ceilings that comply with European safety and quality requirements, ensuring product marketability across CEN member countries.

- Specifiers and Contractors to select the right stretched ceiling materials based on performance criteria such as fire resistance, durability, and moisture stability.

- Building inspectors and regulators to assess conformity of finished stretched ceiling installations, ensuring public safety and adherence to national and European directives.

- Quality control teams within factories to implement effective factory production control systems aligned with the standard's specifications.

The standard is particularly relevant to applications in commercial and residential interiors where aesthetic and functional ceiling solutions using stretched ceiling technologies are sought.

Related Standards

- EN 13501-1: Fire classification of construction products and building elements – Important for understanding fire reaction classifications referenced in oSIST prEN 14716:2014.

- EN ISO 11925-2: Ignitability test method – Provides the base for fire safety testing procedures used in assessing stretched ceilings.

- EN 13823 (SBI Test): Single Burning Item test – Key method for evaluating the fire behavior of ceiling materials.

- ISO 2768: General tolerances – Relevant for dimensional accuracy requirements in stretched ceiling manufacturing.

- CEN/TC 357 standards: Other related standards under the same technical committee focusing on ceiling systems, ensuring harmonized approaches across different ceiling product types.

Keywords: stretched ceilings, ceiling finishing, test methods, fire reaction, durability, conformity assessment, factory production control, materials testing, CEN standard, EN 14716, coated fabrics, internal ceilings, construction standards, building safety, marking and labelling.

Frequently Asked Questions

oSIST prEN 14716:2014 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Stretched ceilings - Requirements and test methods". This standard covers: This document specifies the characteristics, specifications and test methods for stretched ceilings made up of single or multi-layer sheets, coated fabrics or fabrics made up of coated or monofilament yarn with a fastening system intended for internal finishes of ceilings. It also specifies the method of conformity assessment for stretched ceilings.

This document specifies the characteristics, specifications and test methods for stretched ceilings made up of single or multi-layer sheets, coated fabrics or fabrics made up of coated or monofilament yarn with a fastening system intended for internal finishes of ceilings. It also specifies the method of conformity assessment for stretched ceilings.

oSIST prEN 14716:2014 is classified under the following ICS (International Classification for Standards) categories: 91.060.30 - Ceilings. Floors. Stairs. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 14716:2014 has the following relationships with other standards: It is inter standard links to SIST EN 14716:2005, SIST EN 14716:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 14716:2014 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/121. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN 14716:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2014

Napeti stropovi - Zahteve in preskusne metode

Stretched ceilings - Requirements and test methods

Spanndecken - Anforderungen und Prüfverfahren

Plafonds tendus - Exigences et méthodes d'essai

Ta slovenski standard je istoveten z: prEN 14716

ICS:

91.060.30 Stropi. Tla. Stopnice Ceilings. Floors. Stairs

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

DRAFT

prEN 14716

NORME EUROPÉENNE

EUROPÄISCHE NORM

October 2014

ICS 91.060.30 Will supersede EN 14716:2004

English Version

Stretched ceilings - Requirements and test methods

Plafonds tendus - Exigences et méthodes d'essai Spanndecken - Anforderungen und Prüfverfahren

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 357.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2014 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 14716:2014 E

worldwide for CEN national Members.

prEN 14716:2014 (E)

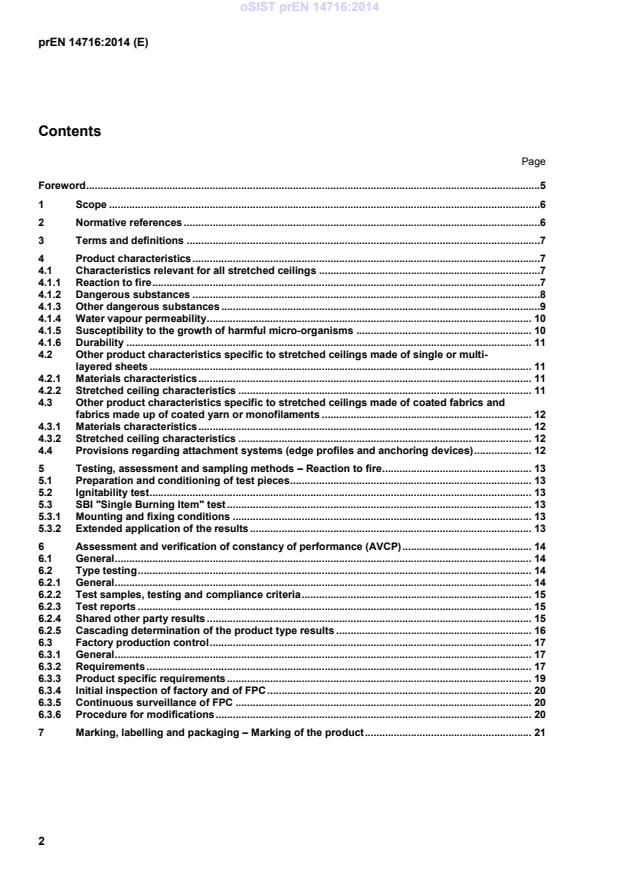

Contents

Page

Foreword .5

1 Scope .6

2 Normative references .6

3 Terms and definitions .7

4 Product characteristics .7

4.1 Characteristics relevant for all stretched ceilings .7

4.1.1 Reaction to fire .7

4.1.2 Dangerous substances .8

4.1.3 Other dangerous substances .9

4.1.4 Water vapour permeability . 10

4.1.5 Susceptibility to the growth of harmful micro-organisms . 10

4.1.6 Durability . 11

4.2 Other product characteristics specific to stretched ceilings made of single or multi-

layered sheets . 11

4.2.1 Materials characteristics . 11

4.2.2 Stretched ceiling characteristics . 11

4.3 Other product characteristics specific to stretched ceilings made of coated fabrics and

fabrics made up of coated yarn or monofilaments . 12

4.3.1 Materials characteristics . 12

4.3.2 Stretched ceiling characteristics . 12

4.4 Provisions regarding attachment systems (edge profiles and anchoring devices) . 12

5 Testing, assessment and sampling methods – Reaction to fire . 13

5.1 Preparation and conditioning of test pieces . 13

5.2 Ignitability test . 13

5.3 SBI "Single Burning Item" test . 13

5.3.1 Mounting and fixing conditions . 13

5.3.2 Extended application of the results . 13

6 Assessment and verification of constancy of performance (AVCP) . 14

6.1 General . 14

6.2 Type testing . 14

6.2.1 General . 14

6.2.2 Test samples, testing and compliance criteria . 15

6.2.3 Test reports . 15

6.2.4 Shared other party results . 15

6.2.5 Cascading determination of the product type results . 16

6.3 Factory production control . 17

6.3.1 General . 17

6.3.2 Requirements . 17

6.3.3 Product specific requirements . 19

6.3.4 Initial inspection of factory and of FPC . 20

6.3.5 Continuous surveillance of FPC . 20

6.3.6 Procedure for modifications . 20

7 Marking, labelling and packaging – Marking of the product . 21

prEN 14716:2014 (E)

Annex A (normative) SBI test . 22

Annex B (normative) Determination of the mass per unit area and thickness of the sheets . 26

B.1 Determination of the mass per unit area. 26

B.1.1 Apparatus . 26

B.1.2 Test pieces . 26

B.1.3 Conditioning . 26

B.1.4 Procedure . 26

B.1.5 Calculation and expression of results . 26

B.2 Determination of the thickness . 27

B.2.1 Apparatus . 27

B.2.2 Conditioning . 27

B.2.3 Procedure . 27

B.2.4 Calculation and expression of results . 27

B.3 Test report . 27

Annex C (normative) Determination of dimensional stability after exposure to moisture . 28

C.1 Scope . 28

C.2 Principle . 28

C.3 Apparatus and reagents . 28

C.3.1 Enclosure (see Figure C.1) . 28

C.3.2 Test solution . 28

C.4 Preparation of the test pieces . 28

C.4.1 General . 28

C.4.2 Stretched ceiling . 29

C.4.3 Related materials . 29

C.5 Procedure . 29

C.6 Expression of results . 29

C.7 Test report . 29

Annex D (normative) Determination of the operating stress . 31

D.1 Determination of the tensile strain at break . 31

D.1.1 Preparation of the test pieces . 31

D.1.2 Procedure . 33

D.2 Calculation of the rate of elongation resulting in the length and the width of a sample of

single or multi-layered sheet (see Figure D.2) . 33

D.2.1 Definition . 33

D.2.2 Schematic presentation of the calculation . 35

D.2.3 Calculation of the reduction of l (Rv %) during the elongation of L . 36

o l o

D.2.4 Calculation of the reduction of L (Rv %) during the elongation of l . 37

o L o

D.2.5 Calculation of the percentage elongation resulting in the length and the width of the

sheet . 38

D.3 Numerical application . 38

D.3.1 Hypothesis . 38

D.3.2 Calculation of l and L . 39

o o

D.3.3 Calculation of A % and A % . 39

l L

D.3.4 Calculation of the percentage reduction Rv % of l according to Poisson's ratio. 40

l o

D.3.5 Calculation of the width l’ reduced by Poisson's ratio . 40

D.3.6 Calculation of the resulting percentage elongation in width: A % . 40

lR

D.3.7 Calculation of the percentage reduction Rv % of L according to Poisson's ratio . 40

l o

D.3.8 Calculation of the reduced width l’ by Poisson's ratio . 41

D.3.9 Calculation of the resulting percentage elongation in the length and the width of the

sample . 41

D.4 Determination of the operating stress . 41

prEN 14716:2014 (E)

Annex E (normative) Determination of dimensional changes after exposure to heat (kaolin bed

method) . 43

E.1 Principle . 43

E.2 Apparatus . 43

E.3 Test pieces . 43

E.3.1 Shape and dimensions . 43

E.3.2 Taking of test pieces . 43

E.4 Procedure . 44

E.4.1 Test temperature . 44

E.4.2 Test . 44

E.5 Expression of results . 44

E.6 Test report . 45

Annex F (normative) Extended application rules within a group of product for the reaction to fire

tests . 46

F.1 Sampling . 46

F.2 Product parameter having an influence on the product's fire performance of stretched

ceilings . 46

F.3 Tests conducted according to EN ISO 11925-2 intended for an extended application . 46

F.3.1 Colour is the changing parameter . 46

F.3.2 Mass per square meter is the changing parameter. 46

F.3.3 Mass per square meter and colour are the changing parameter . 47

F.4 Tests conducted according to EN 13823 intended for an extended application . 47

F.4.1 Colour is the changing parameter . 47

F.4.2 Mass per square meter is the changing parameter. 47

F.4.3 Mass per square meter and colour are the changing parameter . 47

Annex ZA (informative) Clauses of this European Standard addressing the provisions of the EU

Construction Products Regulation . 48

ZA.1 Scope and relevant characteristics . 48

ZA.2 Procedure for AVCP of stretched ceilings . 49

ZA.2.1 System(s) of AVCP . 49

ZA.2.2 Declaration of performance (DOP) . 52

ZA.3 CE marking and labelling . 55

prEN 14716:2014 (E)

Foreword

This document (prEN 14716:2014) has been prepared by Technical Committee CEN/TC 357 “Stretched

ceilings”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 14716:2004.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

prEN 14716:2014 (E)

1 Scope

This document specifies the characteristics, specifications and test methods for stretched ceilings made up of

single or multi-layer sheets, coated fabrics or fabrics made up of coated or monofilament yarn with a fastening

system intended for internal finishes of ceilings.

It also specifies the method of conformity assessment for stretched ceilings.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 71-3, Safety of toys - Part 3: Migration of certain elements

EN 1875-3, Rubber- or plastics-coated fabrics - Determination of tear strength. Part 3: Trapezoidal method.

EN 12149, Wallcoverings in roll form - Determination of migration of heavy metals and certain other elements,

of vinyl chloride monomer and of formaldehyde release

EN 12280-1, Rubber- or plastic- coated fabrics - Accelerated ageing tests - Part 1: Heat ageing

EN 13238, Reaction to fire tests for building products - Conditioning procedures and general rules for

selection of substrates

EN 13501-1, Fire classification of construction products and building elements - Part 1: Classification using

data from reaction to fire tests

EN 13823, Reaction to fire tests for building products - Building products excluding floorings exposed to the

thermal attack by a single burning item

EN ISO 105-B02, Textiles - Tests for colour fastness - Part B02: Colour fastness to artificial light: Xenon arc

fading lamp test (ISO 105-B02:2013)

EN ISO 527-1, Plastics - Determination of tensile properties - Part 1: General principles (ISO 527-1:2012)

EN ISO 527-3, Plastics - Determination of tensile properties - Part 3: Test conditions for films and sheets

(ISO 527-3:1995)

EN ISO 846, Plastics - Evaluation of the action of microorganisms (ISO 846:1997)

EN ISO 1182, Reaction to fire tests for products - Non-combustibility test (ISO 1182:2010)

EN ISO 1421, Rubber- or plastics-coated fabrics - Determination of tensile strength and elongation at break

(ISO 1421:1998)

EN ISO 1716, Reaction to fire tests for products - Determination of the gross heat of combustion (calorific

value) (ISO 1716:2010)

EN ISO 2286-2, Rubber- or plastics-coated fabrics - Determination of roll characteristics - Part 2: Methods for

determination of total mass per unit area, mass per unit area of coating and mass per unit area of substrate

(ISO 2286-2:1998)

EN ISO 2286-3, Rubber- or plastics-coated fabrics - Determination of roll characteristics - Part 3: Method for

determination of thickness (ISO 2286-3:1998)

EN ISO 9001, Quality management systems - Requirements (ISO 9001:2008)

prEN 14716:2014 (E)

EN ISO 11925-2, Reaction to fire tests - Ignitability of products subjected to direct impingement of flame –

Part 2: Single-flame source test (ISO 11925-2:2010)

ISO 2528:1995, Sheet materials - Determination of water vapour transmission rate - Gravimetric (dish)

method

CEN/TS 16516, Construction products - Assessment of release of dangerous substances - Determination of

emissions into indoor air

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

3.1

stretched ceiling

ceiling covering comprising a continuous area obtained from one width or assembled widths kept under

tension at its edges by a fastening system. This stretched ceiling shall be able to be completely dismantled

and re-installed without having to change it. The fastening system is sold separately.

These widths may be single or multi-layered sheets, coated fabrics or fabrics made up of coated yarn or

monofilaments. A stretched ceiling may be perforated or not, with or without openings.

Note 1 to entry: The stretched ceiling may need to be dismantled and re-installed to have access to the plenum space

e.g. for maintenance, reparation or installation of new appliances, etc.

3.2

product family

total range of products within specific variability limits (defined by the manufacturer or a technical

specification) of the product parameters and, if appropriate, of the final use parameters for which the specified

safety characteristics do not change (do not deteriorate)

This means that the test results obtained for one product in the family remain valid for all the products in the

family

3.3

edge profile

element fixed at the periphery of the ceiling to keep the ceiling stretched

3.4

anchoring device

element connecting the stretched ceiling to the edge profile

4 Product characteristics

4.1 Characteristics relevant for all stretched ceilings

4.1.1 Reaction to fire

The manufacturer is required to make a declaration of the reaction to fire performance (i.e. if the stretched

ceiling is subject to regulations). The stretched ceilings shall be classified in accordance with the requirements

of EN 13501-1 when tested according to Clause 5. The resulting class shall be declared.

If it is decided to place a product family on the market as a class F product, no test is required for this product

family.

prEN 14716:2014 (E)

4.1.2 Dangerous substances

4.1.2.1 Very volatile organic compound (VVOC) as defined in CEN/TS 16516

The stretched ceilings shall be tested according to CEN/TS 16516.

If none of these substances is added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

Acetaldehyde

Acetone

Aldehydes

Aliphatic hydrocarbons

Aliphatic alcohols

Amines

Esters

Formaldehyde

4.1.2.2 Volatile organic compounds (VOC) as defined in CEN/TS 16516

The stretched ceilings shall be tested according to CEN/TS 16516.

If none of these substances is added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

benzene

styrene

volatile organic compounds

4.1.2.3 Semi volatile organic compound (SVOC) as defined in CEN/TS 16516

The stretched ceilings shall be tested according to CEN/TS 16516.

If none of these substances is added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

dibutyl pthalate

4.1.2.4 Organic compounds associated with particulate matter (or particulate organic matter) (POM)

and semi-volatile organic compounds subject to content regulations

The stretched ceilings shall be tested according to EN 12149 or CEN/TC 351xxx.

If none of these substances is added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

polybrominated diphenylethers : commercial Pentabromodiphenyl ether

prEN 14716:2014 (E)

polybrominated diphenylethers : commercial Octadibromodiphenylether

polybrominated diphenylethers : decabromodiphenylether

di(2-ethyhexyl)phthalate (DEHP)

4.1.2.5 Inorganic substances

The stretched ceilings shall be tested according to EN 12149 or CEN/TC 351xxx.

If ammonia compounds are not added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

4.1.2.6 Metals

The stretched ceilings shall be tested according to EN 12149 which shall be tested according to CEN/TC

351xxx.

If none of these substances is added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

cadmium and its compounds

lead

4.1.3 Other dangerous substances

4.1.3.1 General

National regulations on dangerous substances, other than those already covered in other clauses of this

standard, may require verification and declaration on release, and sometimes content, when construction

products covered by this standard are place on those markets. In the absence of European harmonised test

methods, verification and declaration on release/content should be done taking into account national

provisions in the place of use.

NOTE An informative database covering European and national provisions on dangerous substances is available at

the Construction web site on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/.

4.1.3.2 Heavy metals and other elements

4.1.3.2.1 Requirements

The migration of heavy metals and other elements, expressed in mg/kg of stretched ceiling, shall not exceed

the values given in Table 1 (after correction as specified in 4.3.1.1.1) when measured in accordance with

test A in EN 12149.

If none of these substances is added during manufacture and if the raw materials are certified by the supplier

as not containing these substances, the test is not necessary.

4.1.3.2.2 Interpretation of results

The analytical results obtained in the tests specified in EN 12149 shall be corrected by subtracting the

analytical correction factors given in Table 2 to obtain a corrected analytical result.

The stretched ceilings are considered as satisfying the requirements of this document if the corrected

analytical result is equal to or less than the limits indicated in Table 1.

prEN 14716:2014 (E)

NOTE 1 Given the reliability of the methods specified in this EN 12149, it is necessary to use the corrected analytical

results to take into account the results of the interlaboratory tests (see Annex D of EN 71-3).

EXAMPLE analytical result for lead: 120 mg/kg.

Corresponding analytical correction in Table 2: 30 %.

Corrected analytical result = 120 - (120 × 30) / 100 = 120 - 36 = 84 mg/kg. This is considered to meet the requirements of

the standard (lead: 90 mg/kg).

NOTE 2 The measuring methods used in EN 12149 are derived directly from EN 71-3 on the safety of toys. Annex D of

EN 71-3, in particular D.4 "Statistical uncertainty of the test procedure and interpretation of results", justifies the

introduction of a correction factor.

Table 1 — Maximum migration of heavy metals and other elements

Heavy metal or element Symbol Maximum migration in mg/kg of

stretched ceiling

Antimony Sb 60

Barium Ba 500

Selenium Se 165

Table 2 — Analytical correction factor

Element Sb Ba Se

Analytical correction factor 60 30 60

(in percentage)

4.1.3.3 Vinyl chloride monomer

The maximum content of vinyl chloride monomer shall be less than 10 mg/kg measured as described in test B

of EN 12149.

If vinyl chloride or the products containing vinyl chloride are not added during manufacture and if the raw

materials are certified by the supplier as containing less than 10 mg/kg of vinyl chloride, the test is not

necessary.

4.1.4 Water vapour permeability

If they are used as a vapour barrier, stretched ceilings in the form of single or multi-layered sheets and full

coated fabrics shall have a water vapour permeability of < 50 g/m /24 h (measured in accordance with the

conditions of procedure B in ISO 2528).

4.1.5 Susceptibility to the growth of harmful micro-organisms

The stretched ceilings shall be tested according to EN ISO 846 – Method A and the result shall be declared.

prEN 14716:2014 (E)

4.1.6 Durability

Whenever required, durability shall be checked by indirect way by assessing:

− testing tensile strength,

− tear strength,

− dimensional stability under the effect of moisture

− heat shrinkage

in accordance with Tables 3 and 4 of this standard, and

− resistance of the assembly

in accordance with paragraphs 4.2.2 and 4.3.2.

4.2 Other product characteristics specific to stretched ceilings made of single or multi-

layered sheets

4.2.1 Materials characteristics

Stretched ceilings made up of single or multi-layered sheets described in this document shall meet the

requirements specified in Table 3 when they are subjected to the tests indicated.

Table 3 — Materials characteristics

Characteristics Units Requirements Test method

Mass per unit area % Nominal value ± 10 Annex B

Thickness % Nominal value ± 10 EN ISO 2286-3 with a

pressure of 2 kPa

Colour fastness to light - ≥ 6 EN ISO 105 – B 02

Dimensional stability after % ≤ 1 in each direction Annex C

a

exposure to humidity

Heat shrinkage % ≤ 4, 5 in each direction Annex E

Breaking strength N/mm longitudinal ≥ 12

transverse ≥ 10

EN ISO 527-3

with a type 2 test piece

Elongation at break % longitudinal ≥ 140

transverse ≥ 150

a

The test may be carried out on the basis of the final use of the ceiling (example: chlorinated atmosphere).

4.2.2 Stretched ceiling characteristics

When tested according to Annex D, the resistance of the assembly shall be ≥ 2 x operating stress expressed

in daN.

prEN 14716:2014 (E)

4.3 Other product characteristics specific to stretched ceilings made of coated fabrics and

fabrics made up of coated yarn or monofilaments

4.3.1 Materials characteristics

Stretched ceilings made of the coated fabrics of coated yarn or monofilaments described in this document

shall meet the requirements specified in Table 4, when subjected to the tests indicated.

Table 4 — Materials characteristics

Characteristics Units Requirements Test method

fabrics with a mass fabrics with a mass

per unit area per unit area

2 2

> 350g /m ≤ 350g /m

Mass per unit area % Nominal value ± 10 EN ISO 2286-2

Colour fastness to light - ≥ 6 EN ISO 105-B 02

Dimensional stability after % ≤ 1 in each direction Annex C

a

exposure to humidity

Dimensional stability after % < 1 in each direction < 10 °C to 60 °C EN 12280-1

exposure to heat

(30 min)

Tensile strength daN/5 cm > 50 > 10 EN ISO 1421

Tear strength daN > 10 > 3 EN 1875-3

a

The test may be carried out on the basis of the final use of the ceiling (example: chlorinated atmosphere).

4.3.2 Stretched ceiling characteristics

When tested according to EN ISO 1421 the resistance of the assembly

− made of fabrics with a mass per unit area > 350g/m shall be > 20 daN/5 cm

− made of fabrics with a mass per unit area ≤ 350g /m shall be > 8 daN/5 cm

4.4 Provisions regarding attachment systems (edge profiles and anchoring devices)

4.4.1 Suitability for dismantling and re-assembly

The fastening system shall allow the stretched ceiling to be completely dismantled and re-installed without any

damage as often as necessary according to the state of art.

4.4.2 Mechanical strength

The stretched ceiling and its attachment system shall be at least equal to the strength of the assembly

specified for the stretched ceiling in 4.2.2 and 4.3.2 as relevant.

prEN 14716:2014 (E)

5 Testing, assessment and sampling methods – Reaction to fire

5.1 Preparation and conditioning of test pieces

The test pieces shall be conditioned prior to the test in accordance with EN 13238.

5.2 Ignitability test

The ignitability test shall be carried out in accordance with EN ISO 11925-2.

The flame shall be applied to the surface of the test piece fixed on the test piece holder by means of small

pins incorporated in the surface of the U-shaped frame

5.3 SBI "Single Burning Item" test

5.3.1 Mounting and fixing conditions

Carry out the reaction to fire test in accordance with EN 13823.

The stretched ceilings shall be tested perpendicularly in the test piece holder trolley for the SBI comprising

one small wing (550 ± 5) mm × (1 500 ± 5) mm and one large wing (1 000 ± 5) mm × (1 500 ± 5) mm.

a) In the case of single or multi-layered sheets, take 850 mm × 1 800 mm of the sheet to make the small

wing and 1 300 mm × 1 800 mm to make the large wing. Stretch the sheet in the transverse direction

across a calcium silicate panel with a tensile force of 30 daN/m determined in accordance with

EN ISO 527-3.

There shall be an air gap of 40 mm (or less) between the stretched ceiling and the substrate when

assembling the ceiling. This air gap is obtained by means of a calcium silicate frame of desired thickness

fixed to the perimeter of the substrate of the small and the large wing.

The final configuration may be obtained by pinching the stretched ceiling at the back of the substrate by

means of an aluminium track and a PVC ring. Adequate tension shall be applied to obtain a satisfactory

degree of flatness and no creasing over the whole of the exposed surface (see Figure A.1 in Annex A).

b) In the case of coated fabrics or those made of coated yarn or monofilaments, take a

1 500 mm × 1 500 mm test piece. Fix the test piece to a metallic frame (see Figures A.2, A.3 and A.4 in

Annex A). This frame comprises an assembly of stainless steel tubes of rectangular cross-section

forming two perpendicular wings, one small and one large.

Attach the test piece to the peripheral members of the frame by means of the steel pins. Prior to the test,

the test piece shall be adequately stretched and flat so that no more that 30 % of the total exposed

surface shrinks by more than 10 mm from the coplanar vertical plane at the back of the U-profile

Then place the frame against the U-profile on the test piece holder trolley. To be representative of the

final use, conduct the test with a ventilated space 80 mm (or less) wide at the back of the test piece in

accordance with EN 13823.

Attach two calcium silicate walls made up of one small wing of (580 ± 5) mm × (1 500 ± 5) mm and one

large wing of (1 080 ± 5) mm × (1 500 ± 5) mm vertically 80 mm from the test piece. The sides furthest

away from the angle and the spaces behind each wing shall be left open.

5.3.2 Extended application of the results

The reaction to fire classification obtained according to 5.3.1 is valid for all dimensions of the air gap. If a

higher air gap dimension is tested then the fire classification is valid for the air gap dimension equal or higher

than the air gap dimension tested.

prEN 14716:2014 (E)

6 Assessment and verification of constancy of performance (AVCP)

6.1 General

The compliance of stretched ceilings with the requirements of this standard and with the performances

declared by the manufacturer in the DoP shall be demonstrated by:

determination of the product-type on the basis of type testing

factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the conformity of the product with its declared performance(s).

6.2 Type testing

6.2.1 General

All performances related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performances unless the standard gives provisions for

declaring them without performing tests. (e.g. use of previously existing data, CWFT and conventionally

accepted performance).

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same AVCP

system on the same product or products of similar design, construction and functionality, such that the results

are applicable to the product in question.

NOTE 1 Same AVCP system means testing by an independent third party, under the responsibility of a notified

product certification body.

For the purposes of assessment, the manufacturer's products may be grouped into families, where it is

considered that the results for one or more characteristics from any one product within the family are

representative for that same characteristics for all products within that same family (see Annex F)

NOTE 2 Products may be grouped in different families for different characteristics.

NOTE 3 Reference to the assessment method standards should be made to allow the selection of a suitable

representative sample.

In addition, the determination of the product type shall be performed for all characteristics included in the

standard for which the manufacturer declares the performance:

- at the beginning of the production of a new or modified stretched ceiling (unless a member of the same

product range), or

- at the beginning of a new or modified method of production (where this may affect the stated properties);

or they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the stretched

ceiling design, in the raw material or in the supplier of the components, or in the method of production (subject

to the definition of a family), which would affect significantly one or more of the characteristics.

Where components are used whose characteristics have already been determined, by the component

manufacturer, on the basis of assessment methods of other product standards, these characteristics need not

be re-assessed. The specifications of these components shall be documented.

Products bearing regulatory marking in accordance with appropriate harmonized European specifications may

be presumed to have the performances declared in the DoP, although this does not replace the responsibility

on the stretched ceiling manufacturer to ensure that the stretched ceiling as a whole is correctly manufactured

and its component products have the declared performance values.

prEN 14716:2014 (E)

6.2.2 Test samples, testing and compliance criteria

The number of samples of stretched ceilings to be tested/assessed shall be in accordance with Table 5.

Table 5 — Number of samples to be tested and compliance criteria

Characteristic Requirement Assessment Number. of Compliance criteria

method samples

Reaction to fire 4.1 EN 13823 See classification given

EN ISO 1716 in EN 13501-1

EN ISO 1182

EN ISO 11925-2

Dangerous substances 4.2 CEN/TS 16516 4.2

EN 12149

CEN/TC 351XXX

Other dangerous 4.3

substances

− Heavy metals EN 12149 4.3.1 Table 1

1 sample

30 m long and

− Vinyl chloride < 10 mg/kg

of a minimum

monomer

1,30 m wide

Water vapour permeability 4.4 ISO 2528 < 50 g/m /24 h

Susceptibility to the growth 4.5 4.5

EN ISO 846

of harmful micro-organisms

Other characteristics Tables 3 and 4

See table 3 and 4

specified in Tables 3 and 4

6.2.3 Test reports

The results of the determination of the product type shall be documented in test reports. All test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...