ISO 10416:2002

(Main)Petroleum and natural gas industries — Drilling fluids — Laboratory testing

Petroleum and natural gas industries — Drilling fluids — Laboratory testing

ISO 10416:2002 provides procedures for the laboratory testing of both drilling fluid materials and drilling fluid physical, chemical and performance properties. It is applicable to both water-based and oil-based drilling fluids, as well as the base or make-up fluid. It is not intended as a detailed manual on drilling fluid control procedures. Recommendations regarding agitation and testing temperature are presented because the agitation history and temperature have a profound effect on drilling fluid properties.

Industries du pétrole et du gaz naturel — Fluides de forage — Essais en laboratoire

General Information

- Status

- Withdrawn

- Publication Date

- 21-Nov-2002

- Withdrawal Date

- 21-Nov-2002

- Technical Committee

- ISO/TC 67/SC 3 - Drilling and completion fluids, well cements and treatment fluids

- Drafting Committee

- ISO/TC 67/SC 3/WG 1 - Drilling, completion and workover fluids

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 28-May-2008

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 10416:2002 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Drilling fluids — Laboratory testing". This standard covers: ISO 10416:2002 provides procedures for the laboratory testing of both drilling fluid materials and drilling fluid physical, chemical and performance properties. It is applicable to both water-based and oil-based drilling fluids, as well as the base or make-up fluid. It is not intended as a detailed manual on drilling fluid control procedures. Recommendations regarding agitation and testing temperature are presented because the agitation history and temperature have a profound effect on drilling fluid properties.

ISO 10416:2002 provides procedures for the laboratory testing of both drilling fluid materials and drilling fluid physical, chemical and performance properties. It is applicable to both water-based and oil-based drilling fluids, as well as the base or make-up fluid. It is not intended as a detailed manual on drilling fluid control procedures. Recommendations regarding agitation and testing temperature are presented because the agitation history and temperature have a profound effect on drilling fluid properties.

ISO 10416:2002 is classified under the following ICS (International Classification for Standards) categories: 75.100 - Lubricants, industrial oils and related products; 75.180.10 - Exploratory, drilling and extraction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10416:2002 has the following relationships with other standards: It is inter standard links to ISO 10416:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 10416:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10416

First edition

2002-12-01

Petroleum and natural gas industries —

Drilling fluids — Laboratory testing

Industries du pétrole et du gaz naturel — Fluides de forage — Essais en

laboratoire

Reference number

©

ISO 2002

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2002 – All rights reserved

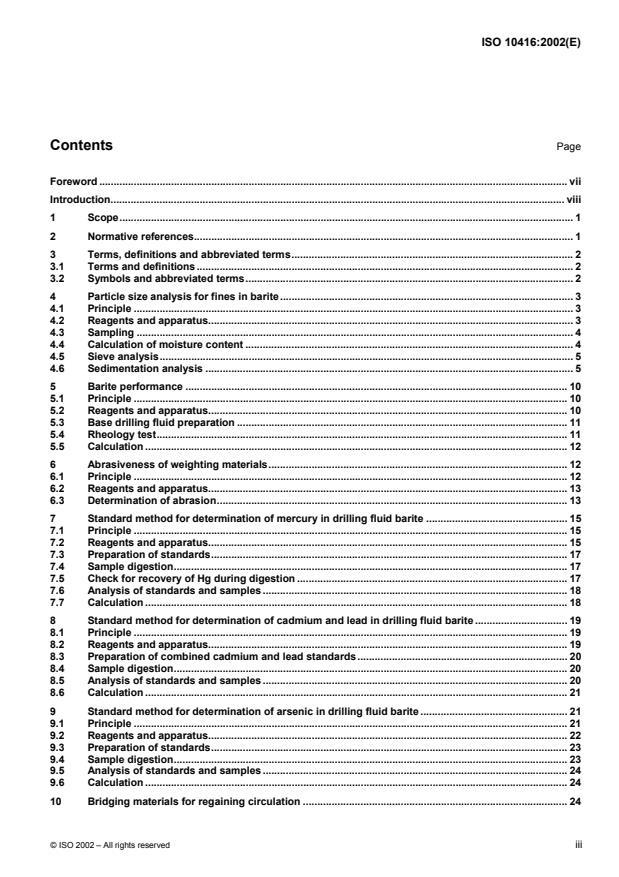

Contents Page

Foreword . vii

Introduction. viii

1 Scope. 1

2 Normative references. 1

3 Terms, definitions and abbreviated terms. 2

3.1 Terms and definitions. 2

3.2 Symbols and abbreviated terms. 2

4 Particle size analysis for fines in barite. 3

4.1 Principle . 3

4.2 Reagents and apparatus. 3

4.3 Sampling . 4

4.4 Calculation of moisture content . 4

4.5 Sieve analysis. 5

4.6 Sedimentation analysis . 5

5 Barite performance . 10

5.1 Principle . 10

5.2 Reagents and apparatus. 10

5.3 Base drilling fluid preparation . 11

5.4 Rheology test. 11

5.5 Calculation . 12

6 Abrasiveness of weighting materials. 12

6.1 Principle . 12

6.2 Reagents and apparatus. 13

6.3 Determination of abrasion. 13

7 Standard method for determination of mercury in drilling fluid barite . 15

7.1 Principle . 15

7.2 Reagents and apparatus. 15

7.3 Preparation of standards. 17

7.4 Sample digestion. 17

7.5 Check for recovery of Hg during digestion . 17

7.6 Analysis of standards and samples . 18

7.7 Calculation . 18

8 Standard method for determination of cadmium and lead in drilling fluid barite . 19

8.1 Principle . 19

8.2 Reagents and apparatus. 19

8.3 Preparation of combined cadmium and lead standards. 20

8.4 Sample digestion. 20

8.5 Analysis of standards and samples . 20

8.6 Calculation . 21

9 Standard method for determination of arsenic in drilling fluid barite . 21

9.1 Principle . 21

9.2 Reagents and apparatus. 22

9.3 Preparation of standards. 23

9.4 Sample digestion. 23

9.5 Analysis of standards and samples . 24

9.6 Calculation . 24

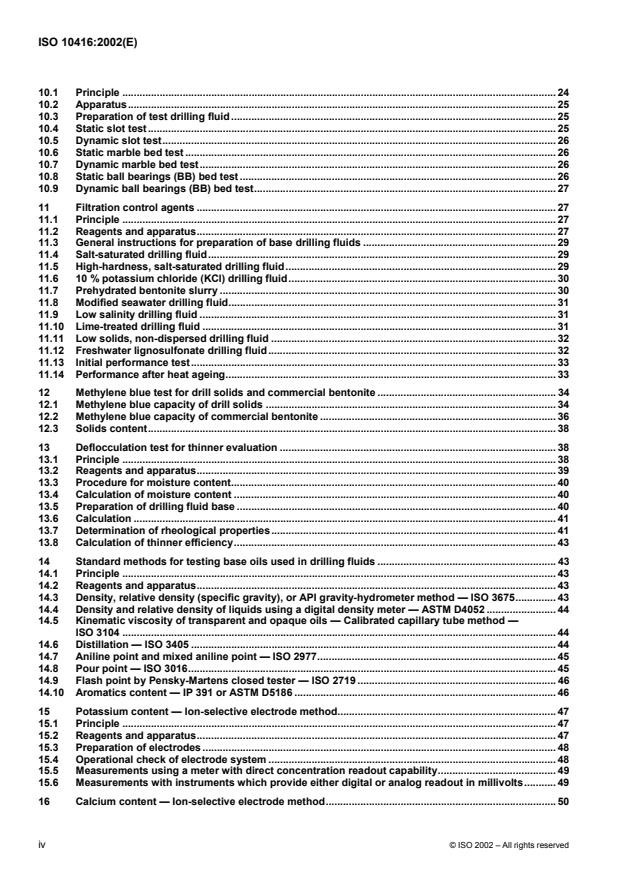

10 Bridging materials for regaining circulation . 24

10.1 Principle . 24

10.2 Apparatus. 25

10.3 Preparation of test drilling fluid. 25

10.4 Static slot test. 25

10.5 Dynamic slot test. 26

10.6 Static marble bed test . 26

10.7 Dynamic marble bed test. 26

10.8 Static ball bearings (BB) bed test. 26

10.9 Dynamic ball bearings (BB) bed test. 27

11 Filtration control agents . 27

11.1 Principle . 27

11.2 Reagents and apparatus. 27

11.3 General instructions for preparation of base drilling fluids . 29

11.4 Salt-saturated drilling fluid. 29

11.5 High-hardness, salt-saturated drilling fluid. 29

11.6 10 % potassium chloride (KCl) drilling fluid. 30

11.7 Prehydrated bentonite slurry . 30

11.8 Modified seawater drilling fluid. 31

11.9 Low salinity drilling fluid . 31

11.10 Lime-treated drilling fluid . 31

11.11 Low solids, non-dispersed drilling fluid . 32

11.12 Freshwater lignosulfonate drilling fluid. 32

11.13 Initial performance test. 33

11.14 Performance after heat ageing. 33

12 Methylene blue test for drill solids and commercial bentonite . 34

12.1 Methylene blue capacity of drill solids . 34

12.2 Methylene blue capacity of commercial bentonite . 36

12.3 Solids content. 38

13 Deflocculation test for thinner evaluation . 38

13.1 Principle . 38

13.2 Reagents and apparatus. 39

13.3 Procedure for moisture content. 40

13.4 Calculation of moisture content . 40

13.5 Preparation of drilling fluid base . 40

13.6 Calculation . 41

13.7 Determination of rheological properties. 41

13.8 Calculation of thinner efficiency. 43

14 Standard methods for testing base oils used in drilling fluids . 43

14.1 Principle . 43

14.2 Reagents and apparatus. 43

14.3 Density, relative density (specific gravity), or API gravity-hydrometer method — ISO 3675. 43

14.4 Density and relative density of liquids using a digital density meter — ASTM D4052 . 44

14.5 Kinematic viscosity of transparent and opaque oils — Calibrated capillary tube method —

ISO 3104 . 44

14.6 Distillation — ISO 3405 . 44

14.7 Aniline point and mixed aniline point — ISO 2977. 45

14.8 Pour point — ISO 3016. 45

14.9 Flash point by Pensky-Martens closed tester — ISO 2719 . 46

14.10 Aromatics content — IP 391 or ASTM D5186 . 46

15 Potassium content — Ion-selective electrode method. 47

15.1 Principle . 47

15.2 Reagents and apparatus. 47

15.3 Preparation of electrodes . 48

15.4 Operational check of electrode system . 48

15.5 Measurements using a meter with direct concentration readout capability. 49

15.6 Measurements with instruments which provide either digital or analog readout in millivolts. 49

16 Calcium content — Ion-selective electrode method.50

iv © ISO 2002 – All rights reserved

16.1 Principle . 50

16.2 Reagents and apparatus. 50

16.3 Preparation of electrodes. 51

16.4 Operational check of electrode system . 51

16.5 Measurements using a meter with direct concentration readout capability. 52

16.6 Measurements with instruments which provide either digital or analog readout in millivolts. 52

17 Density of solids — Stereopycnometer method . 53

17.1 Principle . 53

17.2 Apparatus. 53

17.3 Procedure — Stereopycnometer method . 53

17.4 Calculation — Stereopycnometer method. 54

18 Density of solids — Air comparison pycnometer method. 55

18.1 Principle . 55

18.2 Apparatus. 55

18.3 Procedure — Air comparison pycnometer method. 55

18.4 Calculation — Air comparison pycnometer method . 55

19 Sodium in water-based drilling fluids — Ion-selective electrode method . 56

19.1 Principle . 56

19.2 Reagents and apparatus. 56

19.3 Preparation and operational check of electrode system . 57

19.4 Measurements using a meter with direct concentration readout capability. 58

19.5 Measurements using a meter with readout in millivolts . 58

20 Ageing of water-based drilling fluids . 59

20.1 Principle . 59

20.2 Practices common to preparation, handling and testing over all temperature ranges . 59

20.3 Drilling fluid sample preparation and ageing at ambient temperature. 60

20.4 Drilling fluid ageing at moderate temperatures (ambient to 65 °C) . 61

20.5 Drilling fluid ageing at substantially elevated temperatures (over 65 °C). 62

20.6 Inertness and chemical compatibility in high-temperature ageing cells . 65

20.7 Obtaining supplies and services for the ageing of drilling fluid samples . 66

21 Ageing of oil-based drilling fluids . 66

21.1 Principle . 66

21.2 Apparatus. 67

21.3 Practices common to preparation, handling and testing over all temperature ranges . 68

21.4 Drilling fluid ageing at ambient temperatures. 69

21.5 Drilling fluid ageing at moderate temperatures (ambient to 65 °C) . 70

21.6 Drilling fluid ageing at substantially elevated temperatures (over 65 °C). 71

21.7 Inertness and chemical compatibility in high-temperature ageing cells . 72

21.8 Obtaining supplies and services for the ageing of drilling fluid samples . 73

22 Shale particle disintegration test by hot rolling. 73

22.1 Principle . 73

22.2 Reagents and apparatus. 74

22.3 Procedure. 75

22.4 Calculation . 75

23 Drilling fluid materials — High viscosity polyanionic cellulose (PAC-HV) (regular). 76

23.1 Principle . 76

23.2 Determination of moisture content . 76

23.3 Procedures with test fluid containing PAC-HV . 77

24 Drilling fluid materials — Low viscosity polyanionic cellulose (PAC-LV). 79

24.1 Principle . 79

24.2 Determination of moisture content . 80

24.3 Procedures with test fluid containing PAC-LV . 80

25 Preparation and evaluation of invert emulsion drilling fluids . 83

25.1 Principle . 83

25.2 Reagents and apparatus. 83

25.3 Mixing of initial drilling fluid. 84

25.4 Testing of properties of initial drilling fluid . 85

25.5 Preparation of sample contaminated by seawater .85

25.6 Preparation of sample contaminated by Base Evaluation Clay . 86

25.7 Preparation of sample contaminated by mixed-salt brine . 86

25.8 Procedure for hot rolling . 86

25.9 Procedure for static ageing. 86

25.10 Procedure for testing after heat ageing . 87

26 Permeability plugging in cells with set-screw-secured end caps (HTHP filtration). 87

26.1 Principle . 87

26.2 Safety considerations . 87

26.3 Apparatus — Permeability plugging apparatus (PPA) with set-screw-secured end caps . 89

26.4 Procedure for high temperature, high pressure (HTHP) filtration. 91

26.5 Test conclusion and disassembly. 94

26.6 Data reporting. 95

27 Permeability plugging in cells with threaded end caps (HTHP) . 96

27.1 Principle . 96

27.2 Safety considerations . 96

27.3 Apparatus — Permeability plugging apparatus (PPA) with threaded end caps. 98

27.4 Procedure for high temperature, high pressure (HTHP) filtration. 100

27.5 Test conclusion and disassembly. 102

27.6 Data reporting. 104

Bibliography. 105

vi © ISO 2002 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10416 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore structures for

petroleum and natural gas industries, Subcommittee SC 3, Drilling and completion fluids, and well cements.

Introduction

This International Standard, which establishes testing methodologies for drilling fluid materials, is based on API RP

13I, fifth edition, June 1, 1995 [1]. This International Standard was developed in response to demand for more

exacting testing methodologies. The tests contained herein were developed over several years by a group of

industry experts and were identified as being those which would yield reproducible and accurate results. The tests

are anticipated to be performed in a laboratory setting, but could be applicable in a field situation with more

rigorous apparatus and conditions than normally found in a drilling fluid field-test kit.

These tests are designed to assist in the evaluation of certain parameters for drilling fluids, with these properties

not necessarily used for the maintenance of a drilling fluid in field use. The tests provide either more precision or

different properties than those given in the field-testing standards ISO 10414-1 and ISO 10414-2.

Users of this International Standard should be aware that further or differing requirements may be needed for

individual applications. This International Standard is not intended to inhibit a vendor from offering, or the purchaser

from accepting alternative equipment or engineering solutions for the individual application. This may be

particularly appropriate where there is innovative or developing technology. Where an alternative is offered, the

vendor should identify any variations from this International Standard and provide details.

As with any laboratory procedure requiring the use of potentially hazardous chemicals, the user is expected to have

received proper knowledge and training in the use and disposal of these chemicals. The user is responsible for

compliance with all applicable local, regional, and national regulations for worker and local health, safety and

environmental liability.

This International Standard contains footnotes giving examples of apparatus and reagents, and sometimes the

supplier(s) of those materials which are available commercially. This information is given for the convenience of

users of this International Standard and does not constitute an endorsement by ISO of the products named.

Equivalent products may be used if they can be shown to lead to the same results.

viii © ISO 2002 – All rights reserved

INTERNATIONAL STANDARD ISO 10416:2002(E)

Petroleum and natural gas industries — Drilling fluids —

Laboratory testing

1 Scope

This International Standard provides procedures for the laboratory testing of both drilling fluid materials and drilling

fluid physical, chemical and performance properties. It is applicable to both water-based and oil-based drilling

fluids, as well as the base or “make-up” fluid.

It is not intended as a detailed manual on drilling fluid control procedures. Recommendations regarding agitation

and testing temperature are presented because the agitation history and temperature have a profound effect on

drilling fluid properties.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 2719, Determination of flash point — Pensky-Martens closed cup method

ISO 2977, Petroleum products and hydrocarbon solvents — Determination of aniline point and mixed aniline point

ISO 3007, Petroleum products and crude petroleum — Determination of vapour pressure — Reid method

ISO 3016, Petroleum products — Determination of pour point

ISO 3104, Petroleum products — Transparent and opaque liquids — Determination of kinematic viscosity and

calculation of dynamic visocisty

ISO 3405:2000, Petroleum products — Determination of distillation characteristics at atmospheric pressure

ISO 3675, Crude petroleum and liquid petroleum products — Laboratory determination of density — Hydrometer

method

ISO 3839, Petroleum products — Determination of bromine number of distillates and aliphatic olefins —

Electrometric method

ISO 10414-1:2001, Petroleum and natural gas industries — Field testing of drilling fluids — Part 1: Water-based

fluids

ISO 10414-2:2002, Petroleum and natural gas industries — Field testing of drilling fluids — Part 2: Oil-based fluids

ISO 13500:1998, Petroleum and natural gas industries — Drilling fluid materials — Specifications and tests

ASTM D422, Standard Test Method for Particle-Size Analysis of Soils

ASTM D1141, Standard Practice for Substitute Ocean Water

ASTM D4052, Standard Test Method for Density and Relative Density of Liquids by Digital Density Meter

ASTM D5186, Standard Test Method for Determination of Aromatic Content and Polynuclear Aromatic Content of

Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid Chromatography

ASTM E100, Standard Specification for ASTM Hydrometers

IP 391, Test Method for Determination of Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and

Aviation Turbine Fuels by Supercritical Fluid Chromatography

3 Terms, definitions and abbreviated terms

For the purposes of this International Standard, the following terms, definitions and abbreviated terms apply.

3.1 Terms and definitions

3.1.1

ACS reagent grade

chemical which meets purity standards as specified by the American Chemical Society (ACS)

3.1.2

flash side

side containing residue (“flash”) from stamping and with concave indentations

3.1.3

darcy

k

permeability of a porous medium, where one darcy is the flow of a single-phase fluid of 1 cP viscosity that

completely fills the voids of the porous medium, flowing through the medium under conditions of viscous flow at a

3 −1 −2 −1

rate of 1 cm ⋅s ⋅cm cross-sectional area, and under a pressure or equivalent hydraulic gradient of 1 atm⋅cm

NOTE 1 cP = 1 mPa⋅s.

3.1.4

quarter, verb

mix and divide into four specimens to assure homogeneity of specimens

3.1.5

spurt loss

volume of fluid that passes through the filtration medium before a filter cake is formed

3.1.6

tube sampling

sampling method comprising withdrawal of powdered sample from bag or bulk via a cylindrical device pushed into

the sample, locked shut and withdrawn

3.2 Symbols and abbreviated terms

d inner diameter

D outer diameter

AA atomic absorption spectroscopy

ACS American Chemical Society

API American Petroleum Institute

2 © ISO 2002 – All rights reserved

ASTM American Society for Testing and Materials

BB ball bearings

CAS Chemical Abstracts Service

DCP direct current plasma

DS drill solids

EDTA ethylenediaminetetraacetic acid

HTHP high temperature, high pressure

ICP inductively coupled plasma

ISA ionic strength adjuster

ISE ion-selective electrode

LGS low gravity solids

MBT methylene blue test

PAC-HV high viscosity polyanionic cellulose

PAC-LV low viscosity polyanionic cellulose

PPA permeability plugging apparatus

PPT permeability plugging test

PTFE polytetrafluoroethylene

4 Particle size analysis for fines in barite

4.1 Principle

Fines are the particles in the range of 2 µm to 10 µm equivalent spherical diameter and are considered to be

detrimental to drilling fluids at high concentrations. Both sieve analysis and sedimentation methods for determining

fines concentration are described below.

4.2 Reagents and apparatus

4.2.1 Dispersant solution.

Prepare a solution of 40 g sodium hexametaphosphate and approximately 3,6 g sodium carbonate diluted to 1 l

with deionized or distilled water. The sodium carbonate is used to adjust the pH of the solution to 9,0 or slightly

less. After the initial pH adjustment, check the pH each day the solution is used. When the pH falls below 8,0,

discard the solution.

4.2.2 Oven, capable of maintaining a temperature of 105 °C ± 3 °C.

4.2.3 Mixer, capable of operation at 11 500 r/min ± 300 r/min under load, with single corrugated impeller

1)

approximately 25,4 mm in diameter .

2)

4.2.4 Container for mixing, 180 mm deep, d = 97 mm at top and 70 mm at bottom .

1) Multimixer Model 9B with B29 impeller is an example of a suitable product available commercially. This information is given

for the convenience of users of this International Standard and does not constitute an endorsement by ISO of this product.

2) Hamilton Beach Mixer Cup No. M110-D is an example of a suitable product available commercially. This information is

given for the convenience of users of this International Standard and does not constitute an endorsement by ISO of this product.

4.2.5 Sieves, of mesh sizes 75 µm, 45 µm and 30 µm, having a diameter of 76 mm and a depth of 64 mm from

top of the frame to the wire cloth.

4.2.6 Stopwatch, with direct-reading counter and an accuracy of 0 min to 25 min over the test interval.

4.2.7 Rubber stopper, size 13 (diameters 68 mm top and 58 mm bottom).

4.2.8 Wash bottles, one containing 125 ml dispersant solution diluted to 1 l with deionized water, and one with

deionized water.

4.2.9 Laboratory balance, of sensitivity 0,01 g.

4.2.10 Thermometer, with scale reading including 16 °C to 32 °C, with an accuracy of 0,5 °C.

4.2.11 Beaker, of capacity 250 ml.

4.2.12 Water bath or constant temperature room, capable of maintaining a convenient constant temperature at

or near 20 °C.

4.2.13 Glass sedimentation cylinder, 457 mm high and 63,5 mm diameter, and marked for a volume of 1 l (see

ASTM D422).

4.2.14 Hydrometer, ASTM No. 151H, conforming to ASTM E100, graduated to read specific gravity of the

suspension.

4.2.15 Evaporating dishes.

4.2.16 Laboratory spatulas, of assorted sizes.

4.2.17 Desiccator, with calcium sulfate (CAS number 7778-18-9) desiccant, or equivalent.

3)

4.2.18 Spray nozzle .

4.3 Sampling

Obtain four samples of approximately 10 g and one sample of approximately 80 g of the barite by tube sampling

and quartering.

4.4 Calculation of moisture content

4.4.1 Weigh 10 g ± 0,01 g of barite obtained in 4.3.

4.4.2 Dry to constant mass at a temperature of 105 °C ± 3 °C.

4.4.3 Cool the sample in a desiccator and weigh.

4.4.4 Calculate the moisture content from equation (1), as a percent (mass fraction)

mm−

od

w =100 (1)

h

m

o

3) Spraying Systems Company No. TG 6.5 tip with 1/4 TT body is the trade name of a suitable product supplied by Spraying

Systems. This information is given for the convenience of users of this International Standard and does not constitute an

endorsement by ISO of the product named. Equivalent products may be used if they can be shown to lead to the same results.

4 © ISO 2002 – All rights reserved

where

w is the moisture content, in percent (mass fraction);

h

m is the mass of original sample, in grams;

o

m is the mass of dry sample, in grams.

d

4.5 Sieve analysis

4.5.1 Weigh 10 g ± 0,01 g of barite obtained in 4.3, and place in a mixing container. Add 44 ml of dispersant

solution. Hand-stir the sample and dilute to approximately 350 ml with deionized water. Stir 5 min on mixer.

4.5.2 Wash the sample with the diluted dispersant solution onto a 75 µm mesh sieve. Continue to wash with

approximately 400 ml of the dilute dispersant solution using a wash bottle. Then wash the material on the screen

using tap water from a spray nozzle at 70 kPa for 2 min. While washing, allow the elbow bend of the nozzle to rest

on the rim of the sieve and move the spray of water repeatedly over the surface of the screen. After tap-water

washing, wash the sample at least twice with deionized water; then transfer the residue from the screen to a tared

evaporating dish, using deionized water to remove the residue from the screen.

4.5.3 Dry the residue in the oven to constant mass, cool in a desiccator. Weigh to ± 0,01 g.

4.5.4 Repeat 4.5.1, 4.5.2, and 4.5.3 using 45 µm and 30 µm mesh sieves with separate barite samples.

4.5.5 Calculate m , w and w from equations (2), (3) and (4).

d r f

100 − w

h

m =m (2)

do

m

r

w = 100 (3)

r

m

d

ww=−100 (4)

fr

where

w is the moisture content, in percent (mass fraction), as determined in 4.4.4;

h

m is the mass of original sample, in grams;

o

m is the mass of dry sample, in grams;

d

m is the mass of residue, in grams;

r

w is the residue remaining on the sieve, in percent (mass fraction);

r

w is the part of material finer than the sieve, in percent (mass fraction).

f

4.6 Sedimentation analysis

4.6.1 Weigh 80 g ± 0,1 g of barite obtained in 4.3, and place in a mixing container. Add 125 ml ± 2 ml of

dispersant solution, hand-stir the sample and dilute to approximately 400 ml with deionized water. Stir 5 min on

mixer.

-------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...